Method for preparing titanium dioxide quantum dots by ultrasonication

A titanium dioxide, ultrasonic crushing technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of difficult to achieve large-scale production, long preparation period, complex preparation process, etc., and achieve good industrial application. Prospects, less demand for equipment types, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this example, titanium dioxide quantum dots were prepared using columnar crystal microsphere titanium dioxide powder as a raw material. The specific steps are as follows:

[0028] (1), weigh 2g of columnar crystal microsphere titanium dioxide powder, immerse in liquid nitrogen and carry out freeze embrittlement treatment for 12h;

[0029] (2) Disperse the titanium dioxide powder after freeze embrittlement treatment in 1000mL deionized water, and immediately use water bath ultrasonic to crush the obtained dispersion for 4 hours, and the crushing power is 300W;

[0030] (3) Put the crushed dispersion liquid into liquid nitrogen for freeze embrittlement treatment for 12 hours; then use water-bath ultrasonic to carry out crushing treatment for 4 hours, and the crushing power is 300W;

[0031] (4), repeat step (3) twice, promptly make titanium dioxide quantum dot.

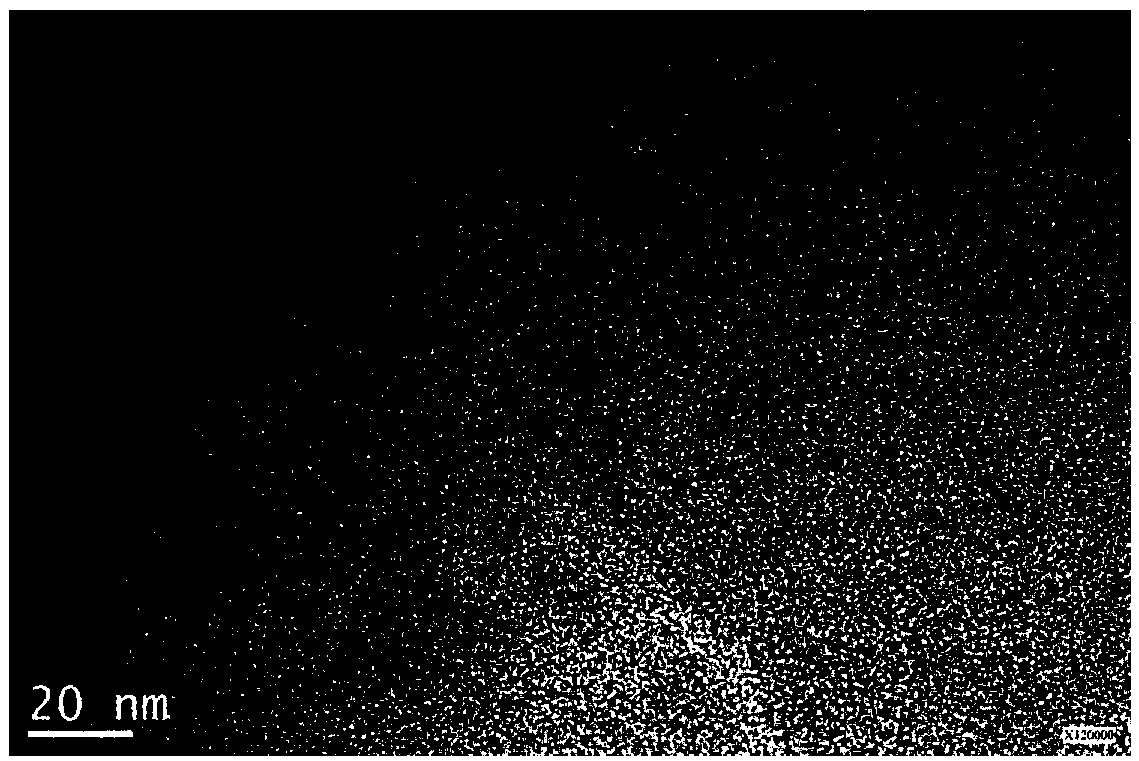

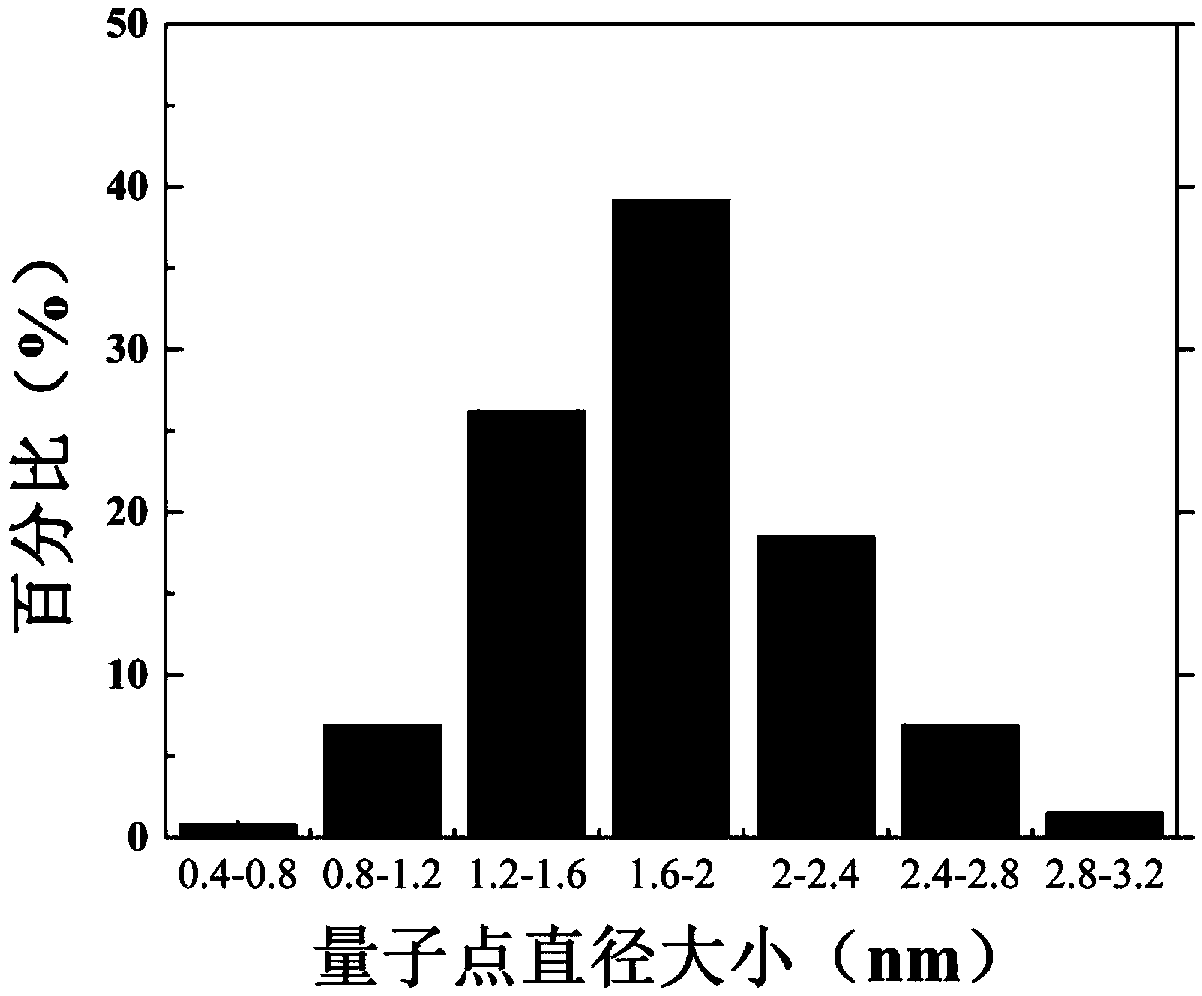

[0032] figure 1 (a) and figure 1 (b) are respectively the front FESEM image and cross-sectional FESEM im...

Embodiment 2

[0037] In this example, titanium dioxide quantum dots were prepared from the same columnar crystal microsphere titanium dioxide powder as in Example 1. The specific steps are as follows:

[0038] (1), weigh 2g of columnar crystal microsphere titanium dioxide powder, immerse in liquid nitrogen and carry out freeze embrittlement treatment for 10h;

