Preparation method of silane modified superhydrophobic TiO2 nanotube material

A silane modification and nanotube technology, applied in the field of superhydrophobicity, can solve the problems of complicated steps and easy peeling off of the modified layer, and achieve the effects of simple preparation process, low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

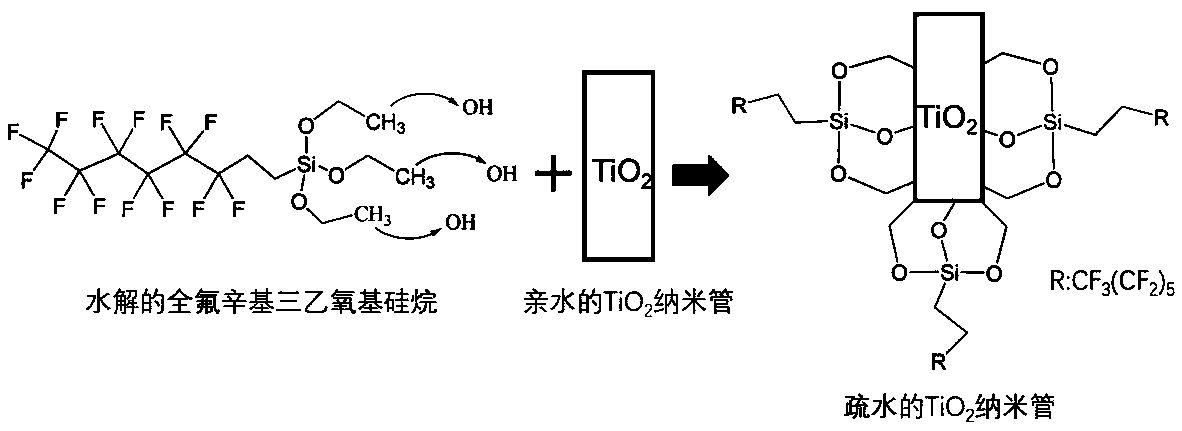

[0022] A silane-modified TiO 2 A method for preparing a nanotube superhydrophobic material, comprising the following steps:

[0023] (1) Take (0.6-2) gTiO 2 Dissolve the nanoparticles in (60-180) mL (8-12) mol / L NaOH solution, (500-700W) ultrasonic for 0.5-1h, mechanically stir in the dark (300-500r / min) for 12-15h The solution is placed in a hydrothermal reaction kettle and reacted at 100-150°C for 24-48h; the reaction product is washed with distilled water until the pH is 7, and then acid-washed with (0.1-0.5) mol / L HCl until the pH of the upper clear layer is 1, and then rinsed with distilled water until the pH is neutral, and dried to obtain TiO 2 Nanotubes, protected from light;

[0024] (2) Take TiO 2 Add the nanotubes into the ethanol solution (2-10) mL with a mass concentration of perfluorooctyltriethoxysilane between 1% and 5%, and (500-700W) ultrasonically shake for 1-2h; add distilled water and undergo hydrolysis reaction Hydrophobic TiO can be obtained in 1-3h...

Embodiment 1

[0025] Embodiment 1 Silane modified TiO 2 Preparation of nanotube superhydrophobic materials

[0026] (1) Take 0.6g TiO 2 Nanoparticles and 60mL 12mol / L NaOH solution, 500W ultrasound for 1h, mechanical stirring (300r / min) in the dark for 15h, then put the above solution in a hydrothermal reaction kettle, hydrothermal reaction at 100°C for 24h; the reaction product was washed with distilled water to pH After it is 7, it is acid-washed with 0.5mol / L HCL until the pH of the upper layer is 1, then washed with distilled water until the pH is neutral, and dried at 150°C to obtain TiO 2 Nanotubes, protected from light;

[0027] (2) Take 0.3gTiO 2 Add nanotubes to 10mL 10g / L perfluorooctyl triethoxysilane and dissolve in 10mL ethanol, 500W ultrasonic vibration for 2h; add 5g distilled water, hydrolyze for 3h to get hydrophobized TiO 2 nanotube material.

Embodiment 2

[0028] Embodiment 2 Silane modified TiO 2 Preparation of nanotube superhydrophobic materials

[0029] (1) Weigh 1g TiO 2 Nanoparticles were dissolved in 80mL 8mol / L NaOH solution, ultrasonicated at 700W for 30min, and mechanically stirred in the dark (500r / min) for 12h, then the above solution was placed in a hydrothermal reaction kettle, and hydrothermally reacted at 150°C for 48h; the reaction product was washed with distilled water until After the pH is 7, pickle with 0.1mol / L HCL until the pH of the upper layer is 1, then rinse with distilled water until the pH is neutral, and dry the above product at 150°C to obtain TiO 2 Nanotubes, protected from light;

[0030] (2) Take 0.6gTiO 2 Add nanotubes to 10mL 10g / L perfluorooctyltriethoxysilane dissolved in 2mL ethanol, 700W ultrasonic vibration for 1h; add 2.5g distilled water, and hydrolyze for 1h to obtain hydrophobized TiO 2 nanotube material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com