Patents

Literature

96results about How to "Layered structure is obvious" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perovskite solar cell and method for manufacturing same

InactiveCN104795501ASimple and fast operationLow costFinal product manufactureSolid-state devicesHole transport layerMetal electrodes

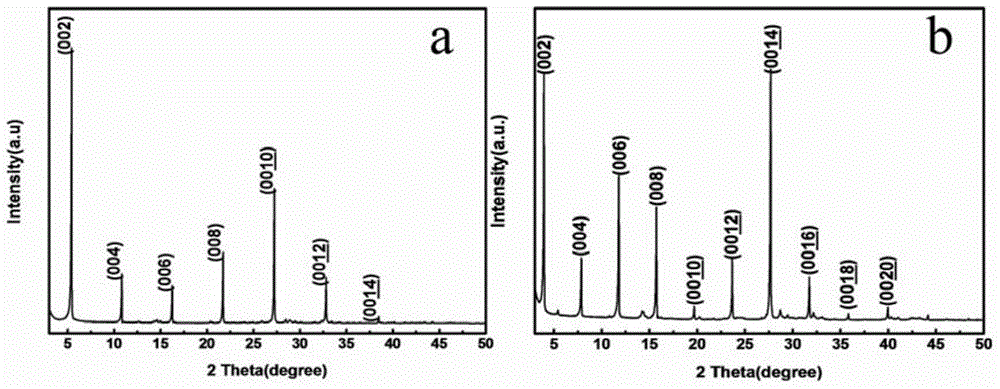

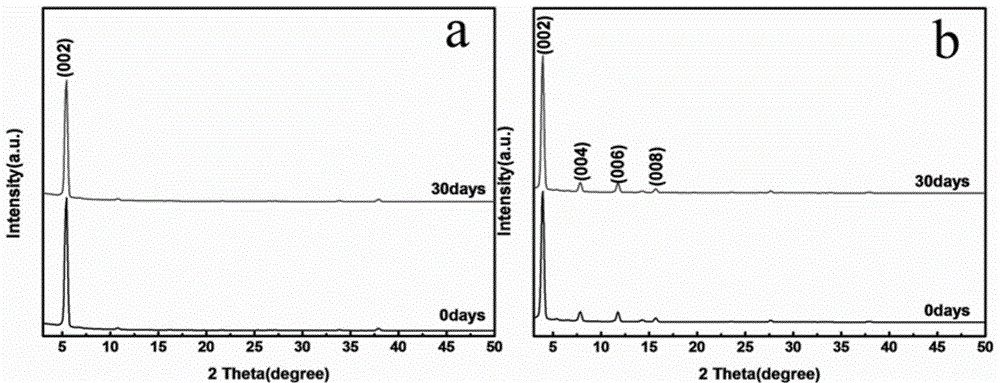

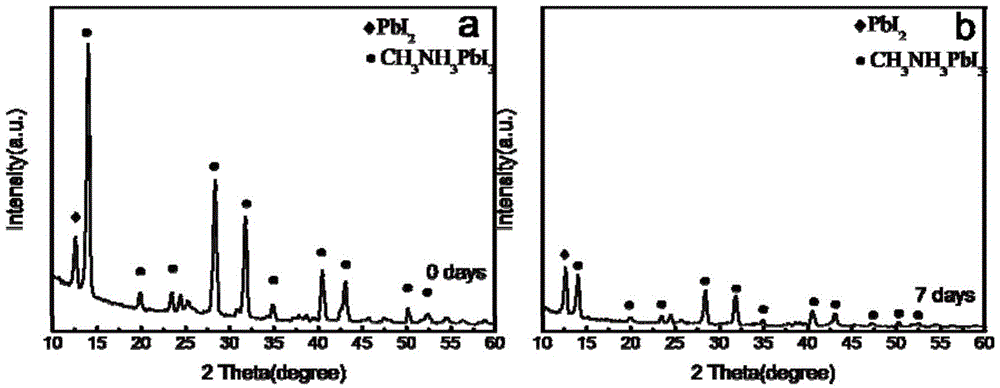

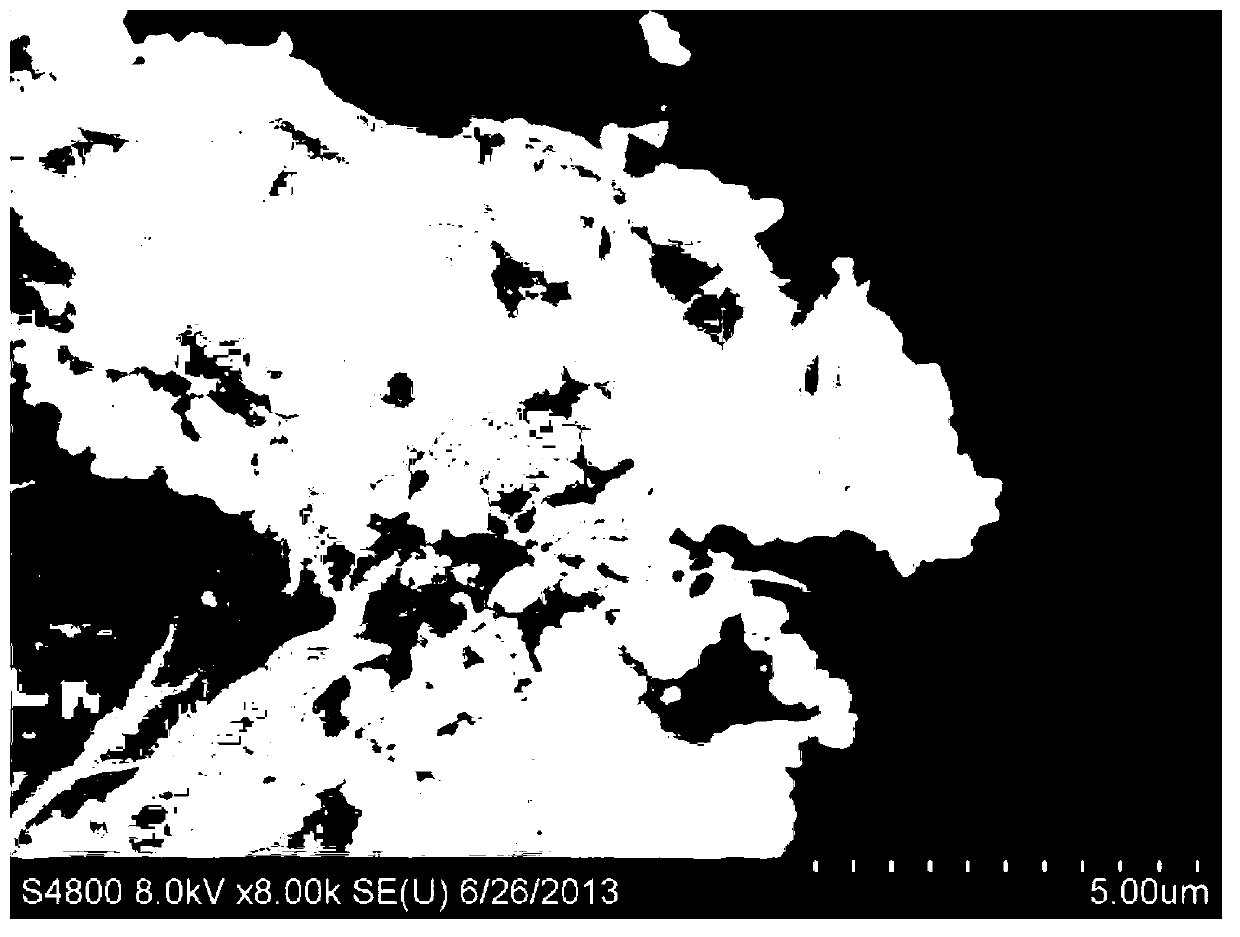

The invention relates to a perovskite solar cell and a method for manufacturing the same. The perovskite solar cell comprises an FTO (fluorine-doped tin oxide) transparent conducting glass substrate, an electron transport layer, a light absorption layer, a hole transport layer and a metal electrode. The light absorption layer is made of (C<6>H<5>CH<2>CH<2>NH<3>)<2>(CH<3>NH<3>)<n-1>Pb<n>I<3*n+1> (the n is equal to 1 or 2) materials which are of two-dimensional layered structures. The perovskite solar cell and the method have the advantages that the layered perovskite light absorption layer is manufactured by the aid of a spin coating process, the method is simple and is excellent in film-forming property, the materials of the light absorption layer can be changed along with the layer number n, gaps of the materials can be adjusted, and the materials are excellent in chemical stability and still can keep the excellent layered structures without chemical decomposition after being exposed at high air humidity (50-80%) for 30 days, solar cell prototype devices with excellent and stable performance can be obtained, and the perovskite solar cell and the method are favorable for promoting perovskite solar cell commercialization progress.

Owner:WUHAN UNIV OF TECH

Lithium ion battery cathode material and preparation method thereof as well as lithium ion battery

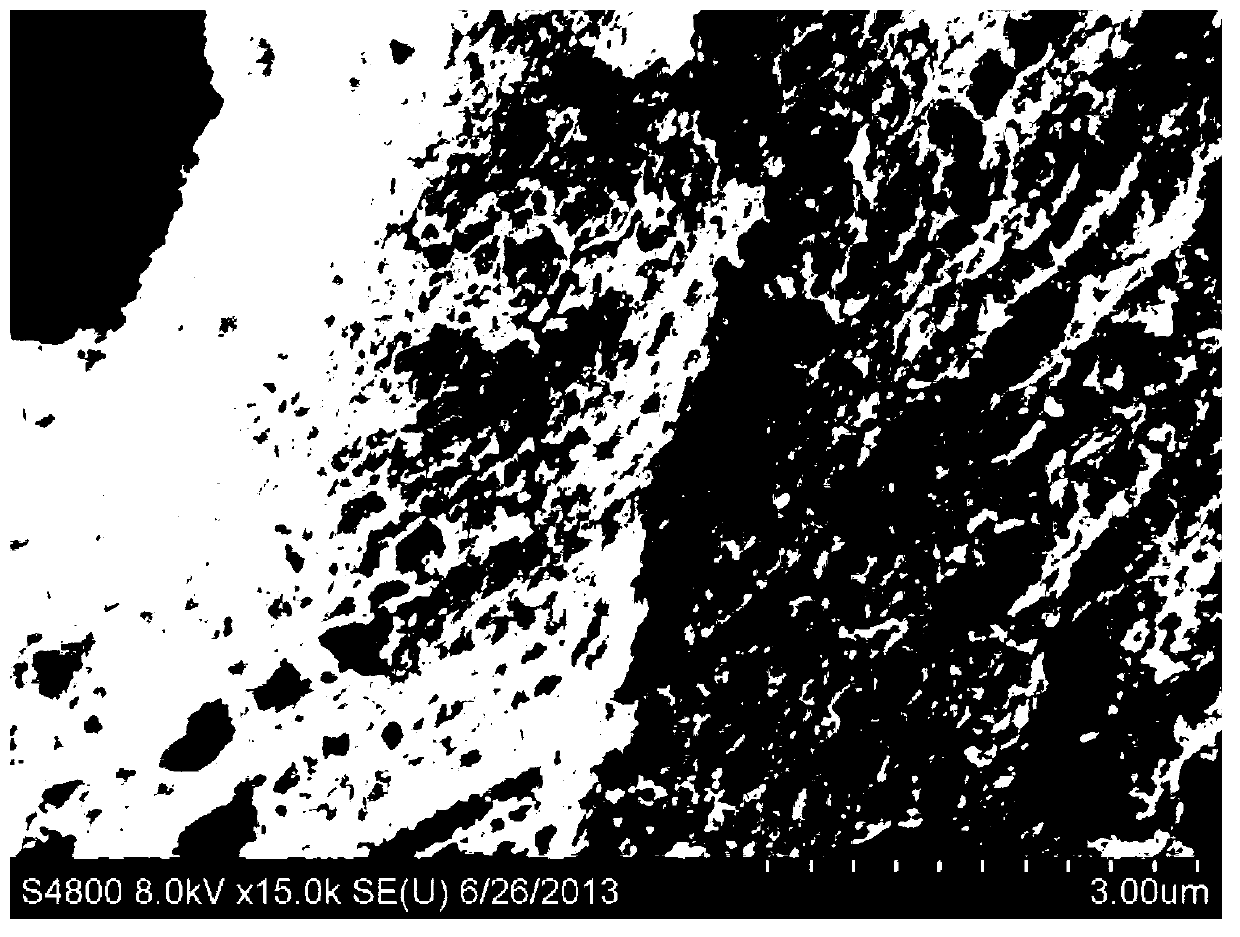

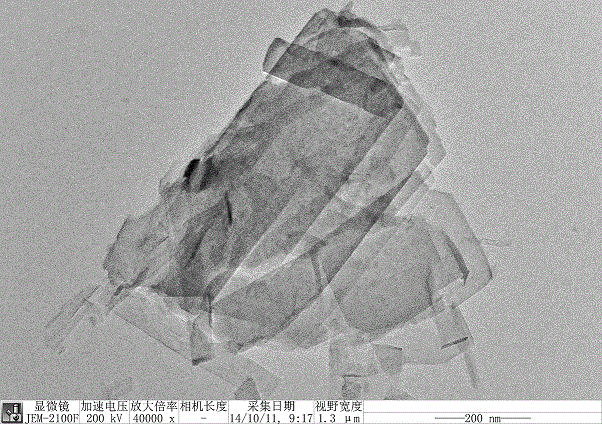

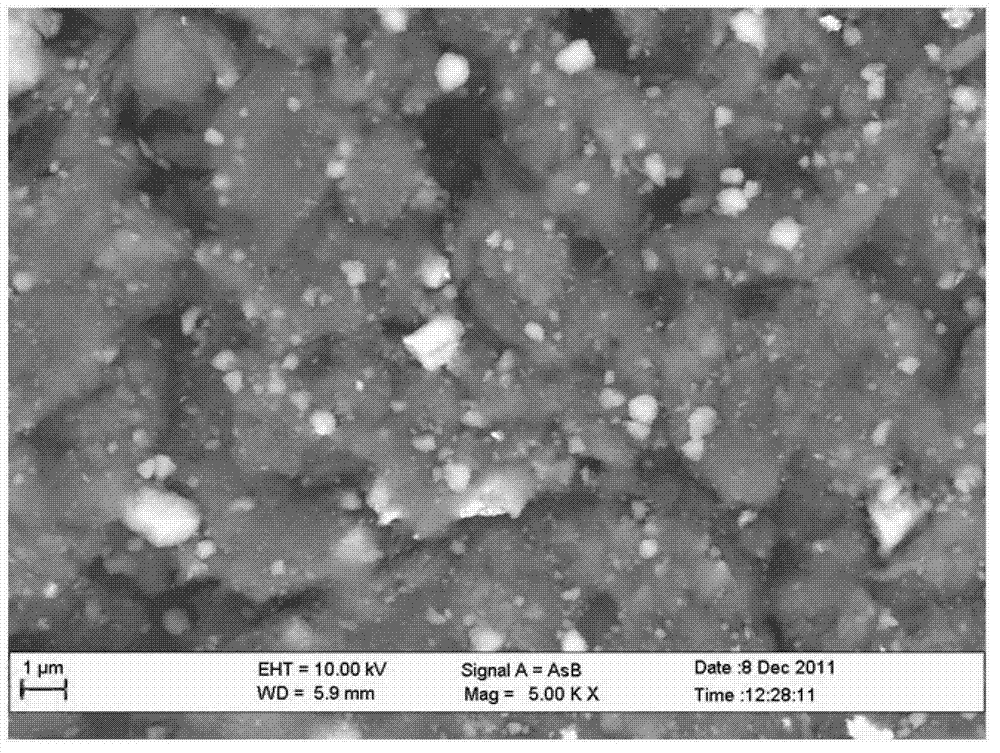

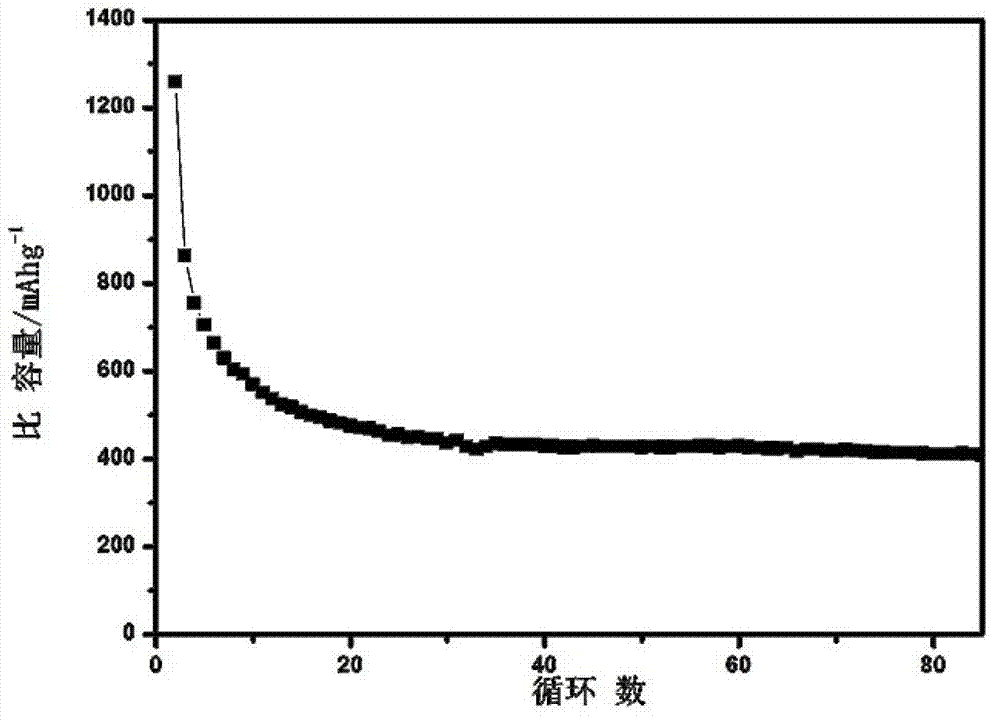

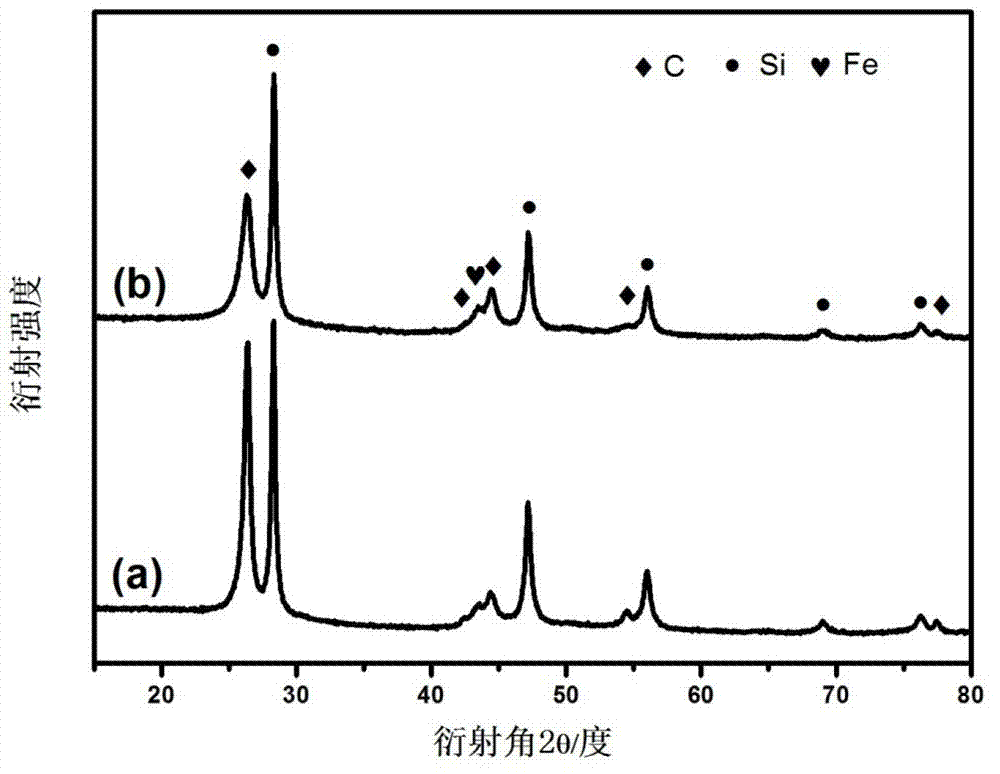

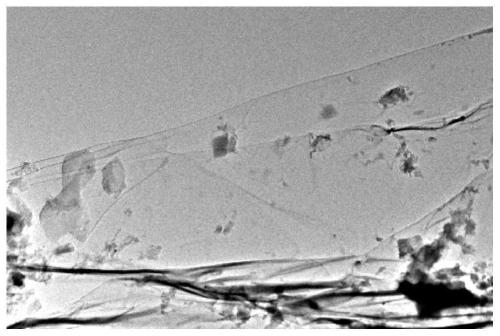

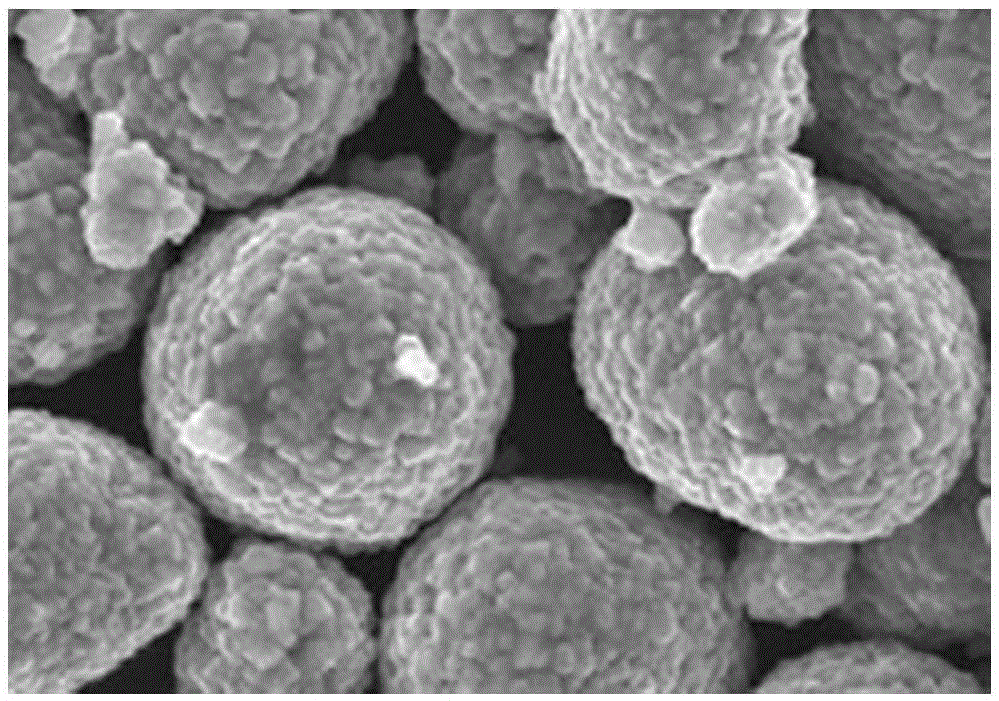

ActiveCN103346325AImprove cycle performanceLayered structure is obviousCell electrodesSecondary cellsNetwork structureGraphene

The invention provides a lithium ion battery cathode material, comprising graphene, nanometer silicon particles distributed in a graphene lamellar structure, and net-shaped carbon materials distributed between the graphene lamellar structure and the nanometer silicon particles. According to the invention, the graphene has a good lamellar structure, nanometer silicon particles are distributed in the graphene lamellar structure, and net-shaped carbon materials are distributed between the graphene lamellar layer and the nanometer silicon particles. According to the lithium ion battery cathode material provided by the invention, carbon materials between the graphene lamellar layer and the network structure are in tight contact with the nanometer silicon particles, thereby improving conductivity of the cathode material, and at the same time, effectively buffering enormous volume change of silicon particles, thus the lithium ion battery cathode material has good cycle performance.

