Preparation method of silicon carbon composite material and application thereof used as lithium ion battery negative electrode material

A technology of silicon-carbon composite materials and silicon sources, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high energy consumption and heavy pollution, and achieve the effects of improving electronic conductance, reducing energy consumption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

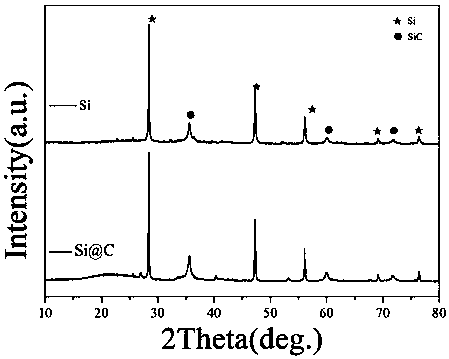

[0022] The preparation method of the silicon-carbon composite material in the present invention includes the following steps: (1), at room temperature, weigh the silicon source, molten salt and reducing agent in a specific proportion, and mix the above-mentioned raw materials and balls in a ball-to-material ratio of 3:1 -5:1 put into the ball milling tank, the volume of the balls should not exceed 2 / 3 of the ball milling tank, mechanically mix at a speed of 300-450r / h for 2-6 hours, put the obtained mixture into a closed inner tank, and then After sealing the hydrothermal tank, heat treatment in an oven at 190-280°C for a certain period of time to obtain the corresponding silicon-containing precursor; (2), the silicon-containing precursor obtained in step (1) is treated with acid to remove metal compounds, silicon dioxide to obtain elemental silicon powder; (3) uniformly mix the elemental silicon powder obtained in step 2) with a carbon source, and perform high-temperature sint...

Embodiment 1

[0025] Embodiment 1: the preparation method of silicon-carbon composite material, it comprises the following steps: (1), select molecular sieve for use as silicon source, select Mg powder for use as reducing agent, select AlCl for use as low temperature molten salt; Select pitch as carbon source, Mg powder and The molar ratio of the molecular sieve is 1:1-2:1, and the molar ratio of Al in the low-temperature molten salt to Si in the molecular sieve is 8:1-12:1. At room temperature, weigh a certain amount of molecular sieve powder, Mg powder and For AlCl3 powder, put the above-mentioned raw materials and balls into a ball mill tank at a ball-to-material ratio of 5:1, and mechanically mix at a speed of 350r / h for 5 hours to fully and evenly mix the raw materials, and put the resulting mixture into a closed In the 20ml polytetrafluoroethylene liner, and then sealed with a stainless steel water heating tank, heat treatment was carried out in a 190 °C oven for 10 hours to obtain the...

Embodiment 2

[0026] Embodiment 2: the preparation method of silicon-carbon composite material, it comprises the following steps: (1), select molecular sieve for use as silicon source, select Mg powder for use as reductive agent, select AlCl for use Low temperature molten salt; Select pitch as carbon source, Mg powder and The molar ratio of the molecular sieve is 1.5:1, and the molar ratio of Al in the low-temperature molten salt to Si in the molecular sieve is 10:1. At room temperature, a certain amount of molecular sieve powder, Mg powder and AlCl3 powder are weighed, and the above raw materials and spherical Put it into a ball mill tank with a ball-to-material ratio of 3:1, and mechanically mix it at a speed of 300r / h for 2 hours to fully and evenly mix the raw materials, and put the resulting mixture into a closed 20ml polytetrafluoroethylene liner After being sealed with a stainless steel hydrothermal tank, heat treatment was carried out in an oven at 230°C for 6 hours to obtain the cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com