Preparation method of high polymer material scaffolds for tissue engineering

A technology of polymer materials and tissue engineering, applied in the direction of scaffolds, devices of human tubular structures, etc., can solve the problems of increased cost, integrity and mechanical properties of scaffolds, etc., to reduce processing energy consumption and ensure structural integrity Sexuality and mechanical properties, the effect of fewer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

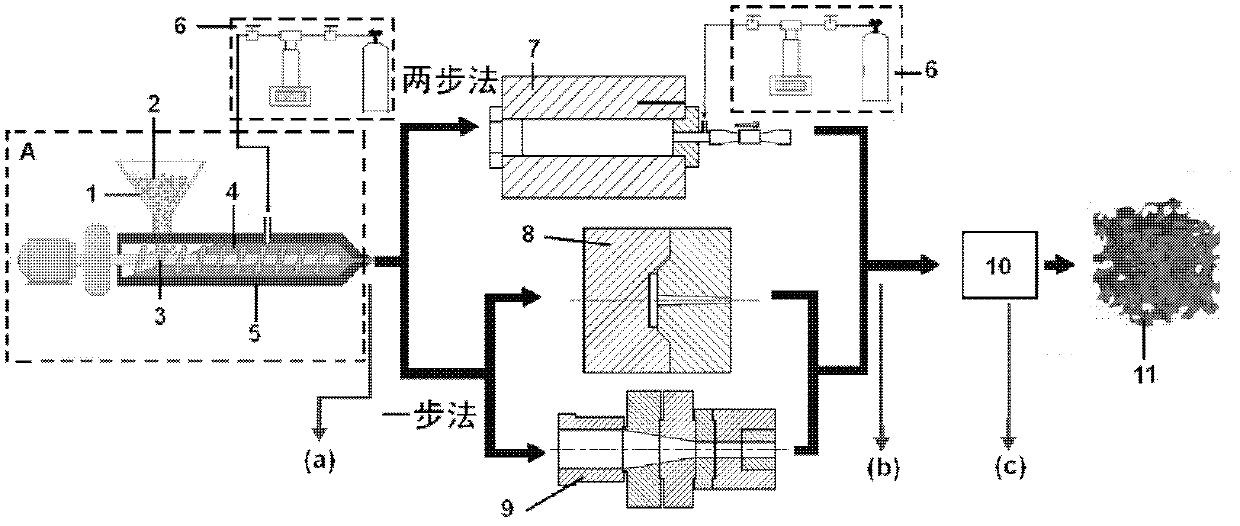

[0046] figure 1 The specific implementation process of the method of the present invention is shown. Such as figure 1 As shown, the equipment required for the implementation of the method of the present invention includes an extruder or injection molding machine A, a supercritical fluid forming and delivery system 6 , an autoclave 7 and a leaching device 10 . Supercritical fluid formation and delivery system 6 is connected with extruder or injection molding machine barrel 5; injection molding machine or extruder barrel 5 is connected with mold 8 or machine head 9; autoclave 7 is connected with supercritical fluid formation and delivery The system 6 is connected, the structure of the screw rod 3 can be changed, and the outer wall of the barrel 5 is equipped with a heating ring (not shown in the figure).

[0047] The whole process of the mixing flow field and supercritical fluid cooperating to prepare the polymer material scaffold for tissue engineering is as follows: start ...

Embodiment 2

[0050] (1) Weigh 70 parts of polylactic acid (PLA) and 30 parts of low-density polyethylene (HDPE) by mass, and mix them evenly.

[0051] (2) Add the blend in step (1) into a single-screw extruder, and prepare a PLA / HDPE blend by means of chaotic mixing.

