A kind of silicon-based composite negative electrode material for lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve problems such as capacity decay, loss of cycle ability, and structural pulverization, and increase distribution density , Low volume expansion effect, avoid entanglement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In the second aspect, the embodiment of the present invention also provides a method for preparing a silicon-based composite negative electrode material for a lithium-ion battery, comprising the following steps:

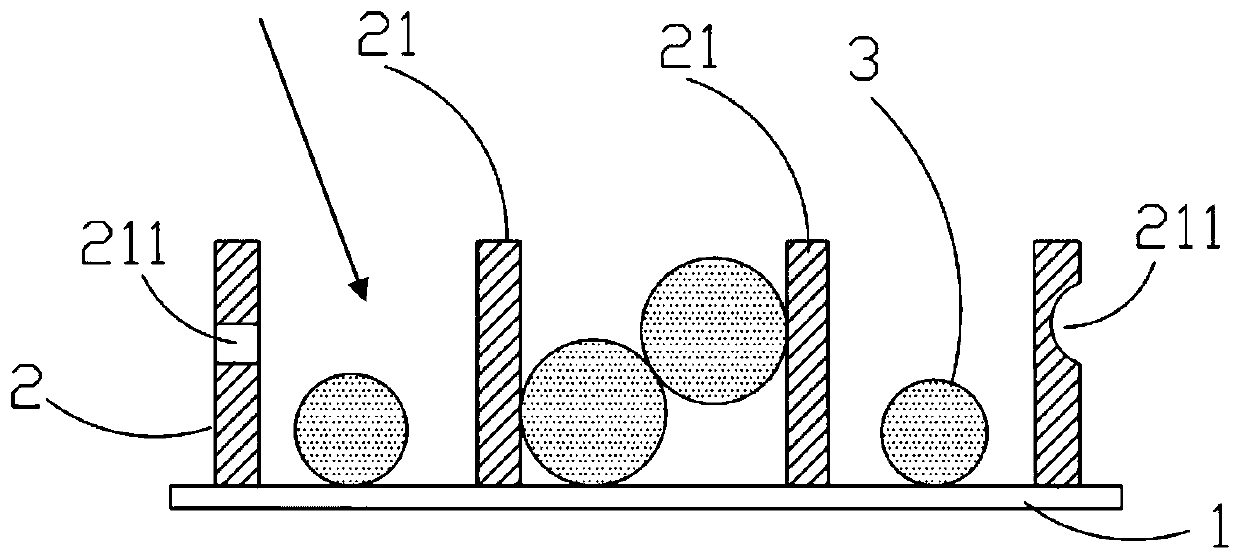

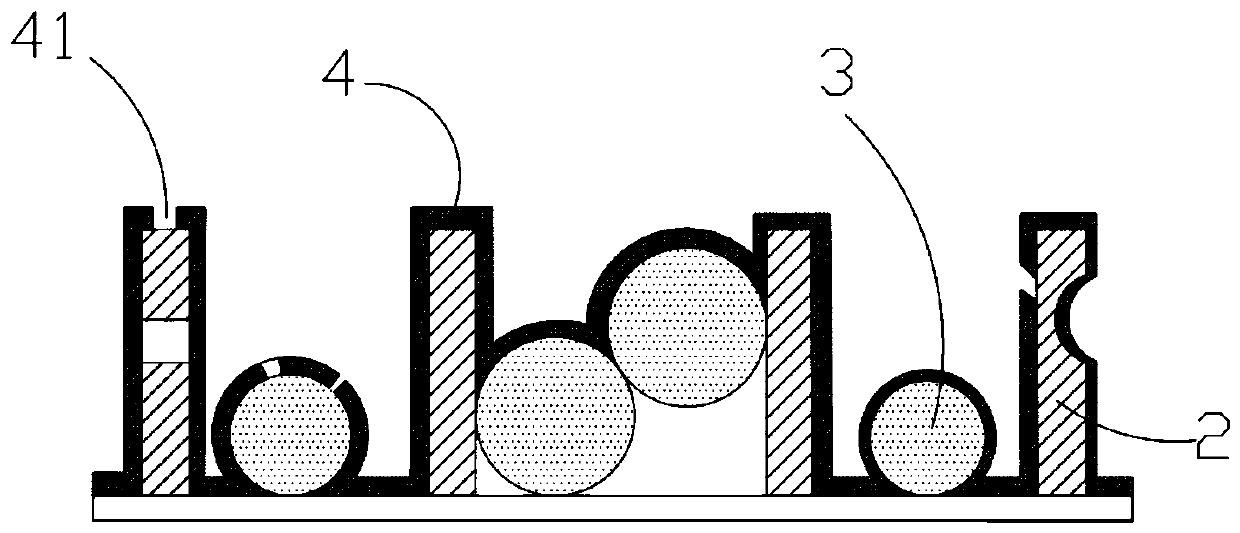

[0052] (1) forming a nano-silicon material array on the substrate; wherein, in the nano-silicon material array, the structure of the nano-silicon material is a nanowire, nanorod or nanotube;

[0053] (2) providing silicon nanospheres and / or silicon oxide nanospheres;

[0054] (3) placing the silicon nanospheres and / or silicon oxide nanospheres on the substrate formed with the nano-silicon material array, so that the silicon nanospheres and / or silicon oxide nanospheres are located on the nanometer Between the gaps of the silicon material, the silicon-based composite negative electrode material for the lithium-ion battery is obtained.

[0055] In one embodiment of the present invention, when the nano-silicon material array is a silicon nanowire array, it is pro...

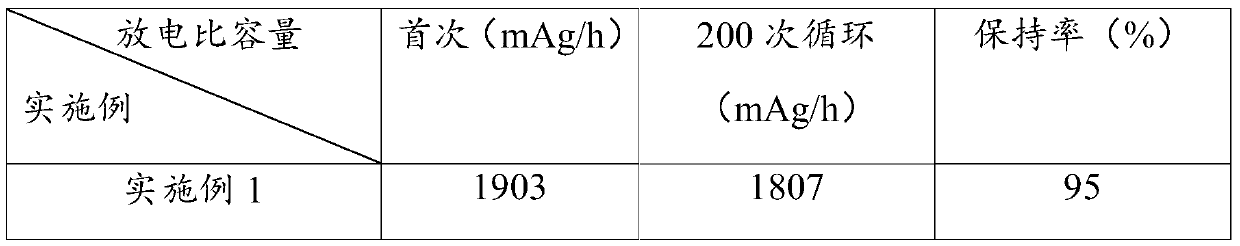

Embodiment 1

[0100] A preparation method for a silicon-based composite negative electrode material for a lithium ion battery, comprising the following steps:

[0101] (1) Silicon nanowire array with porous structure on silicon wafer:

[0102] Mix equal volumes of 5mol / L HF and 0.01mol / L silver nitrate to obtain a mixed solution, place a silicon chip in it, and conduct a silver-attaching reaction at 40°C for 30 minutes; then take out and clean the reacted substrate, and place It was soaked in aqua regia to remove attached silver particles and form silicon nanowires. Then wash off the excess HF with ethanol, and blow dry to form a silicon nanowire array with a porous structure on the silicon wafer (the holes here refer to the holes on the silicon nanowire).

[0103] (2) Preparation of SiO 2 Nanospheres:

[0104] At a stirring speed of 150 rpm, 10 mL of absolute ethanol, 0.2 mL of high-purity water, 0.1 mL of ammonia (25% by mass), 0.25 mL of tetraethyl orthosilicate (TEOS ), after reacti...

Embodiment 2

[0108] A preparation method for a silicon-based composite negative electrode material for a lithium ion battery, comprising the following steps:

[0109] (1) Preparation of silicon nanorod arrays on silicon wafers:

[0110] Adopt 10×10mm 2 The n-type silicon wafer is placed in a tube furnace at 800°C, and oxygen and water vapor are fed into it for thermal generation to obtain a silicon dioxide film with a thickness of 60nm; then the silicon wafer is immersed in a dilute HF solution (commercially available HF and The diluted volume ratio of ionized water is 1:16) and etched for 4 minutes; then the etched substrate is quickly placed in a tube furnace, and silane gas diluted to 5‰ with inert argon is introduced, and the gas flow rate is controlled to be 5ccm. Then 100 sccm of nitrogen gas was introduced, and the temperature was 800° C. and the growth pressure was 20 kPa, and the reaction was carried out for 2 hours, and then cooled to room temperature to obtain silicon nanorod a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com