Owner:宁波富理电池材料科技有限公司

High-temperature abradable seal coating

InactiveCN101653998AReduce oxidation rateStop the spreadMolten spray coatingLayered productsSurface layerAlloy

The invention relates to high-temperature abradable seal coating with single-layer or multi-layer structure, wherein the high-temperature abradable seal coating with single-layer structure is providedwith a bonding bottom layer sprayed on a base body, and an oxygen barrier layer and a seal surface layer are sequentially sprayed on the bonding bottom layer; on the basis of the high-temperature abradable seal coating with single-layer structure, at least another seal surface layer is needed to be sprayed on the seal surface layer to form the high-temperature abradable seal coating with multi-layer structure; the bonding bottom layer is made of NiCrAlY or NiCoCrAlY alloy powder, the oxygen barrier layer is made of composite agglomerated powder of nano yttria, partially stable zirconia and nano Alpha-Al2O3, and the seal surface layer is made of nano Y-PSZ based high-temperature seal coating materials. The high-temperature abradable seal coating has better high temperature stability, thermal shock resistance and abradability during the use.

Owner:WUHAN UNIV OF TECH

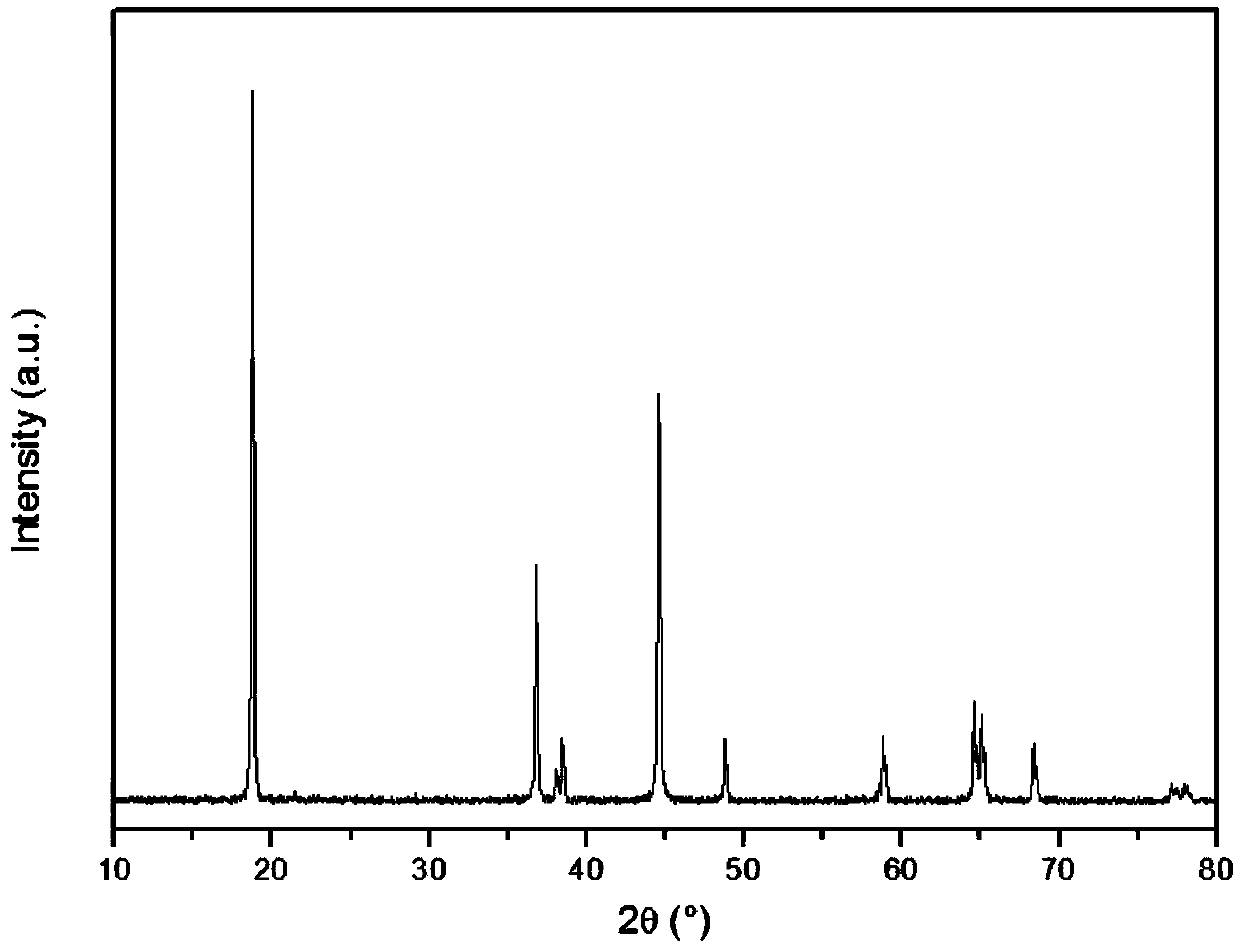

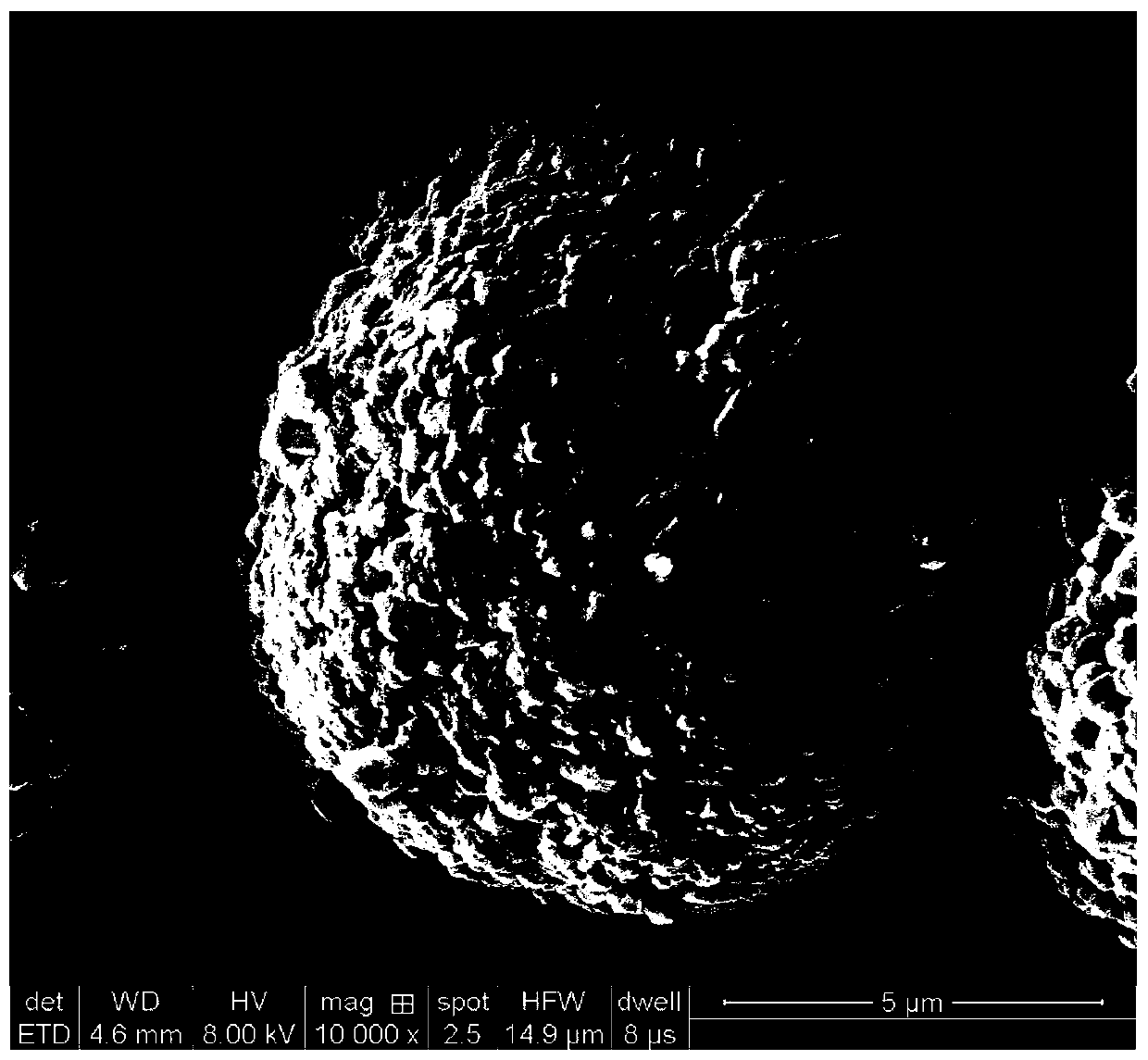

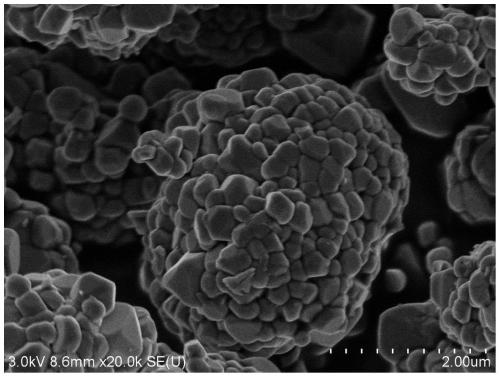

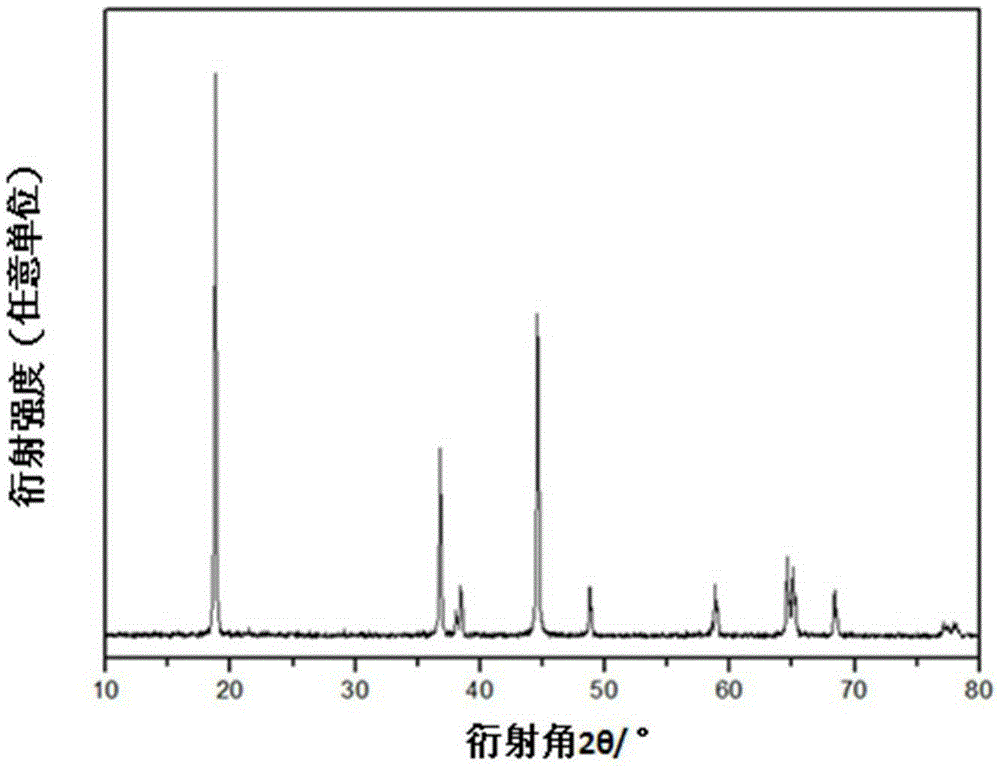

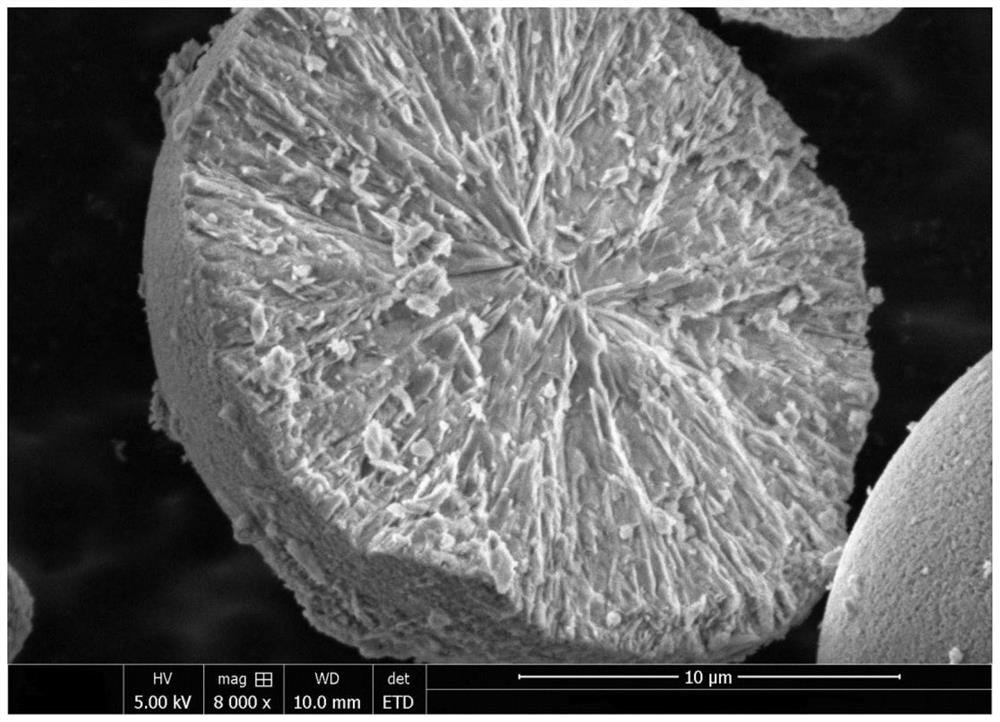

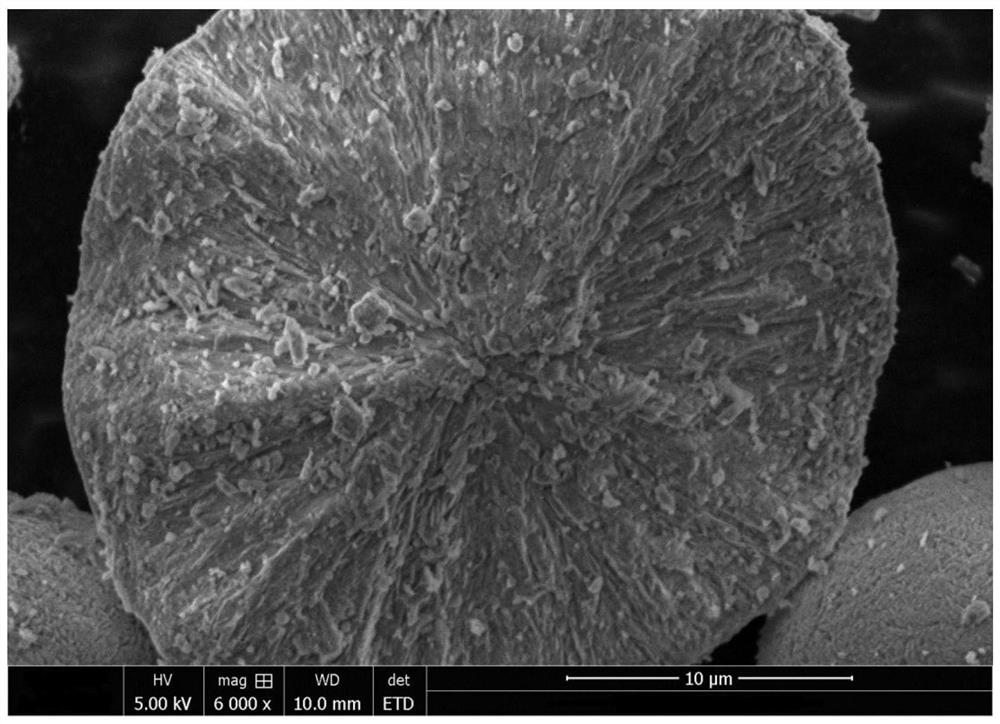

Ternary cathode material, precursor thereof, and preparation method of ternary cathode material and precursor

ActiveCN107585794AHigh activityShorten the diffusion pathCell electrodesSecondary cellsLayered structureSeed crystal

The invention provides a ternary precursor with a composite hetero-structure. The molecular formula of the ternary precursor is Ni<1-a-b>CoM(OH)2@Ni<1-x-y>Co<x>M<y>O<z>, wherein 0<a<1, 0<b<1, 0<a+b<1, 0<x<1, ,0<y<1, 0<x+y<1, 1<z<1.5, and M represents Mn or Al. The ternary precursor comprises a ternary oxide precursor and a ternary hydroxide precursor. The ternary hydroxide precursor is coated on the surface of the ternary oxide precursor. The molecular formula of the ternary oxide precursor is Ni<1-x-y>Co<x>M<y>O<z>, and the molecular formula of the ternary hydroxide precursor is Ni<1-a-b>CoM(OH)2. The invention further provides a preparation method of the ternary precursor. According to the preparation method, a spray pyrolysis method and a co-precipitation method are combined, the ternary oxide precursor obtained by spray pyrolysis is taken as the seed crystal, then a layer of ternary hydroxide precursor is coated on the surface of the ternary oxide precursor through theco-precipitation method to obtain the ternary precursor, and the ternary precursor and lithium salts are mixed and sintered to prepare the ternary cathode material. The ternary cathode material has the advantages of good layered structure, high initial efficiency, high specific capacity, and excellent circulating ratio performance.

