Ranitidine hydrochloride composition tablet medicine for treating digestive system diseases

A technology for ranitidine hydrochloride and digestive system diseases, which is applied in the field of ranitidine hydrochloride composition tablets for the treatment of digestive system diseases, and can solve the problems of poor stability, easy deliquescence and discoloration of ranitidine hydrochloride, etc. Achieve the effects of improving stability, solving extremely deliquescence, and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

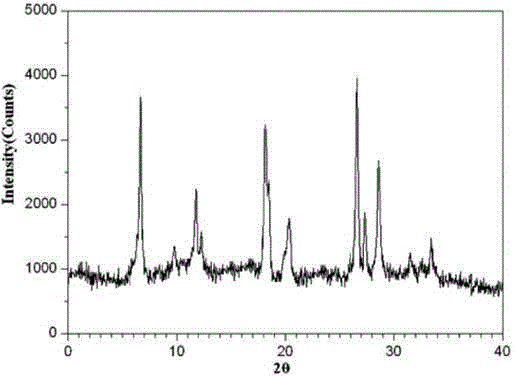

[0028] Example 1: Preparation of ranitidine hydrochloride crystals

[0029] (1) Grind the crude ranitidine hydrochloride, pass through a 60-mesh sieve, then add it into deionized water whose volume is 8 times the weight of ranitidine hydrochloride, and stir at 130 rpm for 10 minutes;

[0030] (2) Add ethanol whose volume is 5 times the weight of ranitidine hydrochloride while stirring at 110 rpm, and raise the temperature to 35°C;

[0031] (3) After the solution is added, let it stand for 2 hours, and add dropwise a mixed solution of acetone and ether whose volume is 8 times the weight of ranitidine hydrochloride at 0°C under the condition of stirring at 165 rpm, the volume ratio of acetone and ether It is 3:1, and the uniform dropwise addition is completed within 2 hours;

[0032] (4) After the dropwise addition was completed, the temperature was lowered to -10°C, and stirring was continued at a stirring rate of 100 rpm for 2 h, and the crystals were precipitated after sta...

Embodiment 2

[0034] Example 2: Preparation of Ranitidine Hydrochloride Tablets:

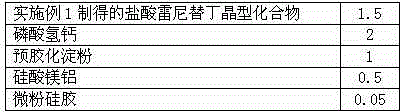

[0035] Prescription: in parts by weight as shown in Table 1

[0036] Table 1 The composition prescription of ranitidine hydrochloride

[0037]

[0038] Preparation:

[0039] (1) Processing of raw and auxiliary materials: pass ranitidine hydrochloride through an 80-mesh sieve with a vibrating sieving machine;

[0040] (2) Weighing: Weighing according to the prescription amount;

[0041] (3) Mixing: Add all the weighed raw and auxiliary materials into the three-dimensional motion mixer, set the motor operating frequency to 200r / min, and start the mixer to mix for 45 minutes;

[0042] (4) Tablet compression: Add the mixed granules into a high-speed tablet press, control the hardness to 8-12kgF, and the difference in tablet weight must meet the internal control standards;

[0043] (5) Packaging.

Embodiment 3

[0044] Example 3: Preparation of Ranitidine Hydrochloride Tablets:

[0045] Prescription: in parts by weight as shown in Table 2

[0046] Table 2 Prescription of ranitidine hydrochloride composition

[0047]

[0048] Preparation:

[0049] (1) Processing of raw and auxiliary materials: pass ranitidine hydrochloride through an 80-mesh sieve with a vibrating sieving machine;

[0050] (2) Weighing: Weighing according to the prescription amount;

[0051] (3) Mixing: Add all the weighed raw and auxiliary materials into the three-dimensional motion mixer, set the motor operating frequency to 200r / min, and start the mixer to mix for 45 minutes;

[0052] (4) Tablet compression: Add the mixed granules into a high-speed tablet press, control the hardness to 8-12kgF, and the difference in tablet weight must meet the internal control standards;

[0053] (5) Packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com