Graphene-zinc-based oxide composite material, preparation method thereof and application of graphene-zinc-based oxide composite material in lithium ion battery negative electrode material

A composite material, graphene technology, applied in the field of lithium-ion batteries, can solve the problems of electrode crushing capacity, attenuation, poor conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing the graphene-zinc-based oxide composite material described in the above technical solution, comprising the following steps:

[0028] mixing graphene oxide with an organic solvent to obtain a graphene oxide dispersion;

[0029] Mixing the graphene oxide dispersion, zinc source, iron source and organic ligands, performing a hydrothermal reaction to obtain a composite material precursor;

[0030] The composite material precursor is calcined to obtain a graphene-zinc-based oxide composite material.

[0031] The invention adopts a hydrothermal-high-temperature solid-phase method to prepare graphene-zinc-based oxide composite materials, the preparation process is simple and convenient, and it is suitable for popularization and application.

[0032] The invention mixes the graphene oxide and the organic solvent to obtain the graphene oxide dispersion liquid. In the present invention, the organic solvent is preferably...

Embodiment 1

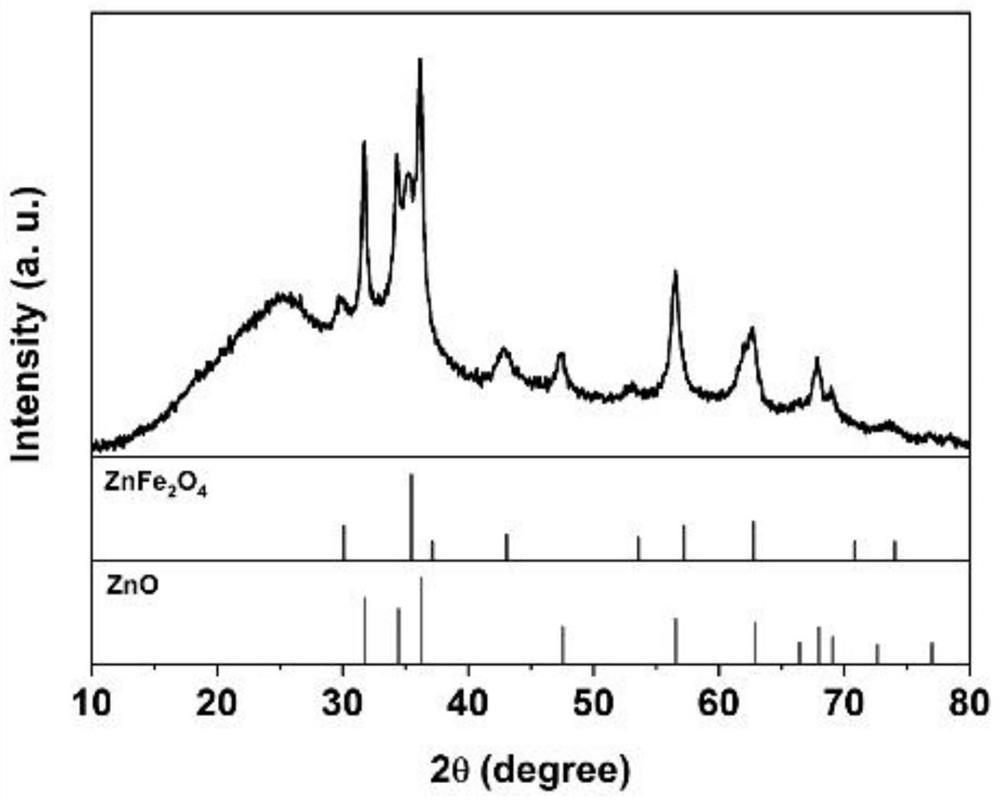

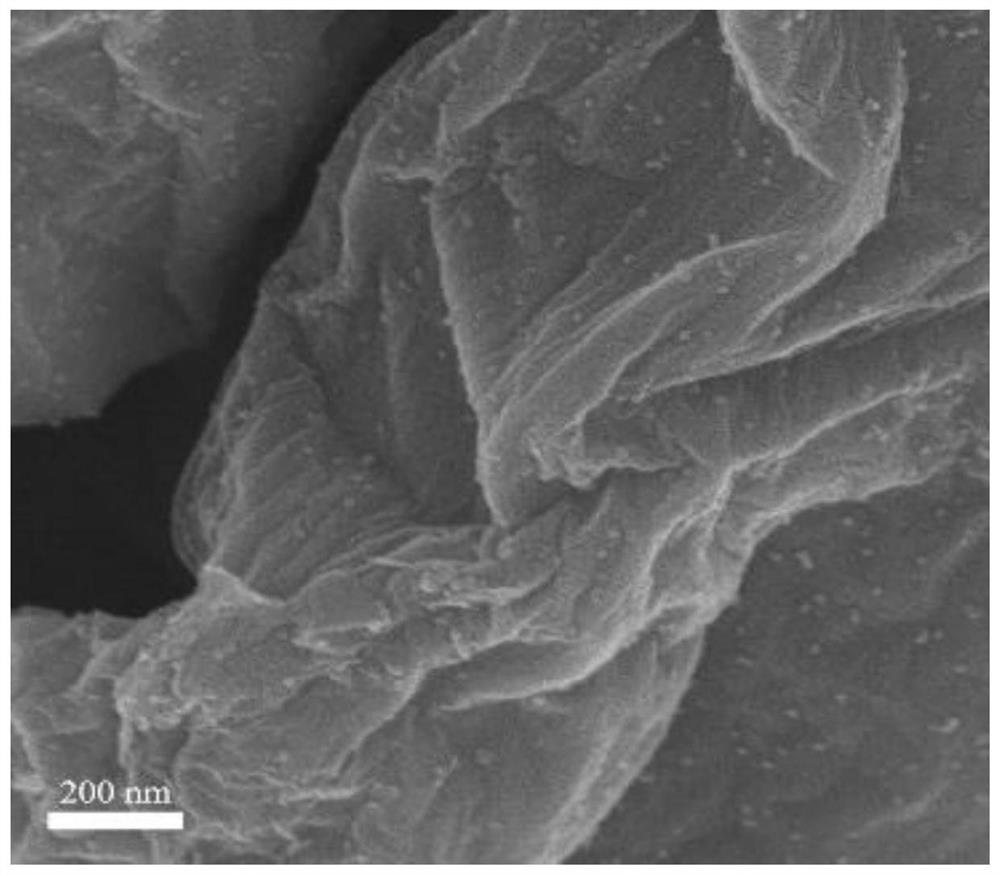

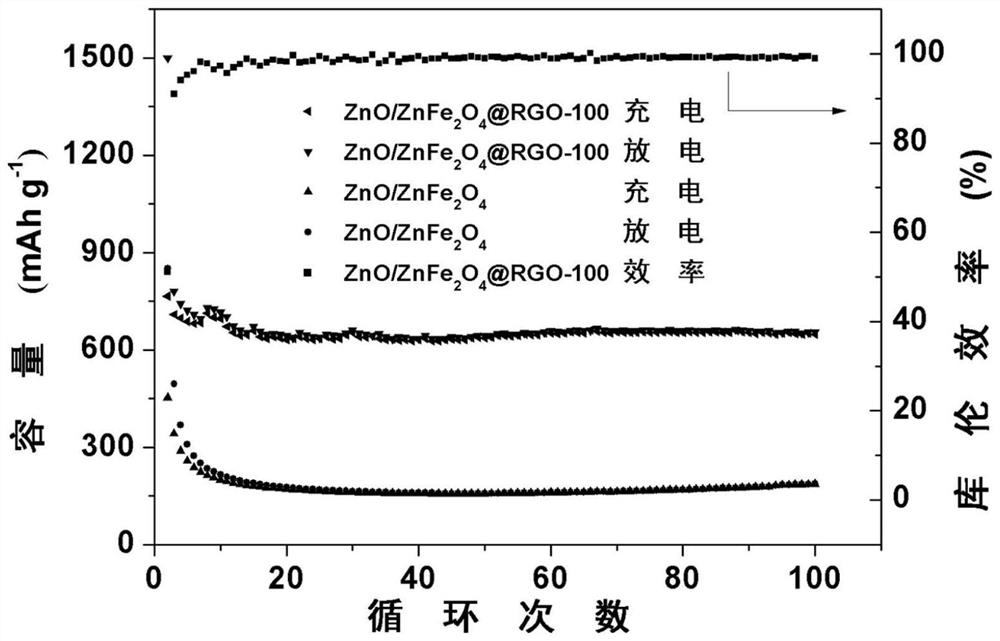

[0044] Preparation of graphene-zinc-based oxide composite ZnO / ZnFe by hydrothermal method-high temperature solid state method 2 o 4 @RGO-100 nanocomposite material: Among them, 100 represents the addition of 100mg graphene oxide in hydrothermal reaction;