Owner:CENT SOUTH UNIV

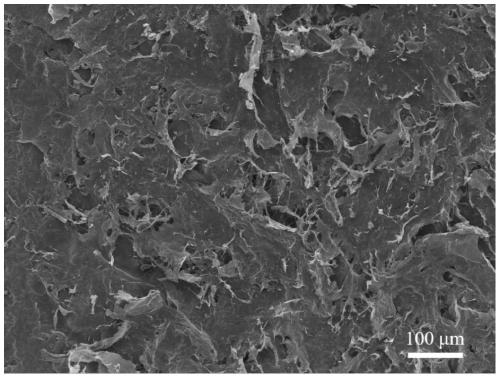

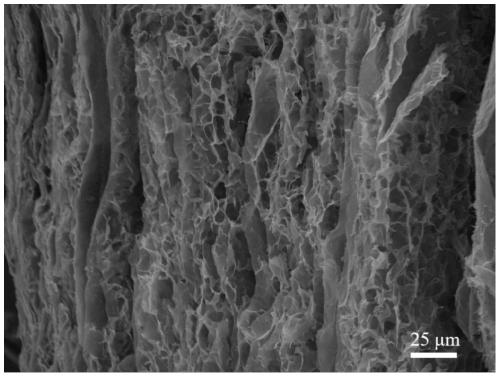

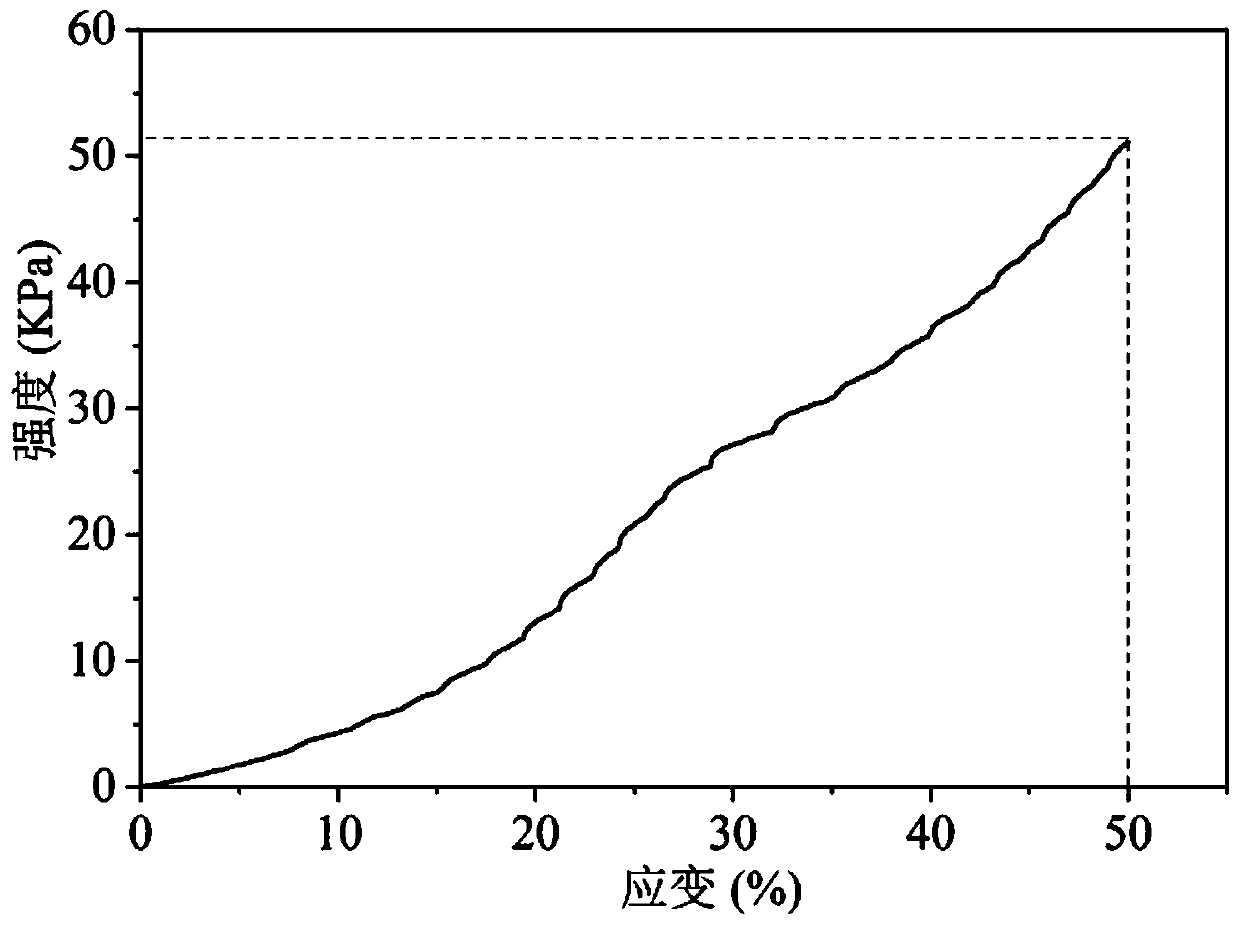

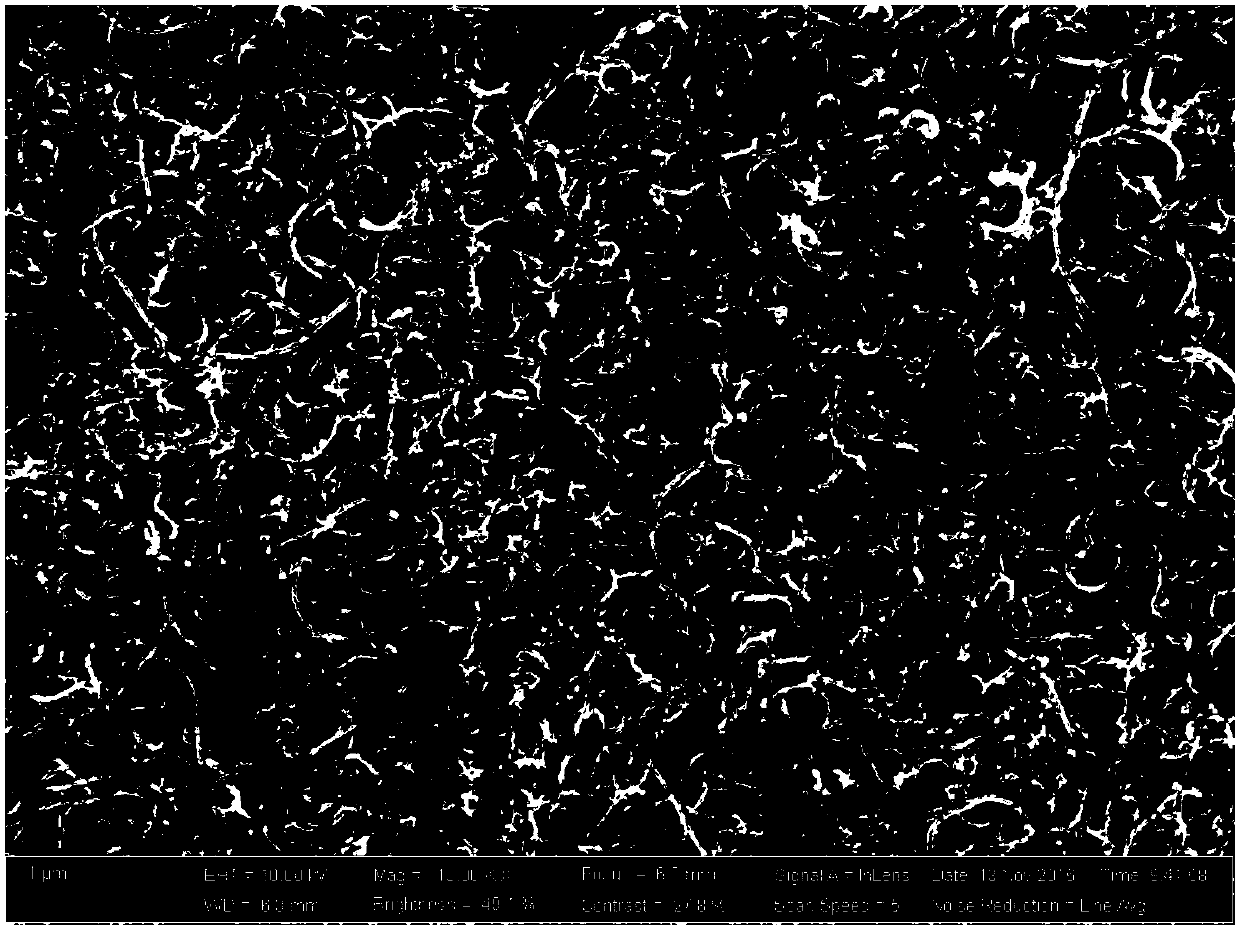

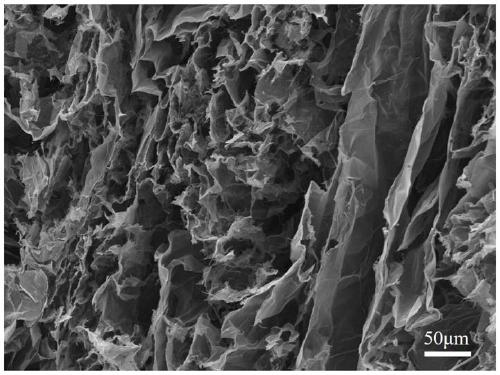

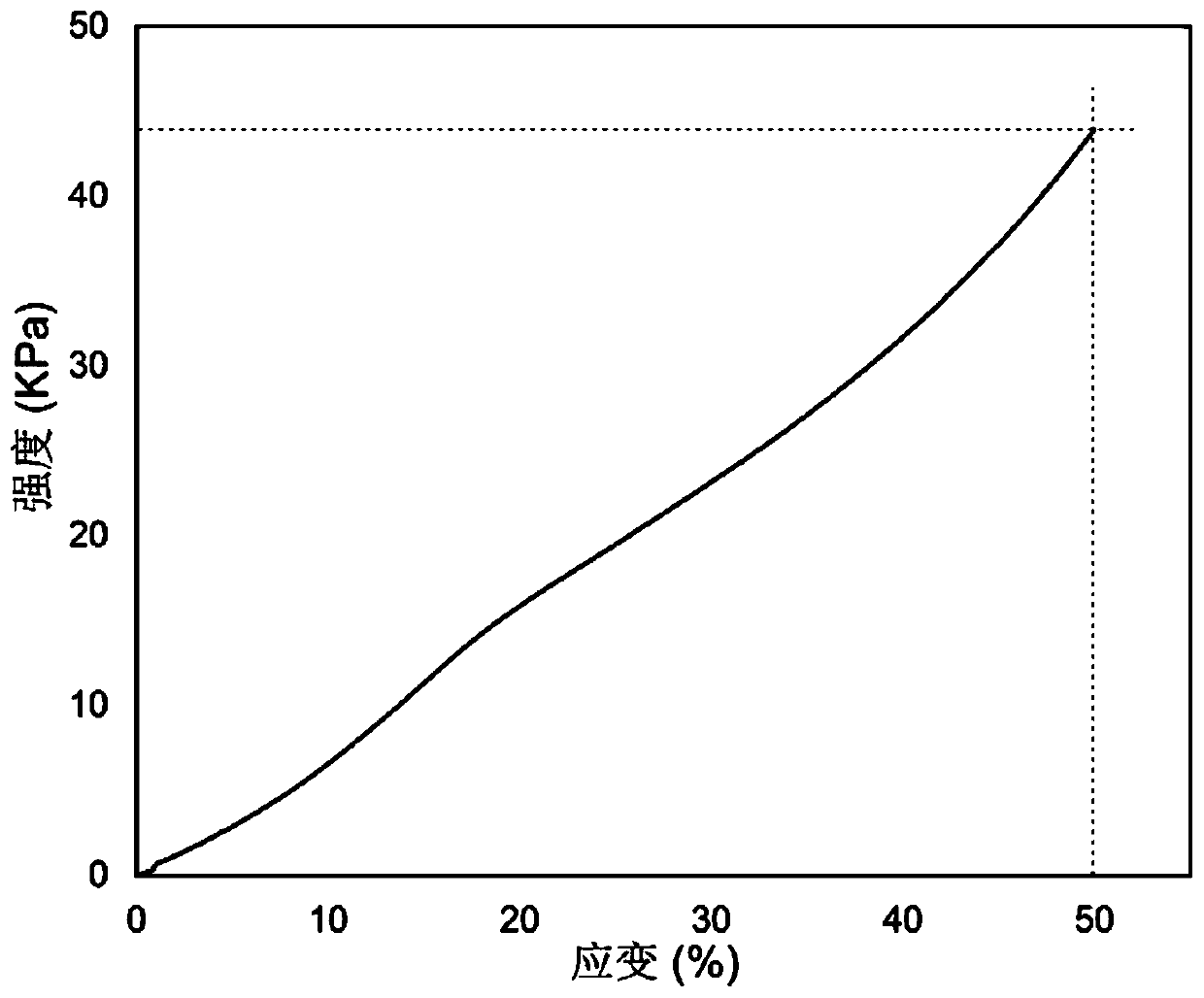

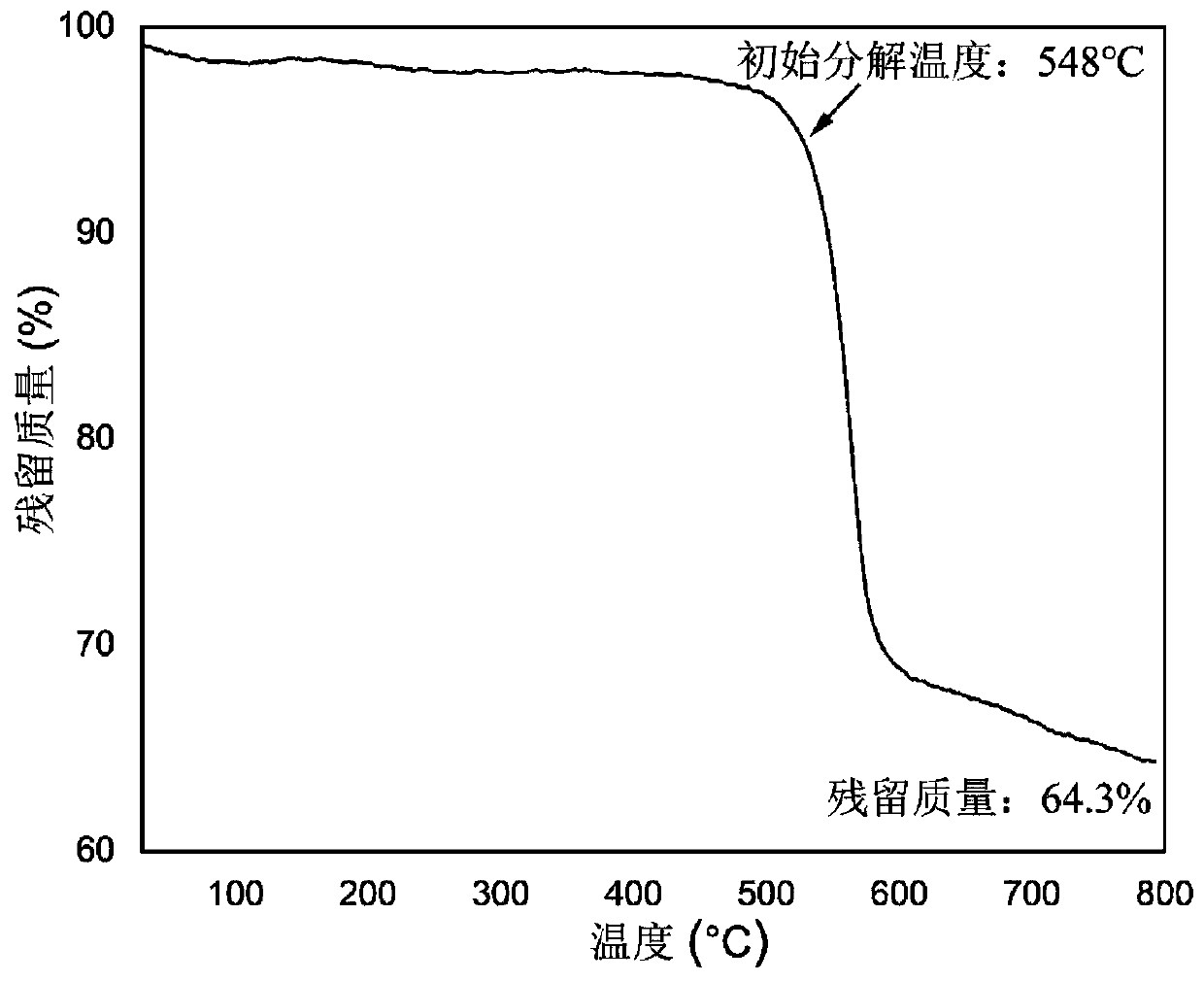

Aramid nanofiber/MXene composite conductive aerogel and preparation method thereof

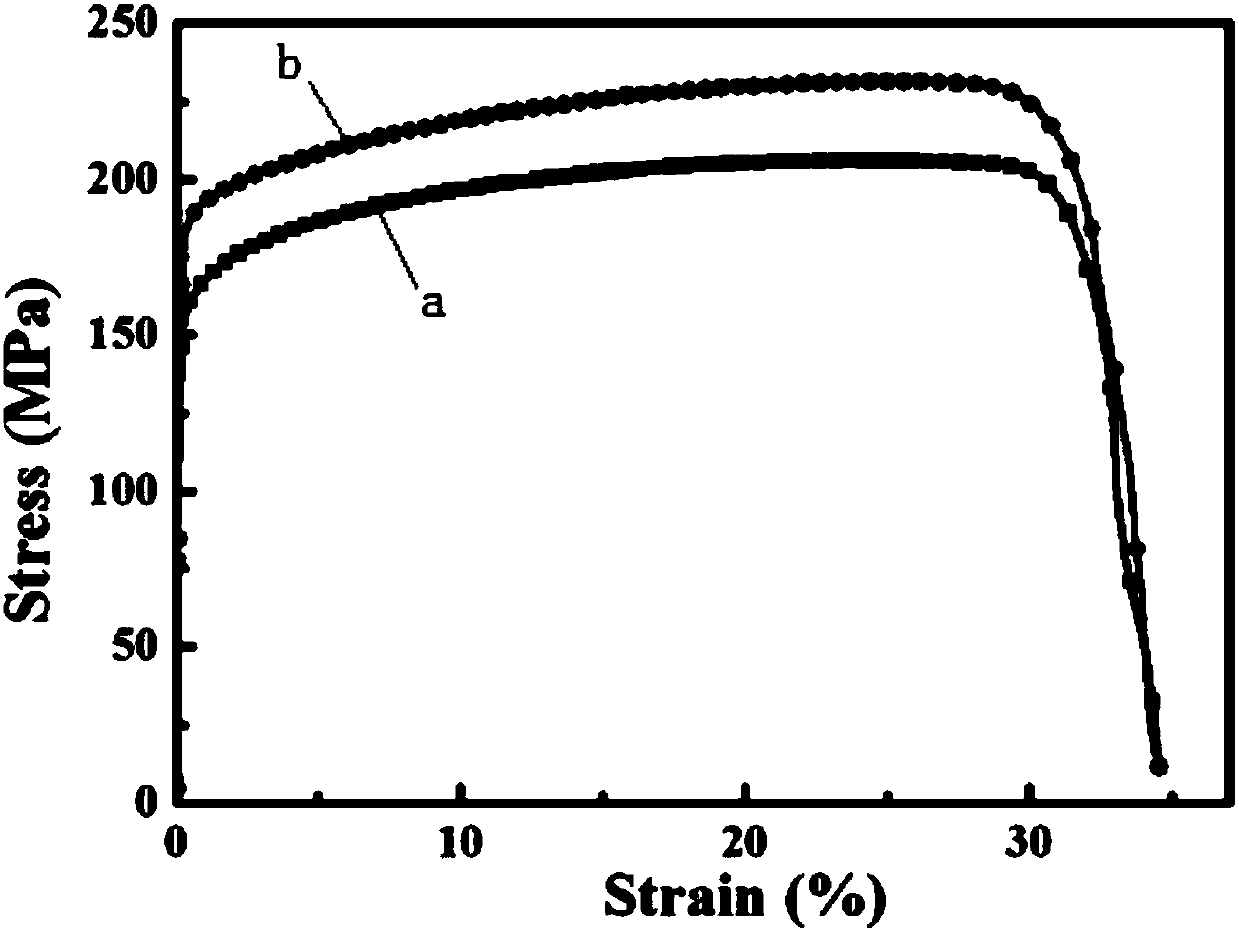

ActiveCN111040238ALarge aspect ratioImprove temperature resistanceForce measurementElectrically conductiveFibrous composites

The invention discloses aramid nanofiber / MXene composite conductive aerogel and a preparation method thereof. By using aramid nanofibers with a nano-scale structure, high strength, a large length-diameter ratio and high temperature resistance as a matrix and using MXene with excellent conductivity, good chemical stability and a unique two-dimensional nano-film structure as a conductive and fillingcoating material, the aramid nanofiber / MXene composite conductive aerogel with low density, high strength and high compression resilience is prepared. The preparation method specifically comprises the following steps: preparing an aramid nanofiber dispersion liquid, preparing an MXene dispersion liquid, preparing an aramid nanofiber / MXene composite dispersion liquid, preparing a gelatinous aramidnanofiber / MXene composite material and the like, thereby obtaining the aramid nanofiber / MXene composite conductive aerogel. The preparation process is simple and easy to implement, and the obtained aramid nanofiber / MXene composite conductive aerogel has wide application prospects in the fields of pressure sensing, intelligent sensors, wearable equipment and the like.

Owner:SHAANXI UNIV OF SCI & TECH

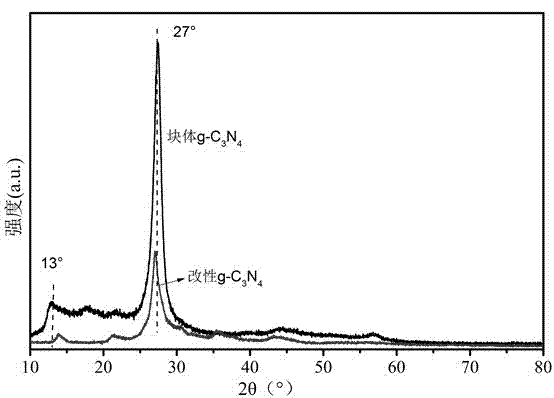

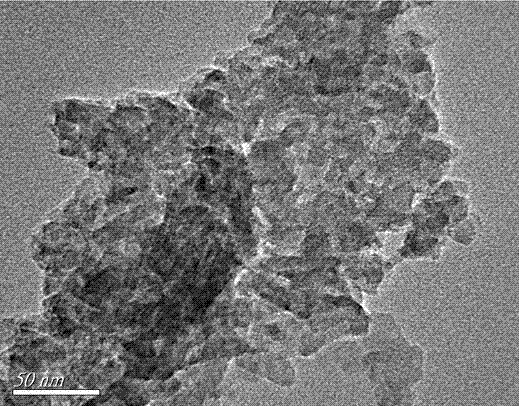

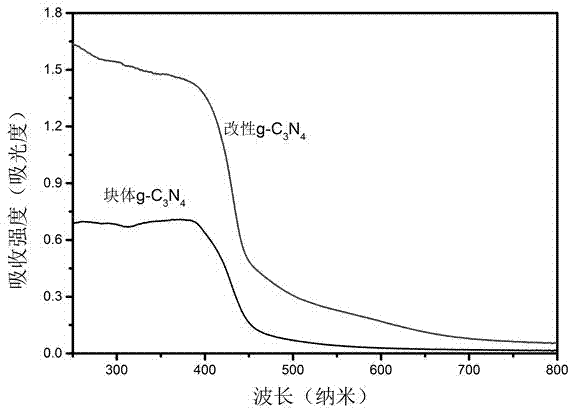

Preparation method of graphite type carbon nitride photocatalytic material

InactiveCN104492470AReduce recombination rateIncrease profitPhysical/chemical process catalystsWater/sewage treatment by irradiationBarbituric acidCatalytic efficiency

The invention discloses a preparation method of a graphite type carbon nitride photocatalytic material, belonging to the field of the material preparation and photocatalytic technology. The graphite type carbon nitride photocatalytic material takes dicyandiamide and barbituric acid as co-precursors, adopts lithium chloride and potassium chloride as heating mediums, and is prepared in protective atmosphere through directly burning. The prepared g-C3N4 has excellent visible light absorption ability and the laminated structure characteristics, and has the degradation efficiency up to 83.8% to rhodamine B within 90min under visible light. The preparation method is simple, the raw materials are easily available, the visible light catalytic efficiency is high, and the graphite type carbon nitride photocatalytic material has wide application prospect in the photocatalytic field.

Owner:JIANGSU UNIV

Preparation and application of laminated structure cobalt and aluminum double hydroxide-reduction and oxidation graphene composite materials

InactiveCN103093967AEasy to makeEasy to operateHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh energy

The invention provides a preparation method of laminated structure cobalt and aluminum double hydroxide-reduction and oxidation graphene composite materials, and belongs to the technical field of composite materials. The method comprises that firstly Co (NO3)2 and AL (NO3)2 are dissolved in water to form mixed solutions; then oxidized graphene is in fully ultrasonic dispersion in the water to form luminous yellow solutions, and the luminous yellow solutions are added to the mixed solutions to be mixed for 20-30 hours; then hexamethylene tetramine is added to a system for backflow of 12-24 hours at the temperature of 100-160 DEG C; and after reaction is completed, the composite materials are gained through filtration, washing and drying. The composite materials prepared through the preparation method simultaneously have an electrical double-layer capacitor of RGO and cobalt and aluminum double hydroxide pseudo-capacitance energy storage characteristics, and thus show high electrochemistry capacitance behaviors, excellent rate capability and good circulatory stability performance, have high energy density and high power density, and can serve as electrode materials of supercapacitors.

Owner:NORTHWEST NORMAL UNIVERSITY

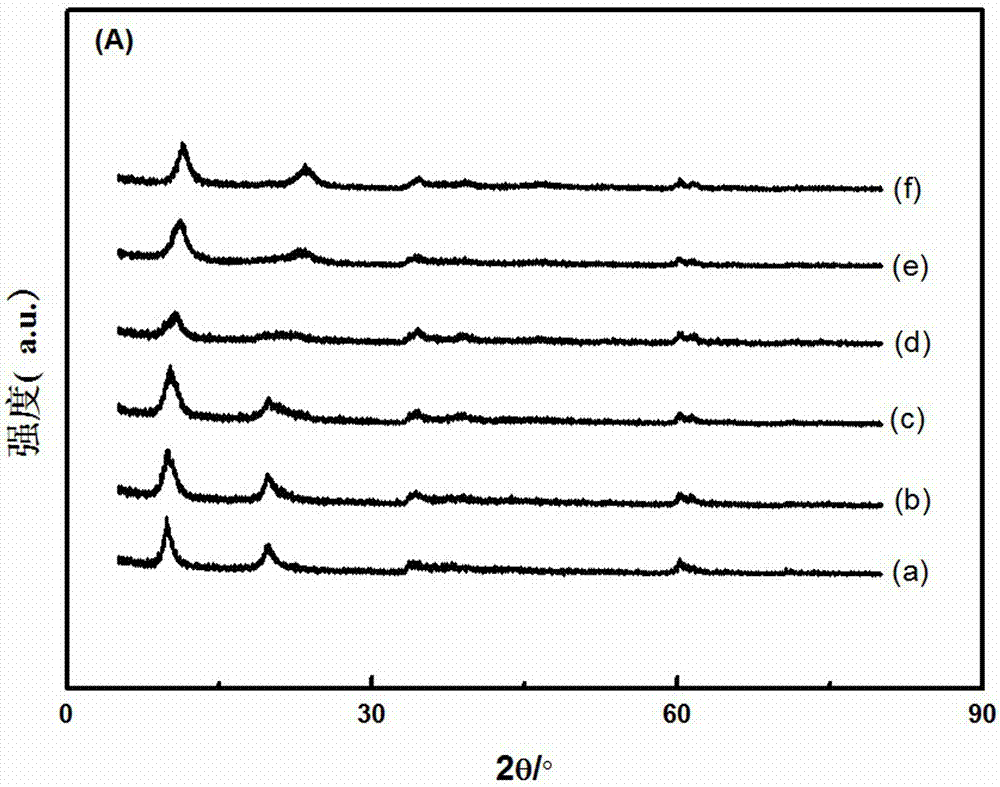

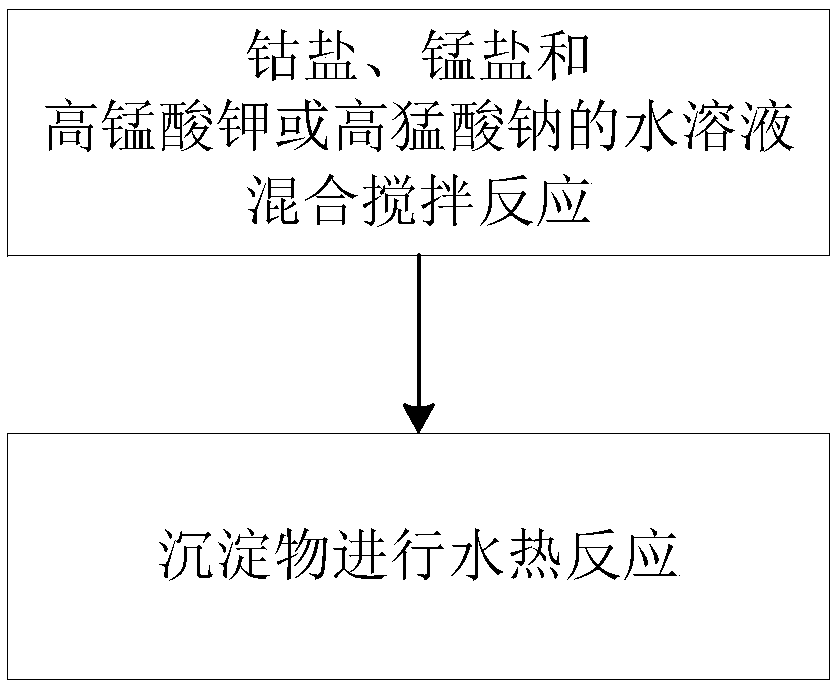

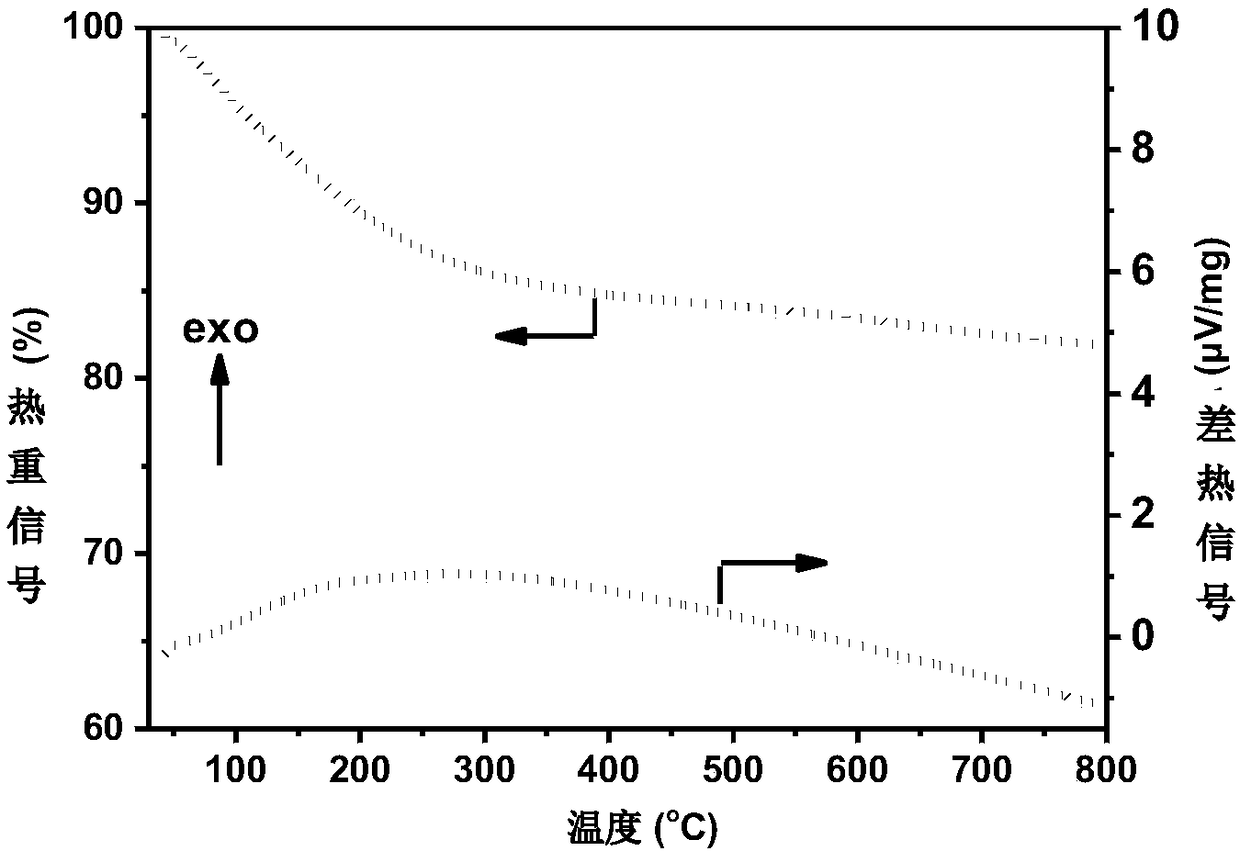

Preparation method of layered cobalt manganese double-metal oxide as well as product thereof

