Lithium ion battery cathode material and preparation method thereof as well as lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of poor cycle performance, insufficient cycle performance of silicon-carbon composite materials, and poor contact between nano-silicon and carbon nanotubes Close and other problems, to achieve the effect of improving conductivity, good cycle performance, and close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a kind of preparation method of lithium ion battery negative electrode material, comprises the following steps:

[0035] a) performing amination treatment on graphene oxide to obtain aminated graphene oxide;

[0036] b) mixing the aminated graphene oxide obtained in step a) with nano-silicon particles, gelatin and a crosslinking agent in water, and reacting the obtained mixed solution to obtain an intermediate product;

[0037] c) subjecting the intermediate product obtained in step b) to a hydrothermal reaction to obtain a hydrothermal reaction product;

[0038] d) calcining the hydrothermal reaction product obtained in the step c) in an inert atmosphere to obtain a lithium ion battery negative electrode material.

[0039] In the present invention, firstly, the graphene oxide is aminated to obtain the aminated graphene oxide. The present invention does not have special limitation to the source of described graphene oxide, adopts the technical s...

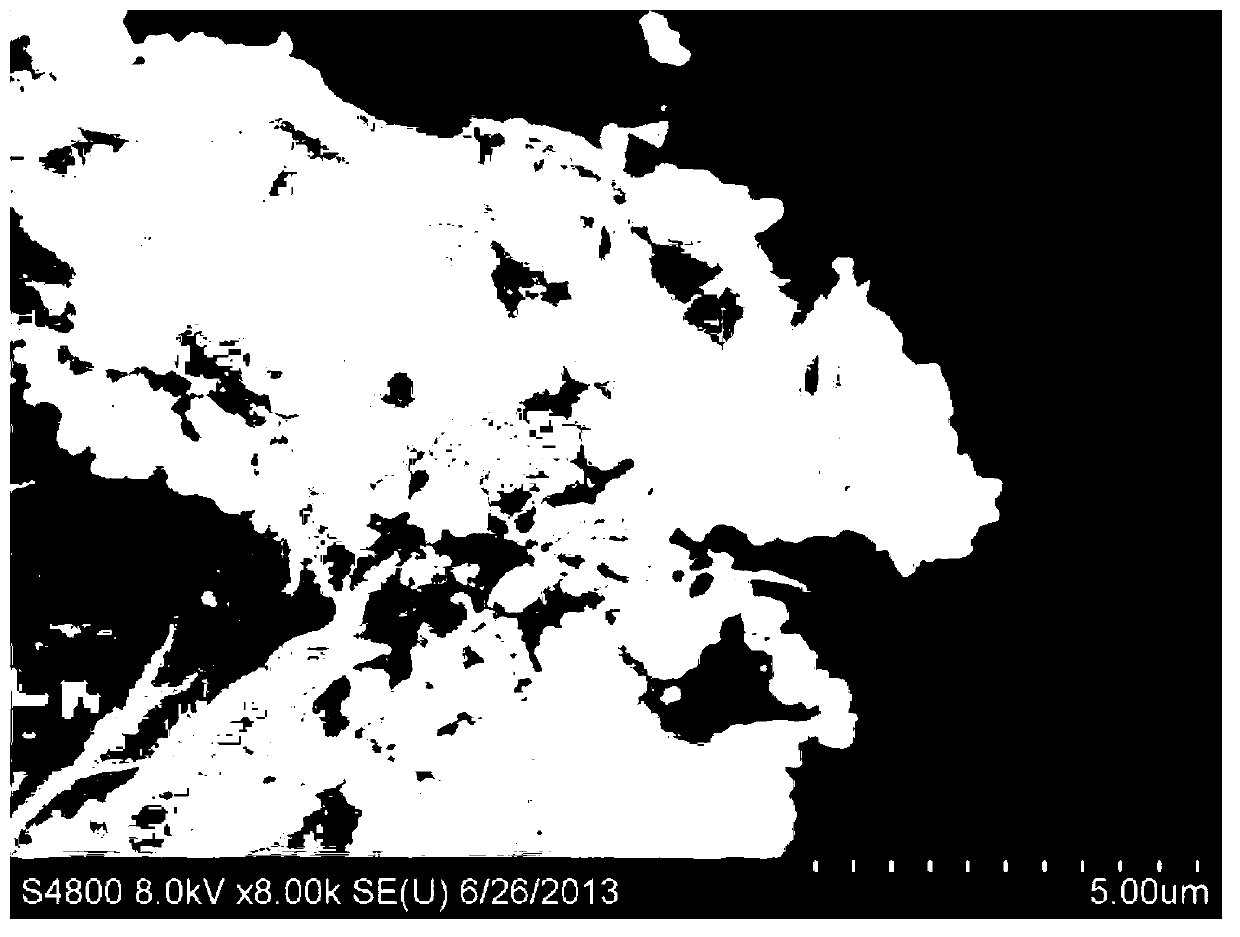

Embodiment 1

[0056] Graphene oxide was prepared by the Hummers Brodie method;

[0057] 200mg of graphite oxide was added to 200mL of dimethylformamide, ultrasonically treated for 2.5h to obtain a graphene oxide suspension, then 30g of triethylenetetramine and 5g of dicyclohexylcarbimide were added thereto, and the resulting mixed solution was After ultrasonication for 5 minutes, react at 120°C for 48 hours, then add 60 mL of absolute ethanol to it, and let it stand overnight; remove the upper clear layer, filter the lower precipitate with a polytetrafluoroethylene membrane, wash with ethanol and deionized water, and remove the obtained solid in Dry at 70°C to obtain triethylenetetramine-modified graphene oxide;

[0058] Mix 250g of triethylenetetramine-modified graphene aqueous solution with a mass concentration of 0.1%, 5g of nano-silicon particles with a particle size of about 10nm, 2.5g of gelatin and 0.5g of formaldehyde, and react at 40°C for 12h to obtain an intermediate product;

...