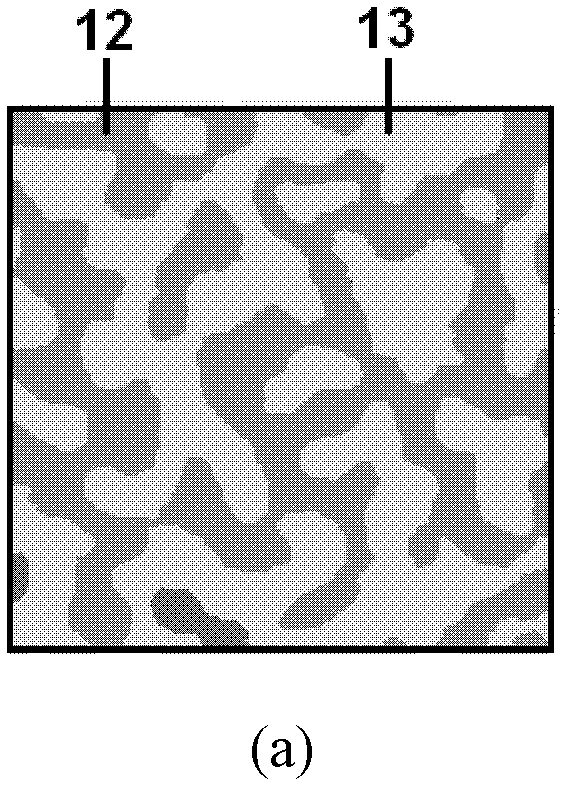

[0052] Figure 4 Shown are scanning electron micrographs of the prepared PLA / HDPE blends. It can be seen from the figure that when the content of HDPE is 30%, the blend forms a good co-continuous phase structure.

Embodiment 3

[0054] (1) Two biodegradable materials, 65 parts of starch acetate (AS) and 35 parts of PLA, were weighed by mass and mixed evenly.

[0055] (2) Add the blend in step (1) into the extruder, and prepare the AS / PLA blend by means of chaotic mixing.

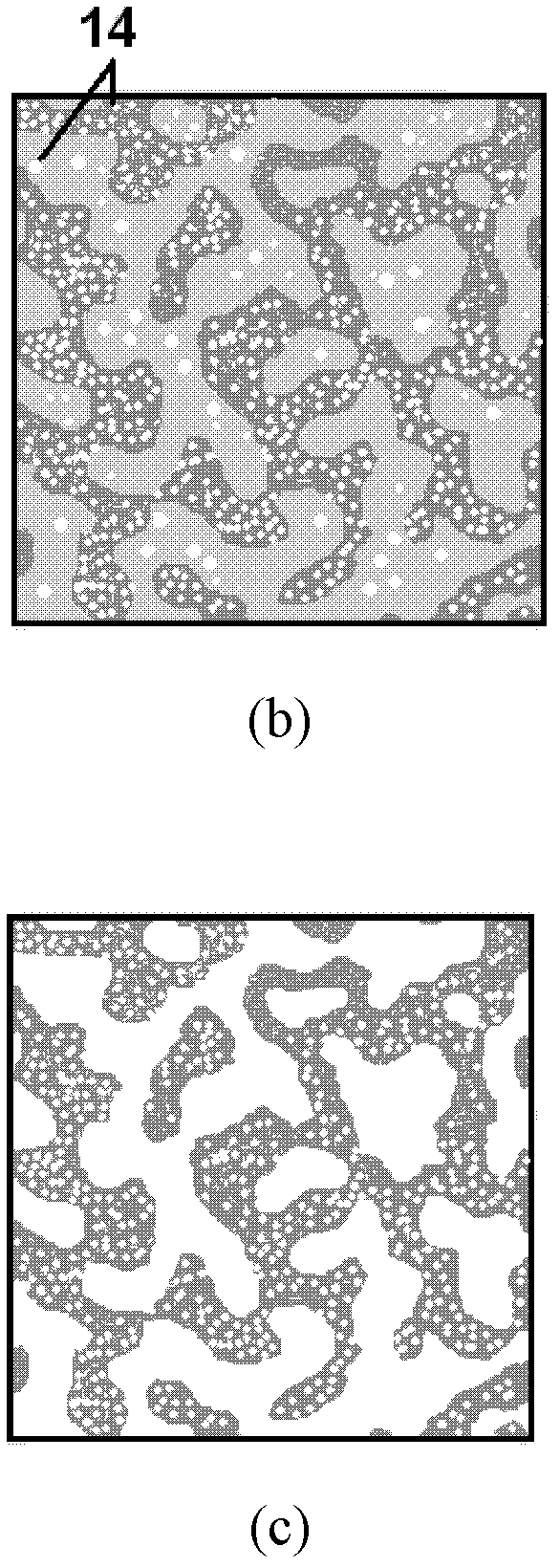

[0056] Figure 5 Shown are scanning electron micrographs of the as-prepared AS / PLA blends. It can be seen from the figure that the blend forms a co-continuous phase structure at a PLA content of 35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com