InactiveCN108380221AUniform precipitationUnique layered structureCatalyst activation/preparationManganese oxides/hydroxidesFiltrationManganese oxide

The invention belongs to the technical field of preparation of cobalt manganese oxide and discloses a preparation method of layered cobalt manganese double-metal oxide as well as a product thereof. The preparation method comprises the following steps: (a) mixing water-soluble cobalt salt containing divalent cobalt and water-soluble manganese salt containing divalent manganese uniformly to form a precursor aqueous solution, adding the precursor aqueous solution into an alkaline aqueous solution of potassium permanganate or sodium permanganate, and mixing, stirring and reacting to generate precipitate; and (b) filtering out the precipitate, performing hydrothermal reaction, performing suction filtration and washing on the product after reaction, removing the residual solvent and drying to obtain the needed layered cobalt manganese double-metal oxide. By the preparation method, the obtained layered cobalt manganese double-metal oxide has uniform shape, enables cobalt and manganese elements to be precipitated uniformly and highly, has large specific surface area and has excellent methylbenzene catalytic combustion cavity; furthermore, the preparation method is simple, simple in requirement on equipment, low in raw material price, low in preparation energy consumption, high in repeatability and suitable for popularization and application.

Owner:HUAZHONG UNIV OF SCI & TECH +1

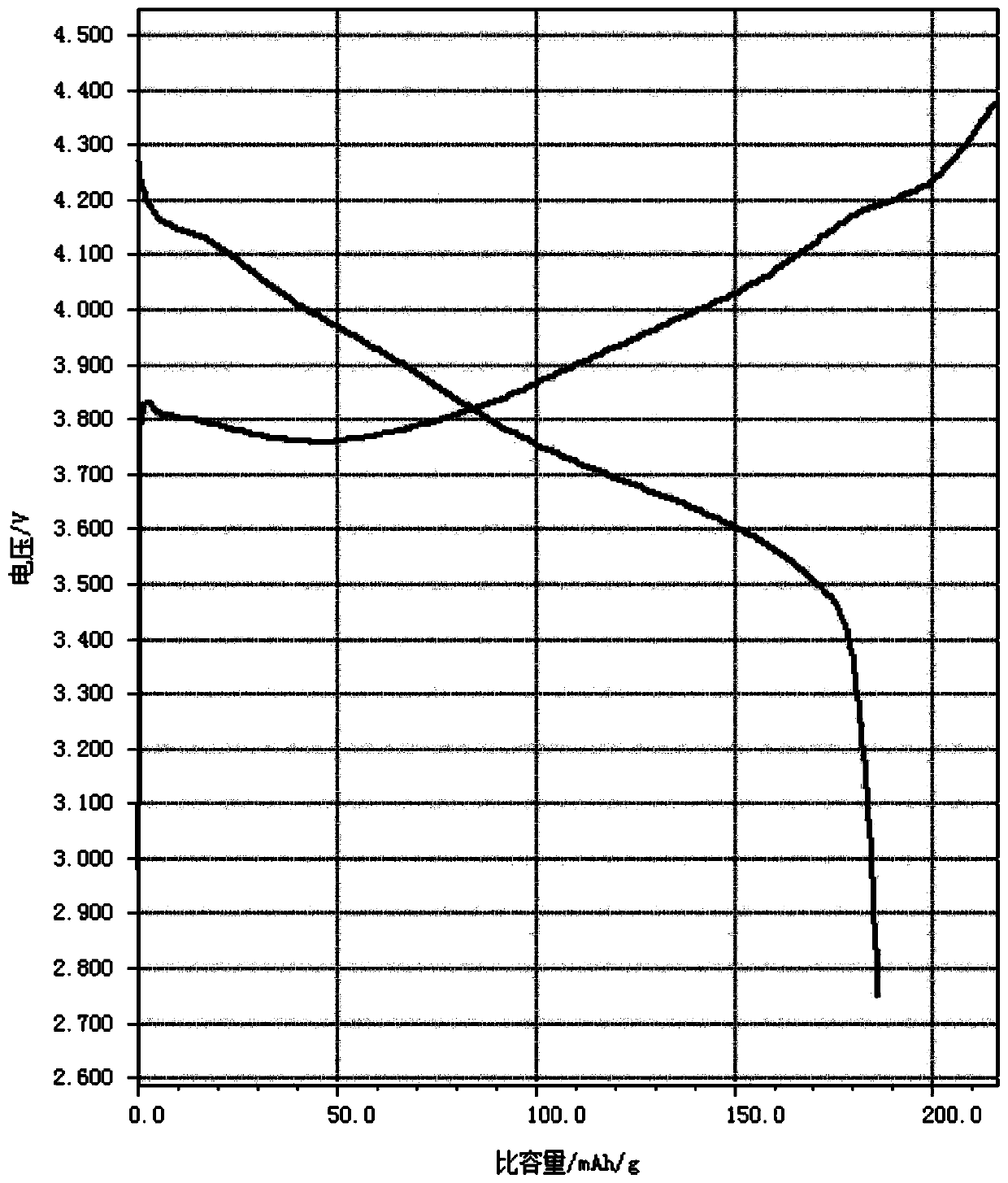

Li-ion supercapacitor

The invention provides a Li-ion supercapacitor. The active material of a positive plate of the Li-ion supercapacitor comprises a porous carbon material and LiNixCoyMnzO2; the porous carbon material is at least one of active carbon, an active carbon fiber, porous graphitized carbon black and graphene; the ratio of the porous carbon material to LiNixCoyMnzO2 is (1:1)-(1:4), wherein x+y+z=1, x:y:z=5:2:3 or x:y:z=5:3:2 or x:y:z=6:2:2 or x:y:z=7:1.5:1.5 or x:y:z=8:1:1; the active material of a negative plate is at least one of synthetic graphite, interphase graphite, mesocarbon microbeads, hard carbon and soft carbon; the mass ratio of the LiNixCoyMnzO2 contained in the positive plate to the active material contained in the negative plate is 0.5-1.6; the electrolyte of the Li-ion supercapacitor consists of an electrolyte salt and an organic solvent; the electrolyte salt is selected from LiPF6 or LiBF4 or LiBOB or LiFSI; and the organic solvent is at lest one of ethylene carbonate, carbonic allyl ester, carbonic methyl ester, methyl carbonate, diethyl carbonate and acetonitrile.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

High-temperature abrasive sealing coating material used for plasma spraying

InactiveCN101659800ASmall grain sizeNo apparent layered structureBlade accessoriesMachines/enginesSpray GranulationMetallurgy

The invention relates to a high-temperature abrasive sealing coating material used for plasma spraying. According to mass percentage, the high-temperature abrasive sealing coating material is mainly prepared from the following raw materials by mass percent: 75 to 90 percent of nanometer zirconia, 5 to 20 percent of nanometer alpha-Al2O3, 1 to 3 percent of hBN and 4 to 7 percent of polybenzoate, wherein the nanometer zirconia and the nanometer alpha-Al2O3 are used as high-temperature resistant basal-phase materials, the hBN is used as a solid lubricator and the polybenzoate is used as a porecreating material. The high-temperature abrasive sealing coating material is prepared through the processing steps of blending, mixing, spraying granulation, sieving, and the like. The high-temperature abrasive sealing coating material provided by the invention has high depositing efficiency, and the coating prepared by the high-temperature abrasive sealing coating material has good high-temperaturestability, heat and shock resistance and abrasive performance, so that the coating material can be used as the coating material for sealing a turbine part, and has stable performance and good effect when used under the condition of 1000 DEG C.

Owner:WUHAN UNIV OF TECH

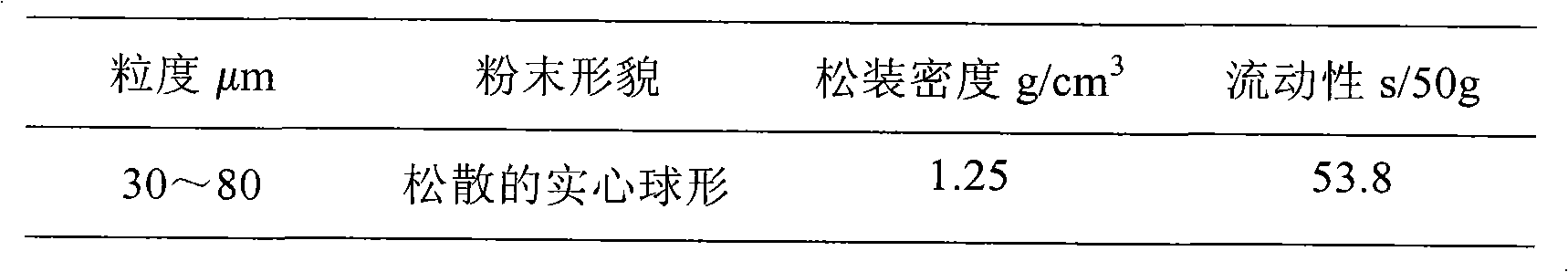

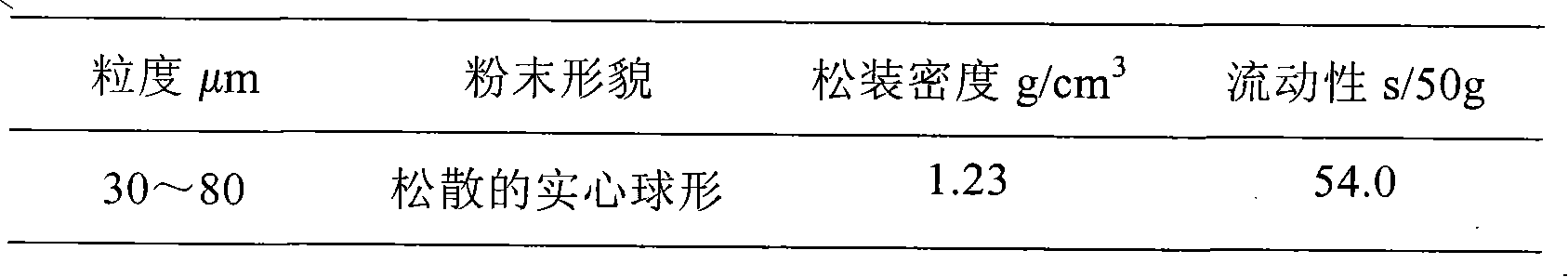

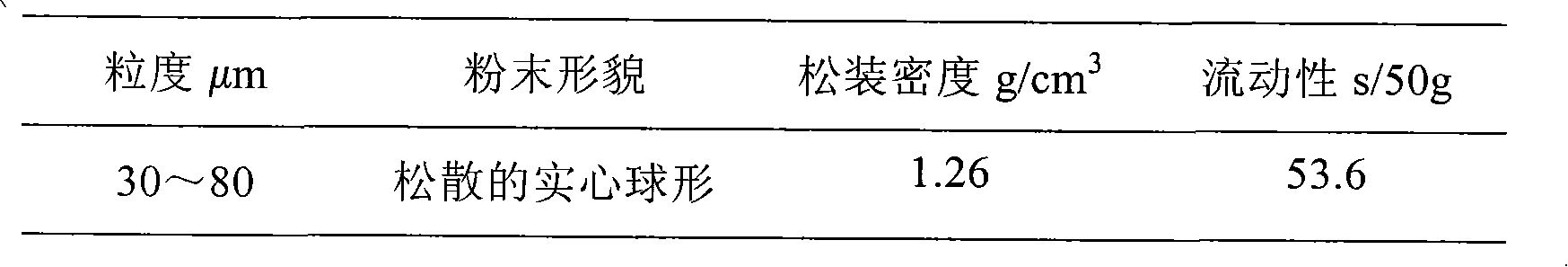

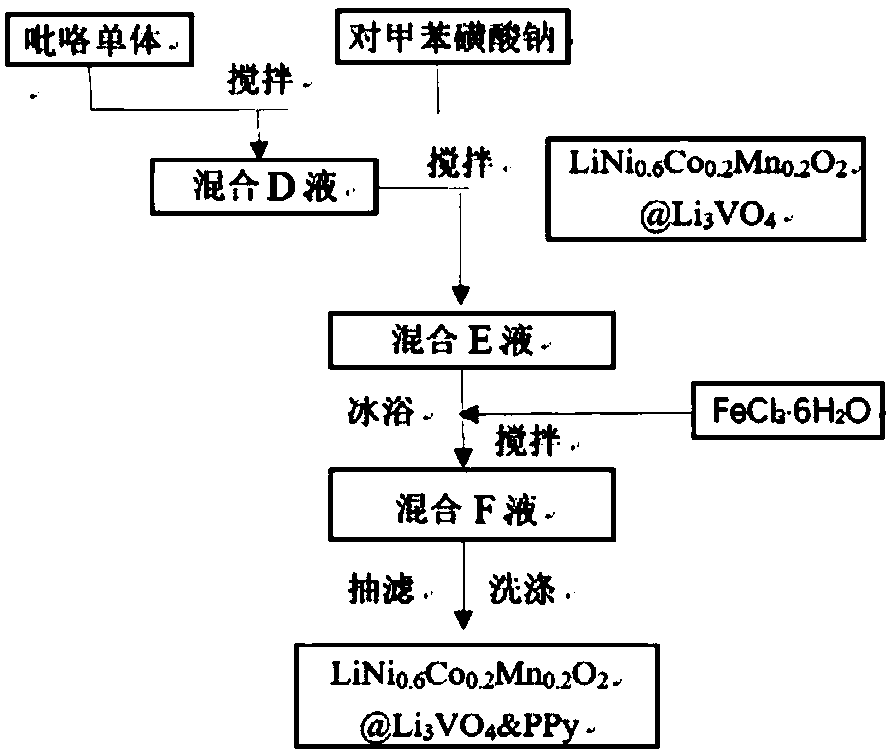

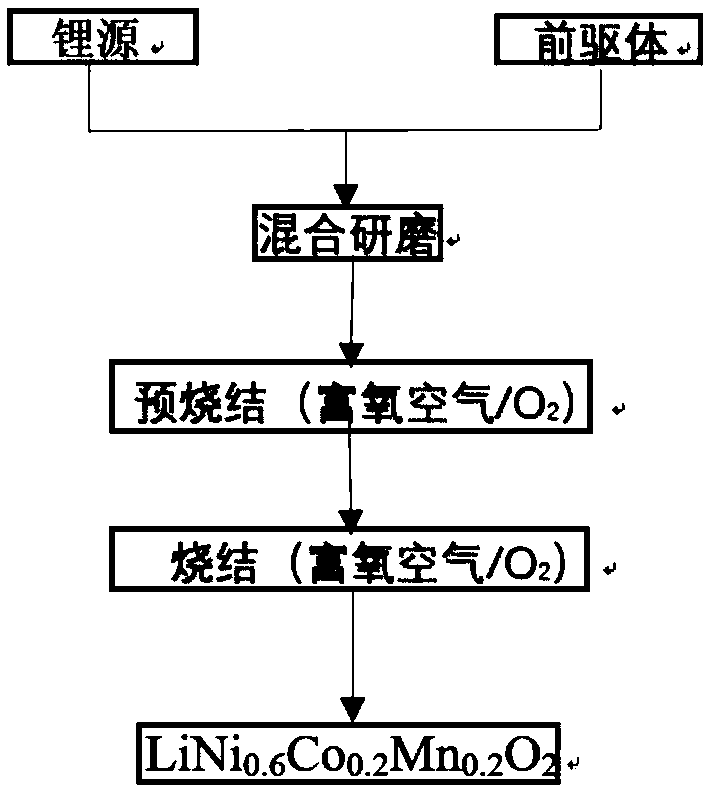

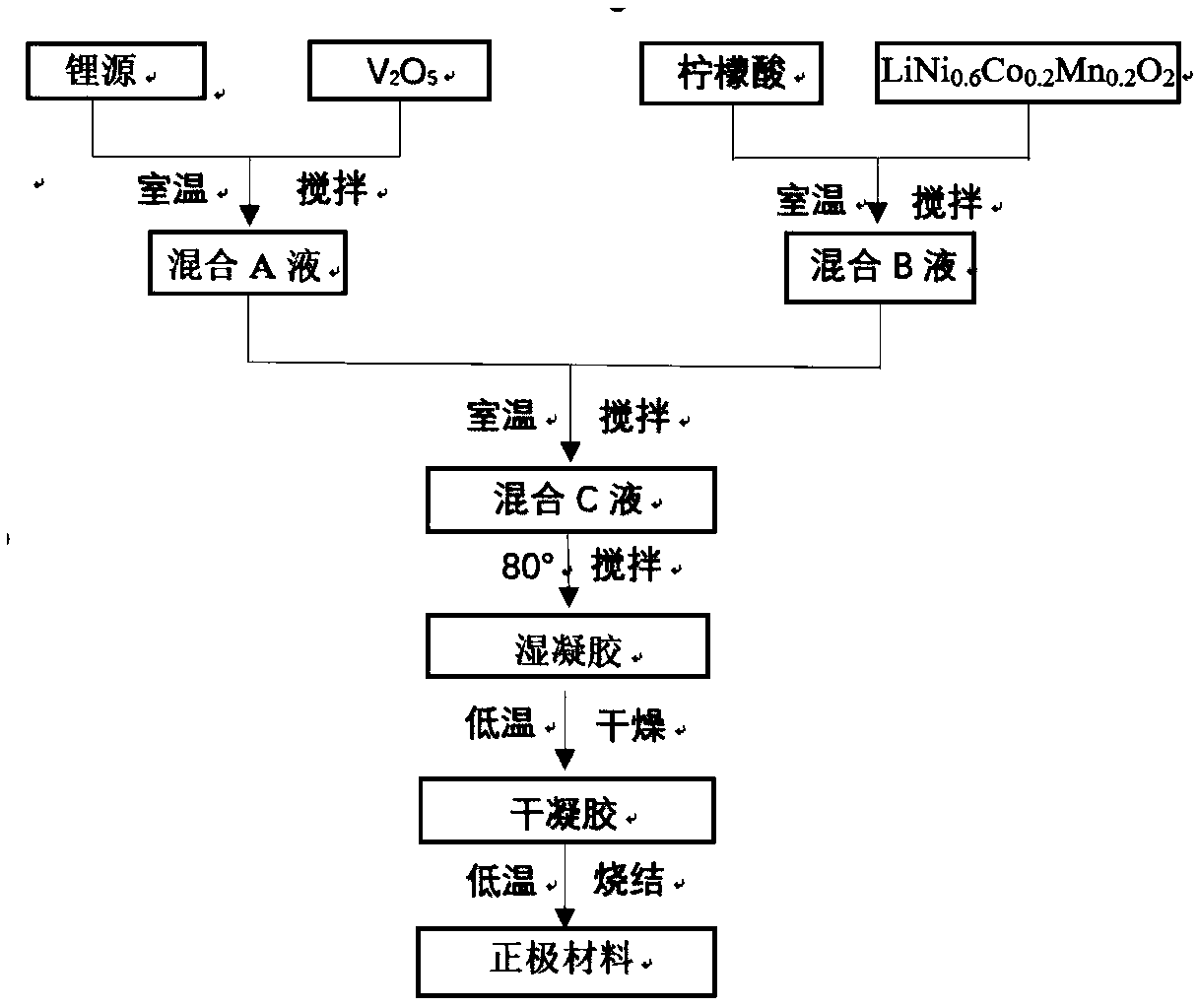

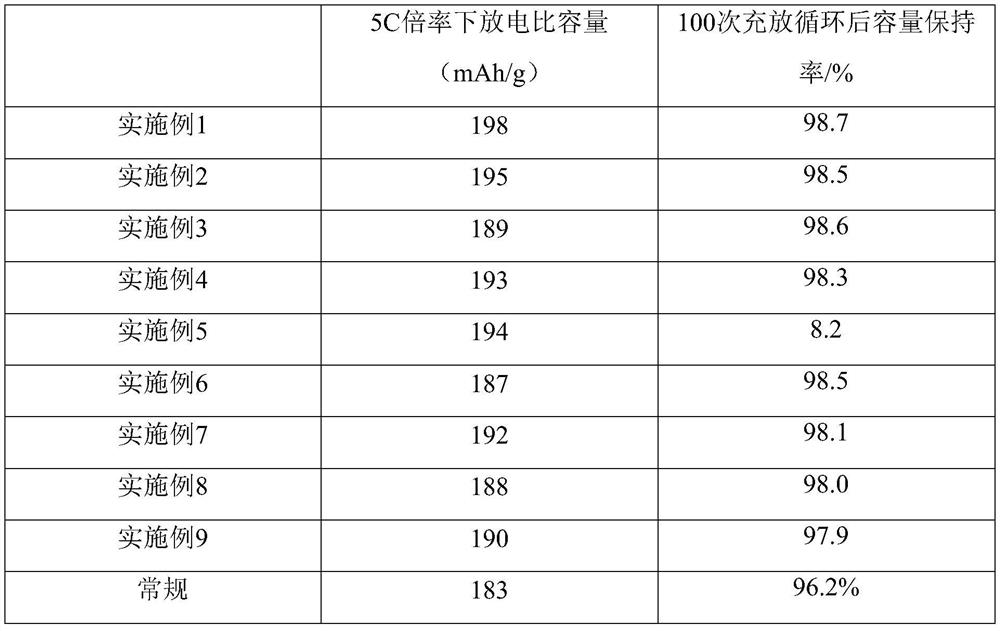

Double-layer coated cathode material LiNi0.6Co0.2Mn0.2O2 for lithium-ion battery and preparation method of double-layer coated cathode material

