Two-dimensional-layered titanium-dioxide nanometer photocatalytic material and preparing method

A titanium dioxide, catalytic material technology, applied in the direction of titanium dioxide, catalyst activation/preparation, titanium oxide/hydroxide, etc., can solve the problems of electronic excitation conduction obstruction, inconspicuous layered structure, low photocatalytic efficiency, etc., to achieve easy regeneration. Recycling, good layered structure, good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

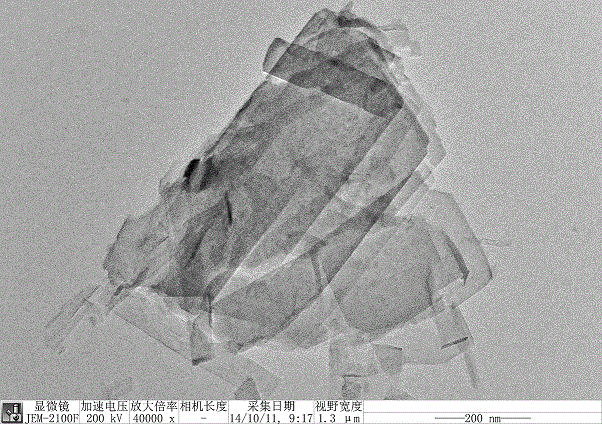

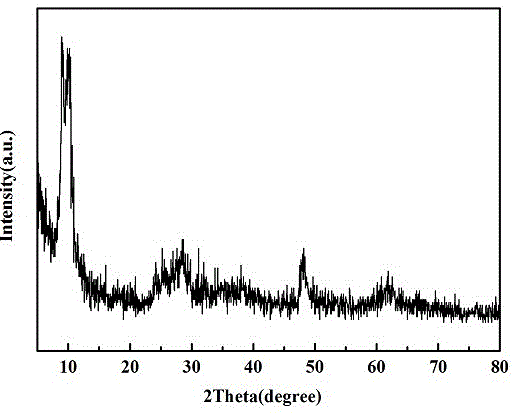

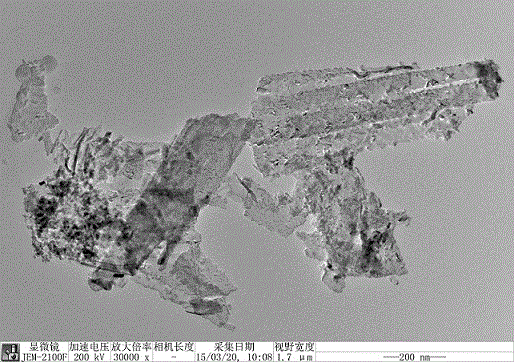

[0026] Add 0.5g of titanium dioxide hydrate and 30ml of 6M NaOH solution into a 30ml high-pressure reactor lined with polytetrafluoroethylene, keep at 150°C for 48 hours, take out the reactant, wash until neutral; then soak with 0.1M hydrochloric acid After 24 hours, use ion exchange to remove impurity ions inside; wash with deionized water until neutral; dry in an oven at 80°C; grind to obtain layered titanium dioxide hydrate (see figure 1 , XRD diagram see figure 2 ). The obtained titanium hydroxide was kept in a muffle furnace at 450° C. for 3 h and calcined, and after grinding, an anatase layered titanium dioxide photocatalyst could be obtained. Its transmission electron microscope pictures are shown in image 3 ; XRD figure see Figure 4 ; Photocatalytic curve see Figure 5 .

Embodiment 2

[0028] Add 0.5g of titanium dioxide hydrate and 30ml of 6M NaOH solution into a 30ml high-pressure reactor lined with polytetrafluoroethylene, keep at 150°C for 72h, take out the reactant, wash until neutral; then soak with 0.1M hydrochloric acid After 24 hours, use ion exchange to remove impurity ions inside; wash with deionized water until neutral; dry in an oven at 80°C; grind to obtain layered titanium hydroxide. The obtained titanium hydroxide was kept in a muffle furnace at 450° C. for 3 h and calcined, and after grinding, an anatase layered titanium dioxide photocatalyst could be obtained.

Embodiment 3

[0030] Take 0.5g of titanium dioxide hydrate and 30ml of 6M NaOH solution and add it to a 30ml high-pressure reactor lined with polytetrafluoroethylene, keep it at 150°C for 96h, take out the reactant, wash until neutral; then soak with 0.1M hydrochloric acid After 24 hours, use ion exchange to remove impurity ions inside; wash with deionized water until neutral; dry in an oven at 80°C; grind to obtain layered titanium hydroxide. The obtained titanium hydroxide was kept in a muffle furnace at 450° C. for 3 h and calcined, and after grinding, an anatase layered titanium dioxide photocatalyst could be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com