High-temperature abrasive sealing coating material used for plasma spraying

A sealing coating and coating material technology, applied in coatings, powder coatings, blade support components, etc., can solve the problems of less research on sealing coatings, wearability defects of coatings, etc., and achieve grain size Small, good chemical stability and thermal shock resistance, the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

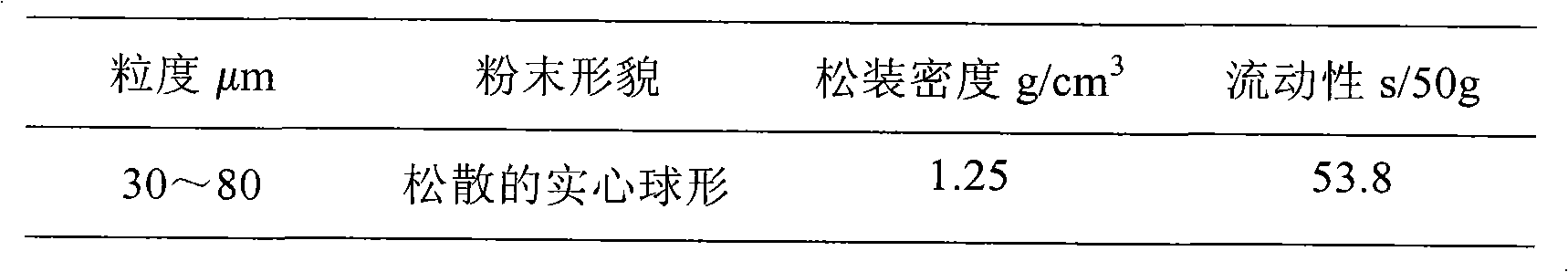

Embodiment 1

[0020] Ingredients: Take 7.8Kg of Y-PSZ powder with a particle size of 20-60nm, and α-Al with a particle size of 15-30nm 2 o 3 1.5 Kg of powder, 0.2 Kg of hBN powder with a particle size of 0.5-2 μm, and 0.5 Kg of polyphenylene with a particle size of 6-10 μm, and mix them uniformly.

[0021] Mixing: Take 0.4kg of dextrin, add it to the raw material powder and mix thoroughly, then add 8.0Kg of distilled water, stir to form a uniformly dispersed and suspended slurry for use.

[0022] Spray granulation: Use centrifugal atomizing nozzle to atomize the slurry into fine droplets and spray them into the granulation tower. The atomizer speed is 18000-20000r / min. Drying in hot air, the temperature in the granulation tower is controlled within the range of 140-170°C, and the temperature can be adjusted so that the powder is fully dried. The dry agglomerated powder is then drawn into a cyclone separator by an aspirator for collection.

[0023] Sieving: Sieve the collected agglomerate...

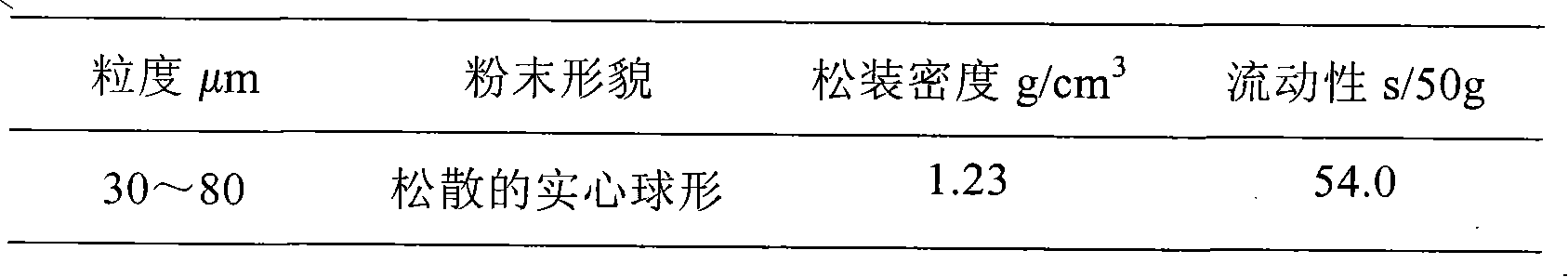

Embodiment 2

[0026] Ingredients: Take 8.1Kg of Y-PSZ powder with a particle size of 20-60nm, and α-Al with a particle size of 15-30nm 2 o 3 1.0 Kg of powder, 0.3 Kg of hBN powder with a particle size of 0.5-2 μm, and 0.6 Kg of polyphenylene with a particle size of 6-10 μm, and mix them uniformly.

[0027] Mixing: Take 0.3kg of dextrin, add it to the raw material powder and mix thoroughly, then add 7.5Kg of distilled water, and stir to form a uniformly dispersed and suspended slurry for use.

[0028] Spray granulation: Use centrifugal atomizing nozzle to atomize the slurry into fine droplets and spray them into the granulation tower. The atomizer speed is 18000-20000r / min. Drying in hot air, the temperature in the granulation tower is controlled within the range of 140-170°C, and the temperature can be adjusted so that the powder is fully dried. The dry agglomerated powder is then drawn into a cyclone separator by an aspirator for collection.

[0029] Sieving: Sieve the collected agglome...

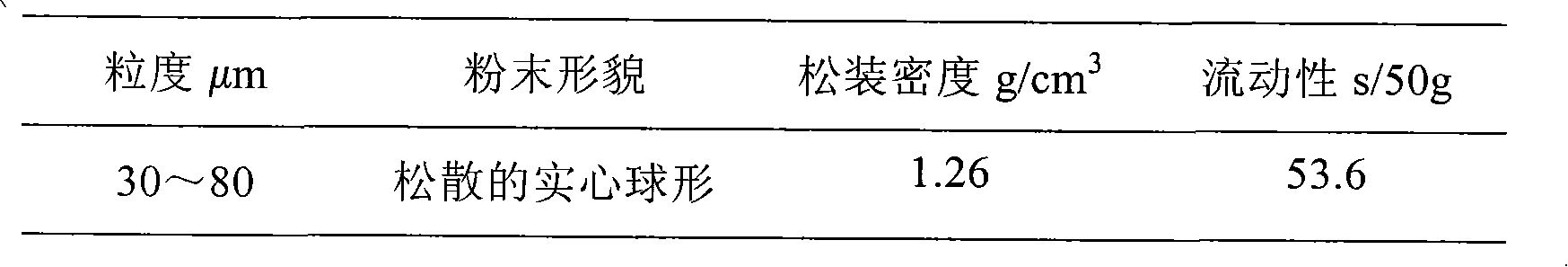

Embodiment 3

[0032] Ingredients: Take 7.5Kg of Y-PSZ powder with a particle size of 20-60nm, and α-Al with a particle size of 15-30nm 2 o 3 2.0 Kg of powder, 0.1 Kg of hBN powder with a particle size of 0.5-2 μm, and 0.4 Kg of polyphenylene with a particle size of 6-10 μm, and mix them uniformly.

[0033] Mixing: Take 0.4kg of dextrin, add it to the raw material powder and mix thoroughly, then add 8.0Kg of distilled water, stir to form a uniformly dispersed and suspended slurry for use.

[0034] Spray granulation: Use centrifugal atomizing nozzle to atomize the slurry into fine droplets and spray them into the granulation tower. The atomizer speed is 18000-20000r / min. Drying in hot air, the temperature in the granulation tower is controlled within the range of 140-170°C, and the temperature can be adjusted so that the powder is fully dried. The dry agglomerated powder is then drawn into a cyclone separator by an aspirator for collection.

[0035] Sieving: Sieve the collected agglomerate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com