[0045] Disperse 0.1g of graphene oxide in a mixed solution of 100mL N,N-dimethylformamide and ethanol by ultrasonic cell disruption, wherein the volume ratio of N,N-dimethylformamide and ethanol is 5:3, to obtain Graphene oxide dispersion;

[0046] 0.63mmol Zn(NO 3 ) 2 ·6H 2 O, 0.68mmol iron acetylacetonate and 0.23mmol terephthalic acid were added to the graphene oxide dispersion, and transferred to an autoclave lined with Teflon, heated to 100°C, and hydrothermally reacted for 6 hours; the resulting system Wash the centrifuge with N,N-dimethylformamide and ethanol in sequence, and dry the solid material obtained by centrifugation at 80°C overnight;

[0047] The composite material precursor was placed in a calciner, a...

Embodiment 2

[0050] Preparation of graphene-zinc-based oxide composite ZnO / ZnFe by hydrothermal method-high temperature solid state method 2 o 4 @RGO-50 nanocomposite material: Among them, 50 represents hydrothermal reaction adding 50mg graphene oxide)

[0051] Disperse 0.05g graphene oxide in a mixed solution of 100mL N,N-dimethylformamide and ethanol by ultrasonic cell disruption, wherein the volume ratio of N,N-dimethylformamide and ethanol is 5:3, to obtain Graphene oxide dispersion;

[0052] 0.63mmol Zn(NO 3 ) 2 ·6H 2 O, 0.68mmol iron acetylacetonate and 0.23mmol terephthalic acid were added to the graphene oxide dispersion, and transferred to an autoclave lined with Teflon, heated to 100°C, and hydrothermally reacted for 6 hours; the resulting system Centrifuge with N,N-dimethylformamide and ethanol in turn, and dry the solid material obtained by centrifugation at 80°C overnight to obtain a composite material precursor;

[0053] The composite material precursor was placed in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com