Polylactic acid stereocomplex, process for production thereof, and nucleating agent for polylactic acid resin

A technology of stereocomplexes and polylactic acid resins, which can be used in transportation, packaging, thin material processing, etc., and can solve the problems of not being able to obtain high melting point stereocomplexes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

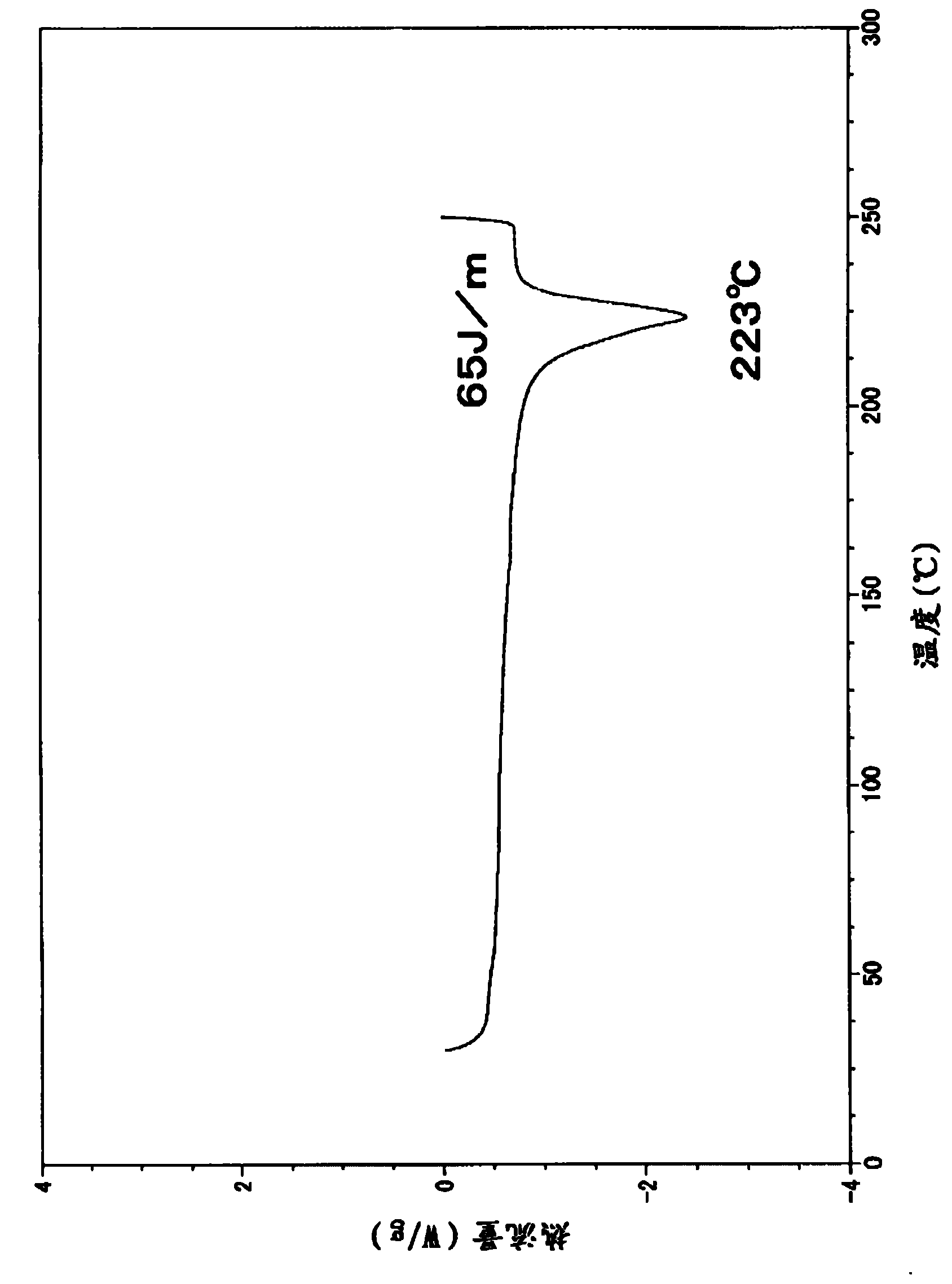

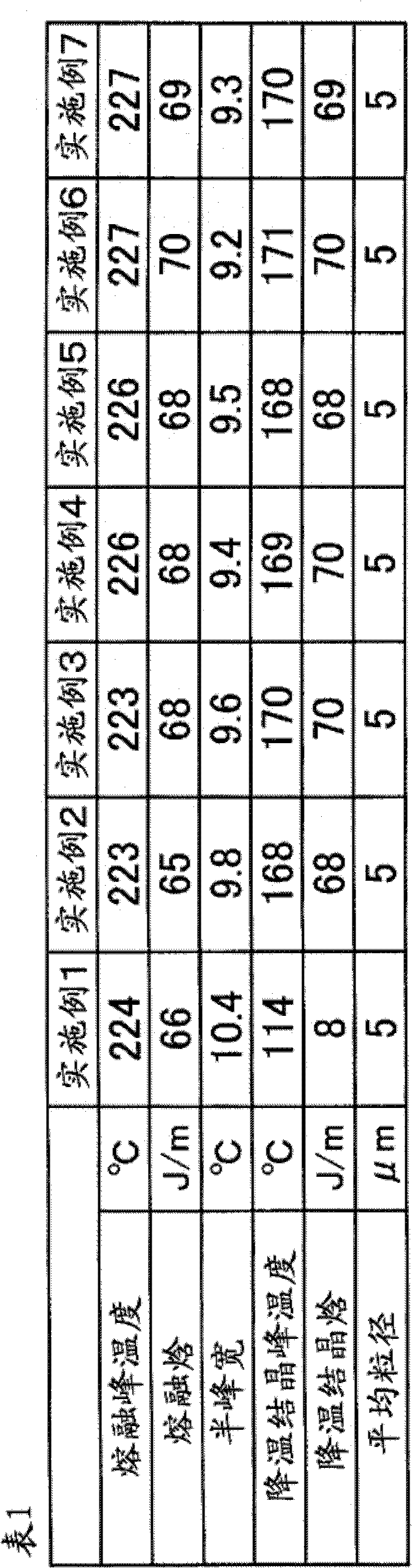

Embodiment 1

[0102] 50 parts of L-lactide was uniformly dissolved in a reaction vessel with a stirring device at 120°C under nitrogen, then the temperature was changed to 140°C, 0.05 part of tin octoate was added, and then polymerization was carried out for 1.1 hours. After the polymerization reaction was finished, the reactant was dissolved in chloroform, precipitated under stirring in methanol (10 times the amount of chloroform), and the monomer was completely removed to obtain (A) poly-L- lactic acid.

[0103] In a reaction vessel equipped with a stirring device, 50 parts of D-lactide were uniformly dissolved at 120°C under nitrogen gas, then the temperature was changed to 140°C, 0.05 part of tin octoate was added, and polymerization was carried out for 1.1 hours. After the polymerization reaction was finished, the reactant was dissolved in chloroform, precipitated under stirring in methanol (10 times the amount of chloroform), and the monomer was completely removed to obtain (B) poly D...

