Monoatomic dispersed in-situ growth nitrogen atom-doped carbon nanosphere graphene foam, preparation method and application

A graphene foam, in-situ growth technology, applied in the direction of graphene, nano-carbon, electrical components, etc., can solve the problems of irreversible capacity attenuation of lithium-sulfur batteries, low utilization rate of active materials, and reduced ionic conductivity, etc., to promote the positive electrode. Redox kinetics, good cycling and rate capability, addressing limited surface area effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

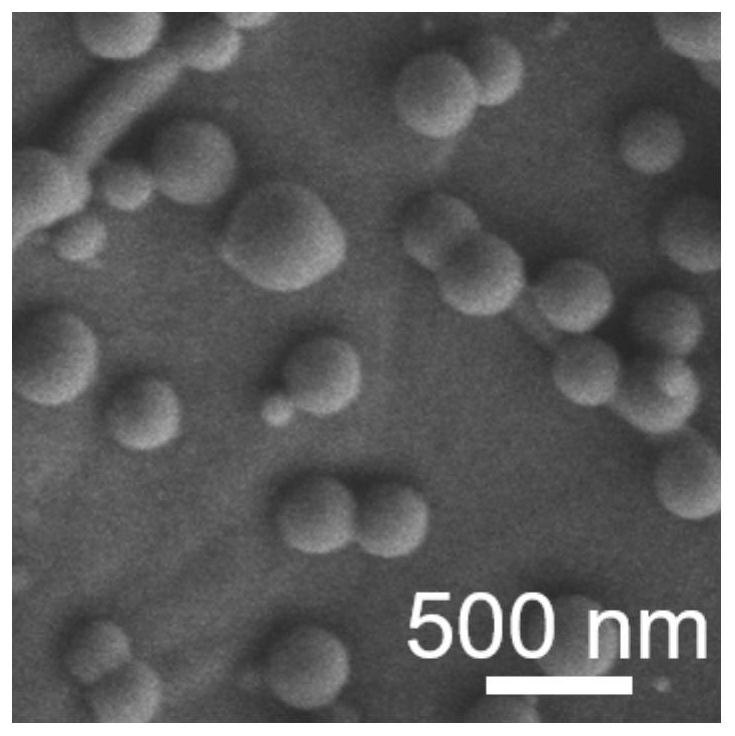

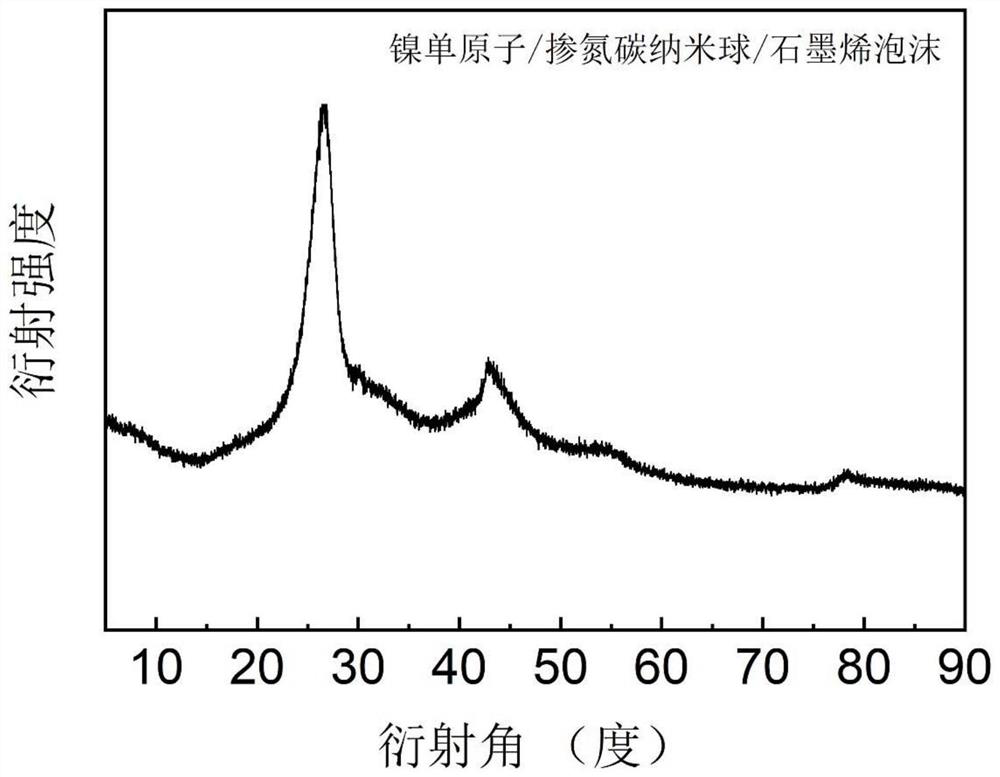

[0084] This embodiment provides a graphene foam of in-situ growth doped nitrogen atom carbon nanospheres dispersed by single atom nickel, and its scanning electron microscope photo is as follows figure 1 As shown, it can be seen that the diameter of the carbon nanospheres is 200-400nm, the surface is smooth, the dispersion is good, and there is no impurity. The X-ray diffraction pattern is as follows figure 2 As shown, it can be seen from the figure that two broad diffraction peaks can be clearly observed at diffraction angles of 25° and 44°, which are attributed to the presence of carbon nanospheres; in addition, sharp peaks at 26° and 44° and The faint diffraction peak at 54° is attributed to the graphene foam structure.

Embodiment 2

[0086] The present embodiment provides the preparation method of the graphene foam of the in-situ growth doped nitrogen atom carbon nanospheres of the monoatomic nickel dispersed in the embodiment 1, comprising the following steps:

[0087] The first step: preparing metal foam nickel / graphene composite material.

