Novel elastic stirring paddle capable of improving fluid mixing effect

A technology of fluid mixing and paddle stirring, which is applied in the field of paddle stirring, can solve the problems of low fluid mixing efficiency and insufficient mixing of flow field structure in stirred reactors, and achieve increased chaotic mixing degree, strong cutting effect, and improved turbulence degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

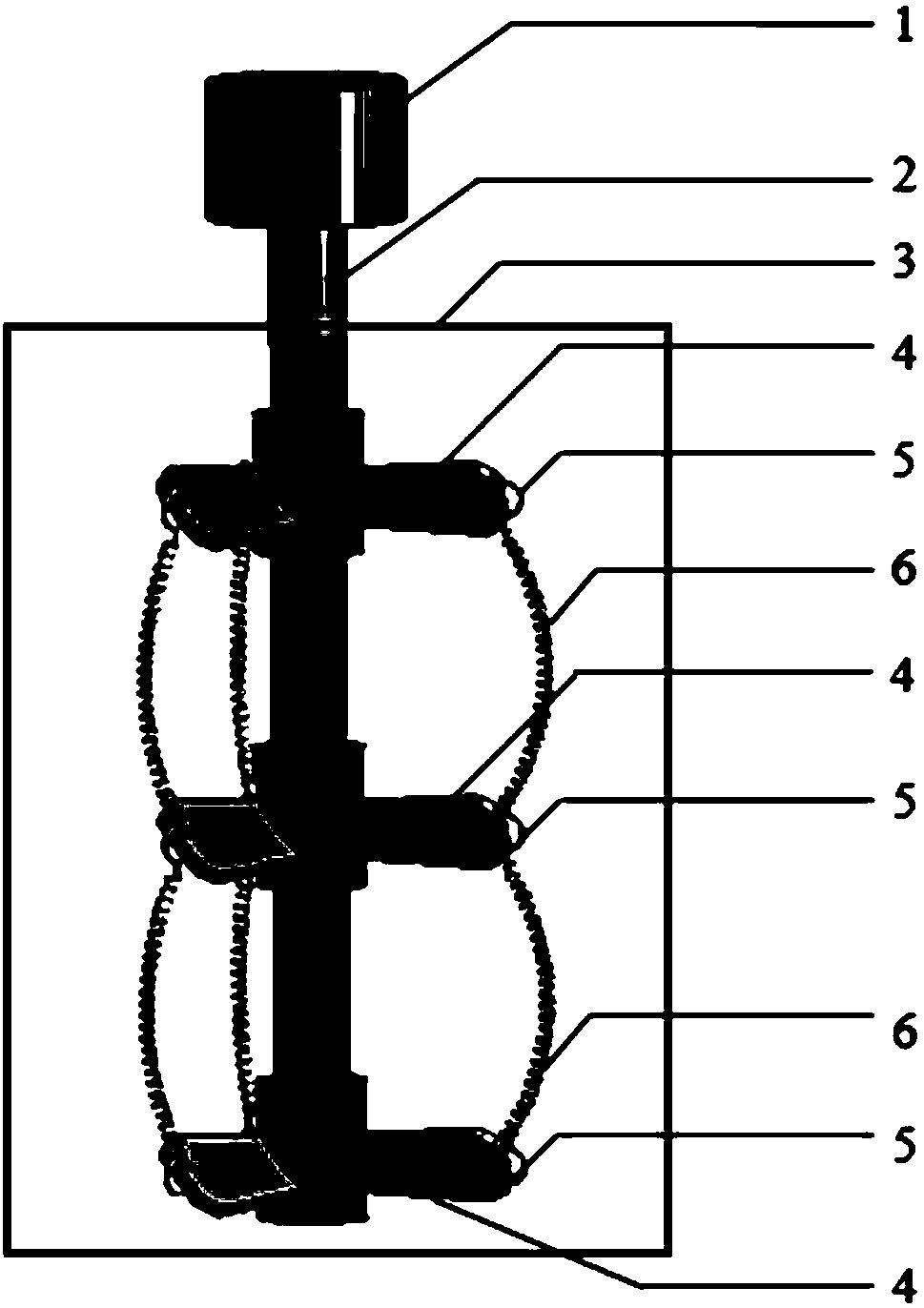

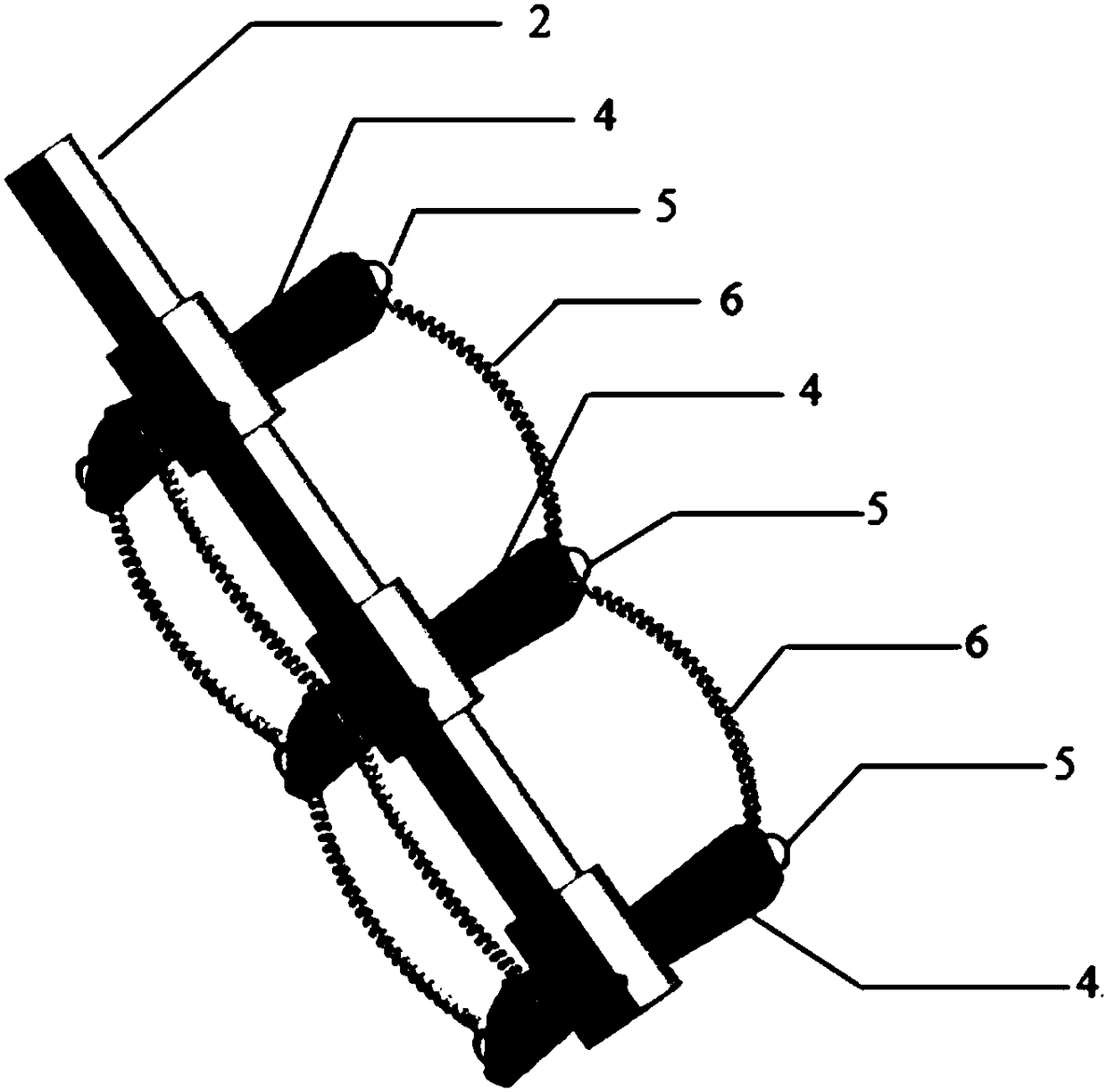

[0036] Such as figure 1 and figure 2 As shown, a novel elastic stirring paddle for improving fluid mixing effect is characterized in that it includes a stirring shaft 2, a rigid stirring paddle 4, a ring 5, a spring 6 and a connecting device 7.

[0037] The stirring shaft 2 is a cylindrical structure.

[0038] The connection device 7 is a cylindrical structure with upper and lower openings and a hollow interior. The connecting device 7 is sleeved on the stirring shaft 2 . The inner diameter of the connecting device 7 matches the outer diameter of the stirring shaft 2 , and the connecting device 7 can be fixed on the stirring shaft 2 or can slide freely on the stirring shaft 2 .

[0039] Three connecting devices 7 are sheathed on the outer wall of the stirring shaft 2 . The stirring shaft 2 is divided into three layers by the connecting device 7 . The connecting device 7 on the upper layer and the lower layer of the stirring shaft 2 is fixed on the outer wall of the stirr...

