Nitrogen-containing high-entropy MXene with sulfur catalysis function, diaphragm composite material and battery

A composite material and lithium-sulfur battery technology, applied in the field of new materials, can solve problems such as the reduction of mixing entropy and the difficulty of atomic layer peeling, and achieve the effects of avoiding the loss of active materials, avoiding the generation of the shuttle effect, and reducing the dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

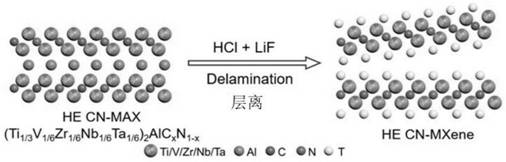

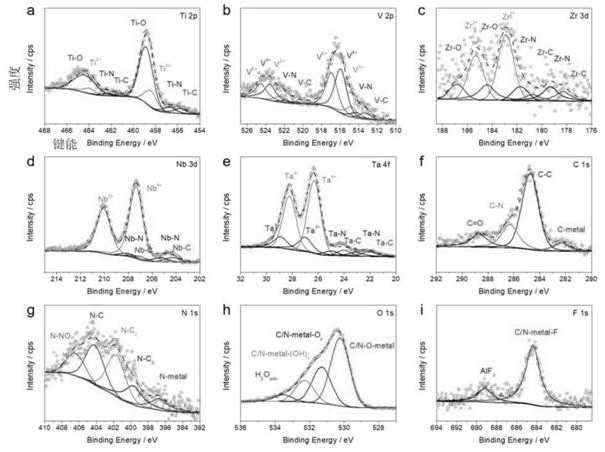

[0045] This embodiment provides a nitrogen-containing high-entropy MXene two-dimensional material (Ti 1 / 3 Nb 1 / 6 Ta 1 / 6 Zr 1 / 6 V 1 / 6 ) 2 C 0.5 N 0.5 method of preparation, such as figure 1 As shown, by etching nitrogen-containing high-entropy MAX phase material (Ti 1 / 3 Nb 1 / 6 Ta 1 / 6 Zr 1 / 6 V 1 / 6 ) 2 AlC 0.5 N 0.5 The Al element in it is obtained.

[0046] Nitrogen-containing high-entropy MAX phase materials (Ti 1 / 3 Nb 1 / 6 Ta 1 / 6 Zr 1 / 6 V 1 / 6 ) 2 AlC 0.5 N 0.5 preparation, including:

[0047] Ingredients step: according to the chemical formula of high entropy MAX phase (Ti 1 / 3 Nb 1 / 6 Ta 1 / 6 Zr 1 / 6 V 1 / 6 ) 2 AlC 0.5 N 0.5 The medium stoichiometric ratio (molar ratio) is Ti 4 AlN 3 , V 2 AlC and (Nb 1 / 3 Ta 1 / 3 Zr 1 / 3 ) 2 AlC is used as the raw material precursor, and its molar ratio is Ti 4 AlN 3 :V 2 AlC:(Nb 1 / 3 Ta 1 / 3 Zr 1 / 3 ) 2 AlC=1:1:3, accurately weigh each raw material precursor according to the corresponding molar ratio;

[00...

Embodiment 2

[0057] This embodiment provides a nitrogen-containing high-entropy MXene two-dimensional material (Ti 1 / 3 Nb 1 / 6 Ta 1 / 6 Zr 1 / 6 V 1 / 6 ) 2 C 0.5 N 0.5 The preparation method, by etching nitrogen-containing high-entropy MAX phase material (Ti 1 / 3 Nb 1 / 6 Ta 1 / 6 Zr 1 / 6 V 1 / 6 ) 2 AlC 0.5 N 0.5 The Al element in it is obtained.

[0058] Nitrogen-containing high-entropy MAX phase materials (Ti 1 / 3 Nb 1 / 6 Ta 1 / 6 Zr 1 / 6 V 1 / 6 ) 2 AlC 0.5 N 0.5 preparation, including:

[0059] Ingredients step: according to the chemical formula of the nitrogen-containing high-entropy MAX phase (Ti 1 / 3 Nb 1 / 6 Ta 1 / 6 Zr 1 / 6 V 1 / 6 ) 2 AlC 0.5 N 0.5 The stoichiometric ratio (molar ratio) of Ti 4 AlN 3 , Nb 2 AlC and (V 1 / 3 Ta 1 / 3 Zr1 / 3 ) 2 AlC is used as the raw material precursor, and its molar ratio is Ti 4 AlN 3 :Nb 2 AlC:(V 1 / 3 Ta 1 / 3 Zr 1 / 3 ) 2 AlC=1:1:3, accurately weigh each raw material precursor according to the corresponding molar ratio;

[0060] Grinding...

Embodiment 3

[0065] This embodiment present invention provides another kind of preparation nitrogen-containing high entropy MAX phase (Ti 1 / 3 Nb 1 / 6 Ta 1 / 6 Zr 1 / 6 V 1 / 6 ) 2 C 0.5 N 0.5 T x The preparation method is similar to Example 1, and the difference is that: in the batching step, (Zr 1 / 3 Nb 1 / 3 Ta 1 / 3 ) 2 AlC, Ti 2 AlN and V 2 AlC is used as the raw material to prepare according to the molar ratio of 3:1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com