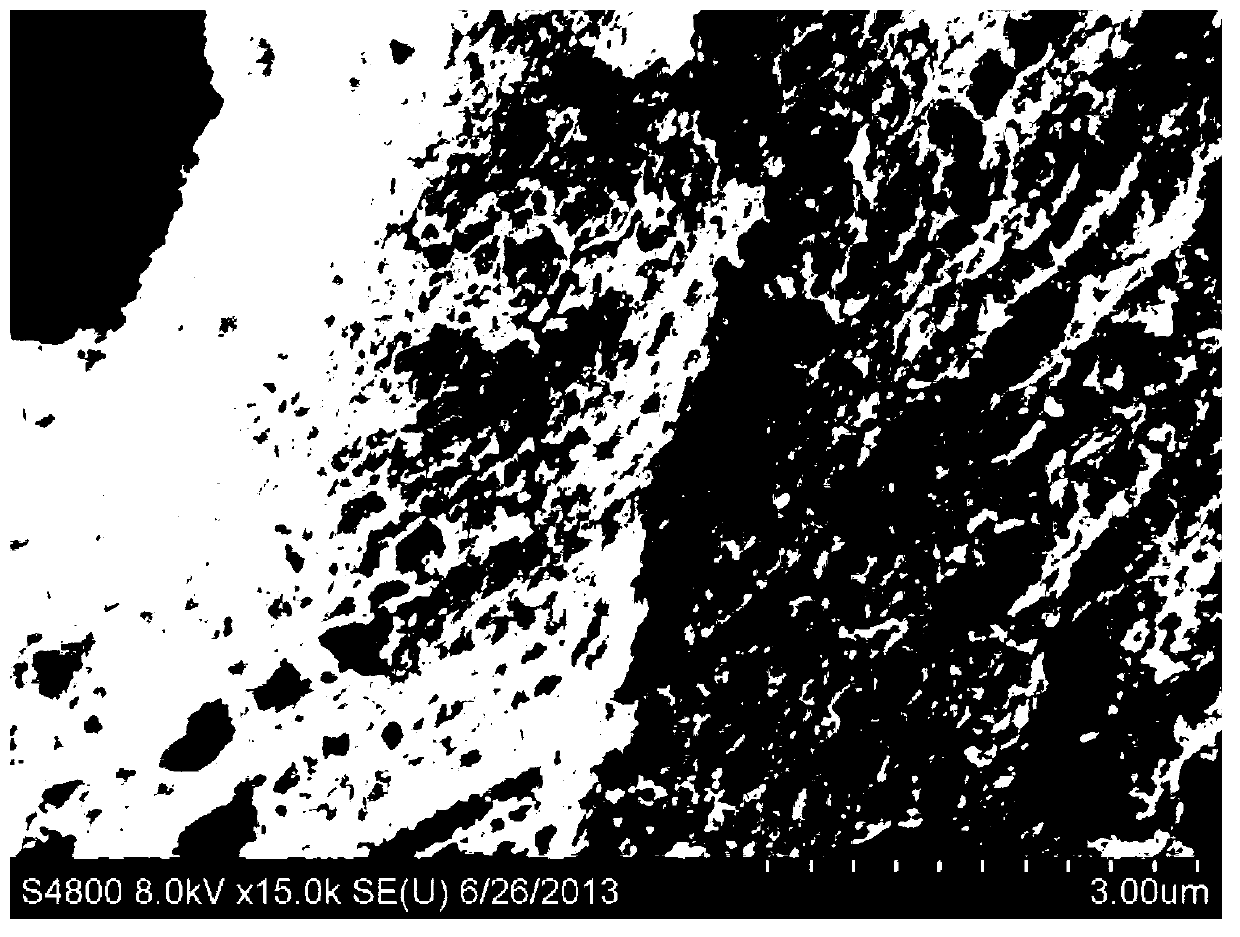

Embodiment 2

[0066]Graphene oxide was prepared by the Standenmaier method;

[0067] Add 200mg of graphite oxide to 200mL of dimethylformamide, sonicate for 2.5h to obtain a graphene oxide suspension, then add 30g of ethylenediamine and 5g of dicyclohexylcarbimide to it, and ultrasonicate the resulting mixed solution After 5 minutes, react at 120°C for 48 hours, then add 60 mL of absolute ethanol to it, and let it stand overnight; remove the upper clear layer, filter the lower precipitate with a polytetrafluoroethylene membrane, wash with ethanol and deionized water, and remove the obtained solid at 70 Drying at ℃ to obtain ethylenediamine-modified graphene oxide;

[0068] Mix 100g of an aqueous solution of ethylenediamine-modified graphene oxide with a mass concentration of 2.5%, 10g of nano-silicon particles with a particle size of about 400nm, 5g of gelatin and 5g of acetaldehyde, and react at 50°C for 10h to obtain an intermediate product;

[0069] The intermediate product was hydrothe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com