Embodiment 2

[0049] As described in Example 1, a novel elastic stirring paddle that improves fluid mixing effect, its numerical value is as follows:

[0050]①In the initial state, the length of the spring 6 is L, the distance between the lower edge of the upper rigid paddle 4 and the upper edge of the adjacent middle rigid paddle 4 is S, L=(0.75~1.2 ) × S.

[0051] When the length of the spring 6 is too short, the "sweeping" range of the blade is reduced, the vibration behavior of the spring is weakened, and it is difficult to transmit the energy of the blade to the far distance of the flow field;

[0052] When the length of the spring 6 is too long, the "sweeping" range of the blade increases, the vibration behavior of the spring increases, but the rotation resistance of the blade increases.

[0053] When the length L of the spring 6=(0.75˜1.2)×S, the mixing effect of the system is better.

[0054] ② The wire diameter d of the spring 6 is 0.3-2mm.

[0055] The wire diameter of the spri...

Embodiment 3

[0070] The stirring paddle among the embodiment 1 is carried out performance test:

[0071] The stirring shaft 2 is driven by the motor 1 and extends into the stirring tank 3 to rotate.

[0072] The stirring tank 3 is a hollow cylinder tank with one end open and one end closed; the diameter of the stirring tank 3 is 0.19m, and the height of the tank is 0.30m;

[0073] The solution in the stirring tank 3 is 0.8% sodium carboxymethylcellulose solution, and the liquid height is 0.20m;

[0074] The stirring speed is 120rpm;

[0075] The mixing time was measured by the acid-base decolorization test to characterize the mixing performance of the impeller. The experimental results are shown in Table 1.

[0076] Table 1

[0077]

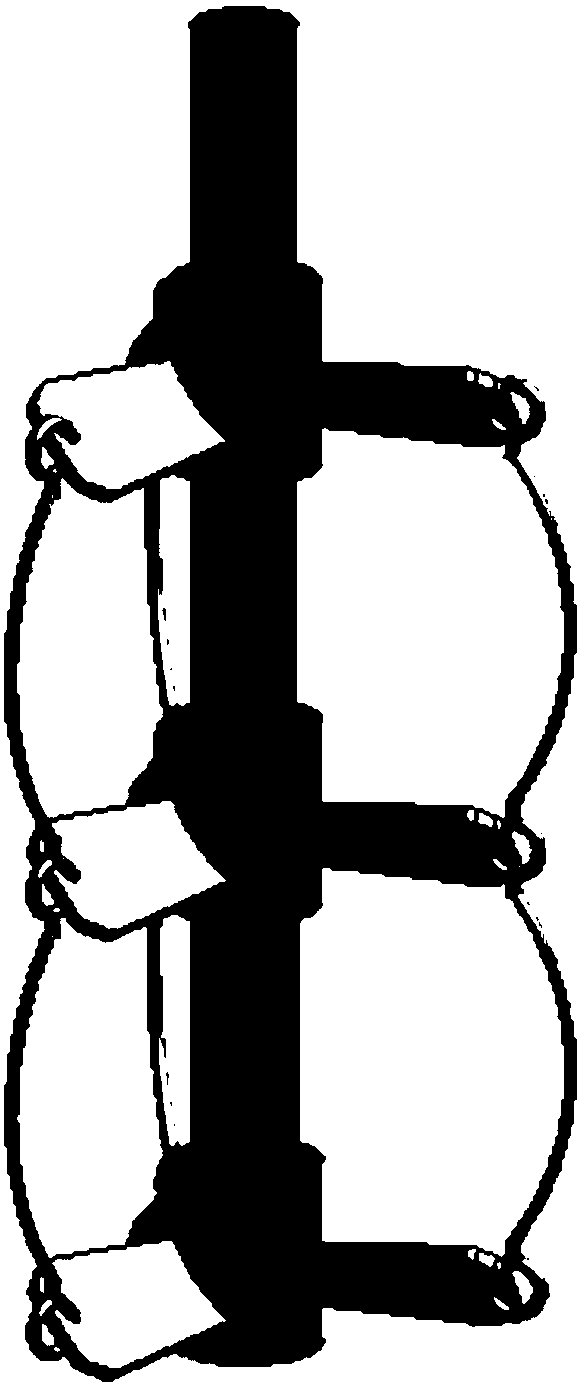

[0078] As can be seen from the experimental results in Table 1, under the same stirring speed condition, the elastic stirring paddle disclosed by the present invention is the same as image 3 Compared to the prior art shown, the mixing time of the sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com