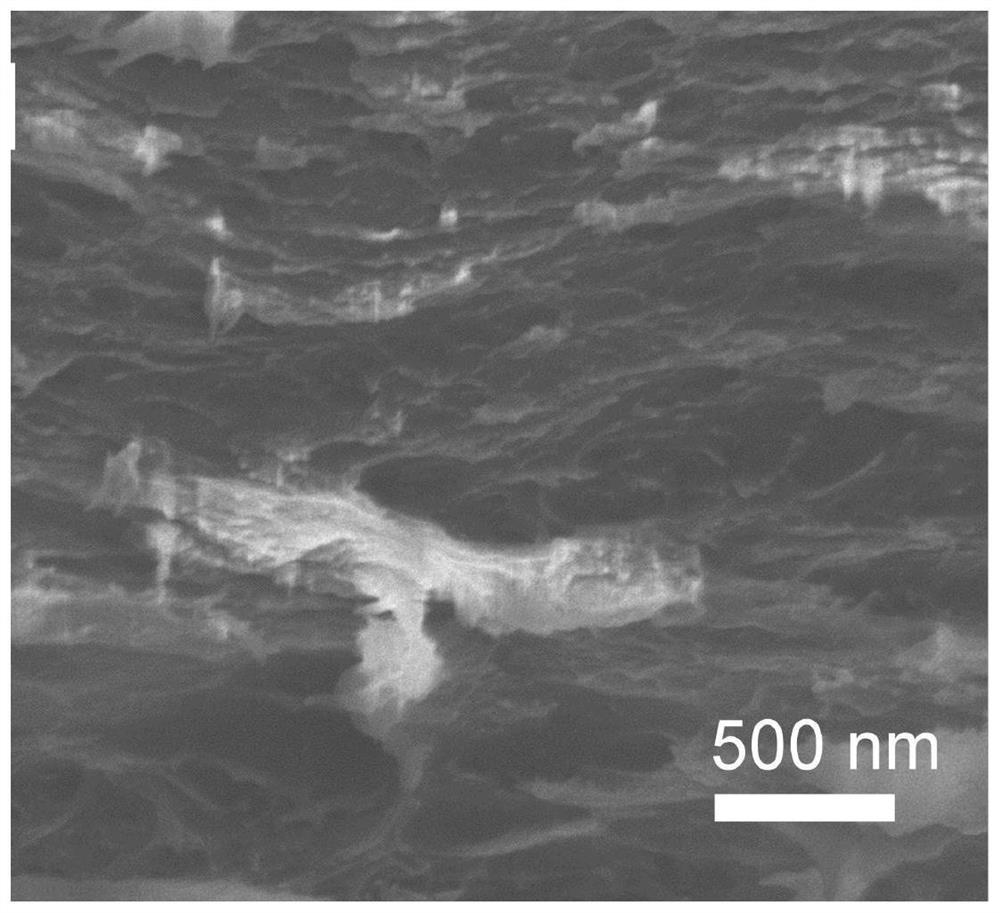

Preparation method of nanocellulose/molybdenum disulfide piezoelectric composite film

A technology of nano-cellulose and molybdenum disulfide, applied in the field of materials, can solve the problems of inability to improve the piezoelectric properties of cellulose, poor piezoelectric properties of cellulose, and great differences in piezoelectric properties, achieve high crystallinity, and prevent agglomeration , The effect of superior piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of nanocellulose / molybdenum disulfide piezoelectric composite film, its steps are as follows:

[0032] 1) Disperse 2.447g of cellulose nanofibers with a water content of 81wt% in 150mL of deionized water, stir with a magnetic stirrer for 30min, then use a cell disruptor to sonicate for 6min, and finally centrifuge at 8500rpm to remove undispersed precipitates to obtain 0.3wt% The prepared nanocellulose dispersion is stored at a temperature lower than 5°C.

[0033] 2) Preparation of molybdenum disulfide nanosheets: 0.6 g of molybdenum disulfide powder and 60 mL of triethanolamine were placed in a 100 mL single-necked flask. Stir at room temperature with a mechanical stirrer (rotating at 1000rpm) for 8h, centrifuge the mixed dispersion obtained at 4500rpm for 30min to get the supernatant, and stir and blend the supernatant with deionized water. Vacuum filtration on the filter membrane, repeated washing three times. The product obtained by the last suctio...

Embodiment 2

[0038] The preparation of nanocellulose / molybdenum disulfide piezoelectric composite film, its steps are as follows:

[0039] 1) Disperse 2.447g of cellulose nanofibers with a water content of 81wt% in 150mL of deionized water, stir with a magnetic stirrer for 30min, then use a cell disruptor to sonicate for 6min, and finally centrifuge at 8500rpm to remove undispersed precipitates to obtain 0.3wt% The prepared nanocellulose dispersion is stored at a temperature lower than 5°C.

[0040] 2) Preparation of molybdenum disulfide nanosheets: 0.6 g of molybdenum disulfide powder and 60 mL of triethanolamine were placed in a 100 mL single-necked flask. Stir at room temperature with a mechanical stirrer (rotating at 1000rpm) for 8h, centrifuge the mixed dispersion obtained at 4500rpm for 30min to get the supernatant, and stir and blend the supernatant with deionized water. Vacuum filtration on the filter membrane, repeated washing three times. The product obtained by the last suctio...

Embodiment 3

[0044] The preparation of nanocellulose / molybdenum disulfide piezoelectric composite film, its steps are as follows:

[0045]1) Preparation of nanocellulose dispersion: Disperse 2.447g of cellulose nanofibers with a water content of 81wt% into 150mL of deionized water, stir for 30min with a magnetic stirrer, then sonicate for 6min with a cell disruptor, and finally centrifuge at 8500rpm to remove untreated cellulose. Disperse the precipitate to obtain a 0.3wt% nanocellulose aqueous dispersion, and store the prepared nanocellulose dispersion at a temperature lower than 5°C.

[0046] 2) Preparation of molybdenum disulfide nanosheets: 3 g of molybdenum disulfide powder, 60 g of urea and 278 g of glycerin were placed in a 250 mL three-neck flask. Stir at room temperature with a mechanical stirrer (rotating at 1000rpm) for 8h, centrifuge the mixed dispersion obtained at 4500rpm for 30min to get the supernatant, and stir and blend the supernatant with deionized water. Vacuum filtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com