A kind of super-hydrophobic textile fabric and its preparation method and application

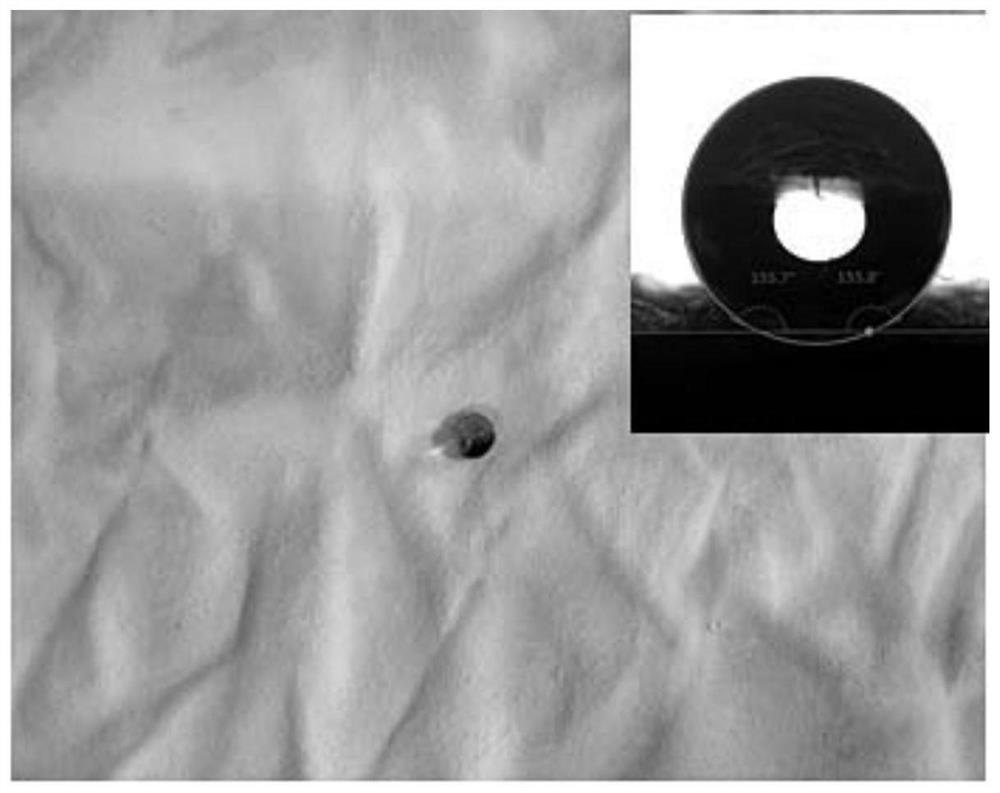

A superhydrophobic, textile cloth technology, applied in the direction of separation methods, textiles and papermaking, chemical instruments and methods, etc., can solve the problems of low separation efficiency, insufficient material bonding, and difficult collection, etc., and achieve low price and simple preparation method , good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

