Advanced porous polymer nanosheet, preparation method and application thereof

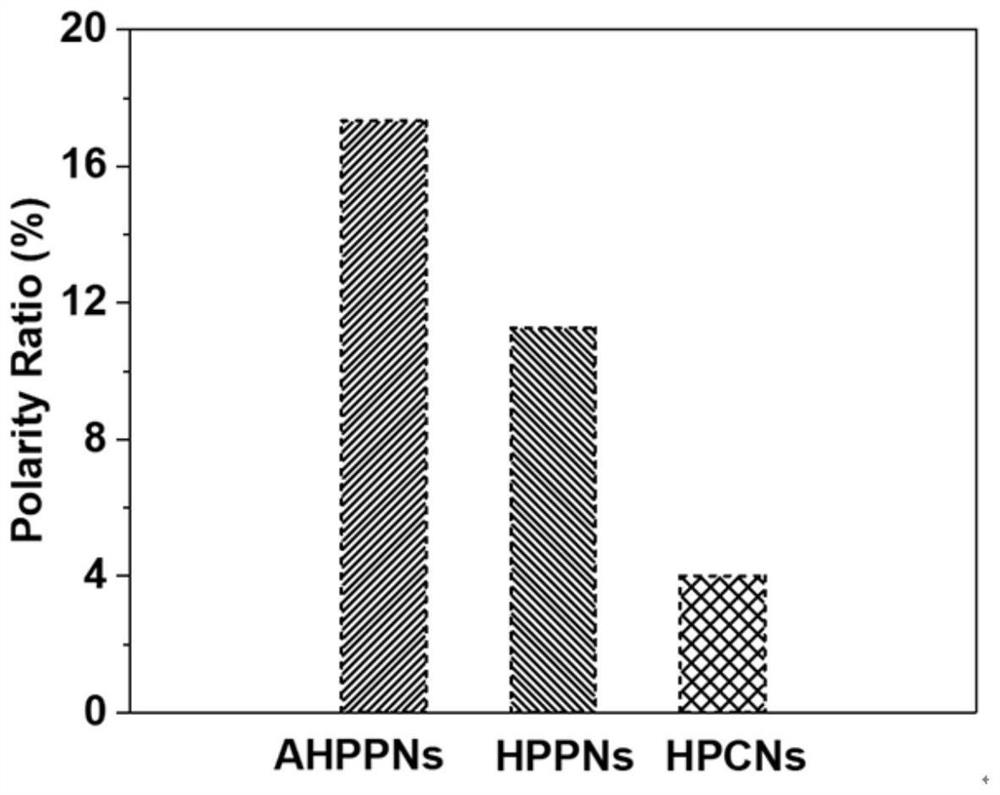

A polymer and nanosheet technology, applied in the field of preparation of porous polymer nanosheets, can solve the problems of weak polarity of porous polymer functional groups, poor rate performance of lithium-sulfur batteries, and low sulfur content of positive electrode materials, etc. Achieve the effect of promoting fast transfer, inhibiting diffusion and loss, and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