[0039] (2) Disperse the titanium dioxide powder after freeze embrittlement treatment in 1000mL of isopropanol and deionized water in a mixed solvent with a volume ratio of 1:1, and the resulting dispersion was immediately crushed by water-bath ultrasonication for 4 hours, with a crushing power of 240W;

[0040] (3) Put the crushed dispersion liquid into liquid nitrogen to carry out freeze embrittlement treatment for 10 hours; then use water bath ultrasonic to carry out crushing treatment for 4 hours, and the crushing power is 240W;

[0041] (4), repeat step (3) 3 times, promptly make titanium dioxide quantum dot.

[0042] After char...

Embodiment 3

[0044] In this example, white amorphous titanium dioxide powder is used as raw material to prepare titanium dioxide quantum dots. The specific steps are as follows:

[0045] (1), weigh 1.5g of white amorphous titanium dioxide powder, immerse in liquid nitrogen and carry out freeze embrittlement treatment for 8h;

[0046](2), disperse the titanium dioxide powder after the freezing embrittlement treatment in 500 mL of deionized water, and the obtained dispersion liquid is immediately crushed by ultrasonic water bath for 6h, and the crushing power is 210W;

[0047] (3), put the dispersion liquid after ultrasonic crushing treatment into liquid nitrogen again to carry out freeze embrittlement treatment for 8h; then use water bath ultrasonic to carry out crushing treatment for 6h, and crushing power is 210W;

[0048] (4), repeating step (3) once to obtain titanium dioxide quantum dots.

[0049] The FESEM images of the raw materials used in this example under different magnification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com