Preparation method of g-C3N4/C composite material containing nitrogen vacancy

A composite material, g-c3n4 technology, applied in the field of photocatalytic materials and nitrogen reduction synthesis of ammonia, can solve the problem of less nitrogen vacancies on the surface, and achieve the effects of high production efficiency, low price and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment is g-C containing nitrogen vacancies 3 N 4 / C composite preparation process. Such as Figure 6 As shown, the following steps are included: Weigh 4.85g of melamine, add 0.15g of citric acid monohydrate into 40ml of absolute ethanol, place in a planetary ball mill to fully disperse at a speed of 300r / min, and ball mill for 12h. The emulsion was transferred to a beaker, and dried in an oven at 80° C. for 12 hours to obtain a uniformly dispersed melamine precursor. Grind the bulk precursor into powder in a mortar, take 3g and transfer it to an alumina crucible, place it in an atmosphere furnace, raise it to 550°C at a rate of 2°C / min, keep it warm for 2h, and then cool down naturally. Sonicate in deionized water for 1 h, and then dry in an oven at 80 °C for 24 h.

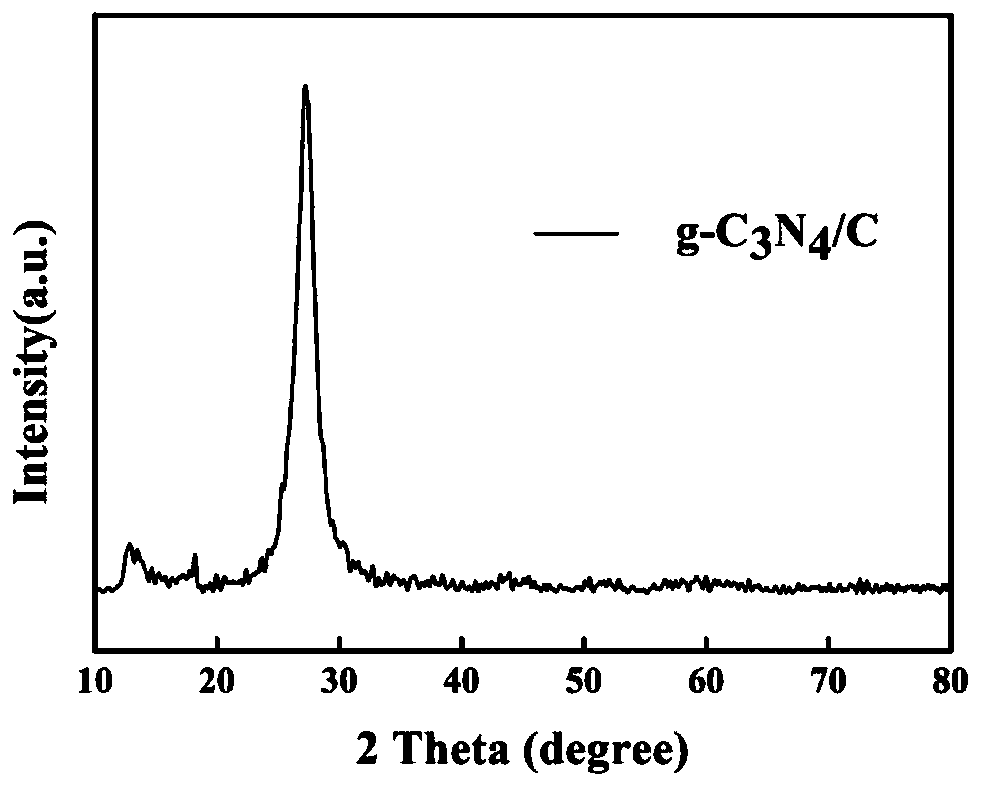

[0031] g-C of nitrogen vacancies prepared according to Example 1 3 N 4 / C composite material can be seen after scanning by X-ray diffractometer figure 1 , g-C 3 N 4 g-C can be clearly see...

