Method for preparing lipophilic spherical zinc oxide dry powder by ultrasonic wet grinding

A wet grinding, zinc oxide technology, applied in chemical instruments and methods, dyed low molecular organic compound treatment, dyed high molecular organic compound treatment and other directions, can solve the problems of powder adhesion, difficult application, difficult dispersion, etc. Good hydrophobicity and lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

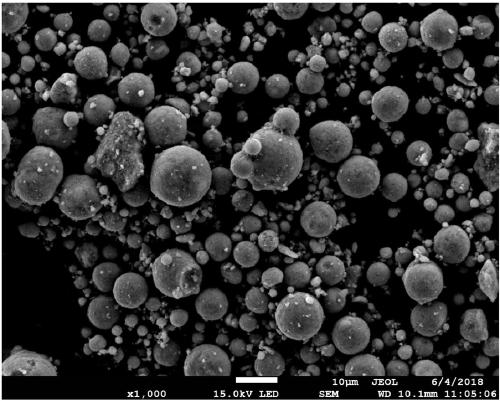

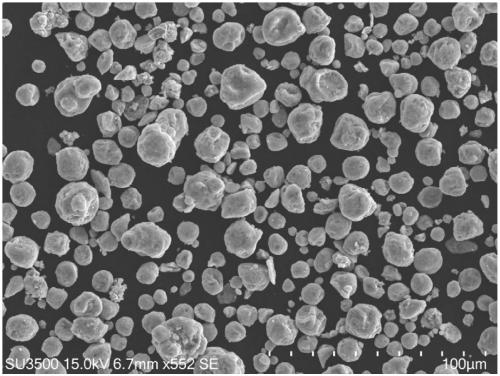

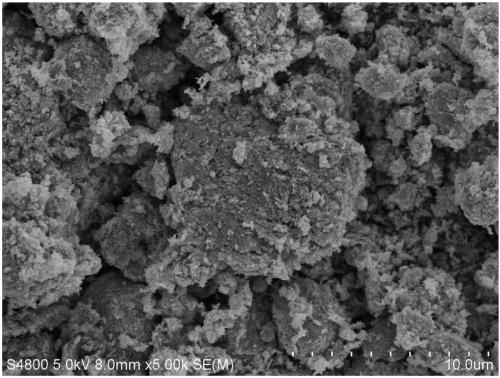

Image

Examples

specific Embodiment 1-6

[0030] Carry out the preparation of lipophilic spherical zinc oxide dry powder according to the formula described in table 1 with the following steps:

[0031] 1) Dissolving the dispersed coupling agent in Table 1 in a solvent to form a dispersed coupling agent solution;

[0032] 2) Put the dispersed coupling agent solution obtained in 1), the primary zinc oxide powder and deionized water to form a mixed solution, and then place it in an emulsifier for emulsification and dispersion for a certain period of time to obtain a pre-dispersion;

[0033] 3) Put the pre-dispersed liquid obtained in 2) in an ultrasonic sand mill for grinding to obtain a grinding liquid, the filling rate of zirconium beads in the sand mill is 20%-80%, the grinding time is 4h-8h, and the grinding temperature is not higher than 50 °C, the grinding speed is 100rpm-1500rpm, and the ultrasonic frequency is 25KHZ-130KHZ, wherein the ultrasonic sand mill is a sand mill using an ultrasonic vibrating rod.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com