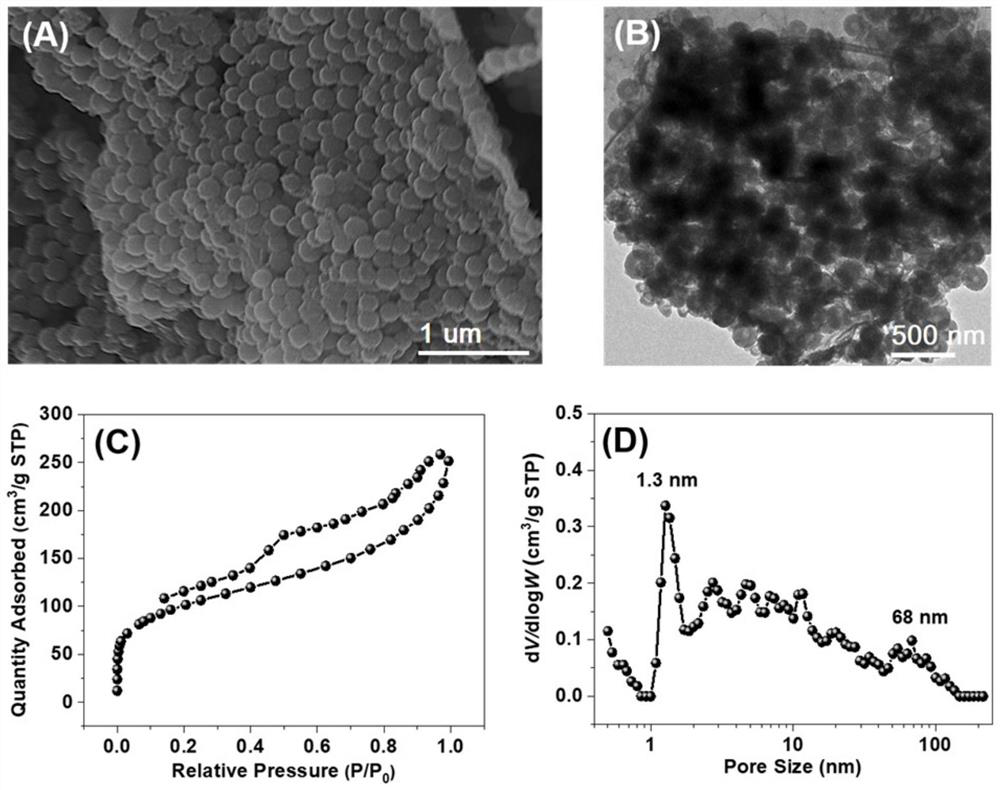

[0043] Fabrication of lithium-sulfur batteries based on advanced porous polymer nanosheets (AHPPNs):

[0044] (1) Add 1.25 mL of hydrazine hydrate to 350 mg of graphene oxide aqueous dispersion and heat for reduction at 80° C. for 4 h. Then, 1.5g of 2-(4aminophenyl)ethanol and 1.25mL of isoamyl nitrite were added to the mixture, heated at 80°C for 12h, suction filtered, washed and dried to obtain hydroxyl-modified graphene. Disperse 0.5g of hydroxyl-modified graphene into 10mL of tetrahydrofuran, under the protection of ice-water bath and inert gas, add 0.9mL of triethanolamine, then slowly add 0.43g of 2-bromo-isobutyryl bromide, and stir at room temperature After reacting for 24 hours, post-treatment to obtain graphene (G-Br) containing bromine functional groups.

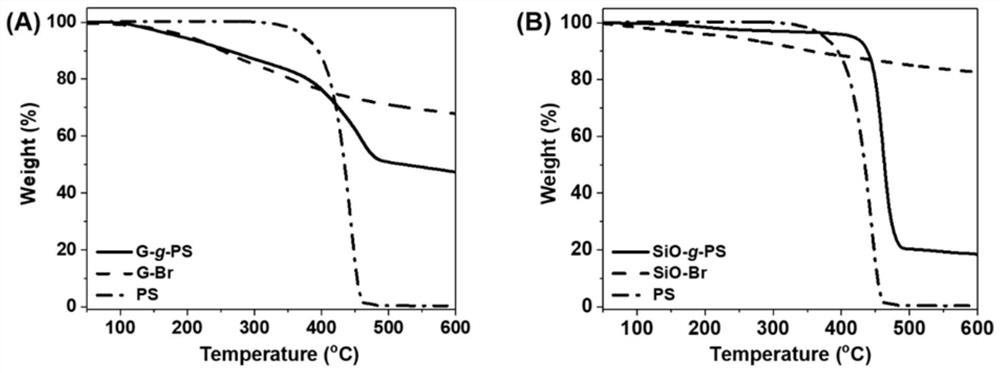

[0045] (2) Disperse 0.2 g of graphene containing bromine functional groups obtained in step (1) in 20 mL of styrene monomer and 10 mL of N, N-dimethylformamide, and add 0.084 mL of N, N ,N',N',N"-pentamethyldiet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com