Embedded type short-screw-flight same-direction asymmetric multi-screw extruder and machining method thereof

A multi-screw extruder and embedded technology, which is applied to the embedded low-flange co-directional asymmetrical multi-screw extruder and its processing field, can solve the problem of self-cleaning dead corners, unstable product quality, and high kneading blocks. Shearing and other problems, to solve the unstable product quality, improve the solid conveying efficiency, and the effect of strong conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

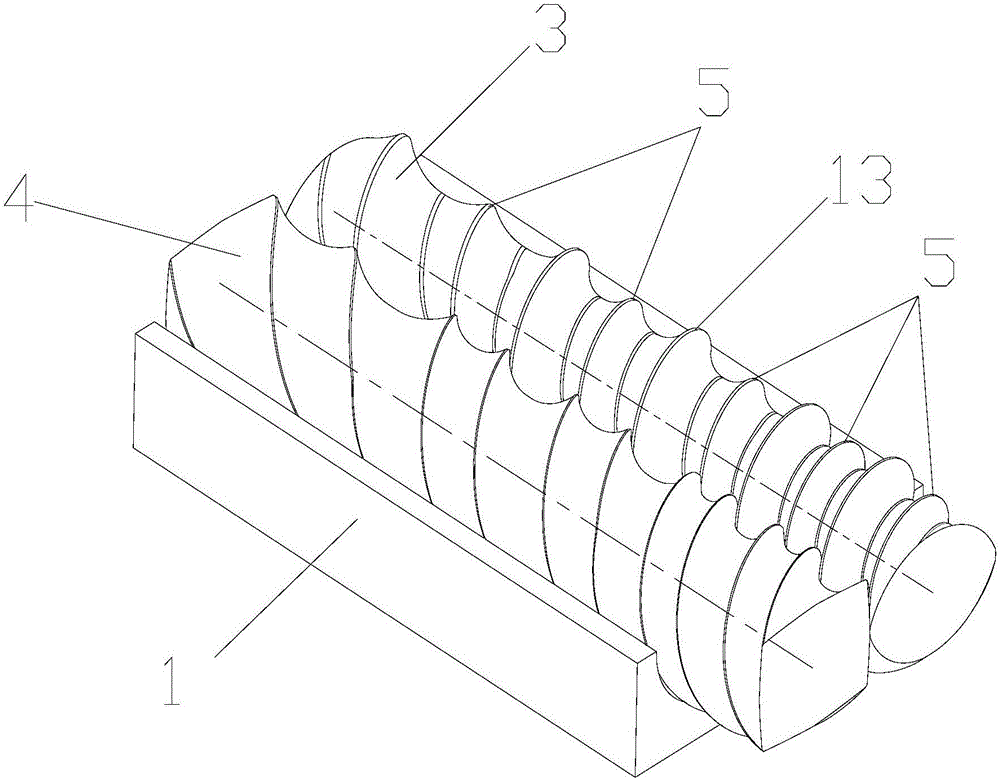

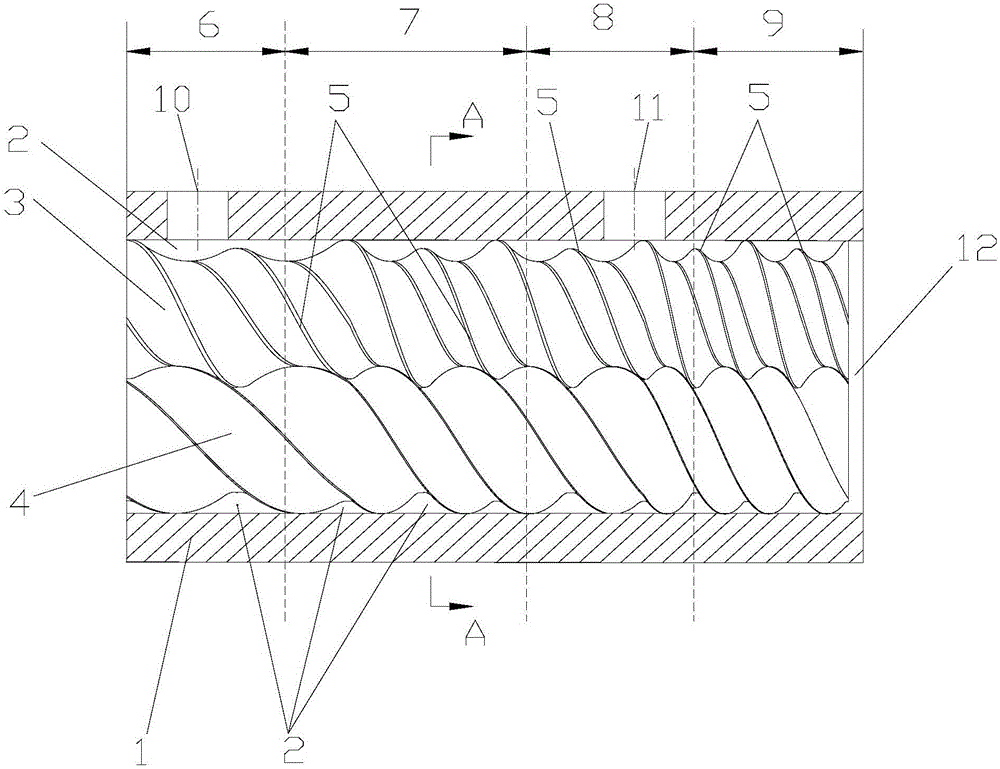

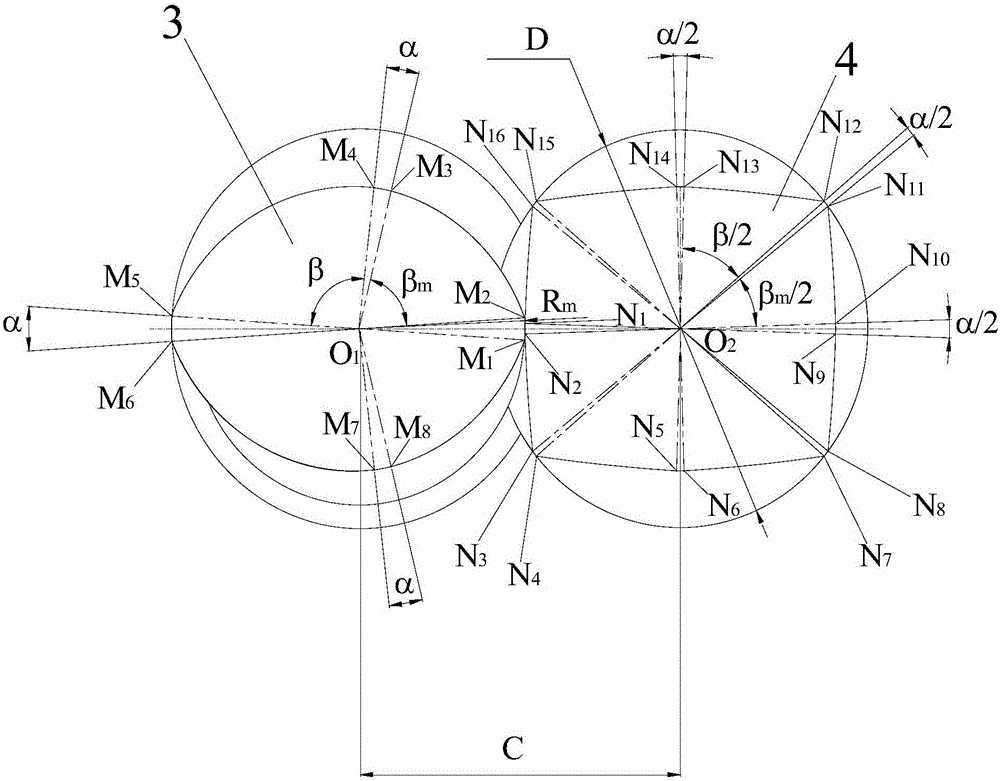

[0036] In this embodiment, a co-rotating asymmetrical multi-screw extruder with embedded short flight, its structure is as follows Figure 1-4 As shown, it includes a barrel 1 and a screw mechanism. The barrel 1 is provided with an inner cavity 2, and the screw mechanism is installed in the inner cavity. The screw mechanism includes a first screw 3 and a second screw 4, and the first screw and the second screw are connected to each other. Engagement, and the outermost edges of the first screw and the second screw are tangent to the inner wall of the inner cavity; the first screw, the second screw and the inner cavity of the barrel form a flow channel; as image 3 As shown, the cross-sectional profile of the first screw is composed of 4 segments of circular arcs and 4 segments of non-circular curved arcs, and the cross-sectional profile of the second screw is composed of 8 segments of circular arcs and 8 segments of non-circular curved arcs; and the first screw is a single head ...

Embodiment 2

[0079] In this embodiment, a co-rotating asymmetrical multi-screw extruder with an embedded short flight, compared with Embodiment 1, the difference is that: Figure 5 As shown, the main flight of the first screw and the flight of the second screw are intermittent flight structures with notches on the edges, and this structure has the effect of further strengthening the mixing; the auxiliary flight of the first screw has a smooth edge screw structure.

Embodiment 3

[0081] In this embodiment, a co-rotating asymmetrical multi-screw extruder with an embedded short flight, compared with Embodiment 1, the difference is that: Figure 6 As shown, the first screw is composed of multiple first kneading blocks with the same structure, and the second screw is composed of multiple second kneading blocks with the same structure. This structure has the effect of further strengthening the melt kneading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com