Method of preparing graphene oxide/ferroferric oxide composite material under normal pressure

A technology of ferroferric oxide and composite materials, which is applied in the field of microwave-absorbing materials, can solve the problems of low output of composite materials, high equipment costs, and high prices, and achieve excellent microwave-absorbing performance, avoid agglomeration, and reduce energy loss and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a kind of preparation method of graphene oxide / ferric oxide composite material, comprises the following steps:

[0050] A) After mixing the graphene oxide polyol dispersion, ferric source, alkaline regulator, surfactant and accelerator, a mixed solution is obtained;

[0051] B) Under normal pressure, after the mixed solution obtained in the above steps is subjected to thermal reaction, a graphene oxide / ferric oxide composite material is obtained.

[0052] In the present invention, firstly, the graphene oxide polyol dispersion liquid, ferric iron source, alkaline regulator, surfactant and accelerator are mixed to obtain a mixed solution.

[0053] The present invention has no special restrictions on the polyols, and the polyols known to those skilled in the art can be used as solvents. Those skilled in the art can select and adjust according to actual production conditions, product requirements and quality requirements. Said polyhydric alcohol is p...

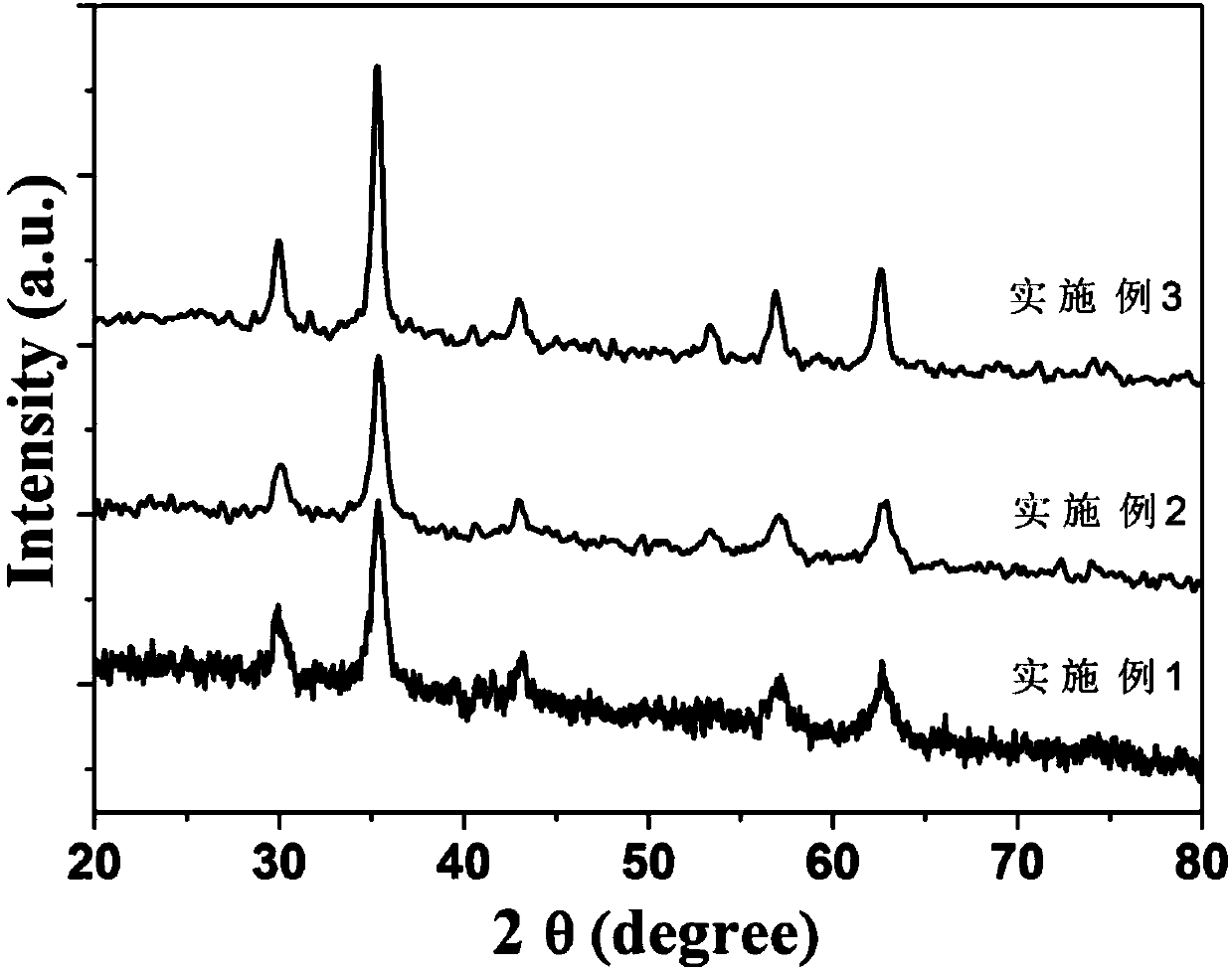

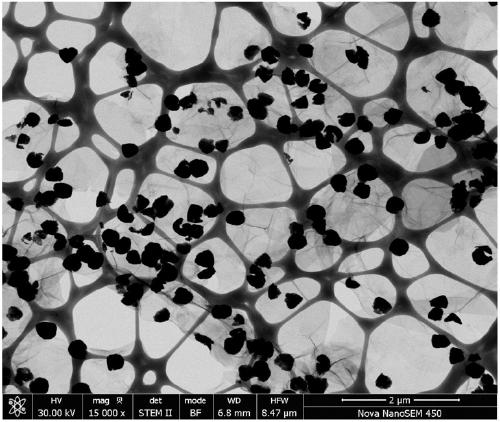

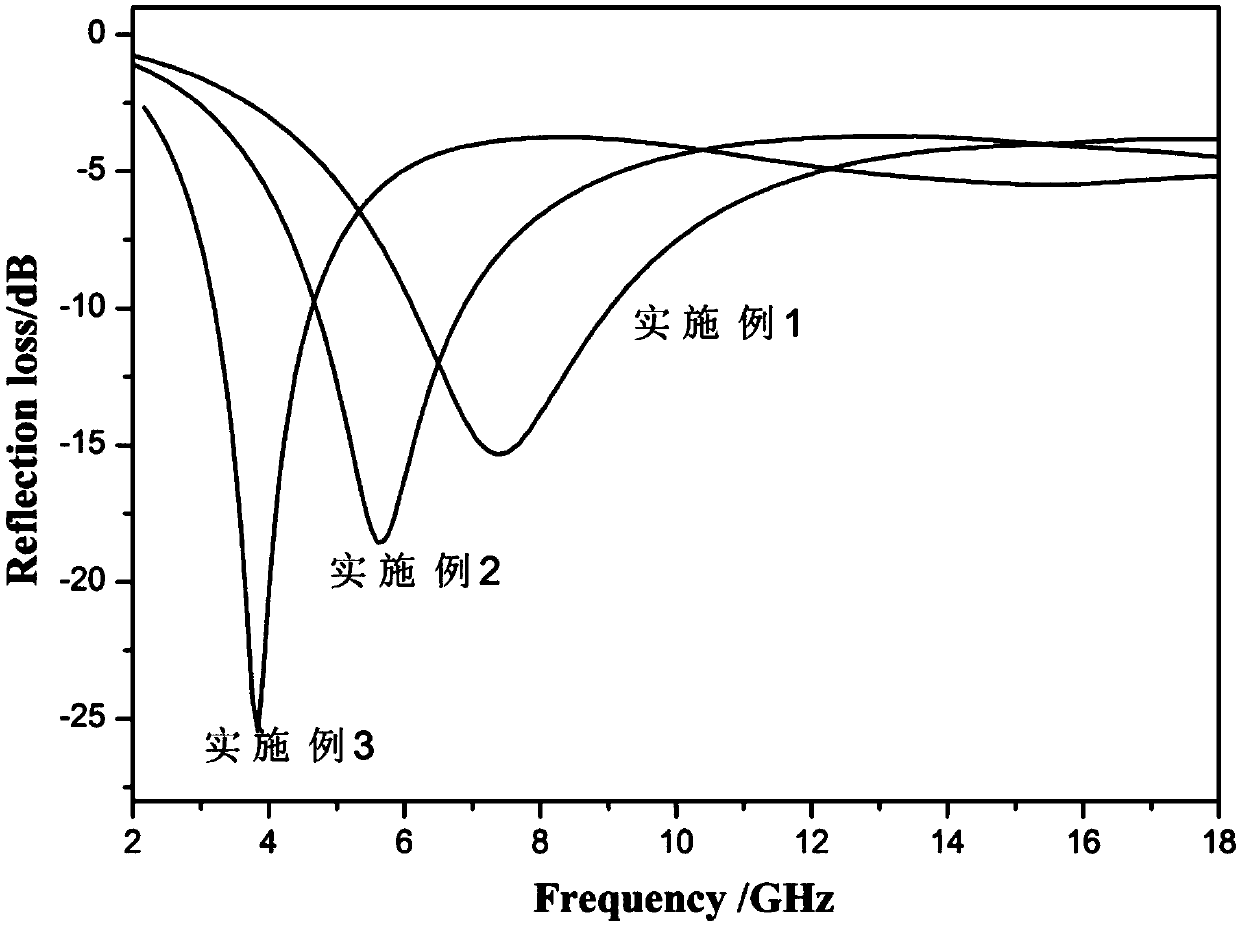

Embodiment 1

[0086] 1] Take the graphene oxide aqueous solution, add a certain proportion of ethylene glycol, and after mixing, use a rotary evaporator to remove the water in the mixed solution to obtain a graphene oxide ethylene glycol dispersion solution. Among them, the mass fraction of graphene oxide aqueous solution is 3‰, ethylene glycol: water = 1:1, the rotary evaporation time is 80min, and the rotary evaporation temperature is 75°C;