InactiveCN108807886AImprove ionic conductivityInhibition of erosionCell electrodesSecondary cellsDouble coatingConductive materials

The invention belongs to the technical field of preparation of cathode materials for lithium-ion batteries and specifically provides a double-layer coated cathode material LiNi0.6Co0.2Mn0.2O2 for a lithium-ion battery, wherein the coating amounts of Li3VO4 and PPy are 1 to 5 weight percent; Li3VO4 is a lithium fast ion conductor; by coating Li3VO 4, a protective layer can be provided and the lithium fast ion conductor also can be provided, so that ionic conductivity of the material is enhanced; in addition, lithium ions consumed during the formation of SEI and CEI films are made up and the cycle performance of the material is improved. The PPy is a fast electronic conductive material; by coating PPy, a second protective layer can be provided and the electronic conductivity of the materialcan be improved. Through double-layer coating of Li3VO4 and the PPy, the ionic conductivity is improved and the electrical conductivity is also improved; the cathode material is enabled to have super-high magnification discharge performance and higher discharge specific capacity; besides, double coating layers can more effectively inhibit the erosion effect of HF on the cathode material and enablethe cathode material to have excellent high voltage cycle stability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

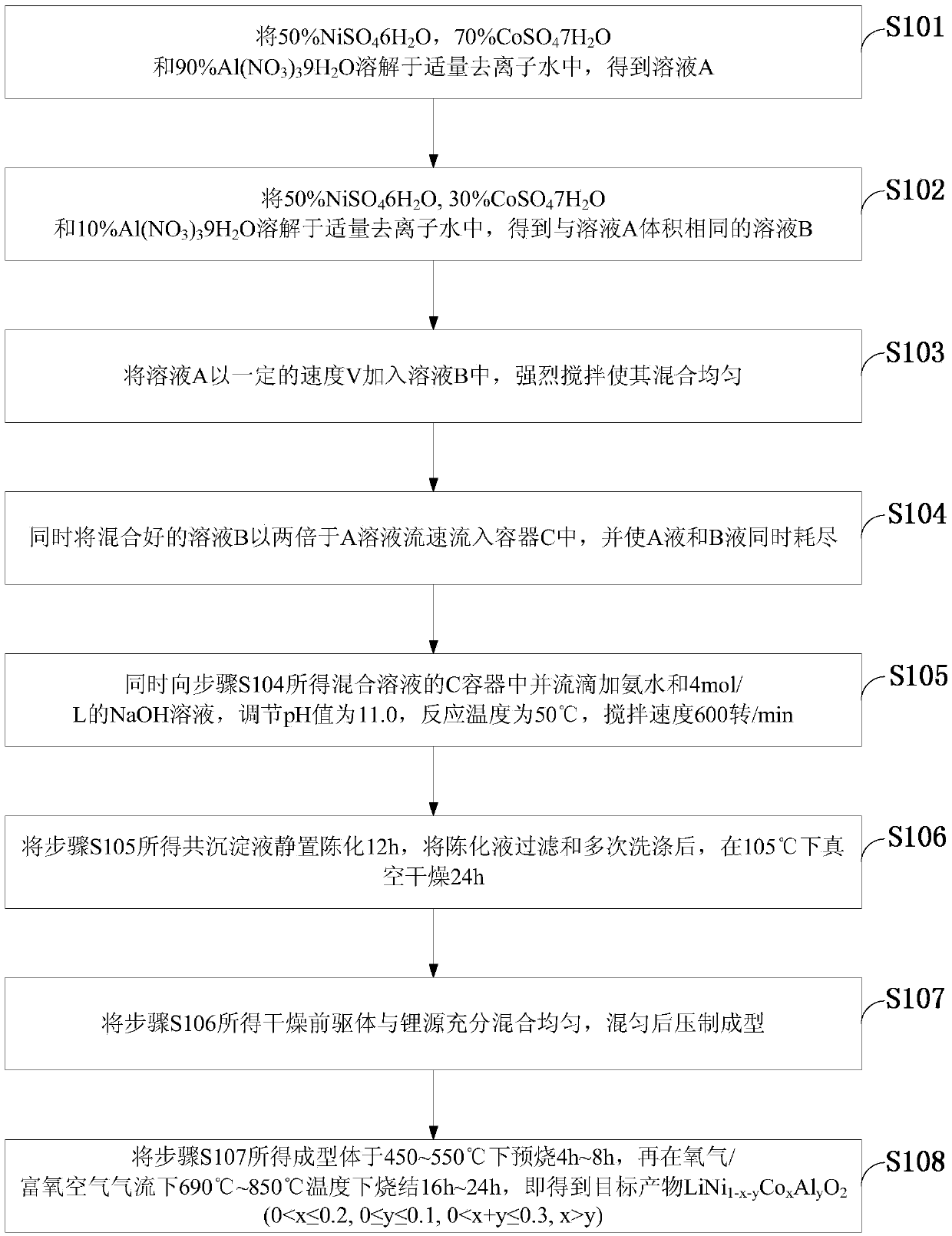

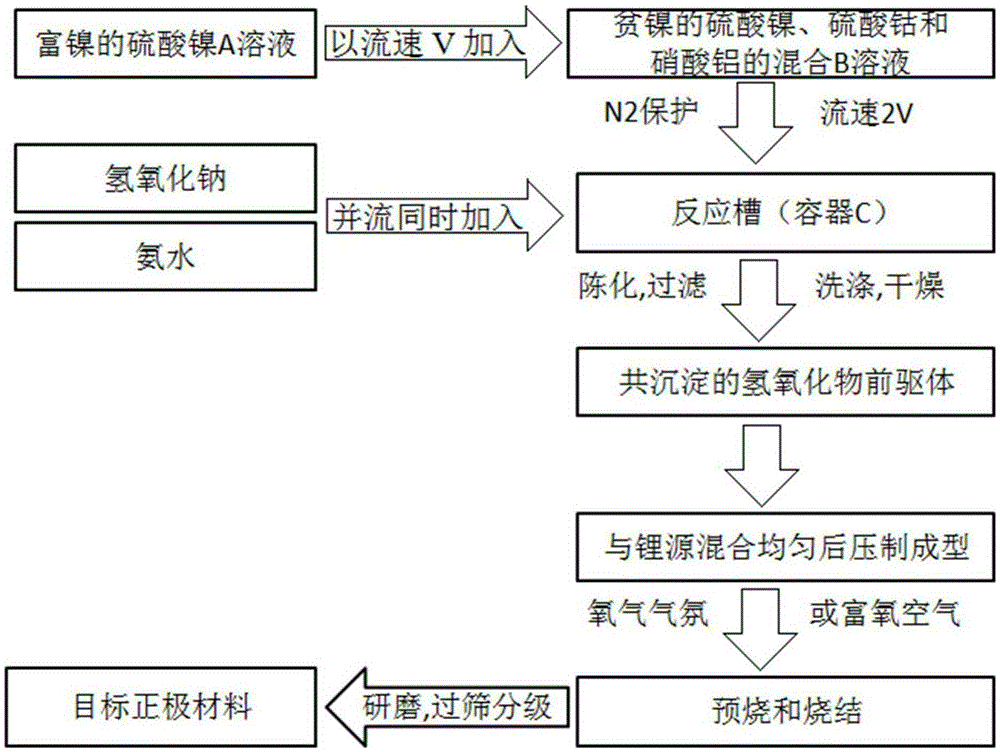

Positive electrode material of high-capacity lithium ion battery and preparation method of positive electrode material

InactiveCN105514373AHigh discharge specific capacityExcellent cycle stabilityCell electrodesSecondary cellsLithium electrodeLarge capacity

The invention discloses a positive electrode material of a high-capacity lithium ion battery and a preparation method of the positive electrode material. The preparation method comprises the following steps: dissolving raw materials into de-ionized water to prepare a mixed solution A and a mixed solution B, which have the same volume and different concentrations; adding a sodium hydroxide solution and an ammonia water solution into a container C in a parallel flow manner to be subjected to co-precipitation, so as to prepare a co-precipitate Ni1-x-yCoxAly(OH)2+y precursor; after ageing, filtering, washing and drying the prepared co-precipitate precursor, uniformly mixing the co-precipitate precursor with a lithium source; pressing and molding mixed materials, putting the mixture into a pipe furnace for presintering, and sintering the mixture in an oxygen / oxygen-enriching air airflow to obtain a target product. The positive electrode material of the lithium ion battery, provided by the invention, has no impure phases and has high crystallization quality; the product has a uniformly-distributed grain diameter and a regular spherical shape, and has a very high specific discharge capacity and relatively excellent circulating stability; the positive electrode material can meet high-energy density and high-power charging and discharging requirements, a process is simple and a manufacturing cost is relatively low.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

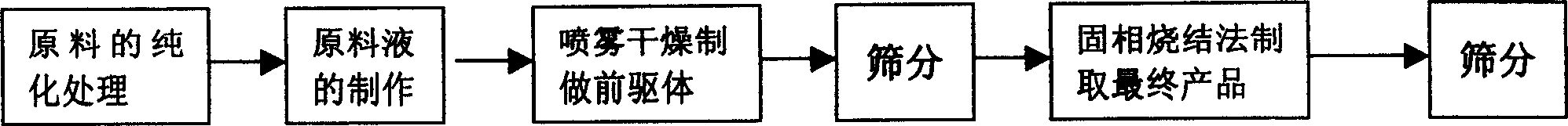

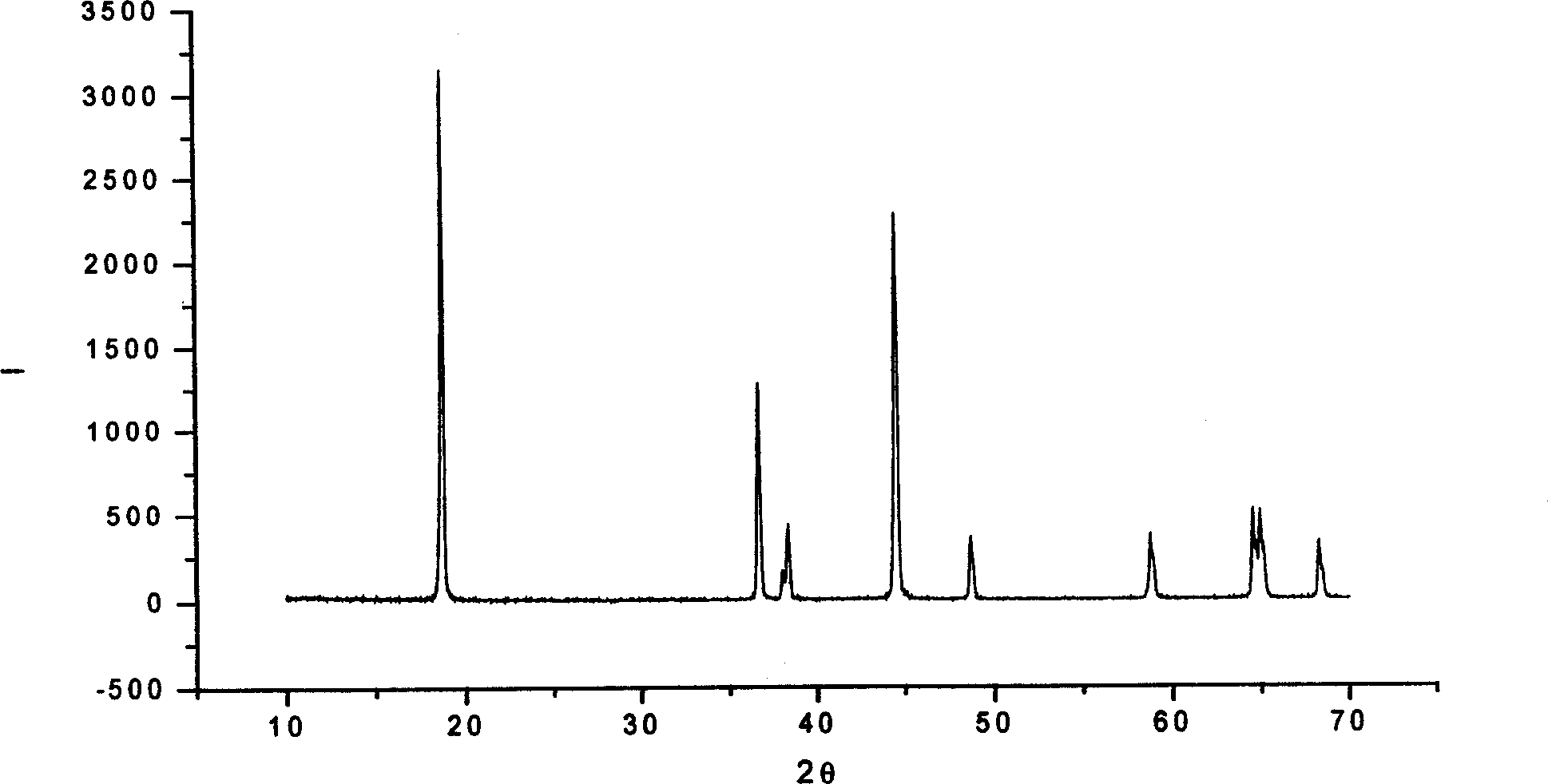

Anode material--lithium nickelate cobalt for lithium ion battery and preparation method thereof

InactiveCN1567620AReduce dosageReduce consumptionElectrode manufacturing processesLithium compoundsLithium chlorideNickel salt

The invention is a method of preparing lithium ion cell anode material-nickel cobalt acid lithium, and its characteristic: in the proportion of its formula, A-group matters: water-soluble lithium salt which is one of the lithium chloride, lithium sulphate, lithium nitrate and lithium acetate, water cobalt salt which is one of the cobalt chloride, cobalt sulphate, cobalt nitrate and cobalt acetate, and water nickel salt which is one of the nickel chloride, nickel sulphate, nickel nitrate and nickel acetate, the molar ratio of the three matters is 1.00-1.1 : 0.2-0.3 : 0.8-0.7; B-group matters: complexant is one of the oxalic acid, tartaric acid, citric acid, succinic acid, malonic acid, and maleic acid; the molar ratio of A to B is 1.0 : 0.6 -0.8; C-group polymers: gelatin, modified starch and polyvinyl alcohol. The beneficial effects: it can effectively reduce cost and the made LiNi1-yCoyO2 has the advantages of both LiCoO2 and LiNiO2, i.e. easy to synthesize, stable-property, high-specific capacity (higher than that of LiCoO2 by above 20%), etc. Additionally, because the use of Co is reduced, thus it reduces the environmental pollution. Therefore, LiNi1-yCoyO2 has a great hope of becoming the preferred substitute for LiCoO2, and its market demand is quite considerable.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD

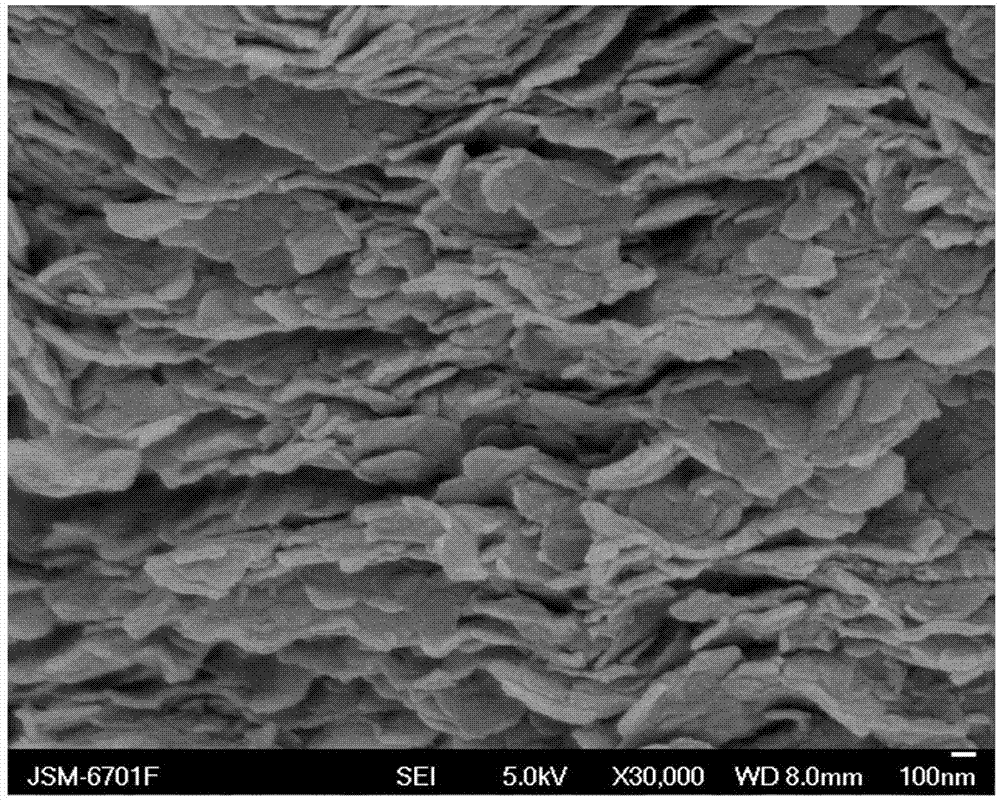

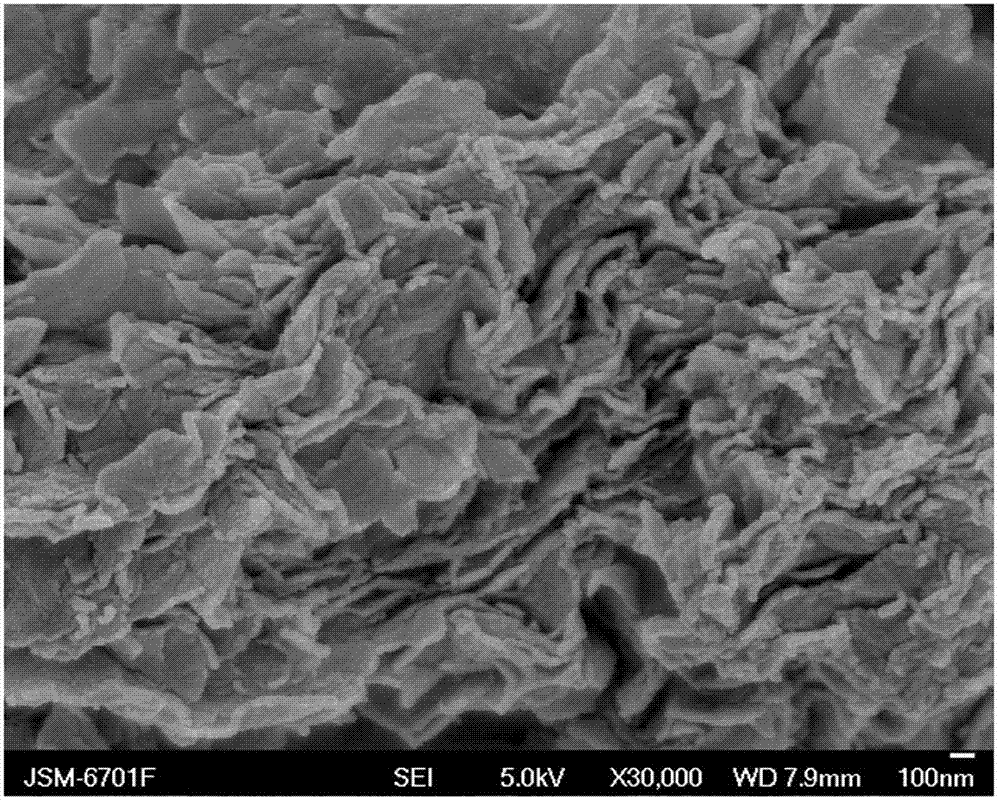

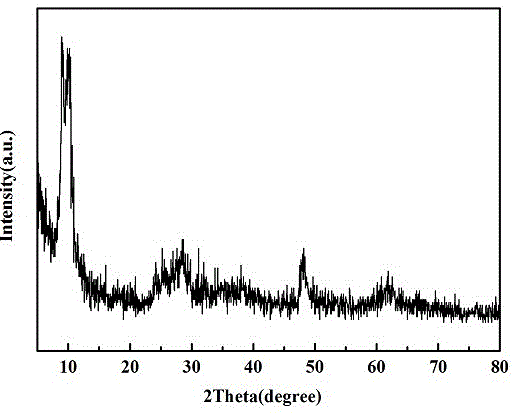

Two-dimensional-layered titanium-dioxide nanometer photocatalytic material and preparing method

ActiveCN105642262AImprove photocatalytic efficiencyEasy to recycleCatalyst activation/preparationTitanium dioxideSulfateCoprecipitation

The invention relates to a two-dimensional-layered titanium-dioxide nanometer photocatalytic material, and meanwhile further provides a preparing method of the two-dimensional-layered titanium-dioxide nanometer photocatalytic material. The photocatalytic efficiency of prepared titanium dioxide is high, and the photocatalytic efficiency ranges from 79.4% to 93.1%. The preparing method is characterized in that a coprecipitation method is combined with a hydrothermal method; the experiment condition is mild and safe, the requirement for a device is low, and the reaction condition is easy to control; the obtained product is the two-dimensional-layered titanium-dioxide nanometer material, the layered structure and continuity are good, the defects caused by a small-size layer structure are greatly reduced, and the two-dimensional-layered titanium-dioxide nanometer material has the quite good promoting effect on electron transmission; a preparing reagent of the two-dimensional-layered titanium-dioxide photocatalytic material comprises titanous sulfate, sodium hydroxide and nitric acid. The reagent is easy to obtain, cost is low, the risk is low, pollution to the environment is quite small, secondary pollution can be avoided in the production process, and waste is easy to recycle.

Owner:长春市铮徽机械制造有限公司

Method for preparing carbon nanotube copper-based laminated composite material

The invention discloses a method for preparing a carbon nanotube copper-based laminated composite material, relates to a method for preparing a carbon nanotube copper-based composite material and aimsto solve the problem that a carbon nanotube copper-based composite material prepared by using a conventional method is unmatched in toughness. The method comprises the following steps: I, performingacidizing treatment on carbon nanotubes, and cleaning copper sheets; II, preparing composite sheets; III, preparing a composite material. By adopting the method, carbon nanotubes are dispersed by using an electrophoretic deposition method, the carbon nanotubes are directly uniformly dispersed on the surface of a metal plate, the dispersion degree of the carbon nanotubes is increased, and a composite material laminated structure can be constructed by using methods of hot-pressing sintering and later rolling. By adopting the composite material laminated structure, breakage of the material is changed, energy consumption in the breakage process is increased, the strength of the composite material can be remarkably improved when being compared with that of a substrate, and meanwhile the toughness is correspondingly improved. The method is adopted to prepare the carbon nanotube copper-based composite material.

