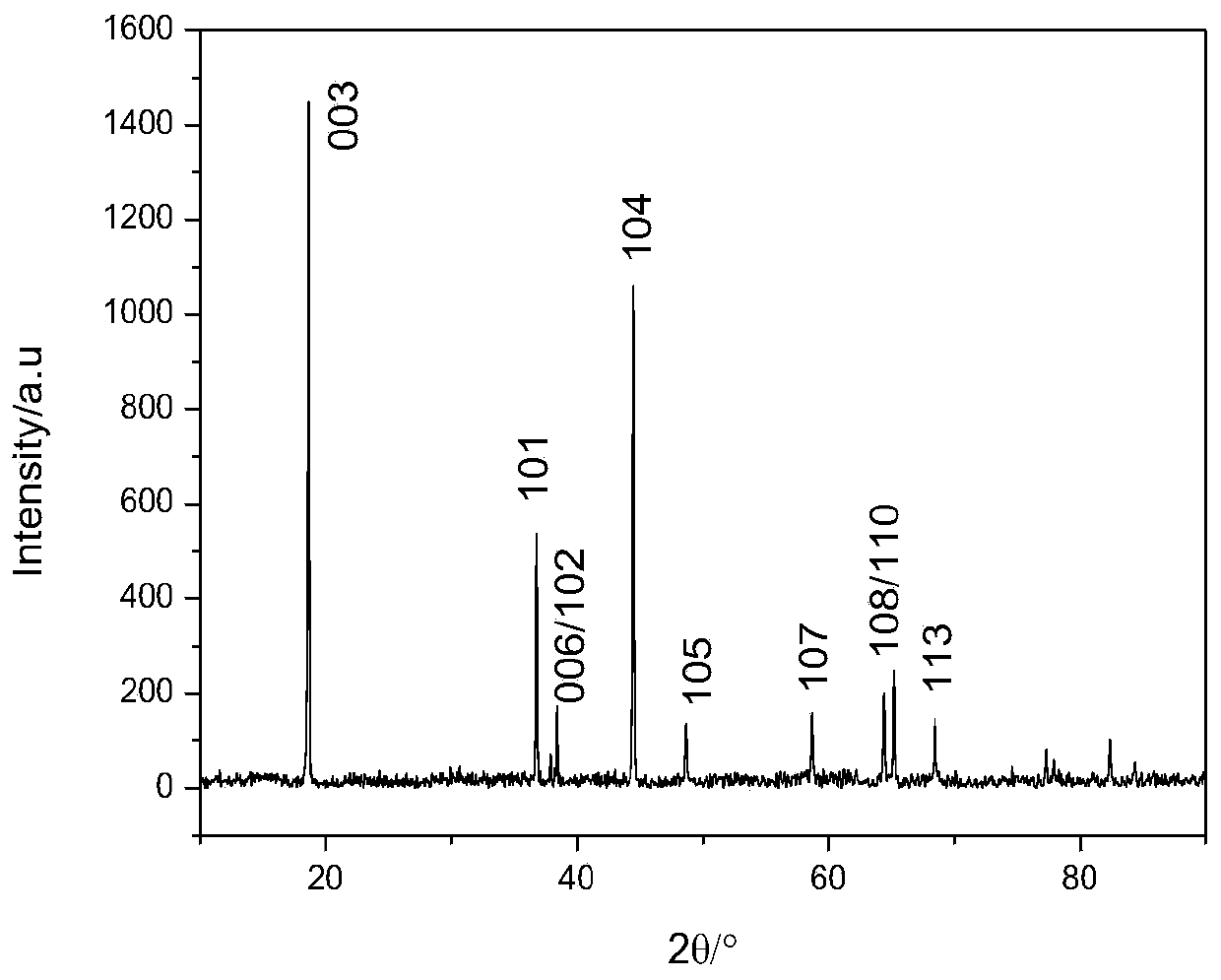

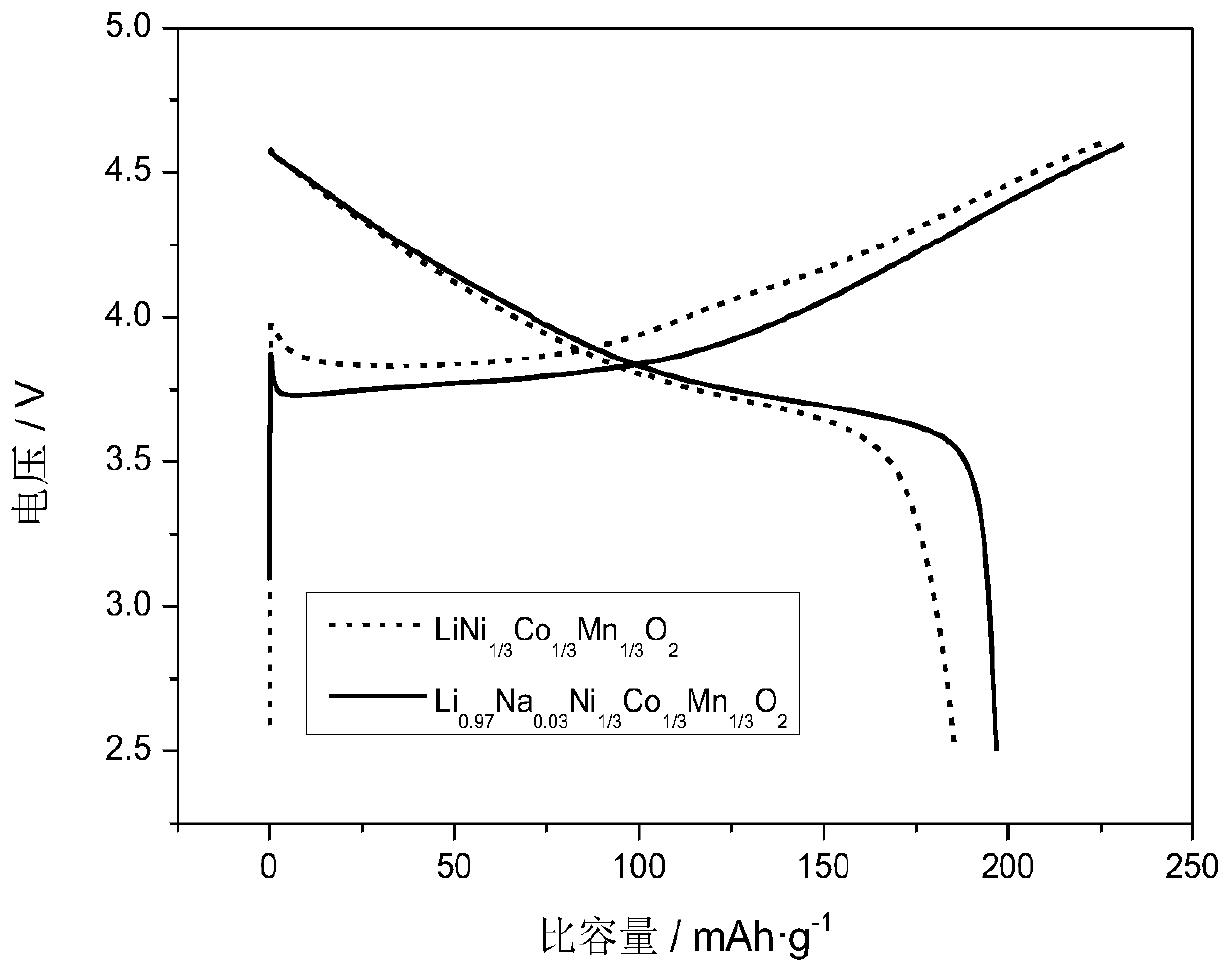

Sodium ion doped ternary positive electrode material and preparation method thereof

A cathode material, a technology of sodium ions, applied in the field of sodium ion-doped ternary cathode materials and their preparation, can solve the problems of poor cycle performance and rate performance, and achieve improved cycle performance and rate performance, low price, good layered effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

