Double-layer coated cathode material LiNi0.6Co0.2Mn0.2O2 for lithium-ion battery and preparation method of double-layer coated cathode material

A technology for lithium ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor cycle performance, and achieve the effects of maintaining stability, modifying cycle performance, and improving electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

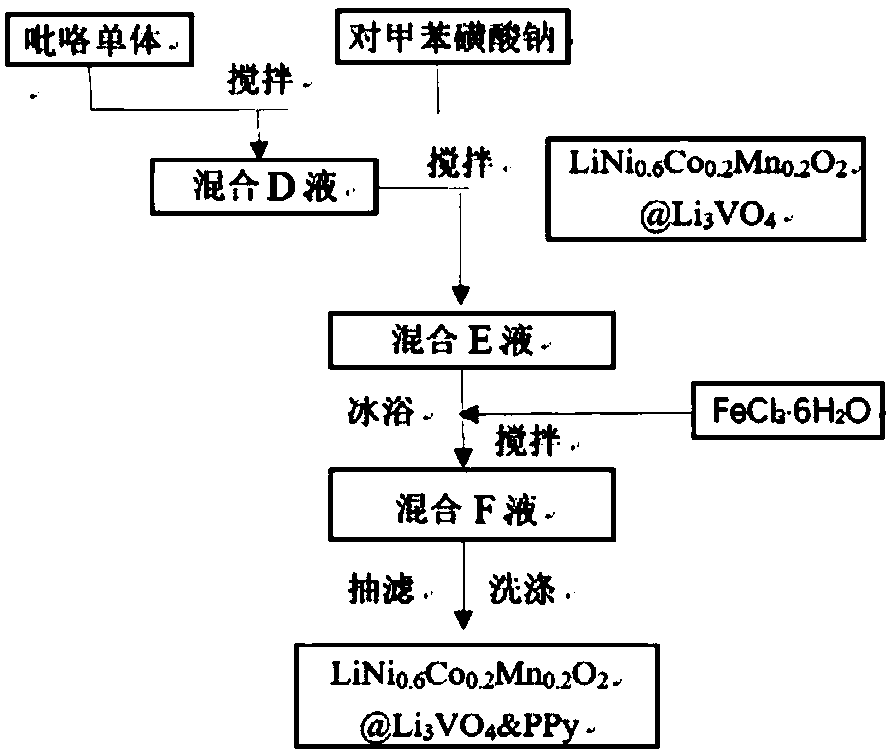

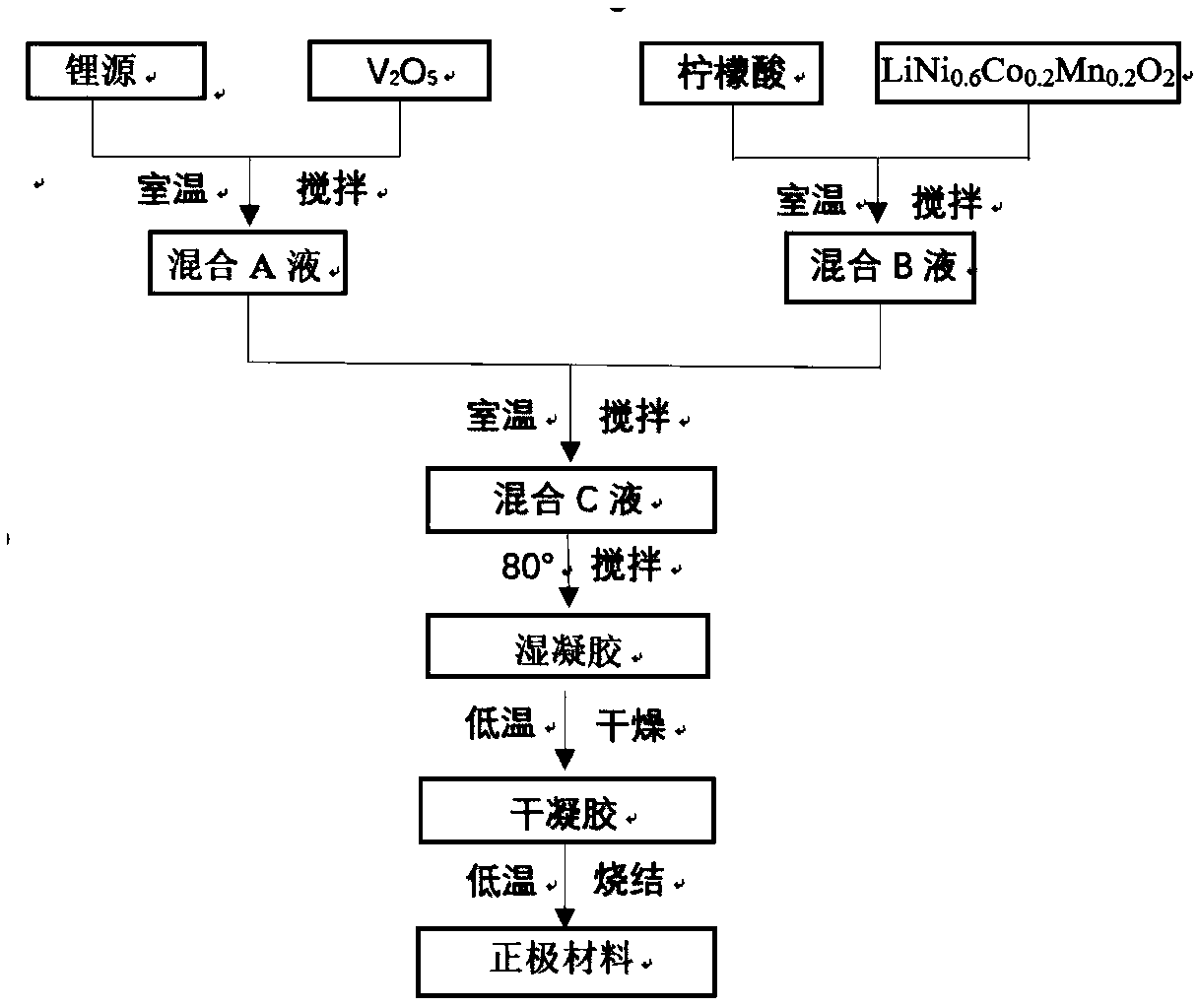

[0039] The present embodiment provides lithium-ion battery cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 @Li 3 VO 4 @PPy, where, Li 3 VO 4 and PPy against the parent material LiNi 0.6 co 0.2 mn 0.2 o 2 Double coating, the coating amount is the parent material LiNi 0.6 co 0.2 mn 0.2 o 2 3wt%; Its preparation process is as follows:

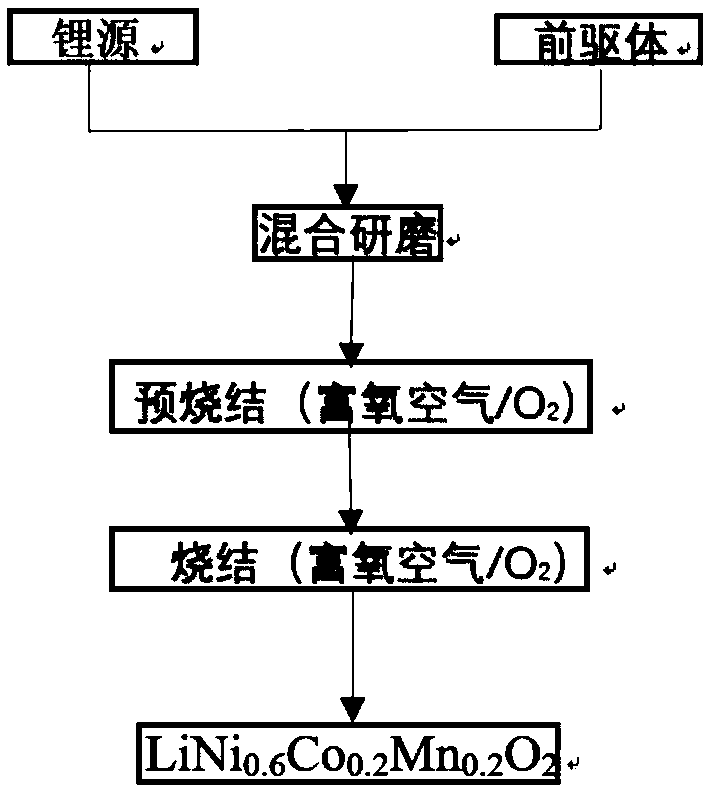

[0040] Weigh 0.42mol of LiOH H 2 O is 17.623g, weigh 36.801g of the precursor and mix, use absolute ethanol as the dispersant, fully grind and mix evenly, then place it in a blast drying oven to completely dry and fully grind, and finally place it in a tube furnace under oxygen Under the atmosphere (oxygen flow rate of 400ml / min), the temperature was raised to 500°C at a speed of 3°C / min and kept for 6 hours, and then the temperature was raised to 820°C at a speed of 2°C / min and held for 15 hours, and the temperature was naturally lowered to 100°C. , namely to get LiNi 0.6 co 0.2 mn 0.2 o 2 Parent cathode material (parent material)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com