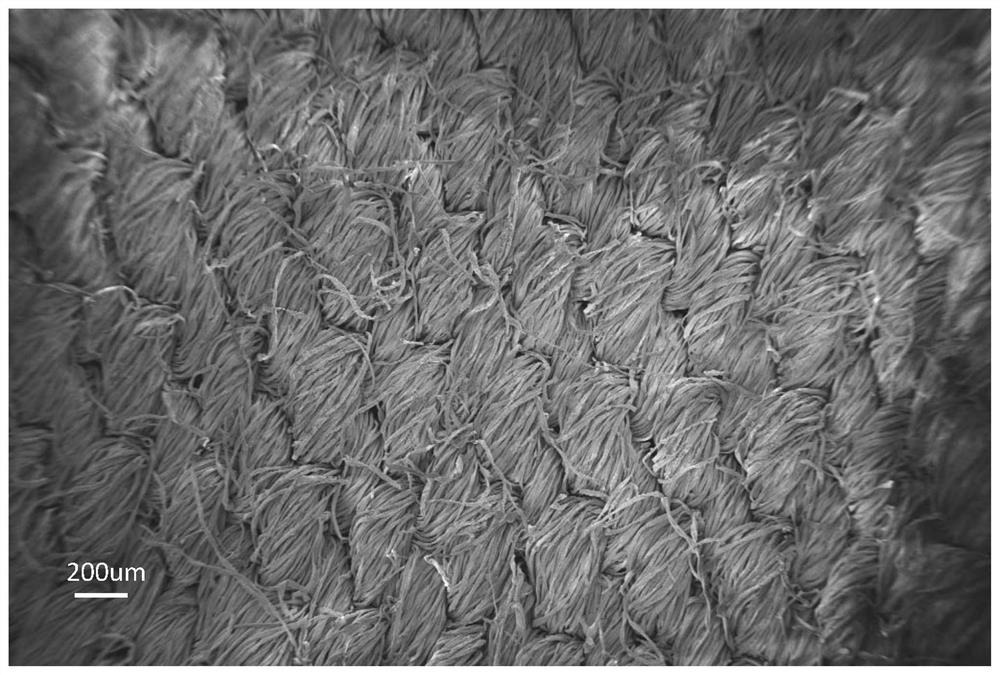

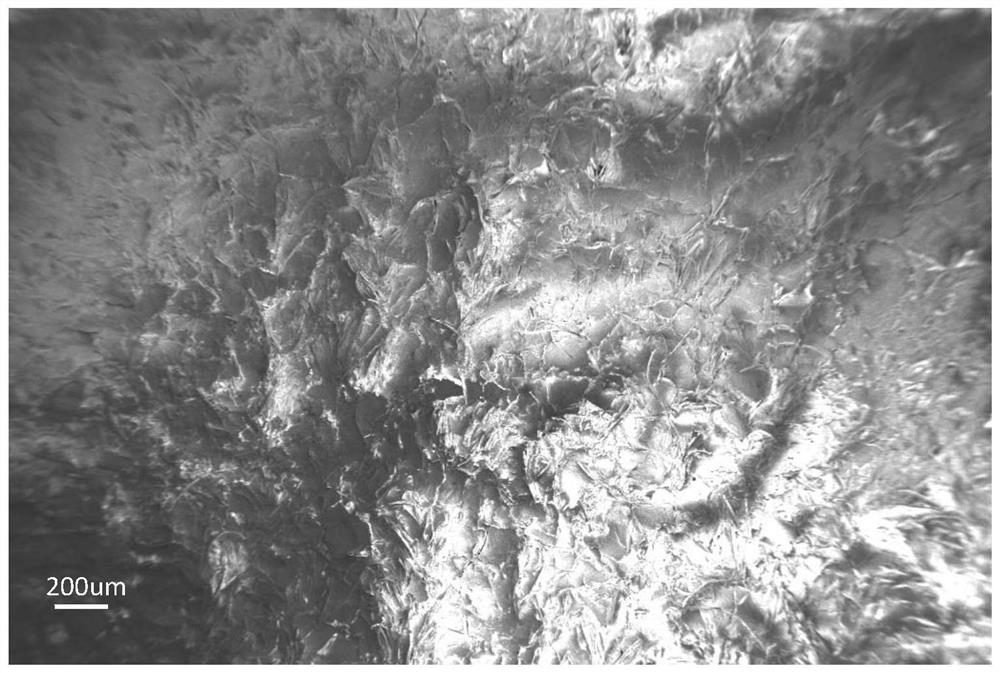

[0032] Take 20 mL of tetrahydrofuran and 2 mL of water to mix, then add 2 g of divinylbenzene, then add 0.05 g of azobisisobutyronitrile, and stir the mixed solution at room temperature for 4 h. Ultrasonic cleaning is performed on the textile cloth with ethanol first, and then ultrasonic cleaning is performed on the textile cloth with water, and then put into an oven for drying. The woven cloth was imbibed with the solution, put into a stainless steel reactor with a polytetrafluoroethylene liner, and placed in an oven at 100 °C for 24 h. Afterwards, the woven fabric is cooled at room temperature to evaporate the organic solvent and water.

Embodiment 2

[0034] Measure 40 mL of ethyl acetate, then add 4 g of divinylbenzene, then add 0.10 g of azobisisobutyronitrile, and stir the mixed solution at room temperature for 4 h. Ultrasonic cleaning is performed on the textile cloth with ethanol first, and then ultrasonic cleaning is performed on the textile cloth with water, and then put into an oven for drying. The woven cloth was imbibed with the solution, put into a stainless steel reactor with a polytetrafluoroethylene liner, and placed in an oven at 100 °C for 24 h. Afterwards, the woven fabric is cooled at room temperature to evaporate the organic solvent and water.

Embodiment 3

[0036] Take 30 mL of tetrahydrofuran and 3 mL of water to mix, then add 3 g of divinylbenzene, then add 0.15 g of azobisisobutyronitrile, and stir the mixed solution at room temperature for 5 h. Ultrasonic cleaning is performed on the textile cloth with ethanol first, and then ultrasonic cleaning is performed on the textile cloth with water, and then put into an oven for drying. The woven cloth was imbibed with the solution, put into a stainless steel reactor with a polytetrafluoroethylene liner, and placed in an oven at 110 °C for 48 h. Afterwards, the woven fabric is cooled at room temperature to evaporate the organic solvent and water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com