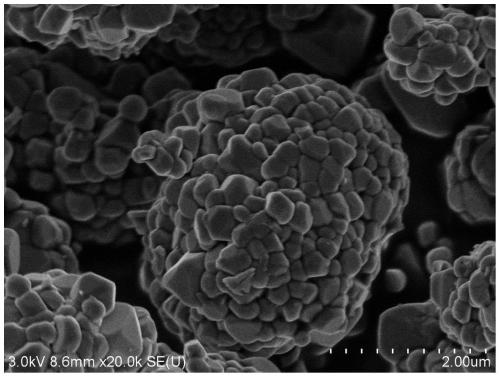

Embodiment 1

[0026] (1) Dissolve manganese sulfate and ammonium bicarbonate in deionized water at a molar ratio of 1:10, mix the solutions, and stir for 3 hours at a stirring speed of 200-500 rpm; the resulting suspension is placed in circulating water suction filtration in a vacuum pump, and washed 3 times with deionized water, and washed 2 times with absolute ethanol to obtain manganese carbonate microspheres;

[0027] (2) Calcining manganese carbonate in a muffle furnace at a heating rate of 5°C / min, raising the temperature to 400-500°C, and calcining for 3-5 hours to obtain manganese dioxide hollow microspheres;

[0028] (3) Weigh lithium hydroxide, manganese dioxide, nickel nitrate and cobalt nitrate at a molar ratio of 1 : 1 / 3 : 1 / 3 : 1 / 3, add absolute ethanol, and dissolve the lithium hydroxide suspension (slightly soluble in absolute ethanol), manganese dioxide suspension (insoluble in absolute ethanol), nickel nitrate solution and cobalt nitrate solution are mixed in a clean large...

Embodiment 2

[0034] (1) Dissolve manganese sulfate and ammonium bicarbonate in deionized water at a molar ratio of 1:10, mix the solutions, and stir for 3 hours at a stirring speed of 200-500 rpm; the resulting suspension is placed in circulating water suction filtration in a vacuum pump, and washed 3 times with deionized water, and washed 2 times with absolute ethanol to obtain manganese carbonate microspheres;

[0035] (2) Calcining manganese carbonate in a muffle furnace at a heating rate of 5°C / min, raising the temperature to 400-500°C, and calcining for 3-5 hours to obtain manganese dioxide hollow microspheres;

[0036] (3) Weigh lithium hydroxide, anhydrous sodium acetate, manganese dioxide, nickel nitrate and cobalt nitrate at a molar ratio of 0.99 : 0.01 : 1 / 3 : 1 / 3 : 1 / 3, add absolute ethanol, and oxidize the hydroxide Lithium suspension (slightly soluble in absolute ethanol), manganese dioxide suspension (insoluble in absolute ethanol), nickel nitrate solution and cobalt nitrate ...

Embodiment 3

[0041] (1) Dissolve manganese sulfate and ammonium bicarbonate in deionized water at a molar ratio of 1:10, mix the solutions, and stir for 3 hours at a stirring speed of 200-500 rpm; the resulting suspension is placed in circulating water suction filtration in a vacuum pump, and washed 3 times with deionized water, and washed 2 times with absolute ethanol to obtain manganese carbonate microspheres;

[0042] (2) Calcining manganese carbonate in a muffle furnace at a heating rate of 5°C / min, raising the temperature to 400-500°C, and calcining for 3-5 hours to obtain manganese dioxide hollow microspheres;

[0043] (3) Weigh lithium hydroxide, anhydrous sodium acetate, manganese dioxide, nickel nitrate and cobalt nitrate at a molar ratio of 0.97 : 0.03 : 1 / 3 : 1 / 3 : 1 / 3, add absolute ethanol, and oxidize the hydroxide Lithium suspension (slightly soluble in absolute ethanol), manganese dioxide suspension (insoluble in absolute ethanol), nickel nitrate solution and cobalt nitrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com