Preparation method of ultrahigh-rate potassium ion battery bismuth-based composite negative electrode material

A negative electrode material, potassium ion technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult control of material morphology, affecting the performance of potassium ion batteries, and low utilization of active materials, so as to increase the magnification and cycle stability, novel and stable structure, and stable electrode material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of an ultra-high rate spindle-shaped carbon-coated bismuth-based potassium ion battery anode material:

[0053] (1) Add 1.94g of bismuth nitrate pentahydrate into 40mL of ethylene glycol, stir for 0.5h to disperse uniformly to obtain a bismuth source solution; add 0.47g of ammonium metavanadate to 20mL of deionized water, stir for 0.5h to disperse uniformly to obtain ammonium metavanadate solution.

[0054] (2) Under stirring, slowly drop the ammonium metavanadate solution into the bismuth source solution, and stir for 0.5 h to obtain a yellow uniform solution.

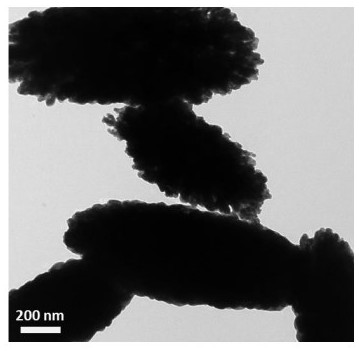

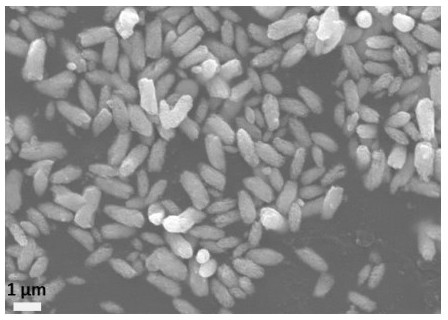

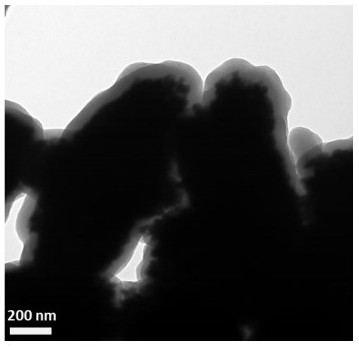

[0055] (3) The yellow homogeneous solution was placed in a 100 mL hydrothermal reaction kettle, and the hydrothermal reaction was carried out at 180 °C for 24 h, and then filtered and dried to obtain BiVO 4 Precursor (bismuth vanadate precursor with spindle morphology and hierarchical structure), TEM images and SEM images are shown in figure 1 and figure 2 , see the X-ray diffraction pa...

Embodiment 2

[0062] Same as Example 1, the difference lies in that step (1) is as follows: add 1.94 g of bismuth nitrate pentahydrate to 40 mL of ethylene glycol, stir for 0.5 h to disperse evenly to obtain a bismuth source solution; add 0.47 g of ammonium metavanadate to 40 mL of deionized In water, stir for 0.5h to disperse uniformly to obtain ammonium metavanadate solution.

Embodiment 3

[0064] Same as Example 1, the difference is that step (1) is as follows: add 1.94 g of bismuth nitrate pentahydrate to 20 mL of ethylene glycol, stir for 0.5 h to disperse evenly to obtain a bismuth source solution; add 0.47 g of ammonium metavanadate to 40 mL of deionized In water, stir for 0.5h to disperse uniformly to obtain ammonium metavanadate solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com