Preparation and application of laminated structure cobalt and aluminum double hydroxide-reduction and oxidation graphene composite materials

A double hydroxide, lamellar structure technology, applied in the field of composite materials, can solve problems such as instability, and achieve the effects of easy operation, excellent rate performance, and high electrochemical capacitance behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Preparation of graphene oxide GO

[0047] a. Take 92mL of concentrated sulfuric acid and place it in an ice-water bath to lower the temperature to 0-5°C, slowly add 4g of natural graphite and 2g of anhydrous sodium nitrate, and continue stirring for 30 minutes.

[0048] b. Add 13 g of potassium permanganate to the above mixed solution, maintain the ice bath for 1 h, take the device out of the ice bath, stir at room temperature for 3 h, and add 180 mL of water dropwise, and stir for 20 min.

[0049] c. Continue to add 560mL water to the mixed solution, and then add 50mL 30% hydrogen peroxide drop by drop. When the static supernatant is colorless, remove the supernatant, then add 560mL water, adjust the pH to 7 with KOH, and remove the supernatant after standing still for 24 hours liquid, filtered, washed with water and ethanol, and dried under vacuum at 60 °C for 24 h to obtain GO.

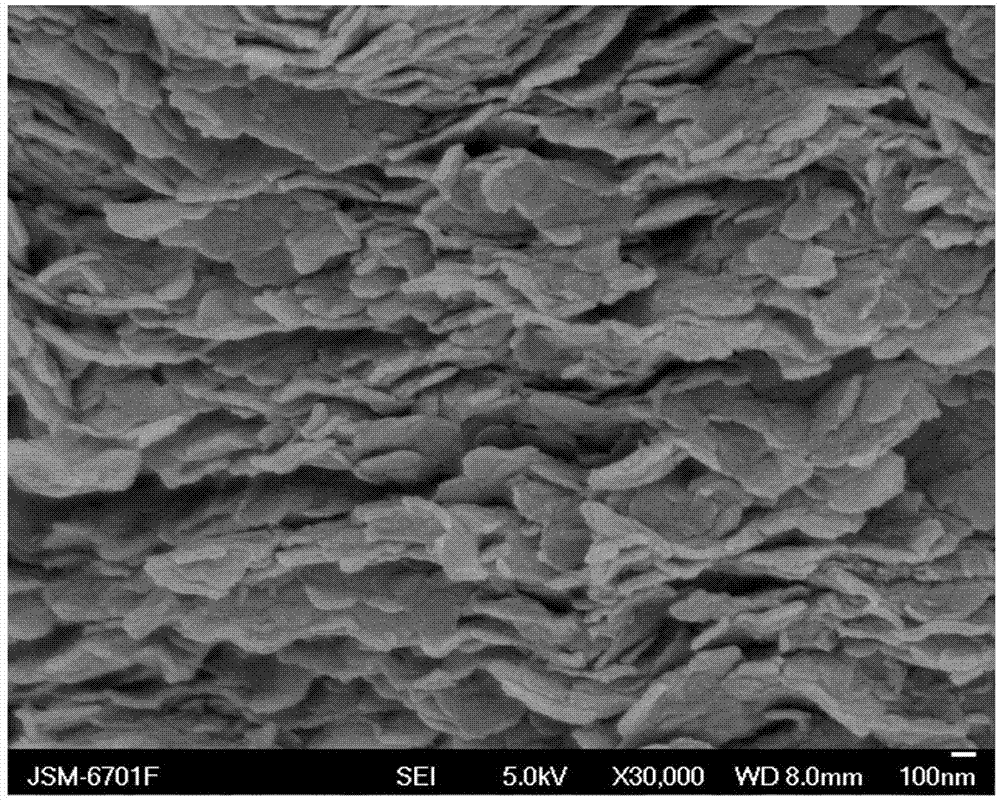

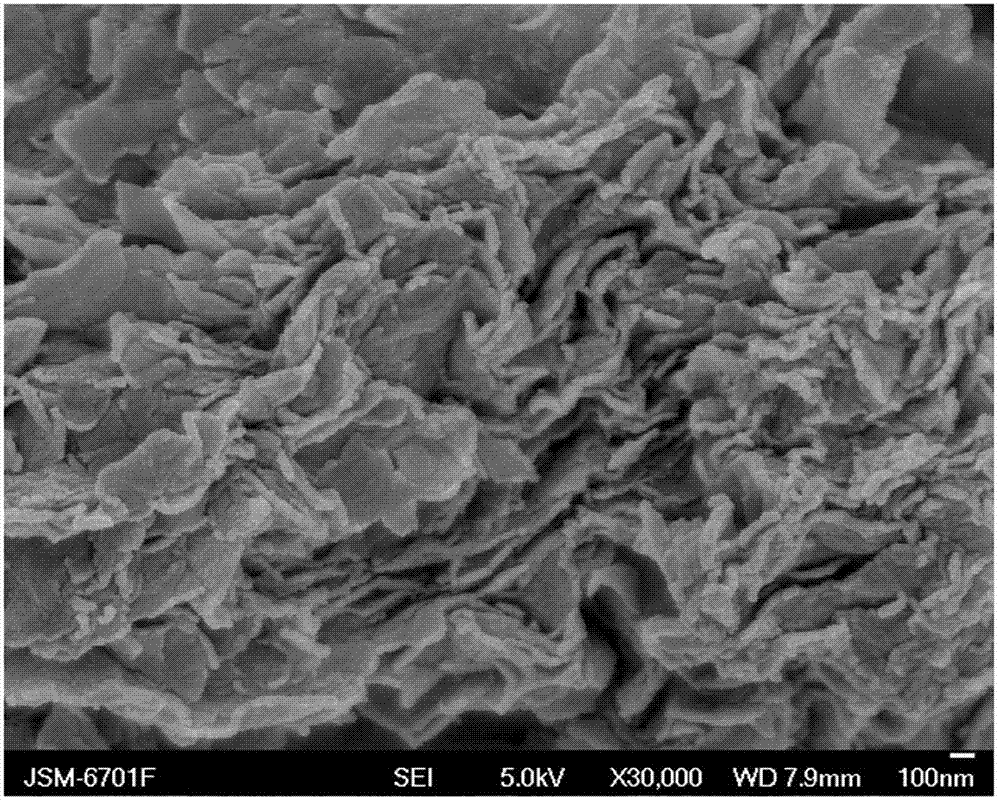

