Precursor for doped lithium ion battery, cathode material and preparation method of precursor and cathode material

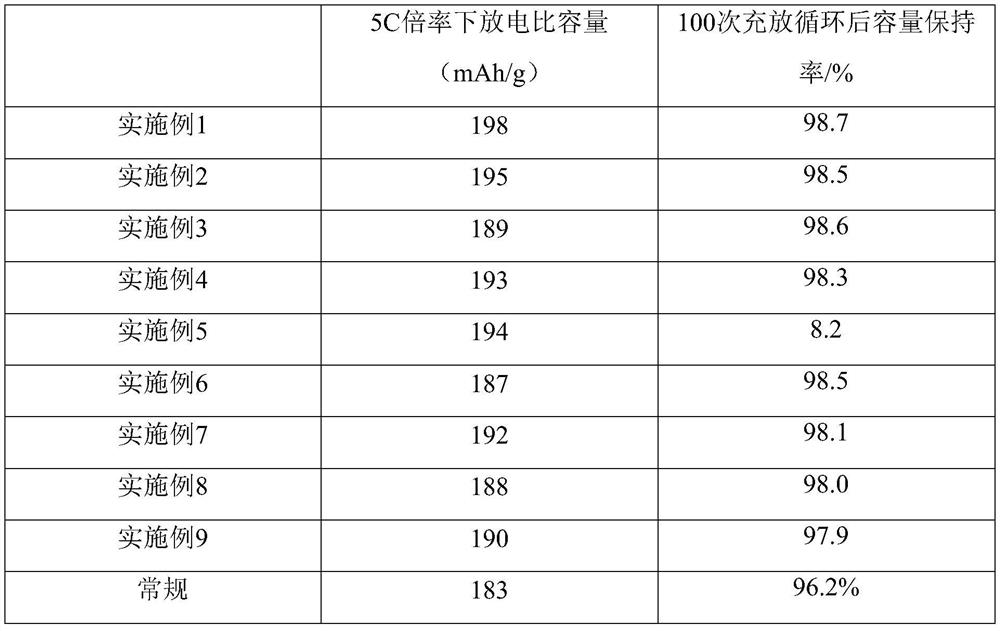

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle performance and rate performance, low discharge specific capacity, etc., and achieve excellent electrochemical performance, stable particle structure, Effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