Owner:HARBIN INST OF TECH

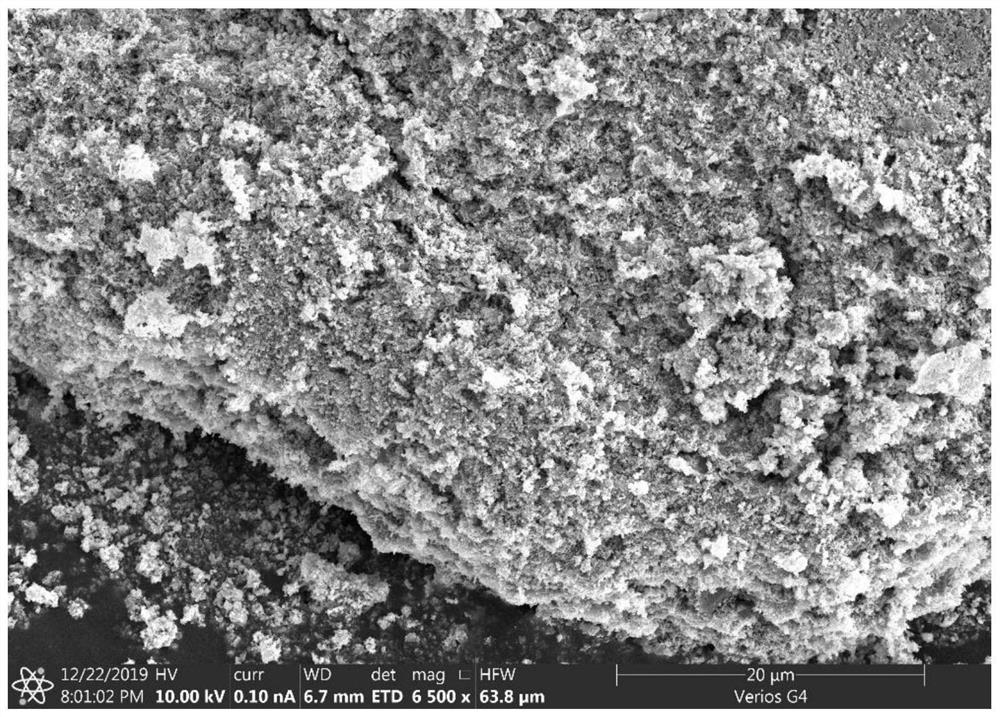

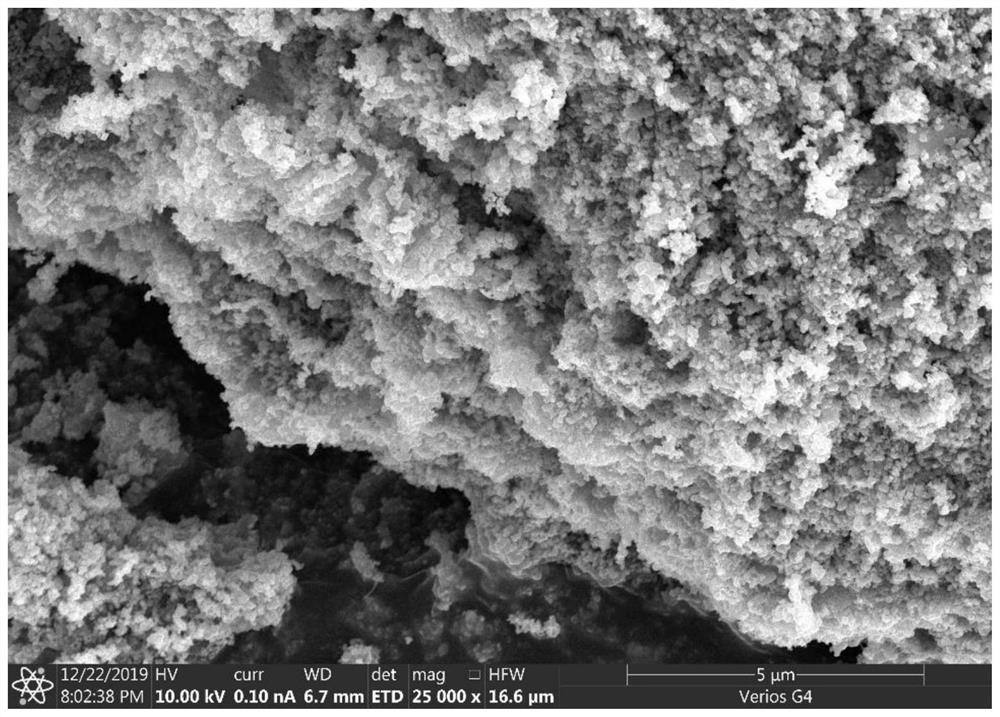

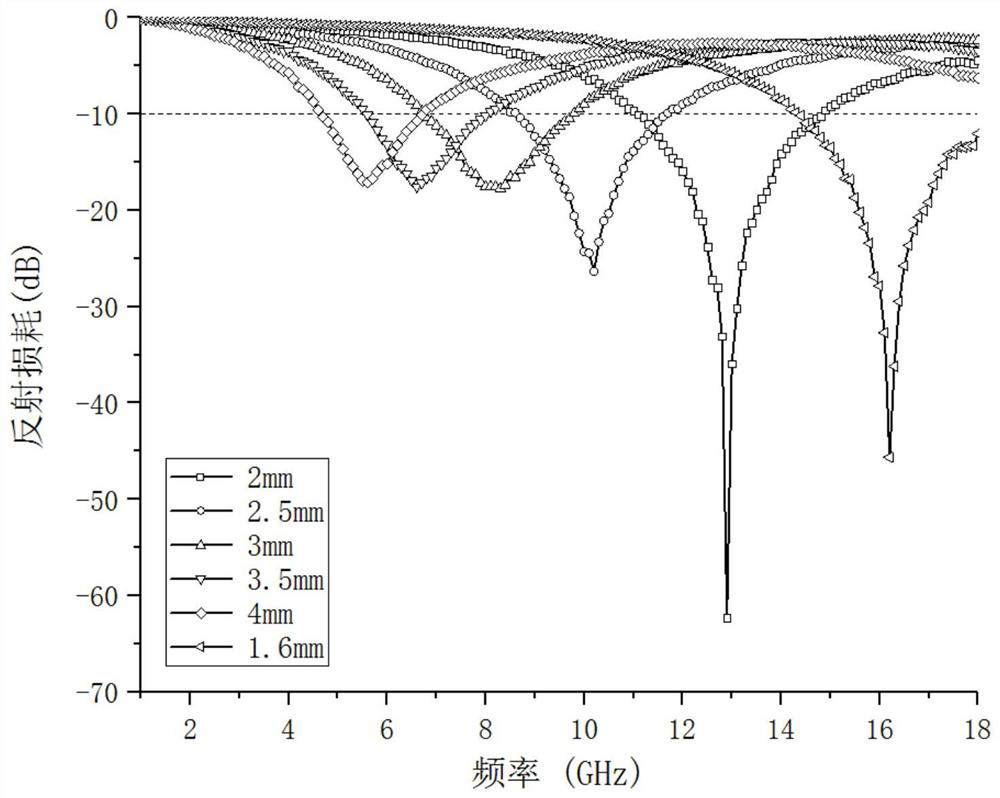

Heating modified MXene/ferroferric oxide composite wave-absorbing material and preparation method thereof

InactiveCN112047386AImproving Impedance MatchingImprove absorbing performanceMaterial nanotechnologyNanomagnetismDielectric lossTube furnace

The invention relates to a heating modified MXene / ferroferric oxide composite wave-absorbing material and a preparation method thereof. Magnetic ferroferric oxide particles (Fe3O4) are grown in situ on the surface of a two-dimensional material MXene (Ti3C2Tx), and the MXene is heated in a tubular furnace to be partially oxidized into titanium dioxide (TiO2) to finally obtain the layered compositematerial. MXene and TiO2 are dielectric loss wave-absorbing materials, and Fe3O4 is a magnetic loss wave-absorbing material, so that the obtained composite material can synergistically absorb electromagnetic waves through dielectric loss and magnetic loss mechanisms, and the wave-absorbing effect is enhanced. Meanwhile, the composite material has a layered structure, so that electromagnetic wavescan be subjected to multiple interlayer reflection in the composite material and are more easily absorbed by the composite material. And finally, the impedance matching of MXene is improved by Fe3O4 and TiO2, the interfacial polarization of the composite material is enhanced by the multi-component structure, and the wave absorbing effect of the composite material is further enhanced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Conductive aramid nanofiber composite aerogel and preparation method thereof

ActiveCN111040237AHigh strengthReduce intensityElectrical/magnetic solid deformation measurementFiberCrystallinity

The invention discloses a conductive aramid nanofiber composite aerogel and a preparation method thereof. By using aramid nano-fibers with a nano-scale structure, high strength, a large length-diameter ratio and high temperature resistance as a matrix and using whisker carbon nanotubes with high crystallinity and high rigid structure are used as a conductive filler and a reinforced filling material, the conductive aramid nanofiber composite aerogel with low density, high strength and high compression resilience is prepared. The preparation method specifically comprises the following steps: preparing an aramid nanofiber dispersion liquid, preparing a whisker carbon nanotube dispersion liquid, preparing a whisker carbon nanotube / aramid nanofiber composite dispersion liquid, preparing a gelatinous whisker carbon nanotube / aramid nanofiber composite material, and the like, thereby obtaining the conductive aramid nanofiber composite aerogel. The preparation process is simple and easy to implement, and the obtained conductive aramid nanofiber composite aerogel has wide application prospects in the fields of pressure sensing, intelligent sensors, wearable equipment and the like.

Owner:SHAANXI UNIV OF SCI & TECH

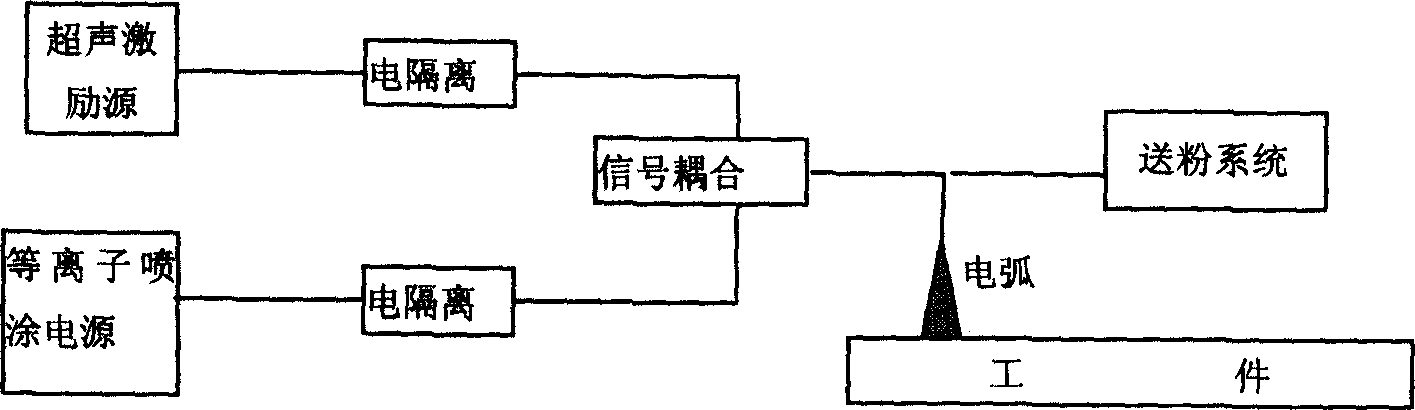

Spraying method of supersonic plasma

InactiveCN1560316AImprove insulation performanceAccelerated corrosionMolten spray coatingPorosityUltimate tensile strength

The invention is an ultrasonic plasma-spraying method, for controlling coating porosity and improving coating binding strength, including the steps: connecting an ultrasonic excitation source in parallel with the anode and cathode of the spray gun of a plasma-spraying device; electrically isolating the excitation source from the DC power supply of plasma spraying; starting a water circuit and an electric circuit of the plasma-spraying device to make high-frequency arc starting, and cooling the spray gun; turning on the excitation source to make ultrasonic alternative signal couple with plasma arc exciting signal so as to generate ultrasonic; starting a powder-feed system in the plasma-spraying device and as passing through high-temperature plasma arc, the sprayed powder is heated, and the ultrasonic acts on the plasma and simultaneously on melting sprayed powder; under the action of high-temperature plasma flame, the molten powder reaches a workpiece surface, disperses and solidifies into a coating.

Owner:TSINGHUA UNIV

Flexible rare-earth transparent light-emitting film and preparation method thereof

The invention relates to a flexible rare-earth transparent light-emitting film and a preparation method thereof. The film is composed of a rare-earth light-emitting material and polyvinyl alcohol (PVA) in a mass ratio of 1:(1-4). The rare-earth light-emitting material comprises LAPONITE RD nano clay containing light-emitting rare-earth organic complex, an oxygen-containing ionic liquid and water, wherein the mass ratio of the LAPONITE RD nano clay containing light-emitting rare-earth organic complex to the oxygen-containing ionic liquid is 1:(1-3); the water accounts for 80-85 wt% of the rare-earth light-emitting material; the average particle size of the nano clay is 30nm; and the mass percent of the rare earth ions in the nano clay is 6-7.5%. The novel high-efficiency flexible rare-earth transparent light-emitting film is peelable and thin, and has the advantages of large area, excellent flexibility, excellent heat stability, excellent photostability and high mechanical strength.

Owner:HEBEI UNIV OF TECH

Preparation method for silicon carbon composite material for lithium ion battery negative electrode

ActiveCN102832376AEvenly distributedImprove cycle performanceCell electrodesCarbon compositesHigh energy

The invention discloses a preparation method for a silicon carbon composite material for a lithium ion battery negative electrode. The method comprises the following steps: primary ball milling: a step of adding a grinding aid into elementary silicon for ball milling; and secondary ball milling: a step of mixing silicon powder obtained after primary ball milling with carbon powder and adding a grinding aid for ball milling again. The mass content of the carbon powder is 20 to 80%. A discharge gas medium employed in the dielectric barrier discharge plasma assisted high-energy ball milling method is inert gas. According to the invention, silicon in the composite material prepared in the invention can be finely and uniformly distributed on a carbon matrix, effective refining of silicon can be carried out on the basis that the integrity of graphite sheets is ensured, reversible capacity of a battery is improved, the problems of volume expansion and poor conductivity of a silicon-based electrode are alleviated, and comprehensive performance of the lithium ion battery is improved.

Owner:SOUTH CHINA UNIV OF TECH

Doped high-nickel high-voltage NCM positive electrode material and preparation method thereof

PendingCN110797529AReduce consumptionIncrease profitCell electrodesSecondary cellsHigh energyManganese

The invention discloses a doped high-nickel high-voltage NCM positive electrode material and a preparation method thereof, and belongs to the field of lithium ion batteries. The preparation method comprises the following steps: simultaneously doping manganese and cobalt to obtain an NCM precursor; and adding a dopant M into the precursor, and sintering the precursor in a high-pressure oxygen atmosphere to obtain a lithium ion battery positive electrode material. The positive electrode material has very high specific discharge capacity and excellent cycling stability, can meet the high-rate charging and discharging requirement, and can achieve long-life safe cycling under high voltage. The positive electrode material is prepared by combining four-solution parallel-flow co-precipitation witha high-pressure solid-phase synthesis method, and the prepared product has the advantages of high purity, high crystallization quality, high particle density, uniform distribution of particles, excellent electrochemical performance and low manufacturing cost, is an ideal positive electrode material with high energy density, and has a wide application prospect.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

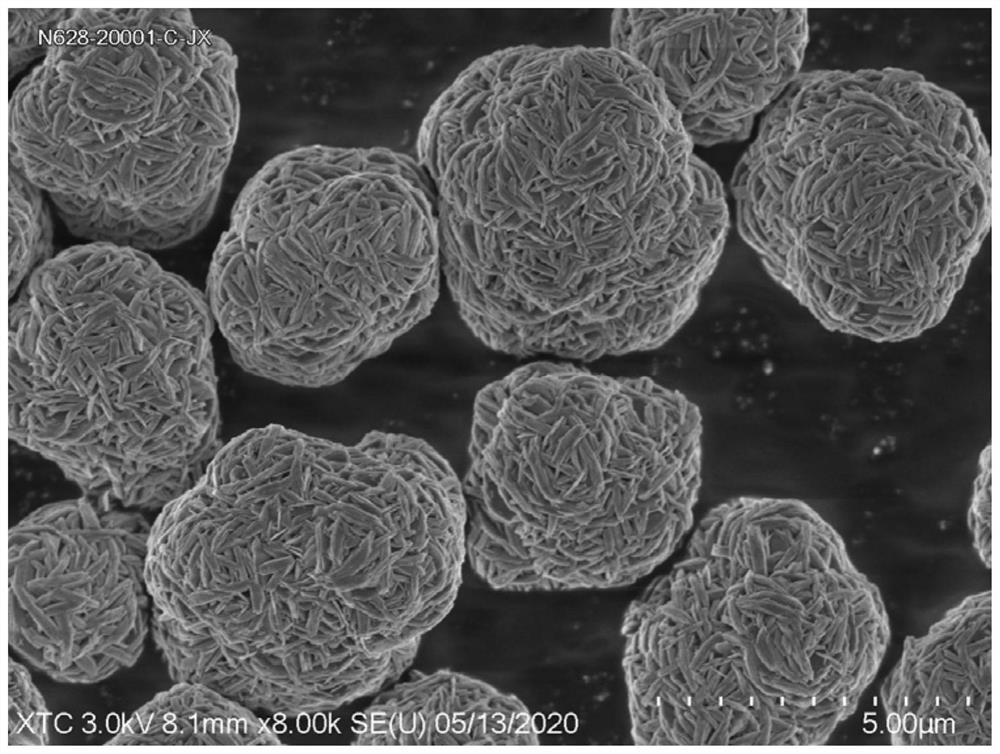

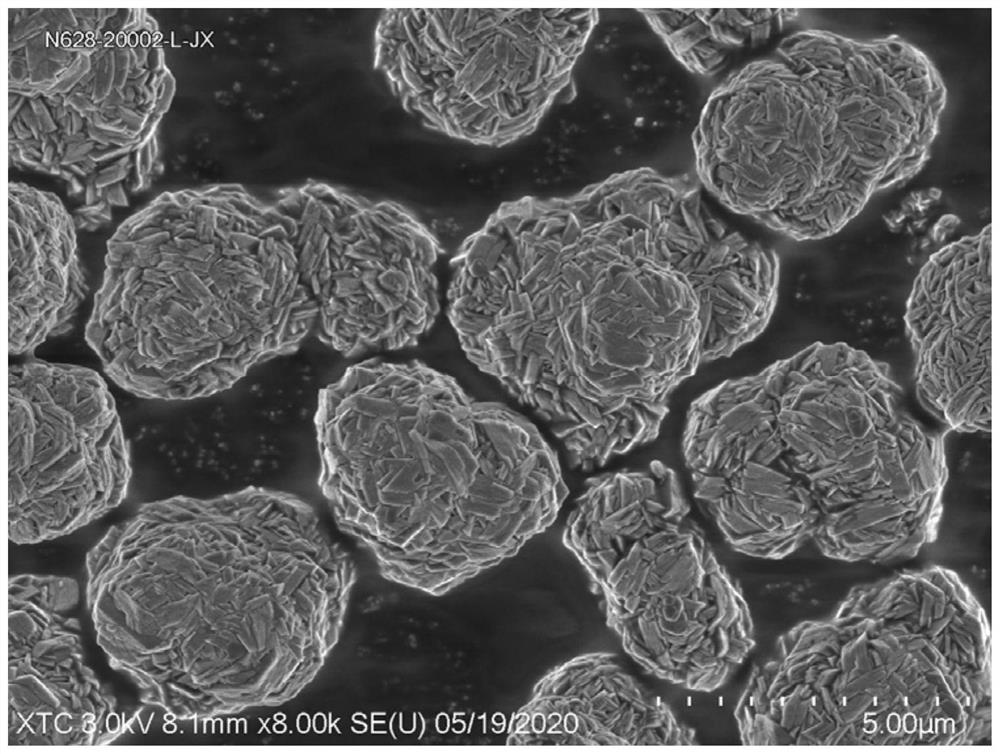

Nickel-manganese-titanium composite material and preparation method and application thereof

The invention belongs to the field of lithium ion batteries, and particularly relates to a nickel-manganese-titanium composite material and a preparation method and application thereof. The nickel-manganese-titanium composite material comprises an inner core and a coating layer coating the surface of the inner core, wherein the inner core is composed of nickel-manganese-titanium oxide, nickel, manganese and titanium are distributed in the inner core in a gradient mode, the content of nickel and manganese is gradually reduced from inside to outside in the radial direction of the inner core, the content of titanium is gradually increased from inside to outside in the radial direction of the inner core, and the component of the coating layer is lithium titanate. A lithium ion battery corresponding to the nickel-manganese-titanium composite material provided by the invention has relatively high capacity and cycling stability.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

