Material for lithium-sulfur battery positive electrode and preparation method thereof

A lithium-sulfur battery and positive electrode technology, applied in the field of lithium-sulfur battery positive electrode materials and its preparation, can solve the problems of reducing the electrochemical performance of composite materials, the inability to synthesize composite materials with high efficiency, and reducing the tap density, so as to improve Coulombic efficiency and cycle stability, good cycle stability and Coulombic efficiency, the effect of reducing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

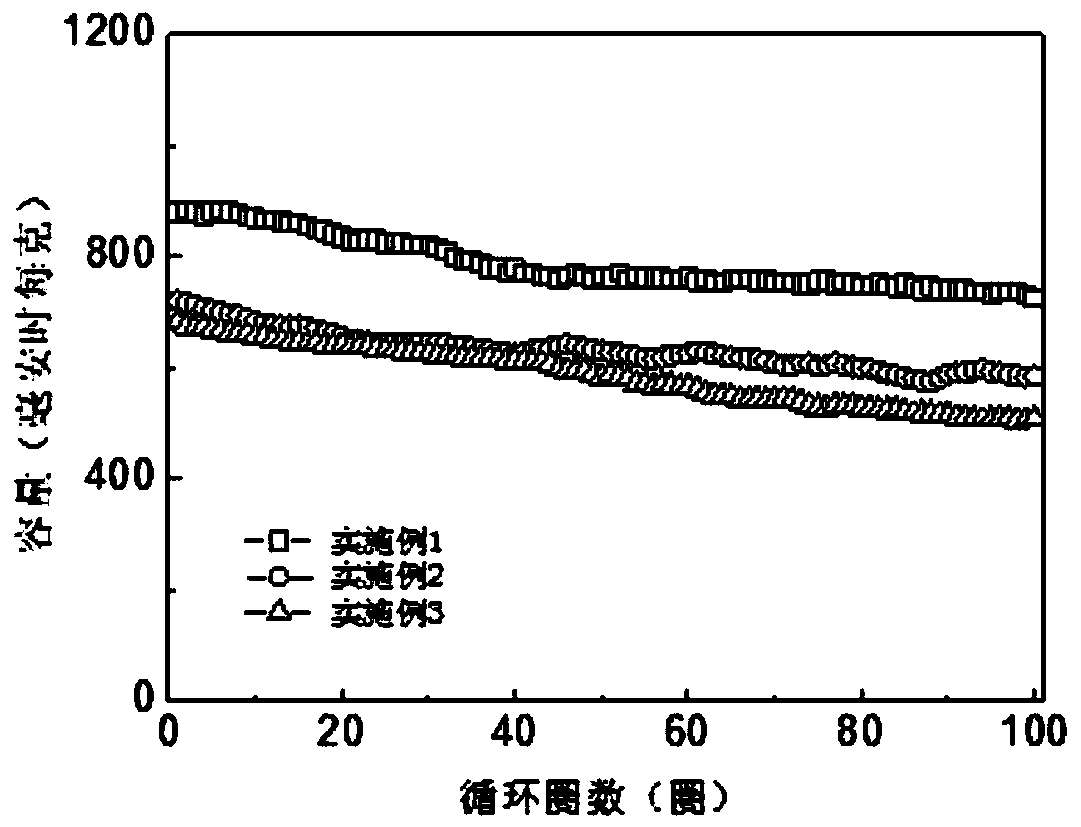

Embodiment 1

[0031] The material used for the positive electrode of the lithium-sulfur battery is a self-supporting mesoporous vanadium nitride nanowire / carbon nanotube composite material with a three-dimensional independent network structure.

[0032] The preparation method of described material comprises the following steps:

[0033] (1) Preparation of vanadium oxide nanowires: first, 0.1 g of ammonium metavanadate with a purity of 99% was added to 40 mL of deionized water, stirred to form a uniform dispersion solution; then nitric acid was added dropwise to adjust the pH value of the dispersion solution to 2, and Stir at room temperature for 1 hour and transfer to a high-pressure reactor with a capacity of 60 mL and heat at 180°C for 24 hours to react. After the reaction is completed, the reaction kettle is naturally cooled to room temperature, and the precipitate obtained from the reaction is repeatedly washed with deionized water and ethanol. 3 times, drying at 80°C for 12 hours under...

Embodiment 2

[0037] The preparation method of described material comprises the following steps:

[0038](1) Preparation of vanadium oxide nanowires: first, 0.3 g of ammonium metavanadate was added to 80 mL of deionized water, and stirred to form a uniform dispersion solution; then nitric acid was added dropwise to adjust the pH value of the dispersion solution to 3, stirred at room temperature for 2 h and Transfer to the reaction kettle and heat at 190°C for 24 hours to react. After the reaction is completed, the reaction kettle is naturally cooled to room temperature, and the precipitate obtained from the reaction is repeatedly washed with deionized water and ethanol for 5 times, and dried under vacuum at 60°C. 12h, the vanadium oxide nanowires were obtained;

[0039] (2) Preparation of mesoporous vanadium nitride nanowires: the vanadium oxide nanowires obtained in step (1) are placed in a flow rate of 30 sccmNH 3 Heated to 550°C at a heating rate of 3°C / min in a tube furnace for reactio...

Embodiment 3

[0042] The preparation method of described material comprises the following steps:

[0043] (1) Preparation of vanadium oxide nanowires: first, 0.2 g of ammonium metavanadate was added to 60 mL of deionized water, stirred to form a uniform dispersion solution; then nitric acid was added dropwise to adjust the pH value of the dispersion solution to 2, stirred at room temperature for 2 h and Transfer to a reaction kettle and heat at 170°C for 24 hours to react. After the reaction is completed, the reaction kettle is naturally cooled to room temperature, and the precipitate obtained from the reaction is repeatedly washed with deionized water and ethanol for 4 times, and dried under vacuum at 70°C. 12h, the vanadium oxide nanowires were obtained;

[0044] (2) Preparation of mesoporous vanadium nitride nanowires: the vanadium oxide nanowires obtained in step (1) are placed in a flow rate of 30 sccmNH 3 Heated to 550°C at a heating rate of 4°C / min in a tube furnace for reaction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com