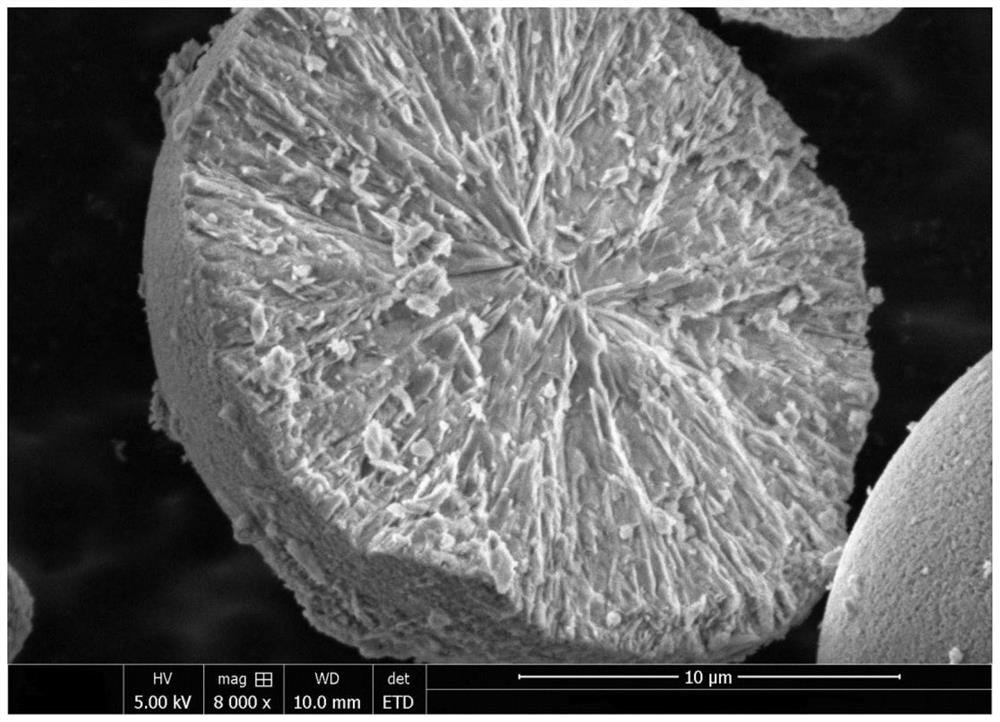

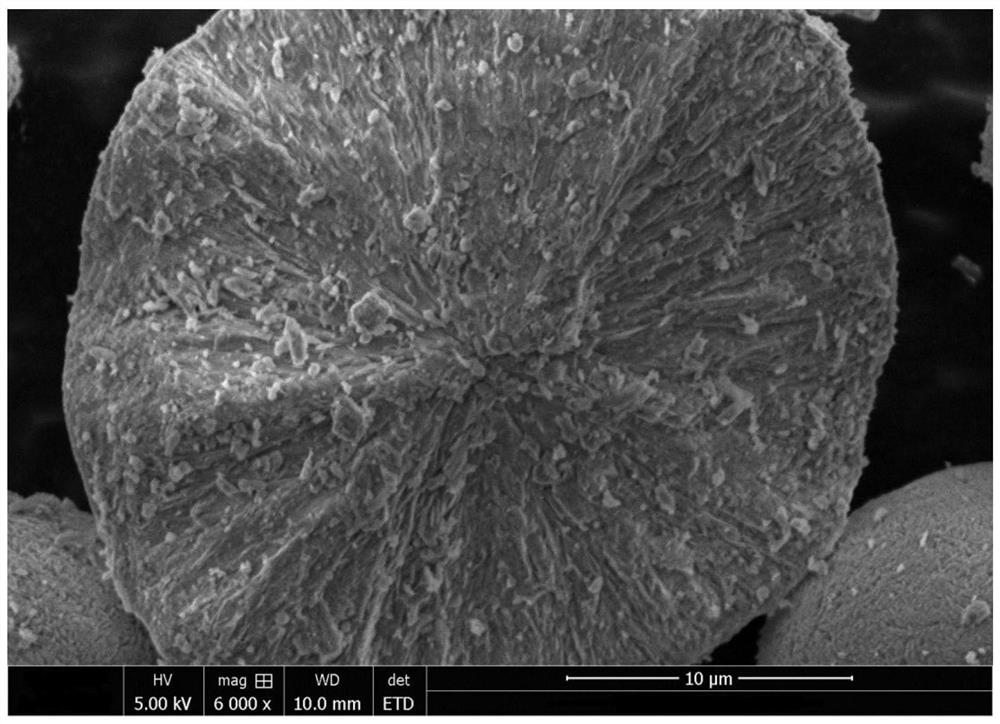

Image

Examples

preparation example Construction

[0023] Embodiments of the present invention also provide a method for preparing a nickel-doped lithium-ion battery for nickel-cobalt manganese precursors including the following steps:

[0024] Step 1, according to the molar ratio Ni: CO: (Mn + Mg) 7: 1: 2 and Mn: Mg of 0.2-x: x (0.02 ≤ x ≤ 0.04), nickelin salt, cobalt salt, manganese salt, Magnesium salt is thoroughly mixed to prepare mixed salt solutions, spare;

[0025] Among them, the nickel salt is at least one of nickel chloride, nickel sulfate, nitrate nickel nitrate; at least one of cobalt chloride, cobalt sulfate, cobalt nitrate; manganese salt is manganese chloride, manganese sulfate, manganese nitrate At least one of the medium; magnesium salt is magnesium chloride, magnesium sulfate, at least one of magnesium nitrate; nickel, cobalt, manganese and magnesium ions in the mixed salt solution of 1 to 3 mol / L;

[0026] Step 2, in the atmosphere of an inert gas, the mixed salt solution, the base solution, and the ammonia w...

Embodiment 1

[0032] 1) Nickel cobalt manganese precursor Ni for preparing doped lithium-doped ion battery 0.7 CO 0.1 Mn 0.18 Mg 0.02 (OH) 2 ;

[0033] Step 1, according to the ratio of molar ratio: CO: (Mn + mg) 7: 1: 2 and Mn: Mg is 0.18: 0.02 (9: 1), mixed sulfate, sulfate, sulfate, magnesium sulfate , A mixed salt solution of 2 mol / L is made of nickel, cobalt, manganese, and magnesium ions, spares;

[0034] Step 2, in the atmosphere of nitrogen, a mixed salt solution, a concentration of 4 mol / L, a concentration of ammonia water, and an ammonia concentration of 10 mol / L are added to the reactor, respectively, and the pH of the control system during the addition of the process. It was 11 to 12.5, and the coprecipitation reaction was performed at a stirring rate of 55 ° C and 200 rpm;

[0035] Step 3, when the particle size of the precursor particles in the reactor reaches the required size, the reaction is stopped, and the material in the reactor is transferred to the aging tank, then c...

Embodiment 2

[0040] 1) Nickel cobalt manganese precursor Ni for preparing doped lithium-doped ion battery 0.7 CO 0.1 Mn 0.18 Mg 0.02 (OH) 2 ;

[0041] Step 1, according to the ratio of molar ratio: CO: (Mn + mg) 7: 1: 2 and Mn: Mg is 0.18: 0.02 (9: 1), mixed sulfate, sulfate, sulfate, magnesium sulfate , Made into a mixed salt solution having a concentration of nickel, cobalt, manganese, and magnesium ions, a mixed salt solution, spare;

[0042] Step 2, in the atmosphere of an inert gas, the mixed salt solution, the concentration of 3 mol / L, a concentration of 8 mol / L is added to the reaction vessel, respectively, in the process of the process, respectively, the process of the process. The pH is 11 to 12.5, and the coprecipitation reaction is carried out at 40 ° C and a stirring rate of 150 rpm.

[0043] Step 3, when the particle size of the precursor particles in the reactor reaches the required size, the reaction is stopped, and the material in the reactor is transferred to the aging tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com