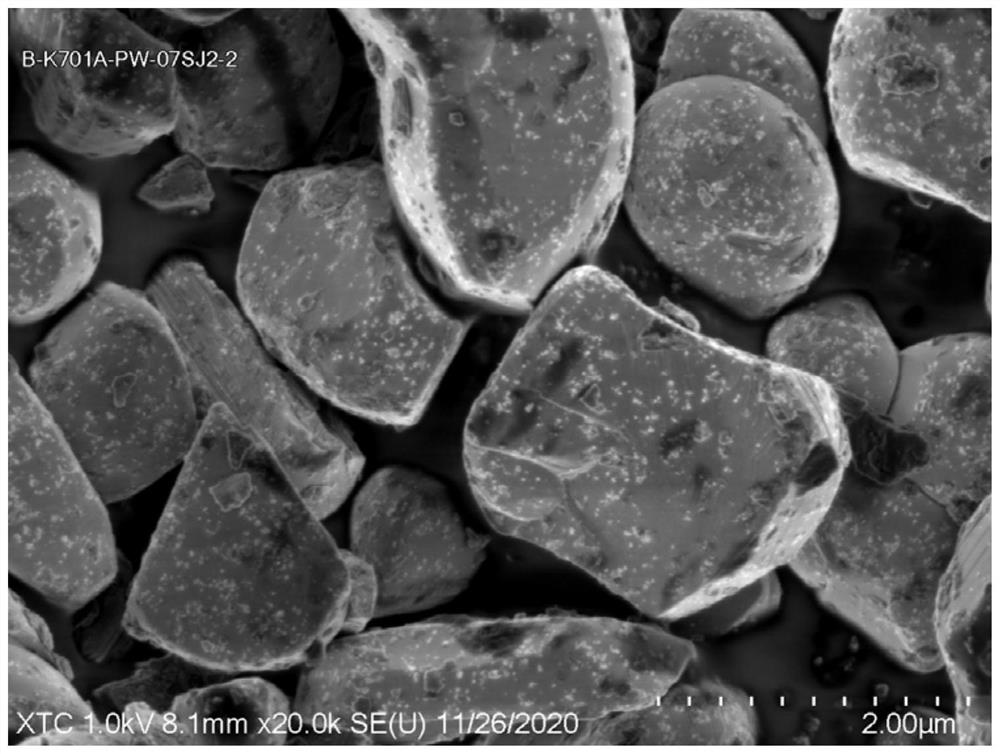

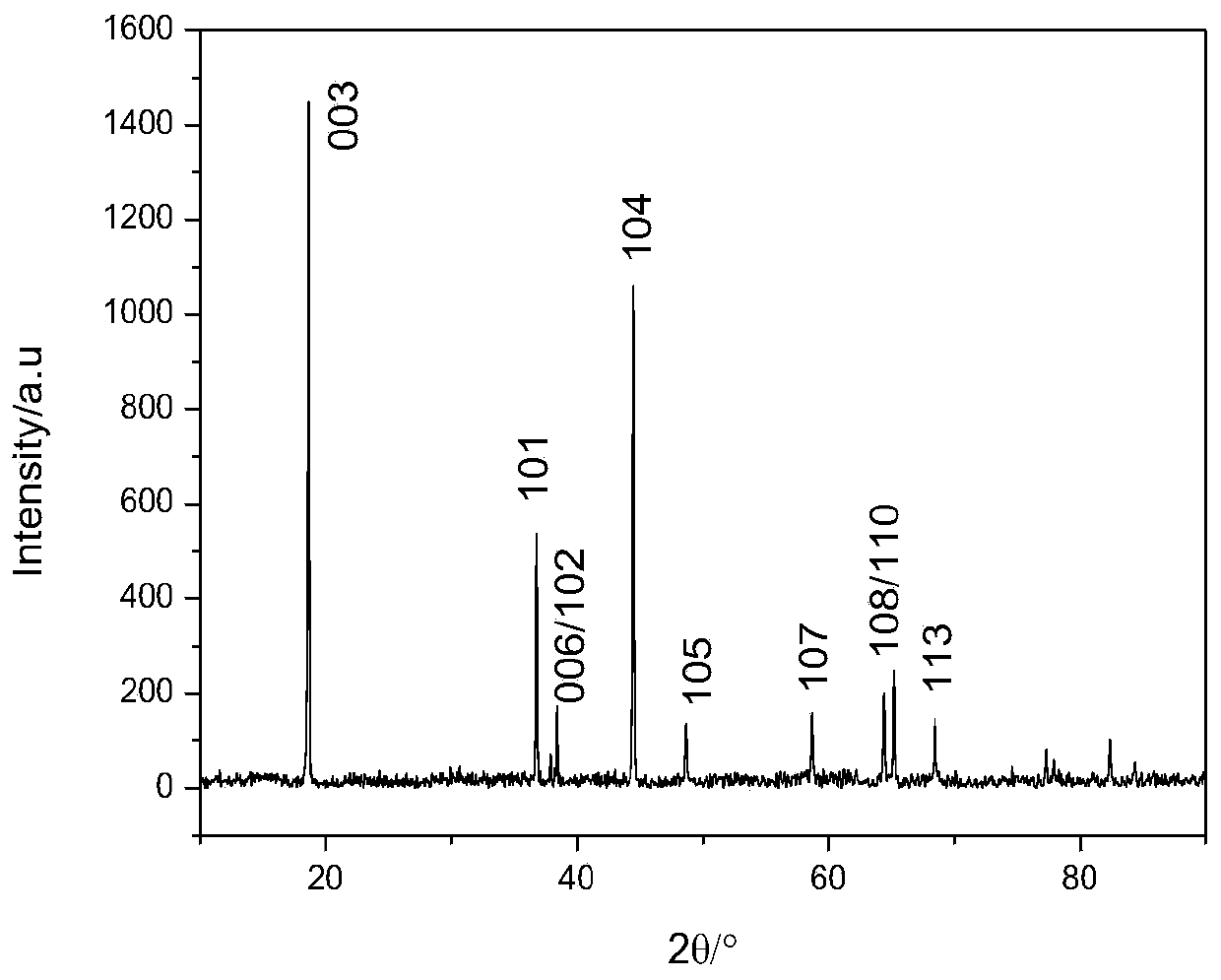

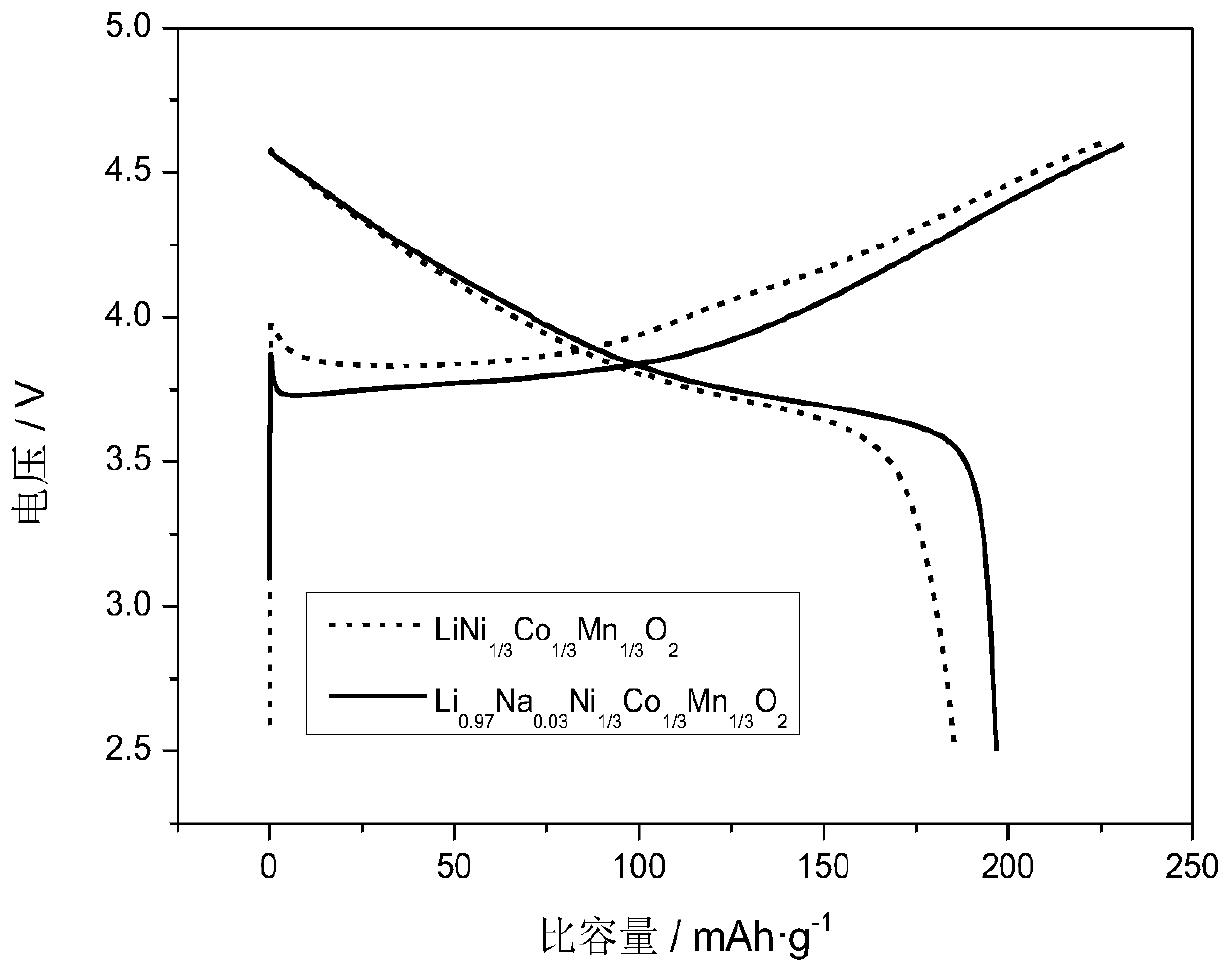

Sodium ion doped ternary positive electrode material and preparation method thereof

PendingCN111463428AUniform particle sizeUniform sizeCell electrodesSecondary cellsMicrospherePhysical chemistry

The invention relates to a sodium ion doped ternary positive electrode material and a preparation method thereof and belongs to the technical field of lithium ion batteries. A general chemical formulaof the positive electrode material is Li<1-x>Na<x>Ni<1 / 3>Co<1 / 3>Mn<1 / 3>O<2>, wherein x is greater than or equal to 0 and less than or equal to 0.05; a manganese source is manganese dioxide hollow microspheres. The preparation method comprises steps of weighing a lithium source, a sodium source, a nickel source, a manganese source and a cobalt source according to a molar ratio, and respectively adding solvent to form uniform solution or turbid liquid, and mixing the solution and the turbid liquid, heating to evaporate the solvent, calcining, grinding and cooling to room temperature twice to obtain the lithium ion battery positive electrode material. The preparation method is advantaged in that the preparation method is easy to operate, and the prepared positive electrode material retains ahollow structure and crystallinity and has advantages of high specific capacity, good cycle performance, good rate capability and the like.

Owner:JIANGNAN UNIV

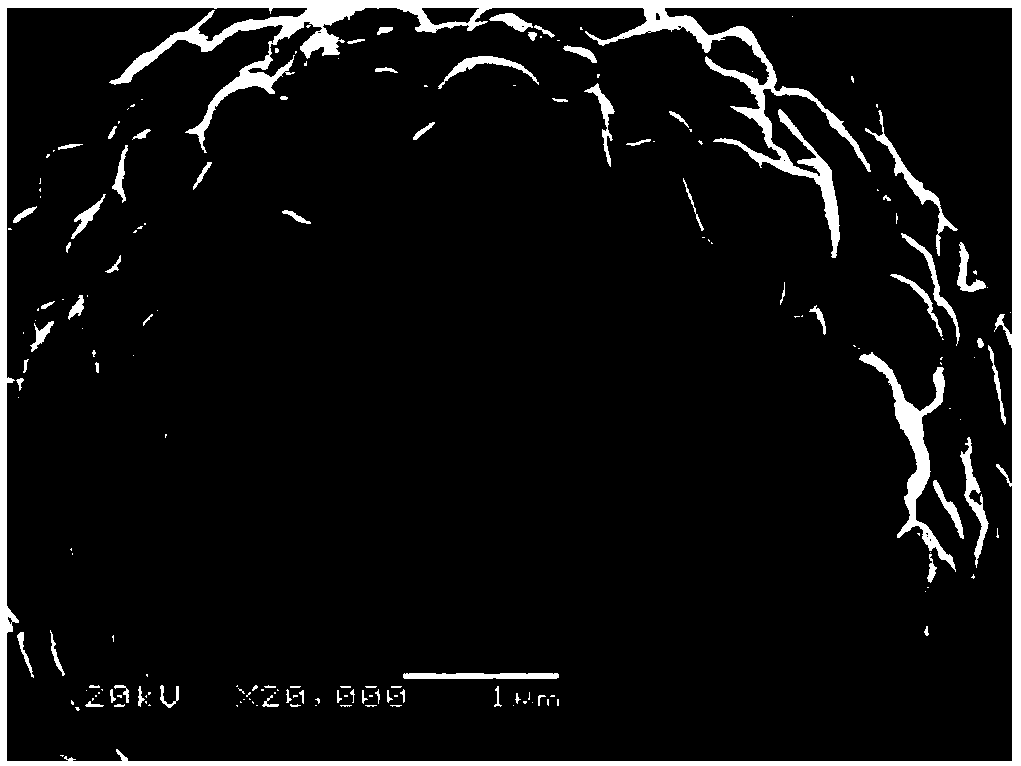

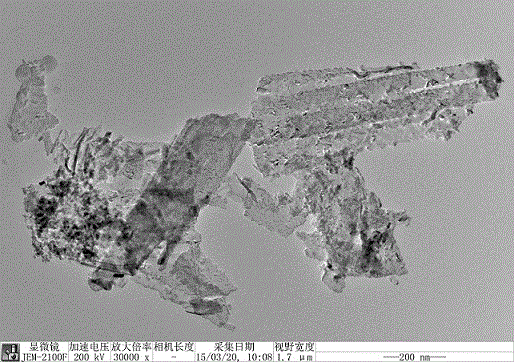

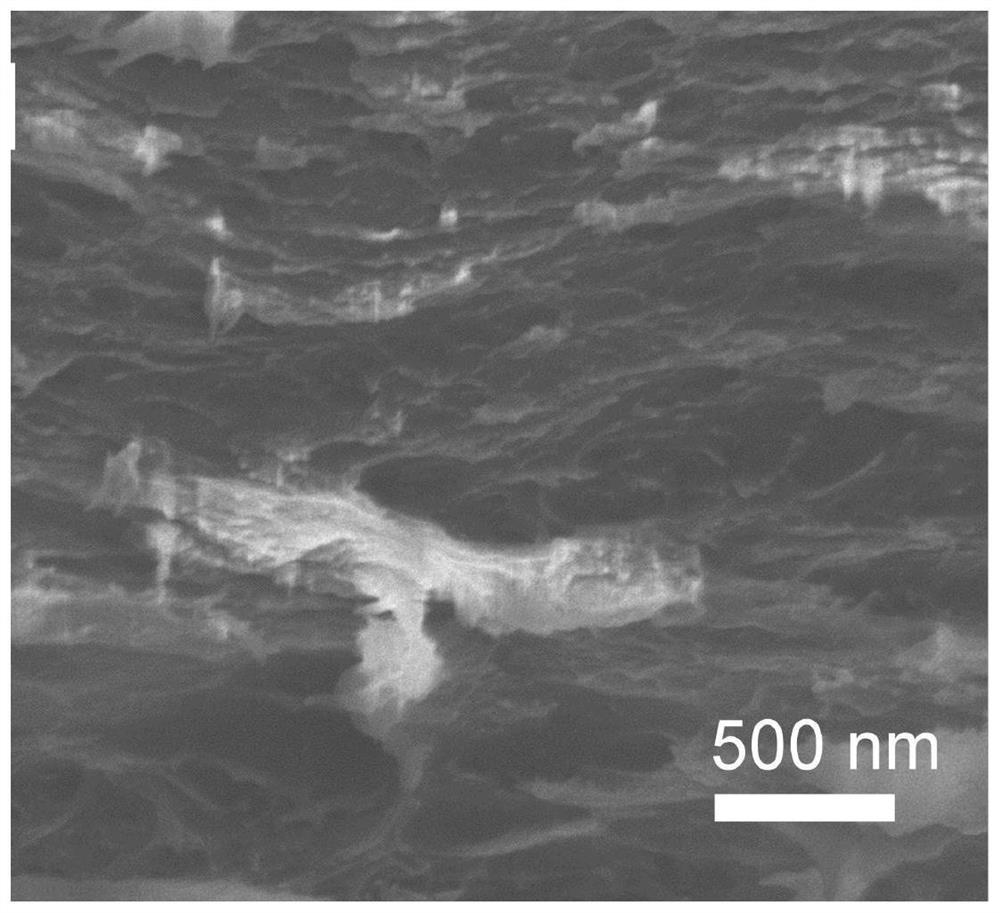

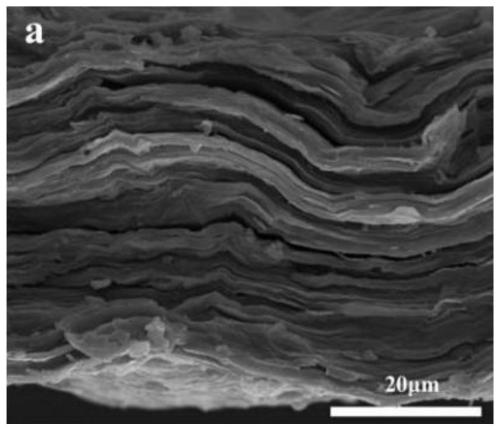

Preparation method of nanocellulose/molybdenum disulfide piezoelectric composite film

The invention discloses a preparation method of a nanocellulose / molybdenum disulfide piezoelectric composite film, the preparation method comprises the following steps: dispersing cellulose nanofibers into deionized water, carrying out ultrasonic treatment and centrifugation to obtain a nanocellulose aqueous dispersion, and storing at low temperature; mixing and dispersing molybdenum disulfide powder and triethanolamine or mixing and dispersing molybdenum disulfide powder and glycerol / urea, taking supernatant, stirring and blending supernatant and deionized water, performing vacuum suction filtration, dispersing a final suction filtration product into deionized water, and drying to obtain a molybdenum disulfide nanosheet; and adding the obtained molybdenum disulfide nanosheet into the nano-cellulose aqueous dispersion, removing bubbles after ultrasonic dispersion, pouring into a mold, and drying to form a film. Along with the addition of molybdenum disulfide, the layered structure of the composite film becomes more obvious, the layered structure becomes more orderly, and good structural compatibility is shown. Besides, the stacked molybdenum disulfide sheets are few, and the defects of the cross section are few, so that the molybdenum disulfide nanosheets are well dispersed in the nanocellulose matrix.

Owner:WUHAN UNIV OF TECH

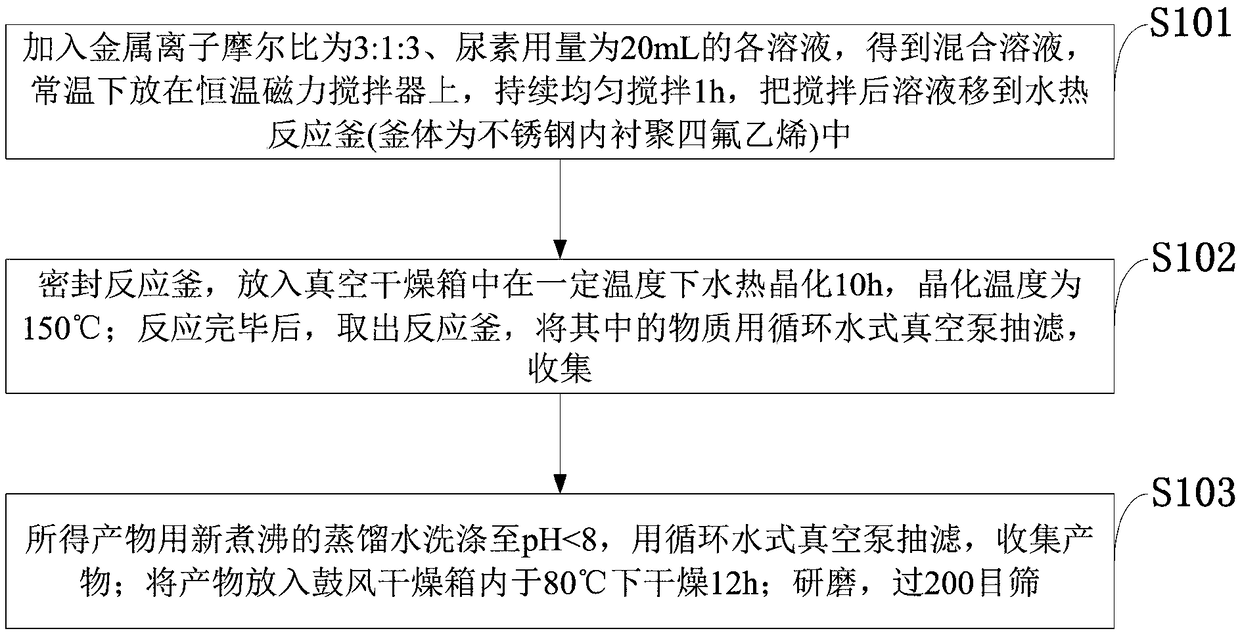

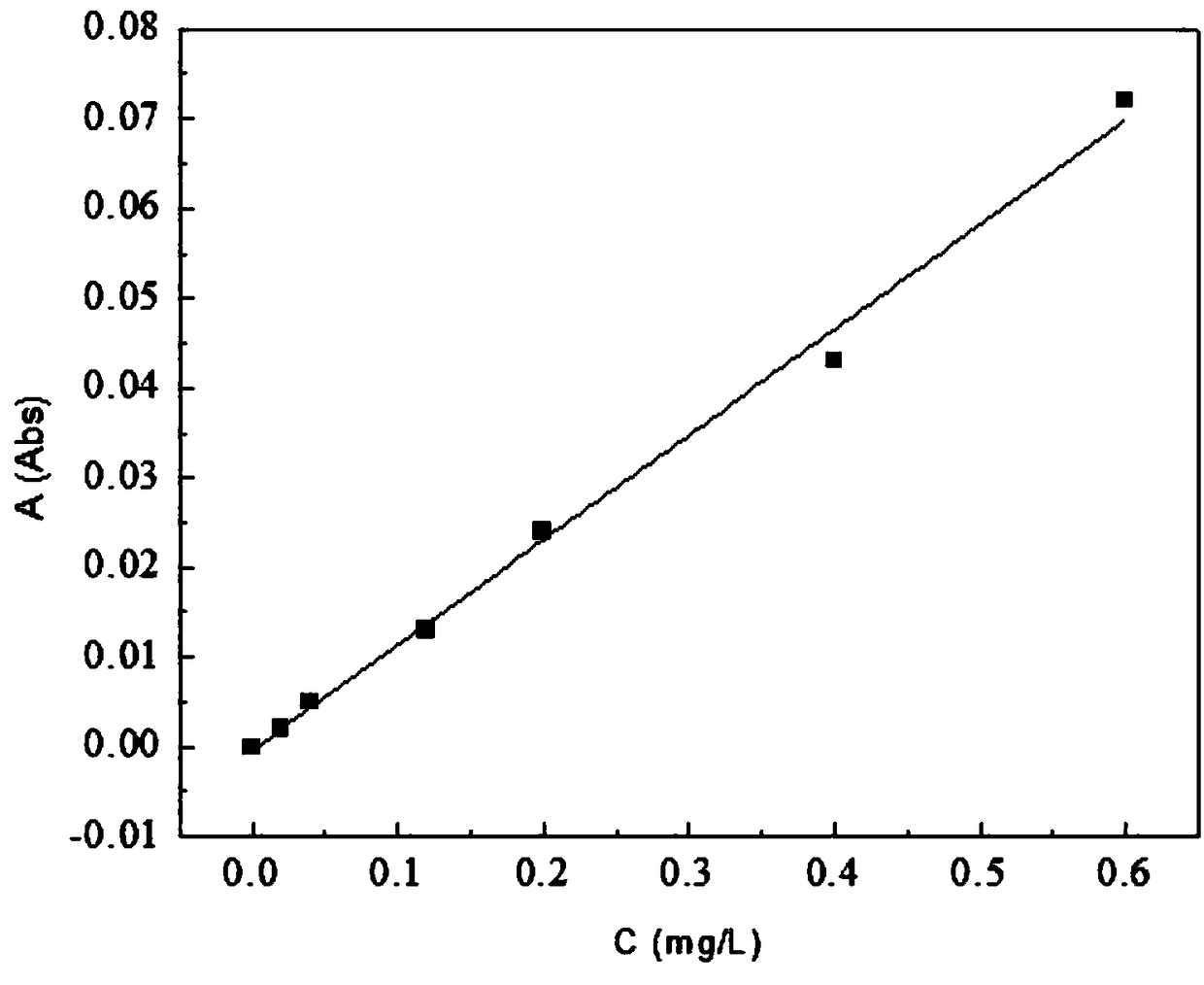

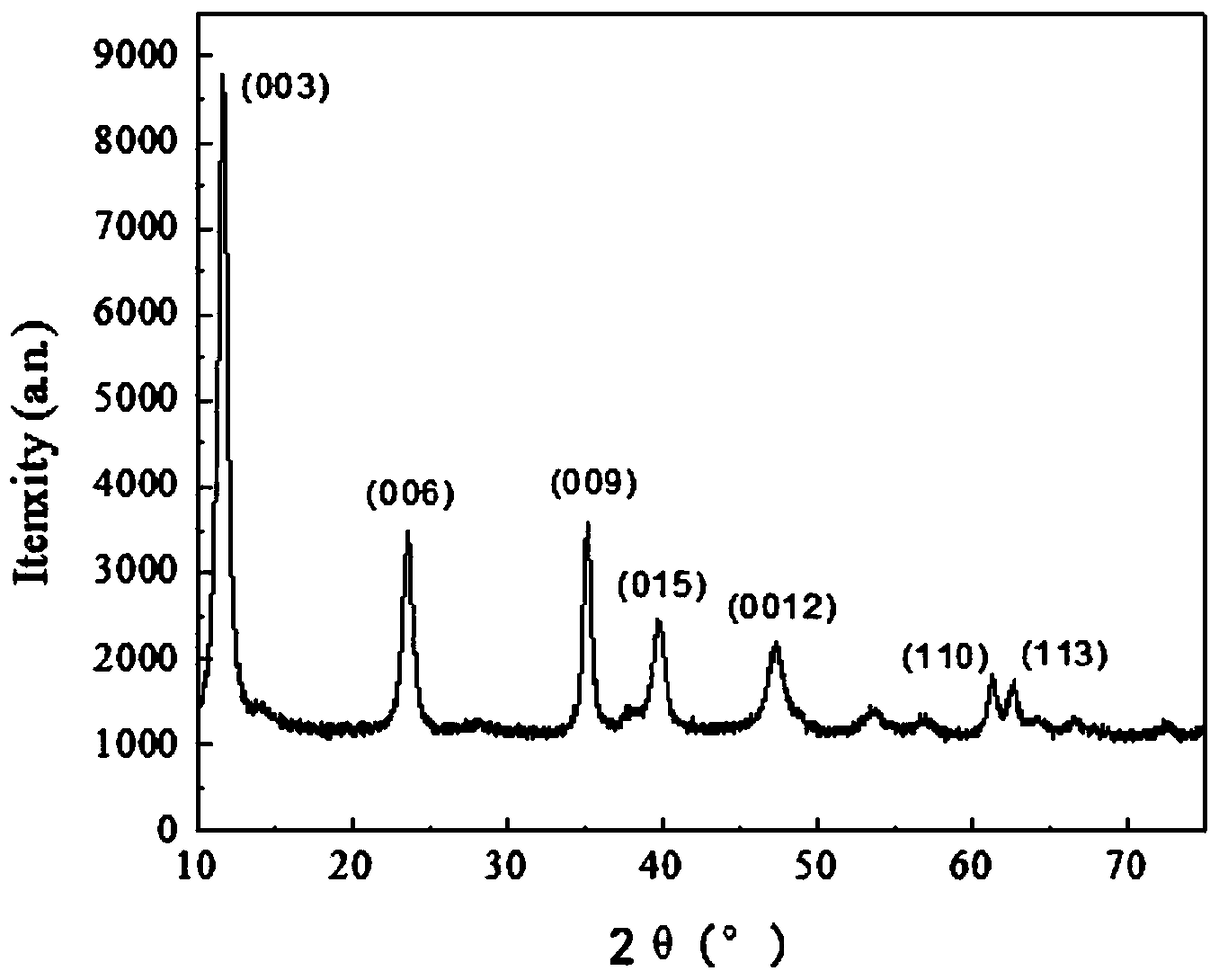

Ni-Mg-Al type hydrotalcite and preparation method and application thereof

InactiveCN109331772ADiffraction peaks are sharpHigh crystallinityOther chemical processesWater contaminantsVacuum pumpAir blast