[0088] Firstly, metal foam nickel was ultrasonically cleaned in acetone, ethanol and deionized water for 5 min, rinsed with deionized water, and dried in a vacuum oven for 1 h; the cleaned metal foam nickel was placed in a CVD system tube furnace, first Exclude the air in the tube, then use a vacuum pump to pump the air pressure in the tube to 5Pa, then flush argon to normal pressure, and repeat this twice; then in Ar:H 2 (200sccm: 200sccm) mixed gas flow, 30min to 1000 ° C; in Ar: H 2 (200sccm: 300sccm) annealing for 20min in airflow to remove the oxide on the surface of metal foam nickel; pass CH 4 As a carbon source, in Ar:H 2 :CH 4 (400sccm: 200sccm: 100sccm)...

Embodiment 3

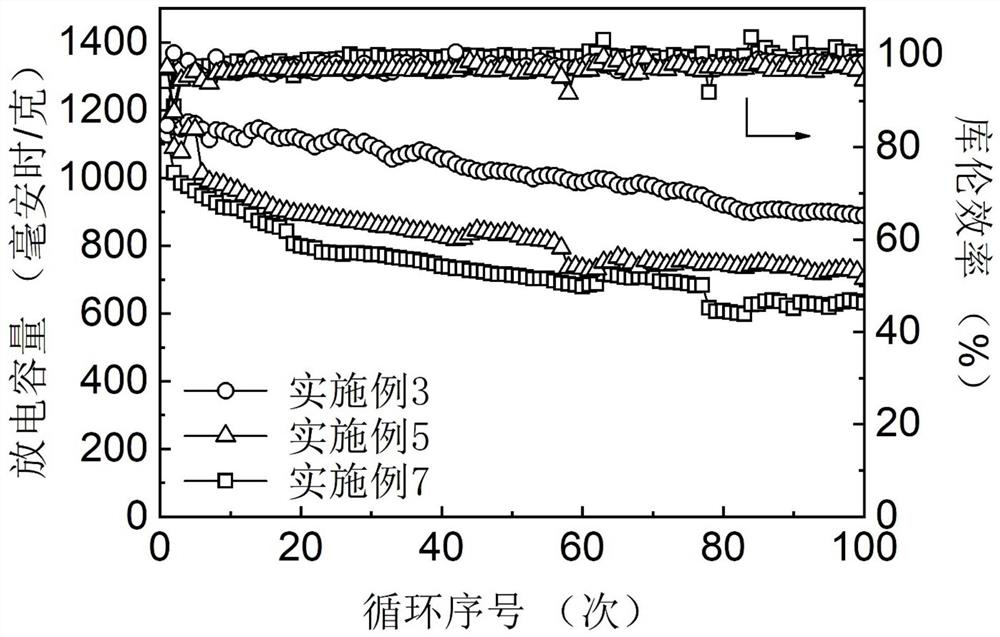

[0094] This embodiment provides a lithium-sulfur battery cathode material, the preparation method of which comprises:

[0095] Weigh the active substance sulfur and the monoatomically dispersed nitrogen-doped carbon nanosphere / graphene foam composite material prepared in Example 2 according to 2:1, dissolve the active substance sulfur in the carbon disulfide solution at room temperature and ultrasonically 0.5h to ensure that the active substance The concentration of sulfur is 0.5mol / L, and then use a dropper to measure a small amount of solution dissolved in the active substance sulfur and titrate the single-atom dispersed nitrogen-doped carbon nanosphere / graphene foam composite material in a fume hood. Put the titrated composite material under the fume hood for 3 hours until all the carbon disulfide is volatilized, then put the dried composite material into a polytetrafluoroethylene-lined stainless steel autoclave, and replace it in a nitrogen-filled glove box. Gas treatment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com