Perovskite solar cell and method for manufacturing same

A solar cell and perovskite technology, applied in the field of solar cells, can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The steps of the method for preparing the perovskite solar cell in this embodiment are as follows:

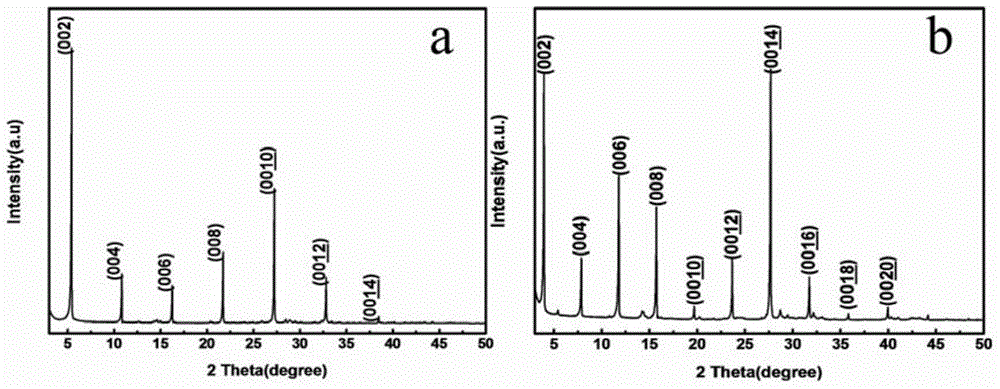

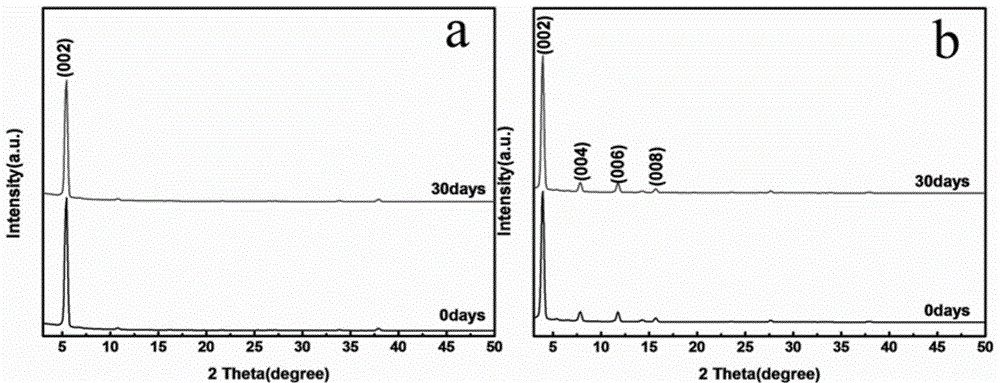

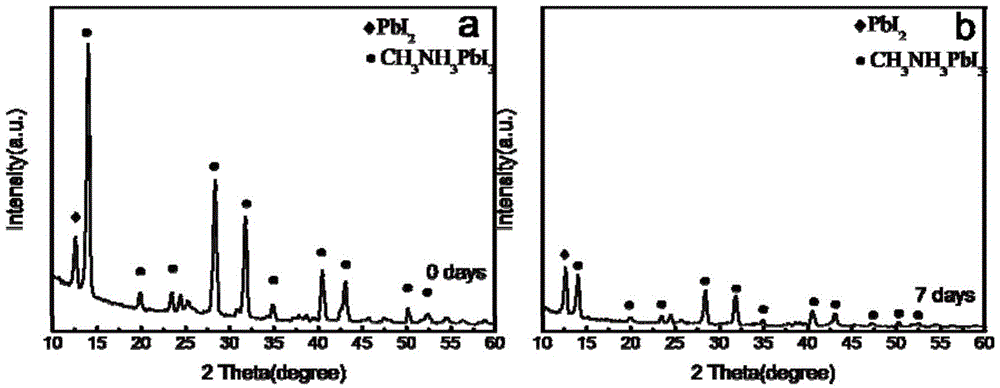

[0045] 1.(C 6 H 5 CH 2 CH 2 NH 3 ) 2 PbI 4 The synthesis of powder crystals is specifically divided into the following two steps:

[0046] Step (a) Synthesis C 6 H 5 CH 2 CH 2 NH 3 I powder crystals: Add 5.44g of hydroiodic acid aqueous solution (47wt%) slowly to 2.47g of phenethylamine (purity ≥98%) under the condition of ice water bath and keep stirring for 1h, in which the hydroiodic acid and phenylethyl The molar ratio of amine is 1:1, and then the mixed solution is stirred at 60°C for 1h, part of the solvent is evaporated, cooled to room temperature and then suction filtered to obtain white crystals. The white crystals are vacuum dried at 60°C for 10h to obtain C 6 H 5 CH 2 CH 2 NH 3 I powder crystal.

[0047] Step (b) Synthesis (C 6 H 5 CH 2 CH 2 NH 3 ) 2 PbI 4 Powder crystal: accurately weigh 0.470g PbI 2 (Purity≥98%) dissolved in 10mL hydroiodic acid aqueous solution (4...

Embodiment 2

[0059] The steps of the method for preparing the perovskite solar cell in this embodiment are as follows:

[0060] 1.C 6 H 5 CH 2 CH 2 NH 3 ) 2 (CH 3 NH 3 )Pb 2 I 7 The synthesis of powder crystals is specifically divided into the following three steps:

[0061] Step (a) Synthesis of CH 3 NH 3 I powder crystals: slowly add 10.35g of hydroiodic acid aqueous solution (47wt%) to 3.58g of methylamine ethanol solution (30-33wt%) in an ice-water bath, and stir continuously for 1h. The molar ratio of methylamine is 1:1, then the mixed solution is stirred at 60°C for 1h to volatilize part of the solvent, cooled to room temperature and suction filtered to obtain white crystals. The white crystals are vacuum dried at 60°C for 10h to obtain CH 3 NH 3 I powder crystal.

[0062] Step (b) Synthesis C 6 H 5 CH 2 CH 2 NH 3 I powder crystals: slowly add 5.44g of hydroiodic acid (47wt%) to 2.47g of phenethylamine (≥98%) in an ice-water bath and keep stirring to obtain a mixed solution for 1h, hydroiod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com