Embodiment 2

[0033] This example is used to illustrate the g-C of nitrogen vacancies 3 N 4 / C composite preparation process. Such as Figure 6 As shown, the following steps are included: Weigh 4.65g of melamine, add 0.35g of citric acid monohydrate into 40ml of absolute ethanol, place in a planetary ball mill to fully disperse at a speed of 300r / min, and ball mill for 12h. The emulsion was transferred to a beaker, and dried in an oven at 80° C. for 12 hours to obtain a uniformly dispersed melamine precursor. Grind the bulk precursor into powder in a mortar, take 3g and transfer it to an alumina crucible, place it in an atmosphere furnace, raise it to 550°C at a rate of 2°C / min, keep it warm for 2h, and then cool down naturally. Sonicate in deionized water for 1 h, and then dry in an oven at 80 °C for 24 h.

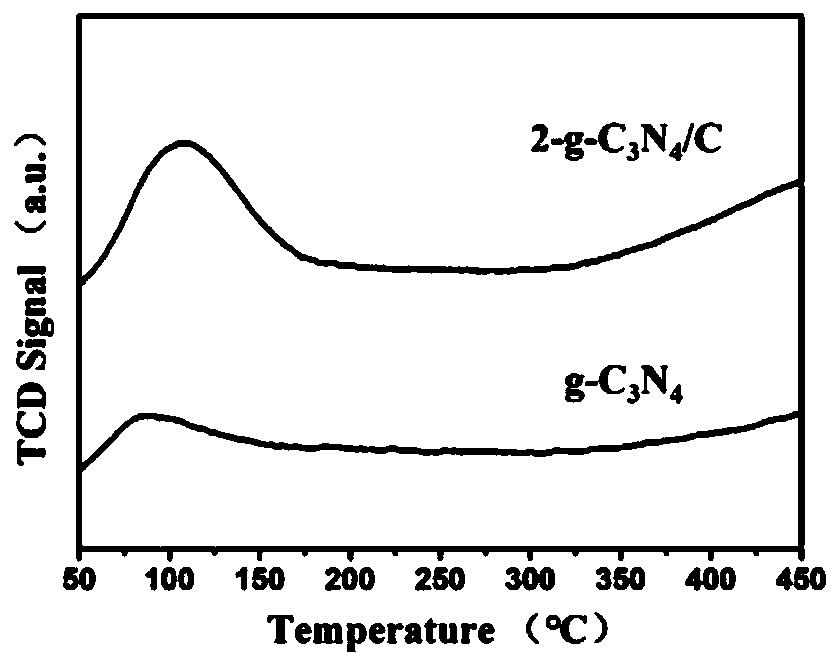

[0034] g-C of nitrogen vacancies prepared according to Example 2 3 N 4 / C composite material by N 2 -The temperature rise desorption curve of nitrogen obtained after the TPD tes...

Embodiment 3

[0036] This example is used to illustrate the use of oxyacids in g-C 3 N 4 Versatility of methods for constructing nitrogen defects on surfaces. Such as Figure 6As shown, the following steps are included: Weigh 4.65g of melamine, add 0.35g of adipic acid into 40ml of absolute ethanol, place in a planetary ball mill to fully disperse at a speed of 300r / min, and ball mill for 12h. The emulsion was transferred to a beaker, and dried in an oven at 80° C. for 12 hours to obtain a uniformly dispersed melamine precursor. Grind the bulk precursor into powder in a mortar, take 3g and transfer it to an alumina crucible, place it in an atmosphere furnace, raise it to 550°C at a rate of 2°C / min, keep it warm for 2h, and then cool down naturally. Sonicate in deionized water for 1 h, and then dry in an oven at 80 °C for 24 h.

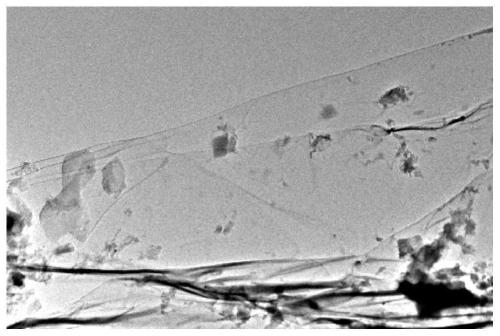

[0037] g-C of nitrogen vacancies prepared according to Example 3 3 N 4 / C composite material observed by transmission electron microscope, see image 3 , it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com