Method for preparing gold nanoclusters based on microfluidic chip

A microfluidic chip, a technology for preparing gold, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the breakthrough in the synthesis method of blocked gold clusters and the application, the complex separation process, and the reaction conditions. Harsh and other problems, to achieve uniform morphology, accurate droplet fusion, good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

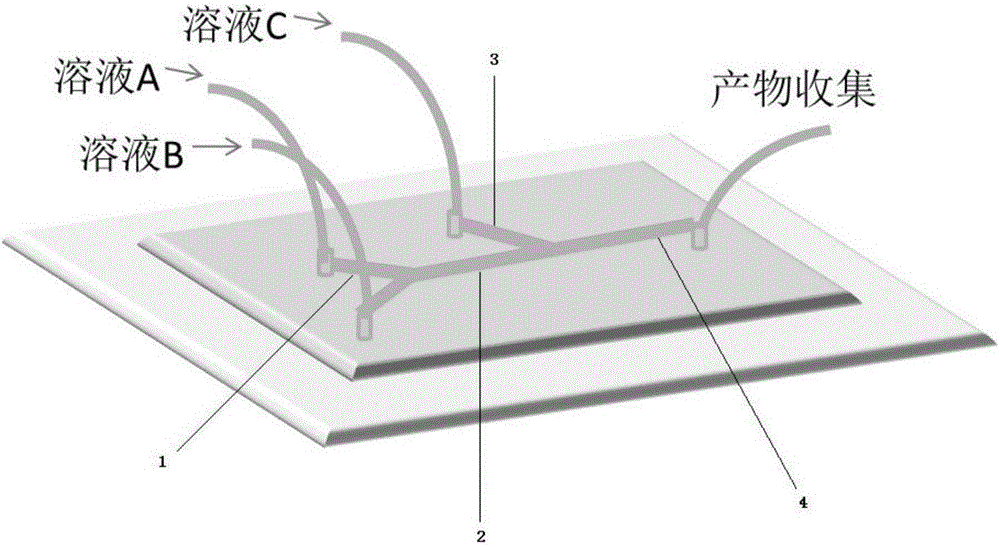

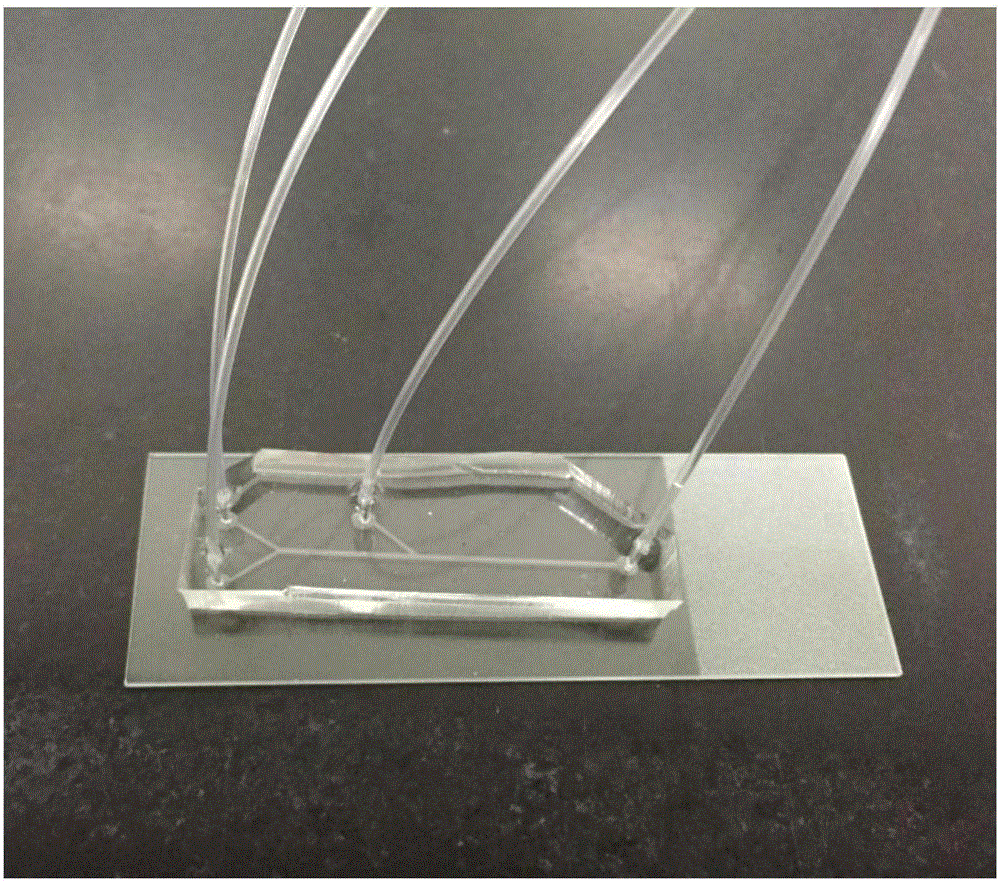

[0037] The mixing of different reactants and the progress of the reaction, using figure 1 The chip with the structure shown is shown in figure 2. The syringe pump continuously infused ethanol solution into reservoir A at a flow rate of 600nl / min, continuously infused deionized water into reservoir B at a flow rate of 300nl / min, and continuously injected deionized water into reservoir C at a flow rate of 100nl / min~900nl / min. Perfuse with 20mg / ml methylene blue dye solution. A laminar mixed fluid is formed at the first Y-shaped channel, and driven by mineral oil, it flows along the channel and meets the methylene blue solution at the second Y-shaped channel, which is realized after collision under the shear stress of the fluid. mix. Keep the flow rate of ethanol and deionized water unchanged, increase the flow rate of methylene blue solution from 100nl / min to 900nl / min, the methylene blue solution can be accurately fused with the previous solution, and the color of the fused...

Embodiment 2

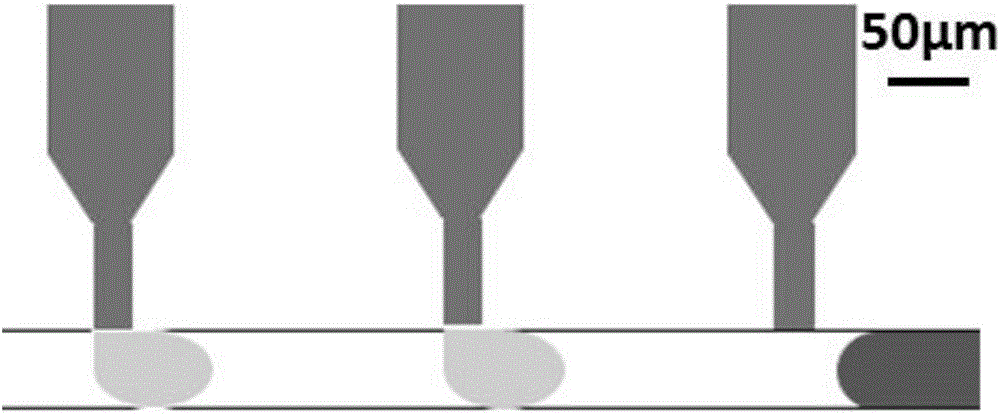

