Magnetic oil-water separation material and preparation method thereof and oil-water separation sponge

An oil-water separation and magnetic technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of complex preparation methods, time-consuming multi-steps, limited application range, etc., and achieve simple preparation process , low equipment requirements and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

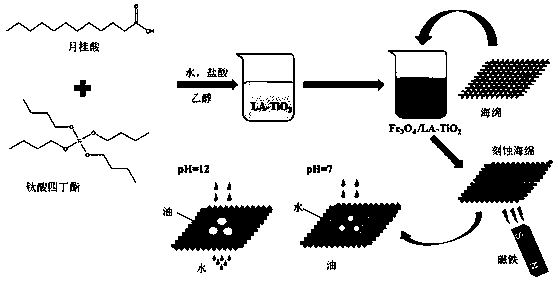

[0036] (1) Take 0.60g of lauric acid (La) and disperse it in 15mL of ethanol under ultrasonic treatment;

[0037] (2) Slowly add 1mL tetrabutyl titanate dropwise to the lauric acid ethanol solution in step (1) and stir for 20min;

[0038] (3) Add 0.06mL deionized water and 0.03mL 0.2M HCl to the mixed solution in step (2) and stir vigorously for 30min;

[0039] (4) Add 0.6g nanometer Fe 3 o 4 Add 10mL of ethanol to prepare a suspension and add it dropwise to the mixed solution in step (3) and stir for 20min to obtain the oil-water separation magnetic material Fe 3 o 4 / La-TiO 2 .

Embodiment 2

[0041] (1) Take 6g of lauric acid (La) and disperse it in 150mL of ethanol under ultrasonic treatment;

[0042] (2) Slowly add 10mL tetrabutyl titanate dropwise to the lauric acid ethanol solution in step (1) and stir for 25min;

[0043] (3) Add 0.6mL deionized water and 0.3mL 0.2M HCl to the mixed solution in step (2) and stir vigorously for 30min;

[0044] (4) 6g nano-Fe 3 o 4 Add 100mL of ethanol to prepare a suspension, add it dropwise to the mixed solution in step (3) and stir for 25min to obtain the oil-water separation magnetic material Fe 3 o4 / La-TiO 2 .

Embodiment 3

[0046] (1) Take 3kg of lauric acid (La) and disperse it in 75L of ethanol under ultrasonic treatment;

[0047] (2) Slowly add 5L tetrabutyl titanate dropwise to the lauric acid ethanol solution in step (1) and stir for 25 minutes;

[0048] (3) Add 0.3L deionized water and 0.15L 0.2M HCl to the mixed solution in step (2) and stir vigorously for 30min;

[0049] (4) 3kg nano-Fe 3 o 4 Add 50mL of ethanol to prepare a suspension and add it dropwise to the mixed solution in step (3) and stir for 30min to obtain the oil-water separation magnetic material Fe 3 o 4 / La-TiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com