Novel hardware punching waste discharging die structure

A metal and scrap technology, applied in the field of mold structure for new metal stamping scraps, can solve the problems of poor product appearance, reduced product quality, flying around, etc., to solve the effect of secondary selection of scraps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

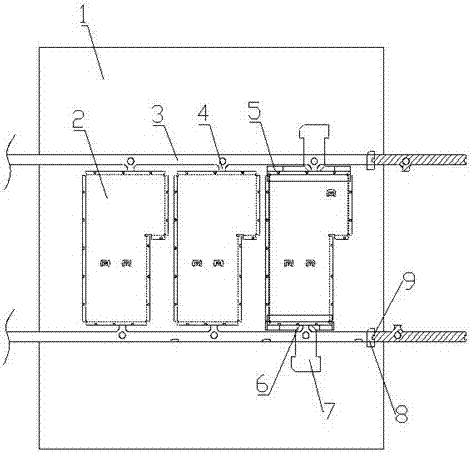

[0012] Such as figure 1 As shown, a new mold structure for metal stamping waste, including a lower template 1, a product to be processed arranged on the lower template 1, and a stamping device for cutting the product to be processed; wherein the product to be processed includes a pair of spare parts arranged in parallel Material 3 and several product bodies 2 arranged between a pair of remaining materials 3, the remaining material 3 and the product body 2 are fixedly connected by a pair of connecting blocks 4, and the remaining material 3 protrudes from the end where some product bodies 2 are set. The template 1 is set; the stamping device includes a lower die stripping block 5, a pair of knife-edge blocks A7 and a pair of knife-edge blocks B8; several product bodies 2 are arranged side by side between a pair of remaining materials 3, and the stamping device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com