[0087] 2] Slowly add a certain amount of ferric chloride, sodium acetate and polyethylene glycol dropwise to the graphene oxide ethylene glycol dispersion solution obtained in step 1], and continue stirring for a period of time to obtain a mixed solution 1. Among them, the mass of ferric chloride is 10 times that of graphene oxide, the mass of sodium acetate is 20 times that of graphene oxide, the mass of polyethylene glycol is 2 times that of graphene oxide, and the stirring time is 30 minutes.

[0088] 3] Slowly add a certain amount of accelerator ...

Embodiment 2

[0100] 1] Take the graphene oxide aqueous solution, add a certain proportion of ethylene glycol, and after mixing, use a rotary evaporator to remove the water in the mixed solution to obtain a graphene oxide ethylene glycol dispersion solution. Among them, the mass fraction of the graphene oxide aqueous solution is 3‰, ethylene glycol: water = 10:1, the rotary evaporation time is 80min, and the rotary evaporation temperature is 75°C;

[0101] 2] Slowly add a certain amount of ferric chloride, sodium acetate and polyethylene glycol dropwise to the graphene oxide ethylene glycol dispersion solution obtained in step 1], and continue stirring for a period of time to obtain a mixed solution 1. Wherein, the mass of ferric chloride is 5 times that of graphene oxide, the mass of sodium acetate is 10 times that of graphene oxide, the mass of polyethylene glycol is equal to that of graphene oxide, and the stirring time is 30 minutes.

[0102] 3] Slowly add a certain amount of accelerato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com