Special halogen-free flame-retardant master batch for polypropylene and preparation method for halogen-free flame retardant master batch

A technology for flame-retardant masterbatch and polypropylene, which is applied in the field of preparation of halogen-free flame-retardant masterbatch for polypropylene, can solve the problems of difficult to stabilize product quality, difficult to control reaction conditions, low content of masterbatch, etc., and achieve low production cost , reduce the harm to workers' health, and the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

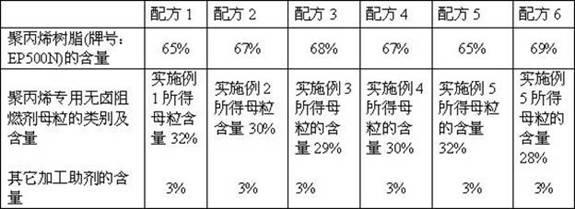

Examples

Embodiment 1

[0023] Proportion according to the following mass percentage composition: phosphorus nitrogen halogen-free flame retardant 75% (brand: NP430, Jiangmen High-end Chemical Co., Ltd.), homopolypropylene (PPH) 22% (brand EP500N, China Ocean Shell Petrochemical Company), Modified ethylene bis fatty acid amide (ethylene bis fatty acid amide grafted with maleic anhydride) 3% (commercially available conventional models). After the above materials are accurately weighed, add PPH and modified ethylene bis fatty acid amide into the pressurized tumbling internal mixer, control the temperature in the internal mixing chamber to 150°C, the rotor speed to 40r / min, and the internal mixing time to 4min. After the material is melted, add the phosphorus-nitrogen halogen-free flame retardant powder into the internal mixer three times, with an interval of 3 minutes between feeding each time; after adding all the materials, banbury for 10 minutes. The rubber head after the above-mentioned internal mi...

Embodiment 2

[0026] Proportion according to the following mass percentage composition: phosphorus nitrogen halogen-free flame retardant 80% (brand: NP430, Jiangmen High-end Chemical Co., Ltd.), homopolypropylene (PPH) 19% (brand EP500N, China Ocean Shell Petrochemical Company), Modified ethylene bis fatty acid amide (ethylene bis fatty acid amide grafted with maleic anhydride) 1% (commercially available conventional models). After the above materials are accurately weighed, PPH and modified ethylene bis fatty acid amide are added to the pressurized tumbling internal mixer, the temperature in the internal mixing chamber is controlled at 160°C, the rotor speed is 40r / min, and the internal mixing time is 4min. After the material is melted, add the phosphorus-nitrogen halogen-free flame retardant powder into the internal mixer three times, with an interval of 3 minutes between feeding each time; after adding all the materials, banbury for 5 minutes. The rubber head after the above-mentioned in...

Embodiment 3

[0029] Proportion according to the following mass percentage composition: phosphorus nitrogen halogen-free flame retardant 85% (brand: FR-202, Shenzhen Hongtaiji Chemical Co., Ltd.), random copolymerized polypropylene (PPR) 13% (brand R370Y, Korea SK company), modified ethylene bis fatty acid amide (ethylene bis fatty acid amide grafted with divinylbenzene) 2% (commercially available conventional models). After the above materials are accurately weighed, PPR and modified ethylene bis fatty acid amide are added to the pressurized tumbling internal mixer. The temperature in the internal mixing chamber is controlled at 160°C, the rotor speed is 45r / min, and the internal mixing time is 6min. After the material is melted, add the phosphorus-nitrogen halogen-free flame retardant powder into the internal mixer three times, with an interval of 5 minutes between feeding each time; after adding all the materials, banbury for 10 minutes. The above-mentioned rubber head after banburying i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com