Porous silicon/titanium dioxide/graphene composite material as well as preparation method and application thereof

A technology of titanium dioxide and composite materials, applied in the direction of titanium dioxide, titanium oxide/hydroxide, graphene, etc., can solve the problems of SEI cracking, high catalyst cost, particle pulverization, etc., to ensure stability, ensure structural stability and Integrity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

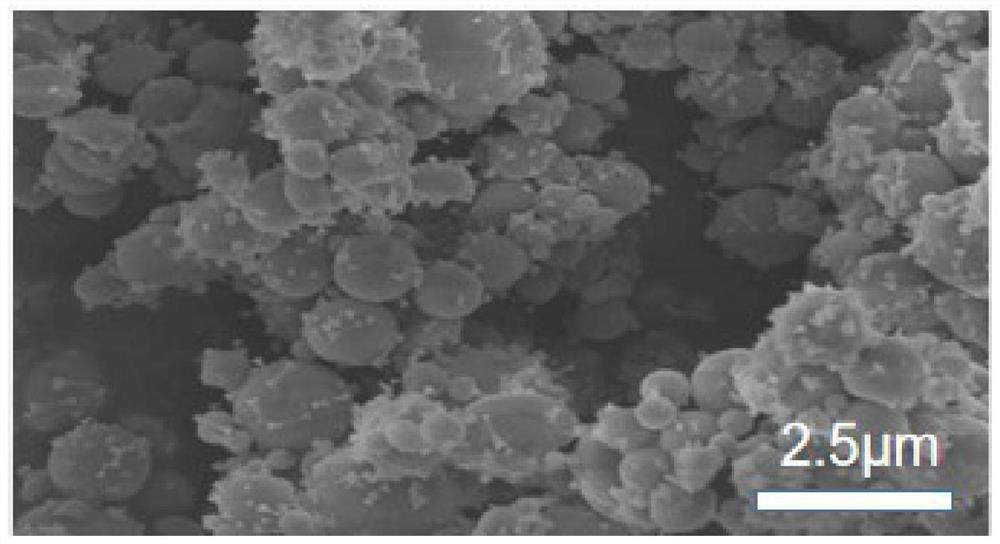

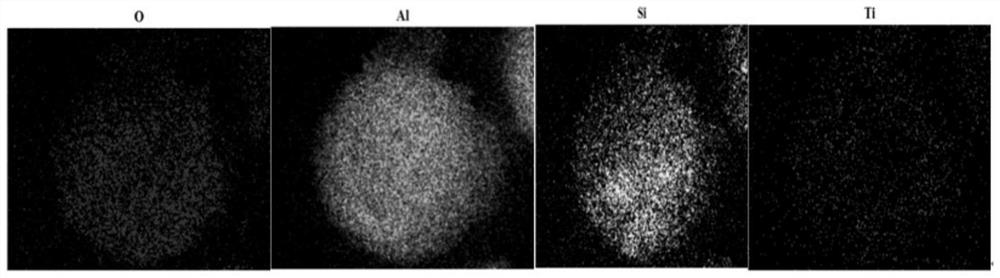

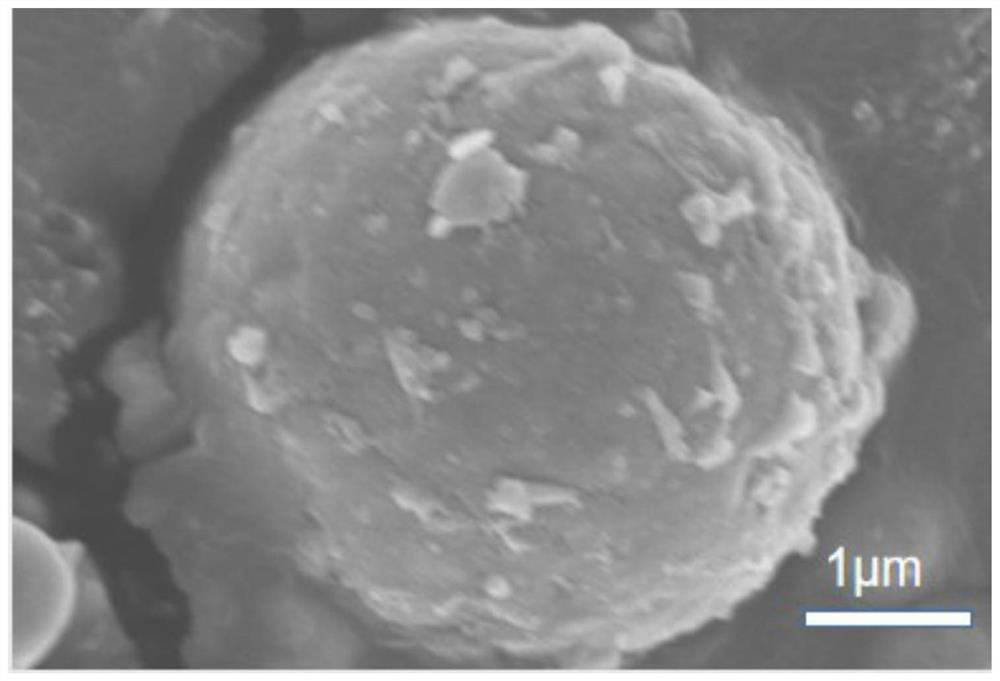

[0059] 1. Weigh 240ml of absolute ethanol and pour it into a flask with a stirring bar, weigh 1g of aluminum-silicon alloy (particle size 1-2μm), pour it into it, and stir magnetically at medium and low speed (500 rpm) for 10 minutes. Then put it into a constant temperature magnetic stirrer for heating and stirring in a water bath (adjust the temperature to 45°C, adjust the stirring speed to a medium and low speed of 500 rpm), measure 0.8ml of ammonia water (mass fraction 28%, density 0.9g / cm 3 ) was slowly added dropwise into the flask with a pipette gun, and then 0.416ml of tetrabutyl titanate was slowly added dropwise into the flask with a pipette gun, and stirred for 16 hours.

[0060] 2. Take it out again and evaporate most of the solution with a rotary evaporator, wash with deionized water, centrifuge (centrifugal speed is 6500-8000 rpm), and then vacuum-dry at 80°C for 12 hours. After that, Grind it with an agate mortar, put it into a high-temperature tube furnace and s...

Embodiment 2