The invention belongs to the technical field of aluminum compounds, and discloses Ni-Mg-Al type hydrotalcite and a preparation method and application thereof. The preparation method comprises the following steps: adding various solutions having a urea use amount of 20 mL in a metal ion mole ratio of 3:1:3 to obtain a mixed solution, putting the mixed solution on a constant-temperature magnetic stirrer at normal temperature, continuously and uniformly stirring for 1 h, and transferring the stirred solution into a hydrothermal reaction kettle; sealing the reaction kettle, putting the reaction kettle into a vacuum drying box for hydrothermal crystallization at certain temperature for 10 h, wherein the crystallization temperature is 150 DEG C; at the end of the reaction, taking out the reaction kettle, sucking and filtering a substance therein with a circulating water type vacuum pump, and collecting the substance; washing the obtained product with new boiled distilled water till the pH isless than 8, sucking and filtering with the circulating water type vacuum pump, and collecting a product; putting the product into an air blasting drying box for drying at 80 DEG C for 12 h; grindingthe product, and sieving the product with a sieve of 200 meshes. The phosphorus removal rate for simulated phosphorus-containing wastewater reaches 95.21 percent.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

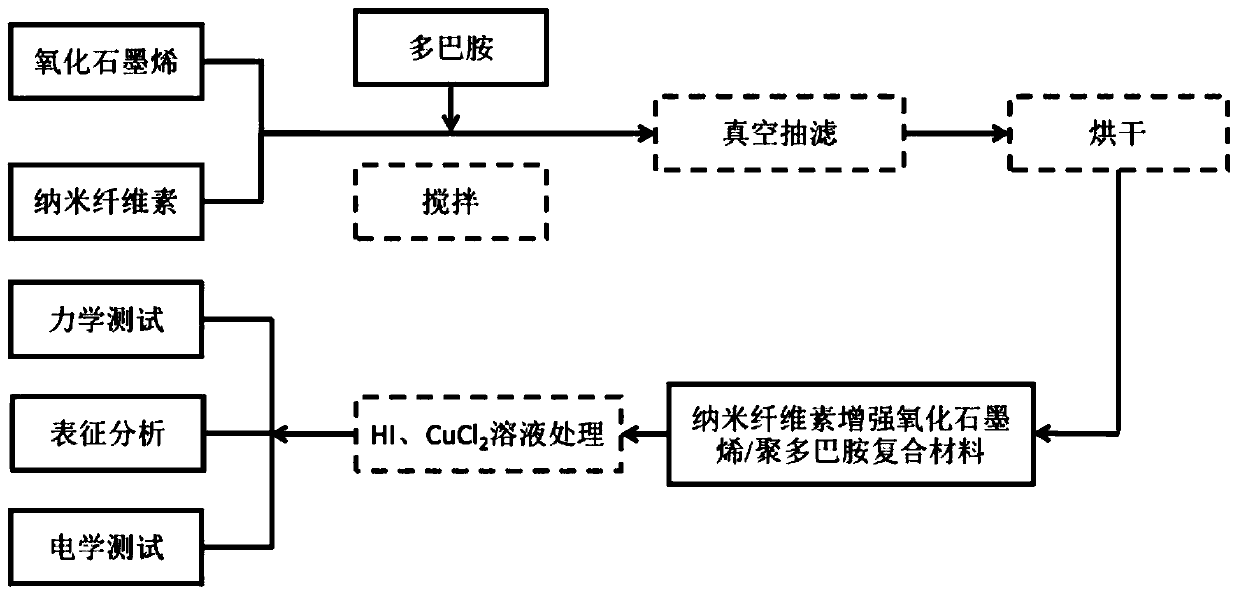

Nano-crystalline cellulose reinforced graphene oxide/ polydopamine laminated bionic material and preparation method thereof

The invention relates to a nano-crystalline cellulose reinforced graphene oxide / polydopamine laminated bionic material and a preparation method thereof, and belongs to the technical field of laminated bionic composite materials. In order to solve the problems of poor tensile strength and toughness of a traditional bionic material, the invention provides a preparation method for the nano-crystalline cellulose reinforced graphene oxide / polydopamine laminated bionic material. Graphene oxide and nano-crystalline cellulose are respectively dissolved in deionized water to be mixed, then, the pH (Potential of Hydrogen) value of the solution is regulated to 8.5, dopamine is added to be stirred evenly, vacuum suction filtration is carried out to form a film, and the film is dried to obtain the nano-crystalline cellulose reinforced graphene oxide / polydopamine laminated bionic material. According to the nano-crystalline cellulose reinforced graphene oxide / polydopamine laminated bionic material, the nano-crystalline cellulose is taken as a reinforcement phase to improve the tensile strength, the elasticity modulus and the toughness of the laminated bionic material; through HI (Hydroiodic Acid) solution reduction and CuCl2 solution processing, the laminated bionic material has better electric conduction performance, and therefore, the laminated bionic material can be applied to fields,including aerospace, flexible anodes, artificial muscles, tissue engineering and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

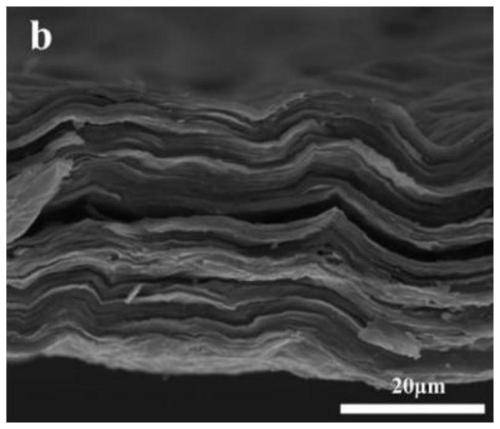

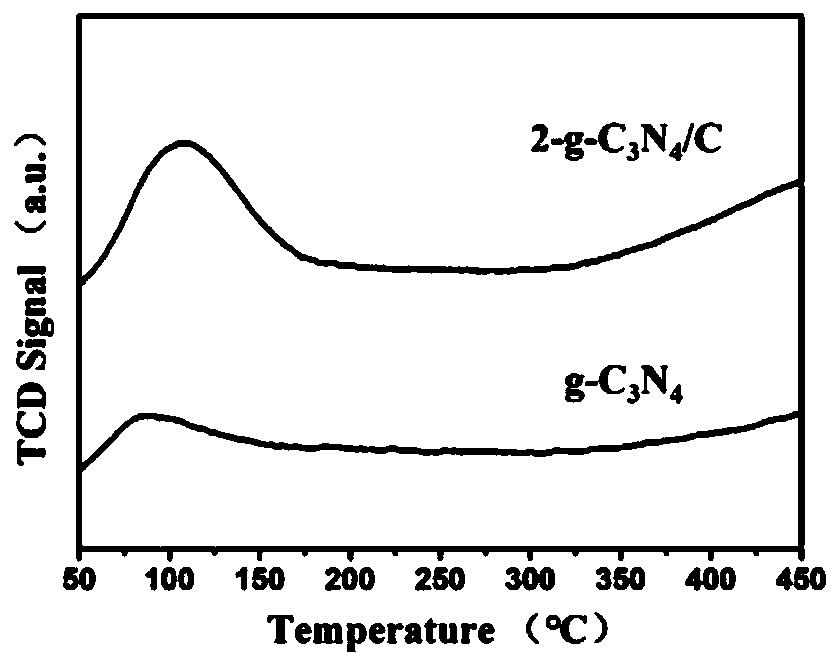

Preparation method of g-C3N4/C composite material containing nitrogen vacancy

PendingCN111151286AGood effectWide variety of sourcesPhysical/chemical process catalystsBulk chemical productionPhoto catalyticPtru catalyst

The invention discloses a preparation method of a g-C3N4 / C composite material containing nitrogen vacancy, wherein the preparation method comprises the following steps: mixing oxyacid and a melamine precursor with absolute ethyl alcohol, dispersing by planetary ball milling, drying an obtained sample, and grinding to obtain a catalyst precursor; calcining the precursor in a tubular furnace, and grinding an obtained sample to obtain the g-C3N4 / C composite material containing the nitrogen vacancy. The prepared g-C3N4 / C composite material containing the nitrogen vacancy has excellent catalytic performance on a photocatalytic nitrogen fixation reaction. Compared with the prior art, the preparation method provided by the invention is wide in raw material source, simple in preparation process and high in catalyst nitrogen vacancy content, and the photocatalytic nitrogen fixation efficiency can be effectively improved.

Owner:NANJING UNIV OF SCI & TECH

High-capacity cathode material for lithium ion batteries and preparation method thereof

InactiveCN105336944AMeet the demand for high-rate charge and dischargeOvercoming the need for high-rate charging and dischargingCell electrodesSecondary cellsFiltrationMixed materials

The invention discloses a high-capacity cathode material for lithium ion batteries and a preparation method thereof. The high-capacity cathode material is LiNi1-x-yCoxAlyO2. While Nickel sulfate solution rich in nickel is added into mixed solution of nickel, cobalt and aluminum poor in nickel, the mixed solution is added to a reaction tank; sodium hydroxide and ammonia-water solution are added into the reaction tank, and a coprecipitate Ni1-x-yCoxAly(OH)2+y precursor is prepared; the precursor undergoes ageing, filtration, washing and drying and then is mixed with a lithium source, and the mixed material is formed by compression; the material formed by compression is placed in a tube furnace to be presintered and sintered in oxygen airflow or oxygen-enriched air flow, and a target product is obtained. The prepared high-capacity cathode material for the lithium ion batteries is free of impure phase and high in crystallization quality, the product particle size distribution is uniform, the high-capacity cathode material has very high discharged specific capacity and cycling stability, an operation process is simple, raw material sources are extensive, the manufacturing cost is low, and large-scale industrial production is achieved easily.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

Non-volatile floating-gate memory based on two-layer nano silicon structure and its preparing method

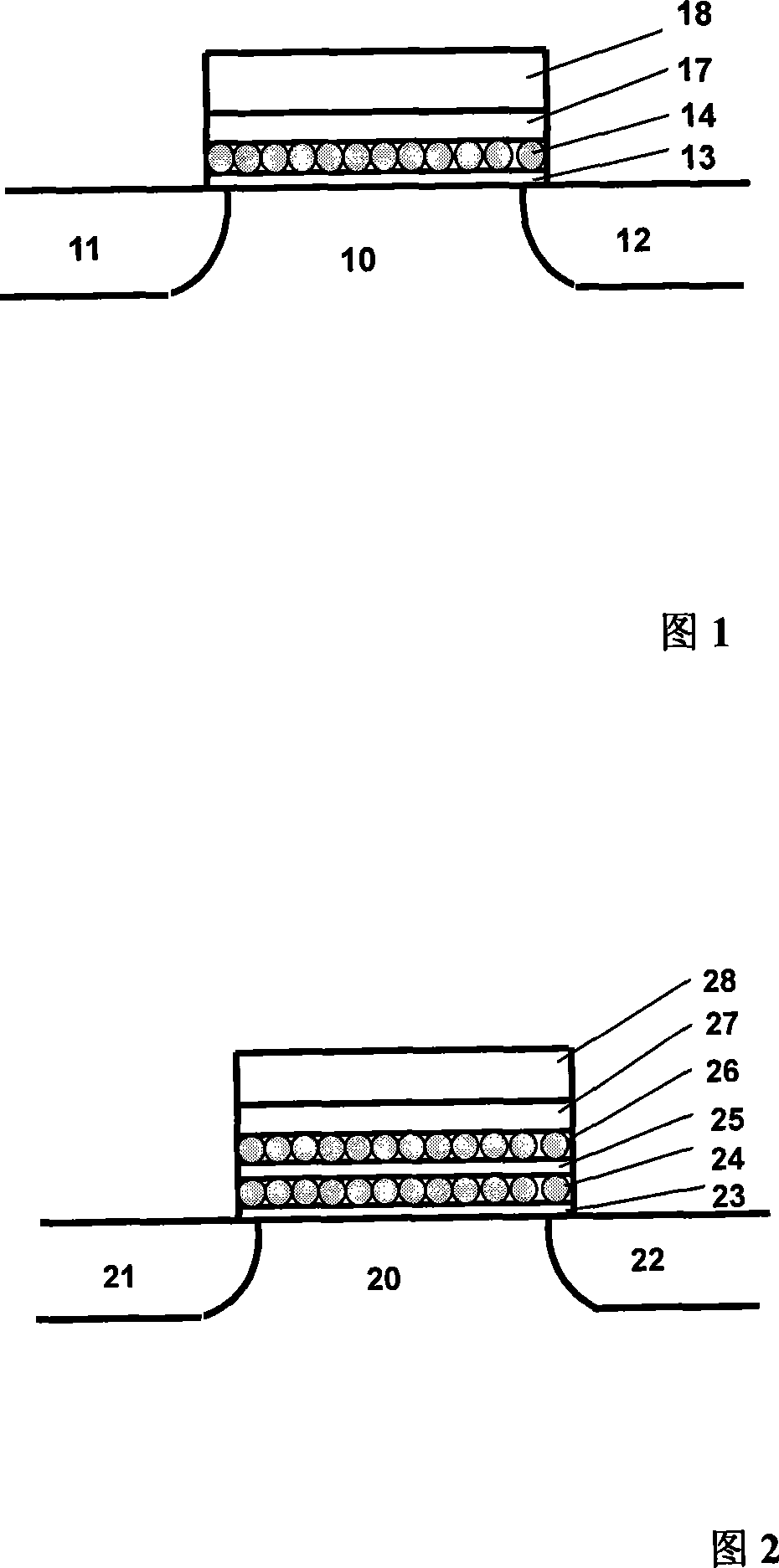

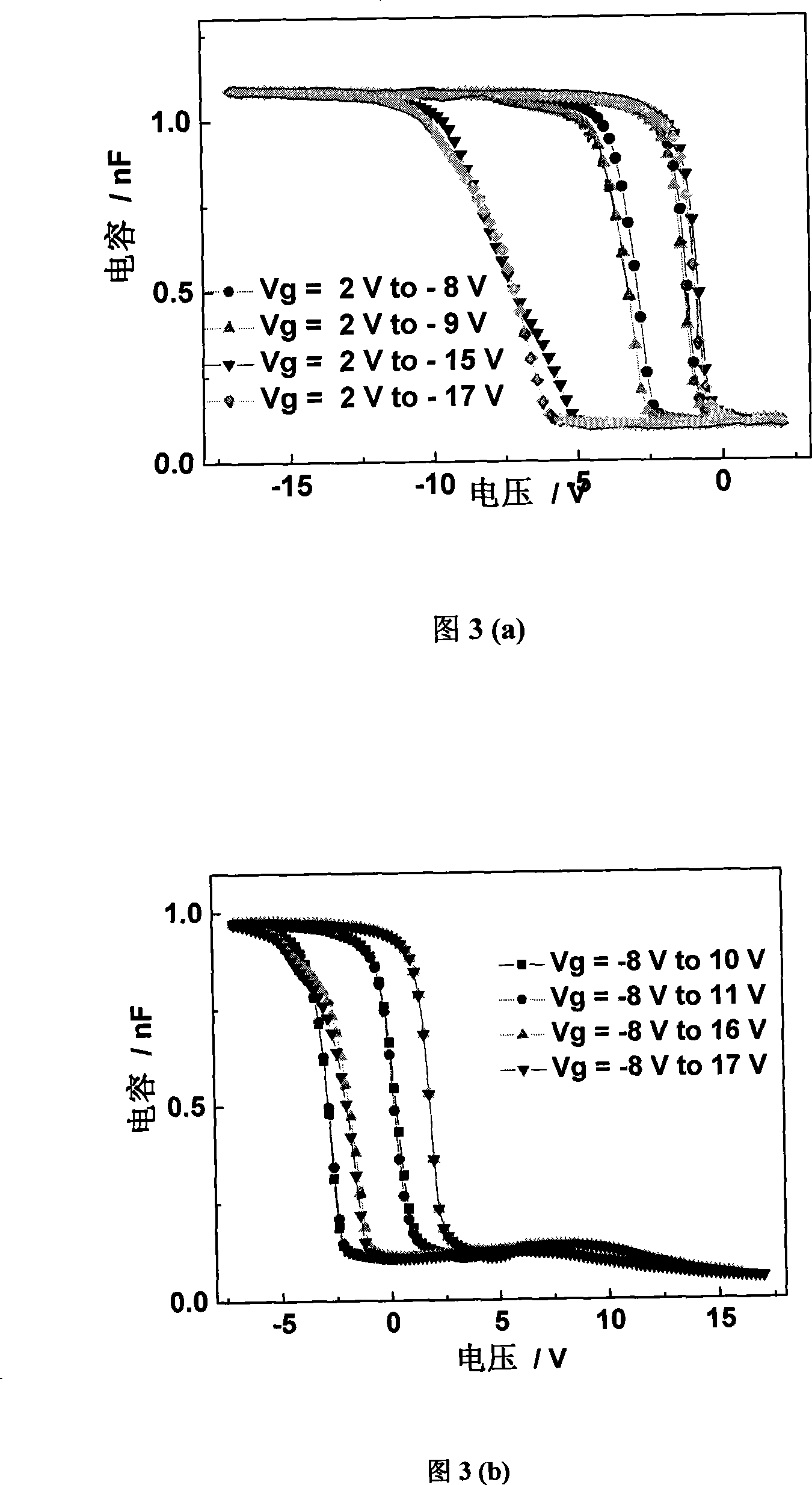

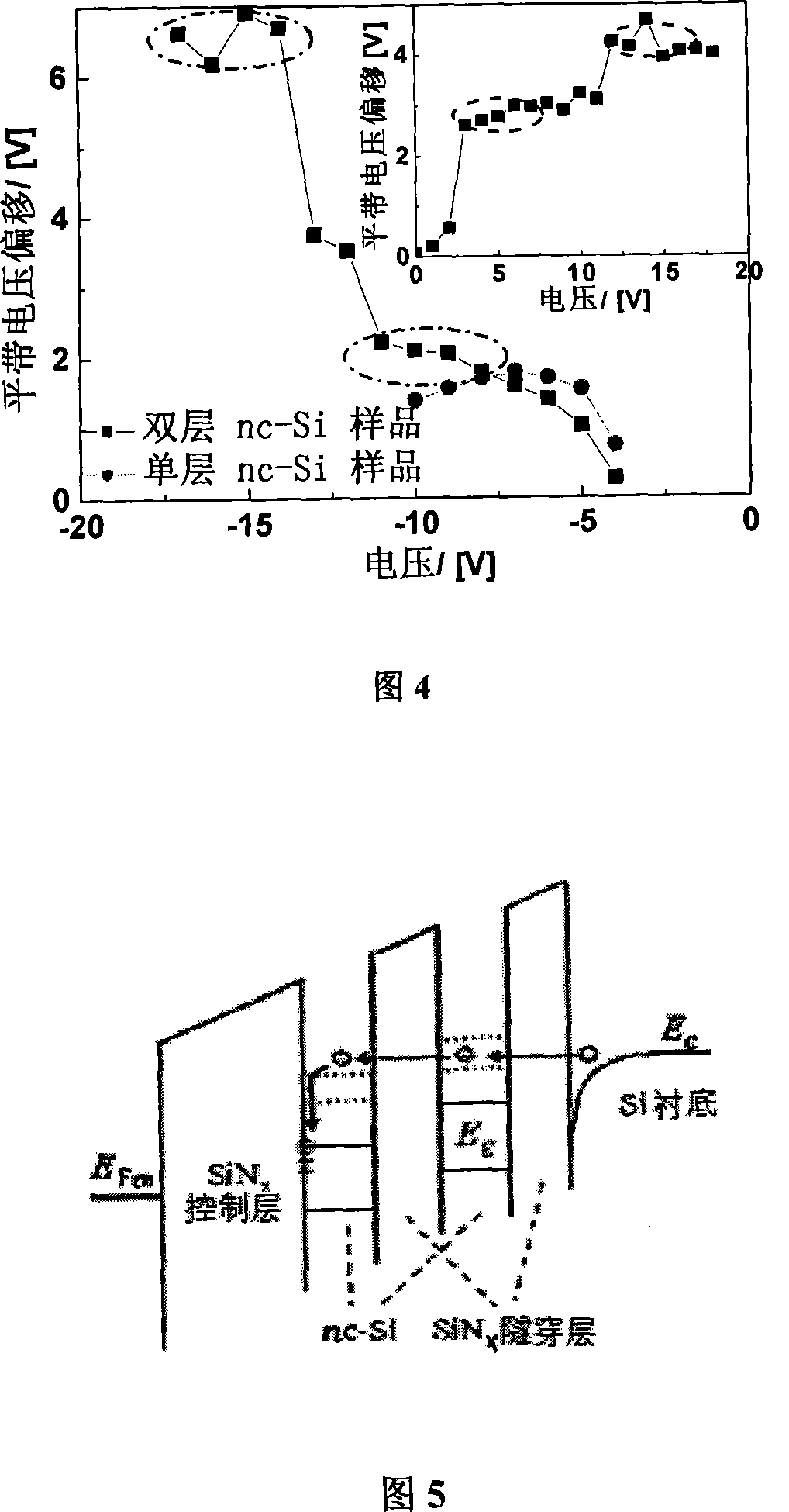

InactiveCN101026194AIncrease storage capacityExtended storage timeTransistorSolid-state devicesNano siliconP type silicon

This invention relates to a semiconductor non-volatile floating grid storage based on double-layer nm Si structure, which takes p-type Si (resistivity: 1-10Ohm.cm) as a substrate and sets source and drain at either side of the substrate, and sets a SiO2 layer formed by a first tunnel dielectric layer of 1-2nm thick or a SiNx layer with the thickness of 3-5nm on the substrate, then a first Si nm layer with the grain size of 2-7nm, then a second tunnel dielectric layer of a SiO2 layer of 1-2nm thick or a SiNx layer of 3-5nm thick, then forms a second Si nm layer with the grain size of 2-7nm to be deposited to form a control SiN dielectric layer in the thickness of 8-20nm and a polysilicon grid is on the SiO or the SiN dielectric layer.

Owner:NANJING UNIV

Precursor for doped lithium ion battery, cathode material and preparation method of precursor and cathode material

PendingCN112447962AEvenly distributedStable structureCell electrodesMagnesium dopingPhysical chemistry

The invention discloses a nickel-cobalt-manganese precursor for a doped lithium ion battery. The precursor is a radial metal hydroxide, the chemical expression of the precursor is Ni0.7Co0.1Mn0.2-xMgx(OH)2, and the x is greater than or equal to 0.02 and less than or equal to 0.04. The invention also discloses a preparation method of the nickel-cobalt-manganese precursor. According to the preparation method, an Mg doping element is directly added in the coprecipitation process, so that the doping element can be uniformly distributed in precursor particles, the modification effect of the dopingelement is effectively exerted, and magnesium doping is beneficial to forming a good layered structure, enhancing the structural stability of the material and improving the cycle performance of the high-nickel ternary material.

Owner:JINGMEN GEM NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com