Heating modified MXene/ferroferric oxide composite wave-absorbing material and preparation method thereof

A composite wave-absorbing material, the technology of ferroferric oxide, which is applied in the direction of iron oxide/iron hydroxide, ferric oxide, nanotechnology for materials and surface science, etc., can solve cumbersome experimental operations and destroy MXene Problems such as layered structure and narrow absorbing frequency band of composite materials can achieve the effect of enhancing interface polarization, improving impedance matching, and enhancing absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

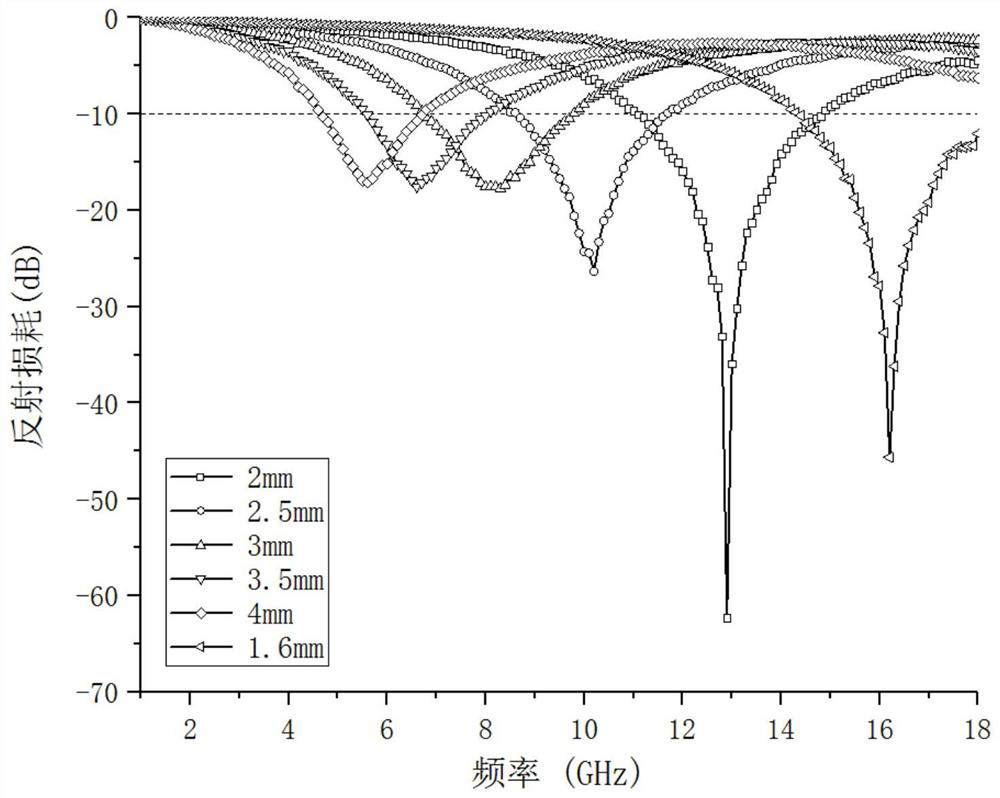

[0026] Example 1: Nitrogen is used as protective gas, and the set temperature of the tube furnace is 400°C

