Propeller pond stirrer for papermaking process

A papermaking process and propeller technology, which is applied in the field of papermaking process propeller pool agitators, can solve the problems of single function, uneven circulation of paddle materials, and decreased stirring rate, and achieves the effects of improving work efficiency, reducing costs and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

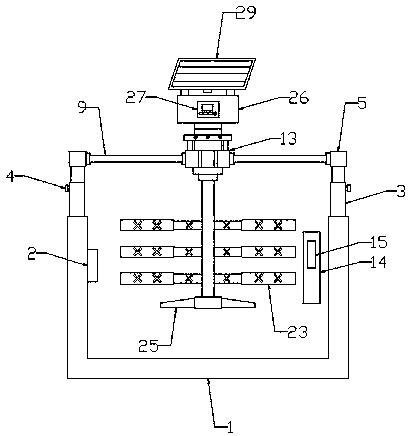

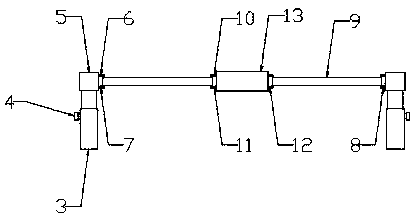

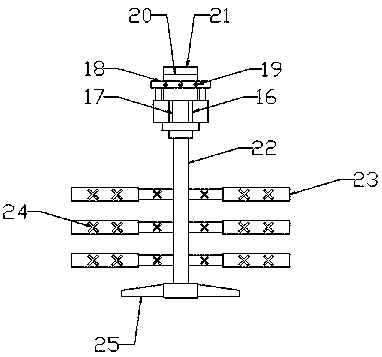

[0024] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-8As shown, a propeller tank agitator for papermaking process includes a storage tank 1, the storage tank 1 is a vertical storage tank, and a concentration sensor 2 is provided on one side of the storage tank 1. An adjustable support frame device is provided above the oar storage pool 1, and the adjustable support frame device is composed of a group of telescopic support frames 3 fixedly installed on the ground above the oar storage pool 1, and positioning Button 4, located at the top of the telescopic support frame 3 and fixedly mounted on the top seat 5 at the top of the telescopic support frame 3, fixed block one 6 located on one side of the top seat 5 and fixedly installed on one side of the top seat 5, positioned on the surface of the fixed block one 6 Circular through hole 7 around the surface of the fixed block 6, the fastening bolt 8 inserted in the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com