Magnetic stirring chaotic mixing method for laminar flow in microfluidic system and device thereof

A microfluidic system and magnetic stirring technology, applied in mixers, chemical instruments and methods, dissolution and other directions, can solve the problems of difficult effective mixing of laminar flow, and achieve the effect of reducing processing difficulty and simplifying the body structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

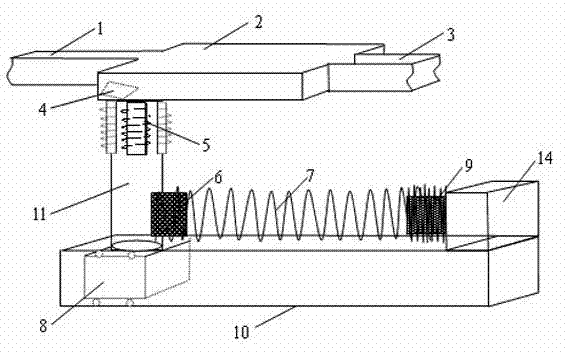

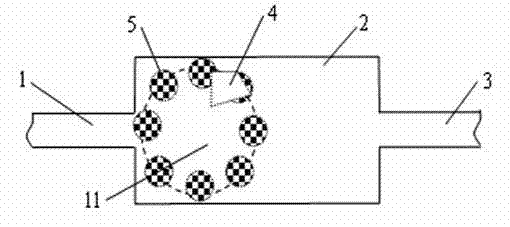

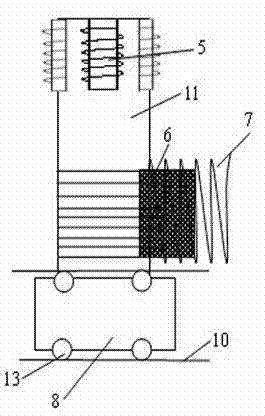

[0021] see figure 1 The schematic diagram of the overall structure of the laminar flow magnetic stirring chaotic mixing device of the microfluidic system of the present invention is shown. The microfluidic chip body can be placed through the chip frame, and the micro-magnetic stirrer 4 is placed in the mixing chamber 2 of the microfluidic chip. Inlet 1 or mixing chamber outlet 3 run out. At the bottom of the mixing chamber 2 of the microfluidic chip, a micro multiphase magnetic field timing generator 11 is vertically arranged, and the top of the micro multiphase magnetic field timing generator 11 is attached to the bottom surface of the mixing chamber 2 or close to the bottom surface of the mixing chamber 2 . The miniature multiphase magnetic field timing generator 11 is made up of a cylinder and multiphase miniature electromagnet group 5, the cylinder is perpendicular to the mixing chamber 2, the top of the cylinder is fixedly connected to the multiphase miniature electromag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com