Embodiment 2

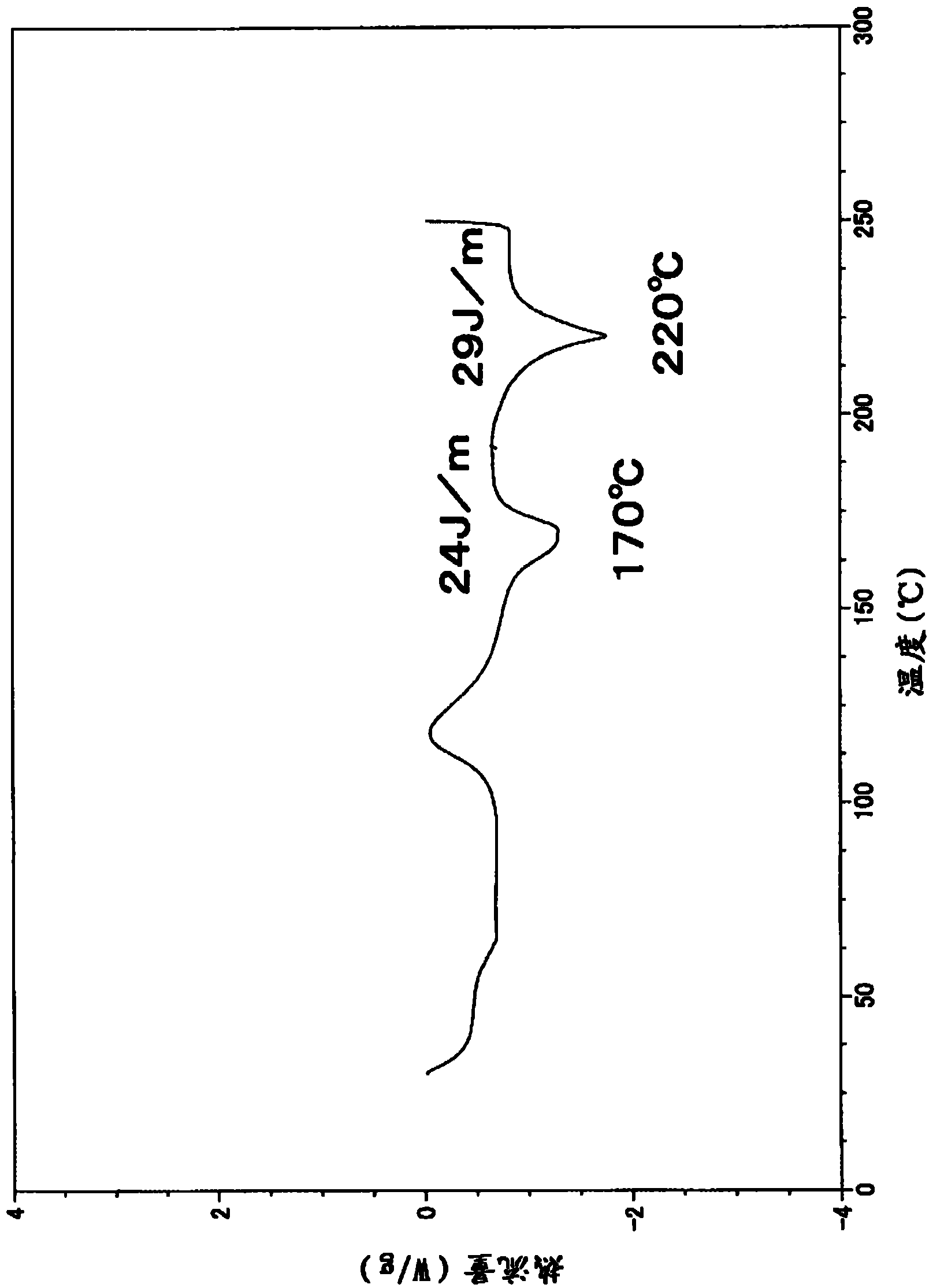

[0107] (A) Poly L-lactic acid and (B) Poly D-lactic acid were prepared in the same manner as in Example 1. (A) poly-L-lactic acid and (B) poly-D-lactic acid and (C-1) crystal nucleating agent (talc: MicroAceP-6 (manufactured by Nippon Talku Co., Ltd.)) in (A) / (B) / (C -1) = 50 / 50 / 1 weight ratio dry-blended in advance, then supplied to a Banbury kneader with a screw rotation speed of 10 rpm, and kneaded at a barrel set temperature of 185°C. In Example 2, dust-like substances were precipitated during kneading, and all of them became dust-like when the kneading time was about 30 seconds, thereby obtaining a polylactic acid resin composition with an average particle diameter of 5 μm. During the mixing of the Banbury type mixer, the mixing state of the sample was observed from the upper window of the mixer. As a result, in Example 2, (A) poly L-lactic acid and (B) poly D-lactic acid were repeatedly mixed. A chaotic hybrid state of stretching and collapsing.

[0108] The above sampl...

Embodiment 3

[0110] (A) Poly L-lactic acid and (B) Poly D-lactic acid were prepared in the same manner as in Example 1. (A) poly-L-lactic acid, (B) poly-D-lactic acid and (C-1) crystal nucleating agent (talc: MicroAce P-6 (manufactured by Nippon Turku Corporation)) and (C-2) crystal nucleating agent ( Phosphate ester metal salt: NA-71 (manufactured by ADEKA Corporation)) dry-blended in advance at a weight ratio of (A) / (B) / (C-1) / (C-2)=50 / 50 / 1 / 1 Mixed, then supplied to a Banbury type kneader with a screw rotation speed of 10 rpm, and kneaded at a barrel set temperature of 185°C. In Example 3, dust-like substances were precipitated during kneading, and all of them became dust-like when the kneading time was about 30 seconds, thereby obtaining a polylactic acid resin composition with an average particle diameter of 5 μm. During the mixing of the Banbury type mixer, the mixing state of the sample was observed from the upper window of the mixer. As a result, in Example 3, (A) poly L-lactic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com