[0068] 1. Weigh 240ml of absolute ethanol and pour it into a flask with a stirring bar, weigh 1g of aluminum-silicon alloy (particle size 1-2μm), pour it into it, and stir it with a medium-low speed (500 rpm) for ten Minutes, then put it into a constant temperature magnetic stirrer and heat and stir in a water bath (adjust the temperature to 45°C, adjust the stirring speed to medium and low speed (500 rpm)), measure 0.8ml of ammonia water and slowly add it dropwise to the flask with a pipette, and then measure Take 0.832ml of butyl titanate and slowly drop it into the flask with a pipette gun, and stir the reaction for 16h.

[0069] 2. Take it out and evaporate most of the solution with a rotary evaporator, then wash it with deionized water, centrifuge (the speed can be 6500-8000 rpm), and then carry out vacuum drying. The drying temperature is 80 ° C, and the drying time is 12 hours. After that, Grinding with an agate mortar, then sintering in a high-temperature tube furnace ...

Embodiment 3

[0074] 1. Weigh 240ml of absolute ethanol and pour it into a flask with a stirring bar, weigh 1g of aluminum-silicon alloy (1-2μm), pour it into it, and stir magnetically at medium and low speed (500 rpm) for ten minutes, then Put it into a constant temperature magnetic stirrer, heat and stir in a water bath (adjust the temperature to 45°C, adjust the stirring speed to medium-low speed (500 rpm)), measure 0.8ml of ammonia water and slowly drop it into the flask with a pipette gun, and then measure 0.208ml The butyl titanate was slowly added dropwise into the flask with a pipette gun, and the reaction was stirred for 16h.

[0075]2. Take it out and evaporate most of the solution with a rotary evaporator, then wash it with deionized water, centrifuge (the speed can be 6500-8000 rpm), and then carry out vacuum drying. The drying temperature is 80 ° C, and the drying time is 12 hours. After that, Grind it with an agate mortar, put it into a high-temperature tube furnace and sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com