[0039] Dissolve chloroauric acid and tetraoctylammonium bromide (molar ratio 1:1.2) in tetrahydrofuran to form a 0.1mol / L solution, dissolve sodium borohydride in ice water to form a 0.5mol / L solution, and use a syringe pump to The tetrahydrofuran solution of chloroauric acid / tetraoctylammonium bromide was continuously perfused into reservoir A at a flow rate of 500 nl / min, and n-dodecyl mercaptan solution was continuously perfused into reservoir B at a flow rate of 300 nl / min using a syringe pump to The flow rate of 300nl / min continuously perfuses 0.5mol / L sodium borohydride solution to the reservoir C, and the tetrahydrofuran mixture meets n-dodecyl mercaptan at the primary Y-shaped channel, and the gold(Ⅲ) in the chloroauric acid It is reduced to gold (I), and the two are mixed into a primary solution under the shearing action of the continuous fluid. Meet, after secondary mixing, realize the mixing of reaction substances, after mixing, a homogeneous mixed solution is forme...

Embodiment 3

[0042] Dissolve chloroauric acid and tetraoctylammonium bromide (1:1.3) in methanol to form a 0.15mol / l solution, and dissolve sodium borohydride in ice water to form a 0.6mol / L solution. Use a syringe pump to continuously perfuse the methanol solution of chloroauric acid / tetraoctylammonium bromide to the reservoir A at a flow rate of 600 nl / min, and use a syringe pump to continuously perfuse the n-hexanethiol solution to the reservoir B at a flow rate of 300 nl / min. Continuously perfuse 0.6mol / L sodium borohydride solution into the reservoir C at a flow rate of 150nl / min, and the tetrahydrofuran mixture meets n-hexanethiol at the first Y-shaped channel, and the gold (Ⅲ) in the chloroauric acid is absorbed It is reduced to gold (I), and the two are mixed into a primary solution under the shearing action of the continuous fluid, and the solution moves downstream of the channel, and meets the monodisperse reducing body solution C at the secondary Y-shaped channel, and after secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com