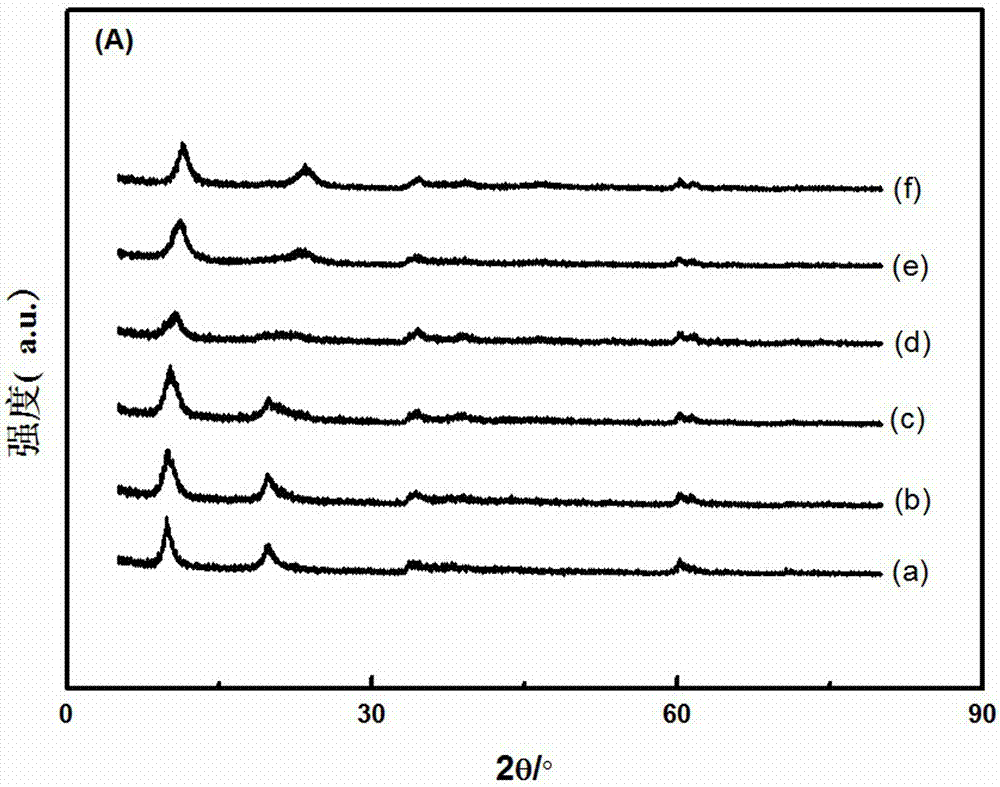

[0050] (2) Preparation of cobalt aluminum double hydroxide-reduced graphene oxide c...

Embodiment 2

[0062] Step (2) In the preparation of the cobalt-aluminum double hydroxide-reduced graphene oxide composite material with a lamellar structure, 30mg of graphene oxide GO was dissolved in 60mL of water, and ultrasonically dispersed for 2 hours to form a bright yellow solution. Others were the same as those in the examples 1 is exactly the same.

[0063] In the composite material, the mass percentages of cobalt aluminum double hydroxide and reduced graphene oxide are 1.47% and 98.53%.

[0064] The specific capacitance of the electrode material is 795F / g, the energy density is 27.6Wh / kg, and the power density is 250W / kg.

Embodiment 3

[0066] Step (2) In the preparation of the cobalt-aluminum double hydroxide-reduced graphene oxide composite material with a sheet structure, 40 mg of graphene oxide GO was dissolved in 80 mL of water, and ultrasonically dispersed for 2 hours to form a bright yellow solution. Others are identical to Example 1.

[0067] In the composite material, the mass percentages of cobalt aluminum double hydroxide and reduced graphene oxide are 1.87% and 98.13%.

[0068] The specific capacitance of the electrode material is 830.4F / g, the energy density is 28.8Wh / kg, and the power density is 250W / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com