Sodium ion battery negative electrode material and preparation method thereof

A sodium ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problems of poor conductivity, large volume expansion, cycle stability and rate of molybdenum disulfide materials Poor performance and other problems, to achieve the effect of improving cycle rate performance, low cost, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

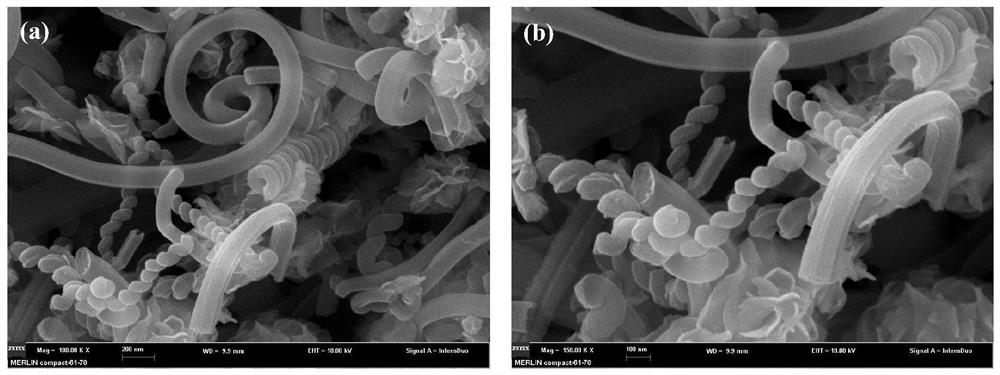

[0034] (1) Put 0.1g of copper tartrate in a quartz boat, pave it evenly, then place it in a tube furnace, feed nitrogen, raise the temperature to 280°C under the protection of nitrogen, then stop feeding nitrogen, and feed acetylene gas, and keep it warm for 1 h, then stop feeding acetylene gas, feed nitrogen gas, cool to room temperature under the protection of nitrogen gas, take out the sample, and obtain helical carbon nanofibers.

[0035] (2) Place the helical carbon nanofibers obtained in step (1) in a tube furnace, and raise the temperature to 700°C under the protection of nitrogen, and then keep warm for 2 hours to obtain carbonized helical carbon nanofibers, namely N-CNF.

[0036] (3) Acidify the carbonized helical nanocarbon fiber obtained in step (2) with concentrated nitric acid (the concentrated nitric acid completely submerges the carbonized helical nanocarbon fiber). After acidifying for 2 hours, filter it with a sand core funnel and wash it repeatedly with distil...

Embodiment 2

[0040] Accurately weigh 1g of CNF, 2g of ammonium molybdate and 10g of thiourea obtained in step (3) of Example 1, add them into a beaker in turn, stir for 1h, then place in a reaction kettle, heat to 280°C and keep for 18h. After cooling, use a centrifuge to centrifuge 6 times until the solution is neutral, then dry it in a freeze dryer, and finally place it in a tube furnace, raise the temperature to 500°C under the protection of nitrogen, and keep it warm for 3 hours to obtain the negative electrode of the sodium ion battery Material, denoted as 1:2-CNF / MoS 2 .

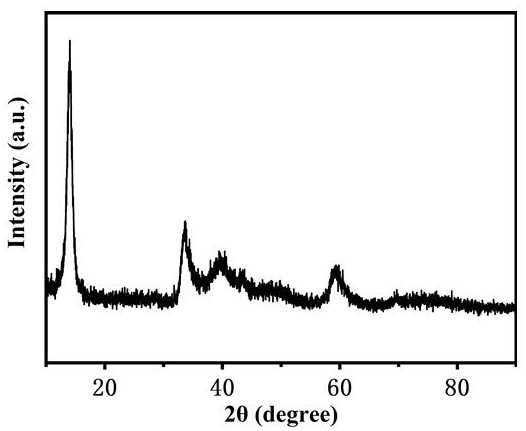

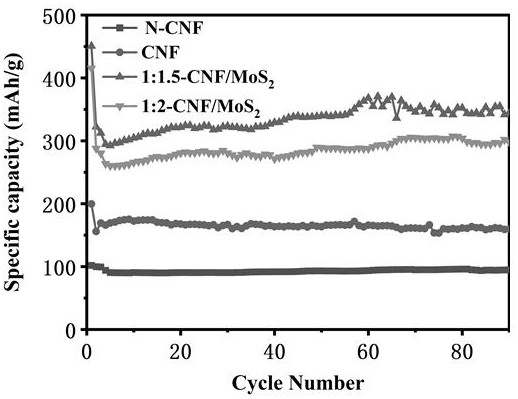

[0041] N-CNF, CNF, 1:1.5-CNF / MoS 2 、1:2-CNF / MoS 2 The cycle performance graph at 100mA / g current density is as follows image 3 shown by image 3 It can be seen that the specific capacity of the helical carbon fiber can be significantly improved by acidification treatment, and the grafted MoS 2 , electrode materials with high specific capacity and high cycle stability can be obtained. 1:1.5-CNF / MoS 2 It has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com