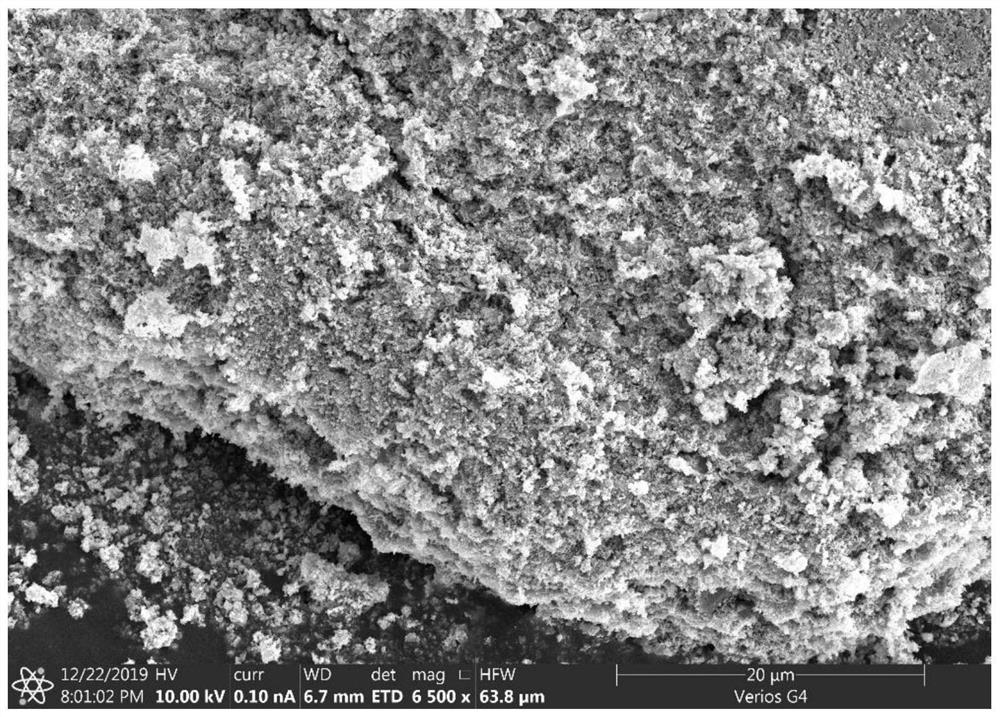

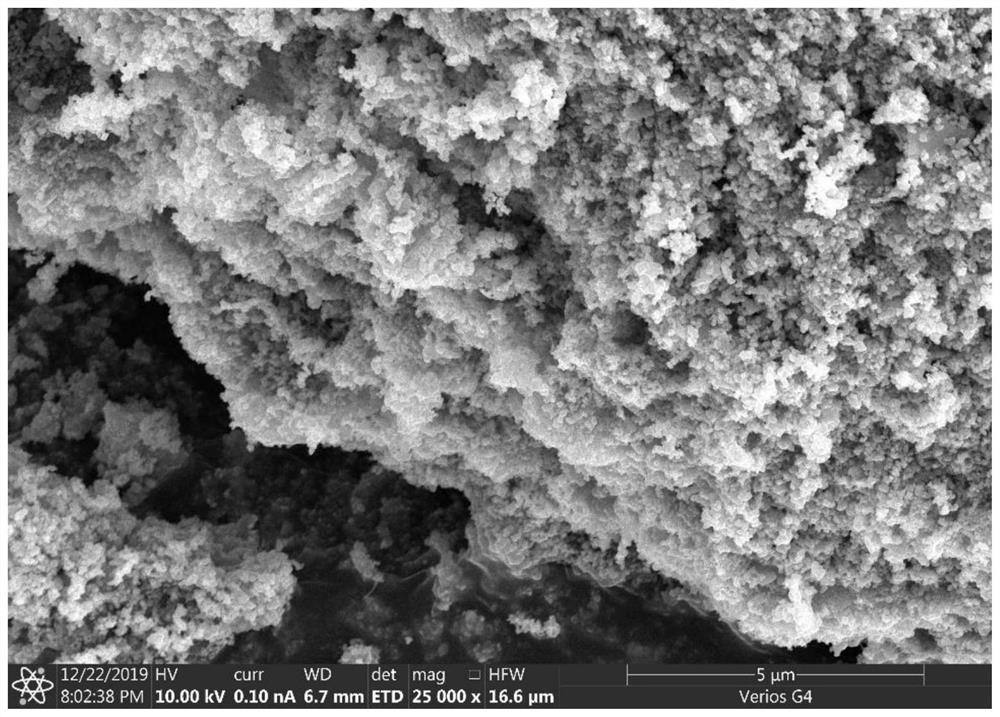

[0027] Step 1. Measure 3.75ml of distilled water and slowly add it dropwise to 11.25ml of concentrated hydrochloric acid. Weigh 1 g of lithium fluoride and 1 g of aluminum carbon-titanium oxide, slowly add to the obtained hydrochloric acid, and magnetically stir at 250 rpm for 24 h in a water bath at 30°C. The product was centrifuged and washed four times with distilled water, and dispersed into 100 ml of distilled water to obtain an MXene dispersion.

[0028]Step 2. Measure 20ml of the MXene dispersion obtained in step 1, weigh 0.7g of anhydrous ferric chloride, and 0.6g of ferrous sulfate heptahydrate, and disperse them in 80ml of distilled water. At 600 rpm, under a nitrogen atmosphere, the water bath was heated to 80° C., 4 ml of ammonia water was added dropwise, and the reaction was continued for 30 minutes. The resulting product was washed three times with disti...

Embodiment 2

[0030] Example 2: Argon is used as the protective gas, and the set temperature of the tube furnace is 600°C

[0031] Step 1. Measure 3.75ml of distilled water and slowly add it dropwise to 11.25ml of concentrated hydrochloric acid. Weigh 1.5 g of lithium fluoride and 1 g of aluminum carbon-titanium oxide, slowly add to the obtained hydrochloric acid, and stir magnetically at 250 rpm for 24 h in a water bath at 40°C. The product was centrifuged and washed four times with distilled water, and dispersed into 100 ml of distilled water to obtain an MXene dispersion.

[0032] Step 2. Measure 20ml of the MXene dispersion obtained in step 1, weigh 0.7g of anhydrous ferric chloride, and 0.6g of ferrous sulfate heptahydrate, and disperse them in 80ml of distilled water. At 600 rpm, under a nitrogen atmosphere, the water bath was heated to 80° C., 4 ml of ammonia water was added dropwise, and the reaction was continued for 30 minutes. The resulting product was washed three times with d...

Embodiment 3

[0034] Example 3: Helium is used as the protective gas, and the set temperature of the tube furnace is 800°C

[0035] Step 1. Measure 3.75ml of distilled water and slowly add it dropwise to 11.25ml of concentrated hydrochloric acid. Weigh 1.2 g of lithium fluoride and 1 g of aluminum carbon-titanium oxide, slowly add to the obtained hydrochloric acid, and stir magnetically at 250 rpm for 24 h in a 35° C. water bath. The product was centrifuged and washed four times with distilled water, and dispersed into 100 ml of distilled water to obtain an MXene dispersion.

[0036] Step 2. Measure 20ml of the MXene dispersion obtained in step 1, weigh 0.7g of anhydrous ferric chloride, and 0.6g of ferrous sulfate heptahydrate, and disperse them in 80ml of distilled water. At 600 rpm, under a nitrogen atmosphere, the water bath was heated to 80° C., 4 ml of ammonia water was added dropwise, and the reaction was continued for 30 minutes. The resulting product was washed three times with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com