Nano-crystalline cellulose reinforced graphene oxide/ polydopamine laminated bionic material and preparation method thereof

A technology of nanocellulose and polydopamine layer, which is applied in the field of layered biomimetic composite materials, can solve the problems of poor tensile strength and toughness, and achieve the effect of improving tensile strength and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

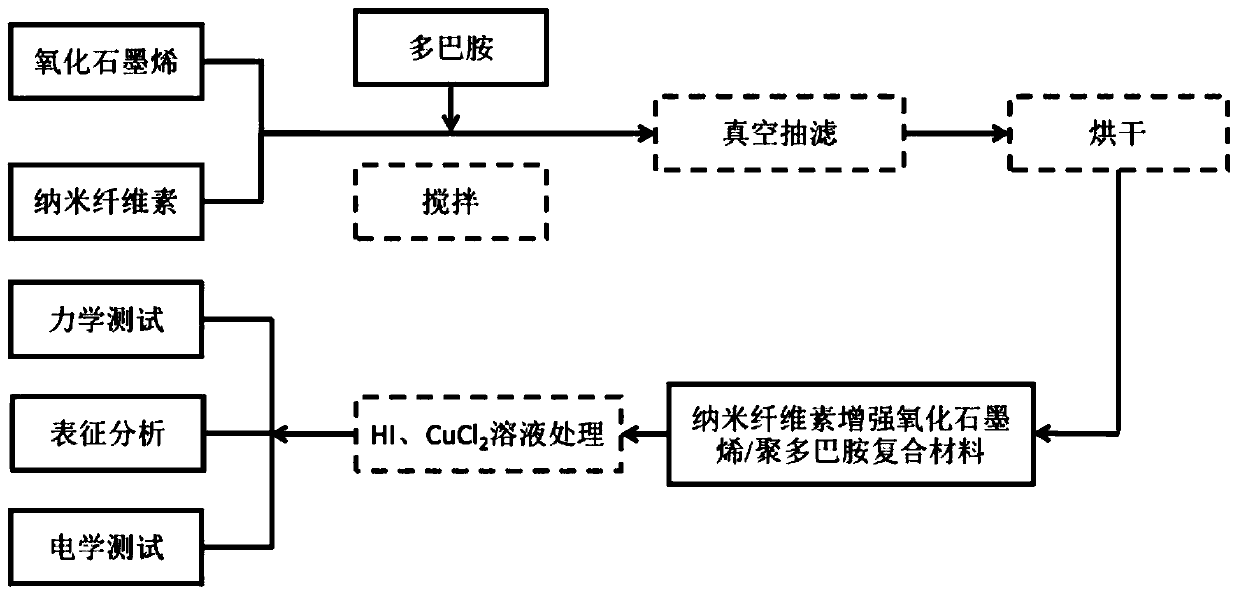

[0046] This embodiment provides a method for preparing nanocellulose-reinforced graphene oxide / polydopamine layered biomimetic material, comprising the following steps:

[0047] Step 1, weighing graphene oxide, nanocellulose and dopamine of certain quality respectively, the quality of described dopamine is 5wt% of above-mentioned three kinds of raw materials total mass;

[0048] Step 2. Dissolve graphene oxide and nanocellulose in deionized water respectively, mix the obtained graphene oxide solution and nanocellulose solution evenly, add Tris buffer solution to adjust the pH value of the obtained solution to 8.5, add dopamine and stir for a certain time time to obtain a mixed solution;

[0049] Step 3: vacuum filter the mixed solution obtained in step 2 to form a film, and dry the obtained film at a certain temperature for a certain period of time to obtain a nanocellulose-reinforced graphene oxide / polydopamine layered biomimetic material.

Embodiment 2

[0051] This embodiment provides a method for preparing nanocellulose-reinforced graphene oxide / polydopamine layered biomimetic material, comprising the following steps:

[0052] Step 1, weigh graphene oxide, nanocellulose and dopamine of certain quality respectively, the quality of described dopamine is 5wt% of above-mentioned three kinds of raw materials total mass, the quality of described nano-cellulose is above-mentioned three kinds of raw materials total mass 4.5-20 wt%; the nanocellulose used in this embodiment has a diameter of 20-50 nm.

[0053] Step 2. Dissolve graphene oxide and nanocellulose in deionized water respectively, mix the obtained graphene oxide solution and nanocellulose solution evenly, add Tris buffer solution to adjust the pH value of the obtained solution to 8.5, add dopamine and stir for a certain time time to obtain a mixed solution;

[0054] Step 3: vacuum filter the mixed solution obtained in step 2 to form a film, and dry the obtained film at a ...

Embodiment 3

[0057] This embodiment provides a method for preparing nanocellulose-reinforced graphene oxide / polydopamine layered biomimetic material, comprising the following steps:

[0058] Step 1, weigh graphene oxide, nanocellulose and dopamine of certain quality respectively, the quality of described dopamine is 5wt% of above-mentioned three kinds of raw materials total mass, the quality of described nano-cellulose is above-mentioned three kinds of raw materials total mass 4.5-20 wt%; the nanocellulose used in this embodiment has a diameter of 20-50 nm.

[0059] The preparation method of graphene oxide in this example is to measure 46ml of concentrated sulfuric acid, add 2g of graphite powder and 1g of sodium nitrate respectively, then slowly add 6g of potassium permanganate, control the solution temperature at 0-10°C, and stir for 80-100min. Heat the solution to 30-40°C, stir for 20-40min, add 220ml deionized water dropwise to the solution, control the solution temperature at 90-100°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com