Method for preparing composite sodium negative electrode for sodium-ion battery

A technology of sodium ion battery and sodium compound, which is applied in electrode manufacturing, battery electrodes, secondary batteries, etc., to achieve the effects of inhibiting the growth of sodium dendrites, stabilizing the volume change of electrodes, and controlling the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of composite sodium negative electrode by hot melt infusion method using carbon felt as carrier material

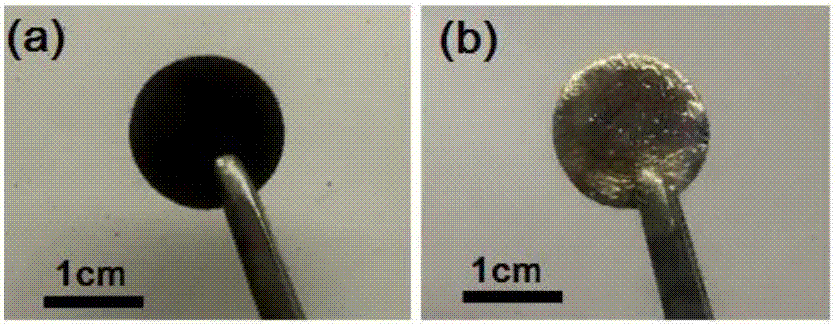

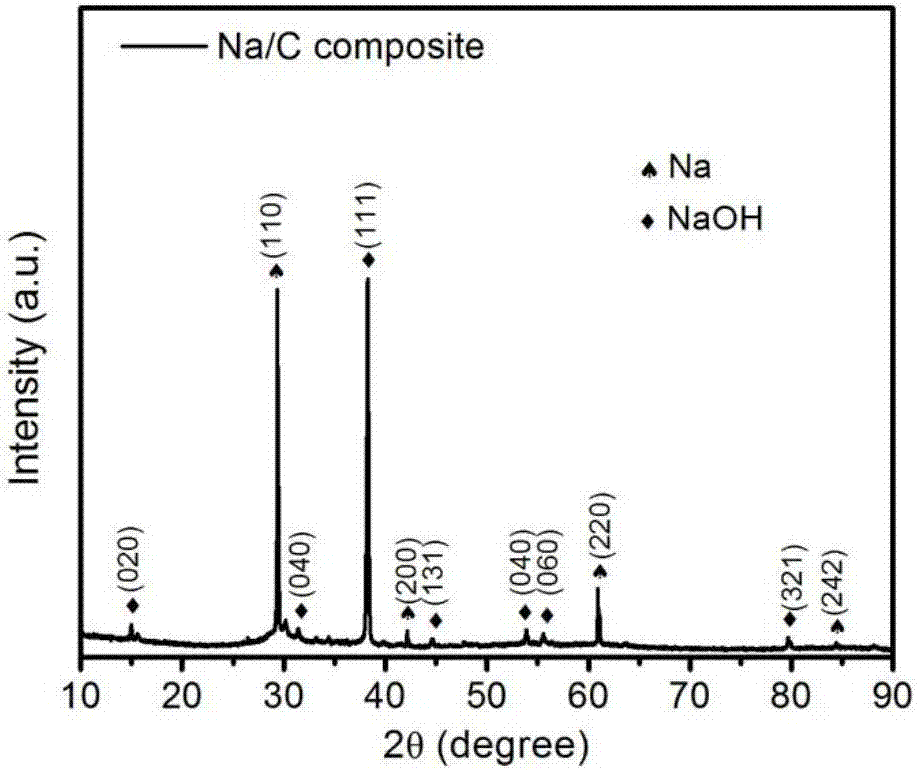

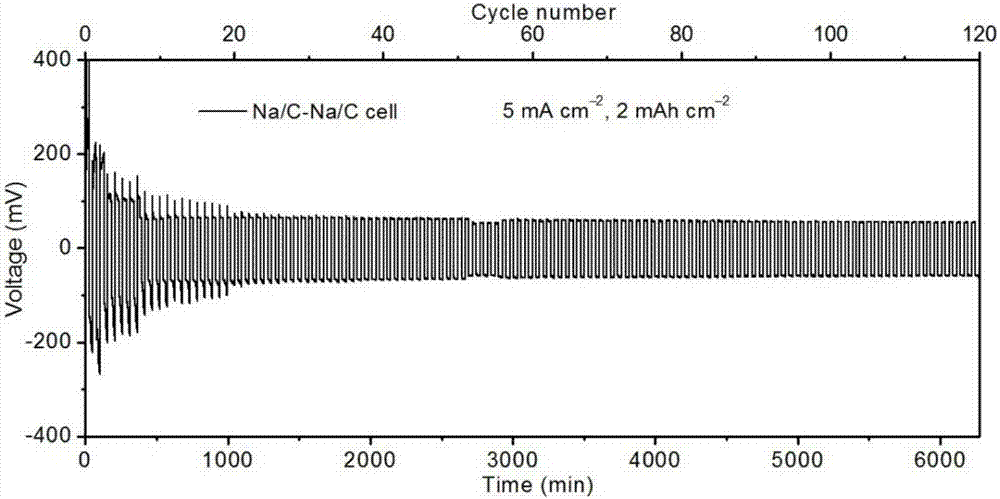

[0026] The method of preparing the composite sodium negative electrode with carbon felt as the carrier material is as follows: punching the carbon felt of the size of the electrode sheet, setting the temperature of the hot-melt sodium sheet to 300°C, completely melting the sodium block into a sodium metal liquid, and then dissolving the prepared carbon Put the felt electrode sheet into the metal sodium liquid until it is completely soaked, and finally take it out and cool it naturally to form a composite sodium negative electrode. in, figure 1 The photo shown in a is the prepared carbon felt electrode sheet, figure 1 The photo shown in b is the final composite sodium negative electrode prepared, figure 2 It is the XRD pattern of the composite sodium negative electrode. This composite negative electrode was assembled into a sodium-ion symm...

Embodiment 2

[0027] Example 2: Preparation of composite sodium negative electrode by hot melt infusion method using carbon cloth as carrier material

[0028] The method of preparing a composite sodium negative electrode with carbon cloth as a carrier is mainly divided into: punching carbon cloth with the size of an electrode sheet, setting the temperature of the hot-melt sodium sheet to 500°C, completely melting the sodium sheet into a sodium metal liquid, and then dissolving the prepared Put the carbon cloth into the metal sodium liquid until it is completely soaked, and finally take it out and let it cool naturally to form a composite sodium negative electrode. The composite negative electrode was assembled into a sodium-ion symmetric battery. Electrochemical tests showed that at a certain current density, a stable voltage plateau was maintained after many cycles, and it had the effect of inhibiting the growth of sodium dendrites and stabilizing the volume change of the electrode.

Embodiment 3

[0029] Example 3: Preparation of composite sodium negative electrode by hot melt infusion method using carbon paper as carrier material

[0030] The method of preparing composite sodium negative electrode with carbon paper as the carrier is mainly divided into: punching carbon paper with the size of the electrode sheet, setting the temperature of the hot-melt sodium sheet to 250°C, completely melting the sodium sheet into a sodium metal liquid, and then dissolving the prepared Put the carbon paper electrode sheet into the metal sodium liquid until it is completely soaked, and finally take it out and let it cool naturally to form a sodium metal electrode. The composite negative electrode was assembled into a sodium-ion symmetric battery. Electrochemical tests showed that at a certain current density, a stable voltage plateau was maintained after many cycles, and it had the effect of inhibiting the growth of sodium dendrites and stabilizing the volume change of the electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com