Lift pipe reactor pre-lifting device and process flow thereof

A pre-lifting and reactor technology, applied in the petroleum industry, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as insufficient heat supply, reduced yield of target products, insufficient cracking of raw material oil, etc., and achieve operational flexibility The effect of improving, increasing the circulation capacity and reducing the feeding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, method and steps of the riser reactor pre-lifter proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , features and their effects are described in detail below.

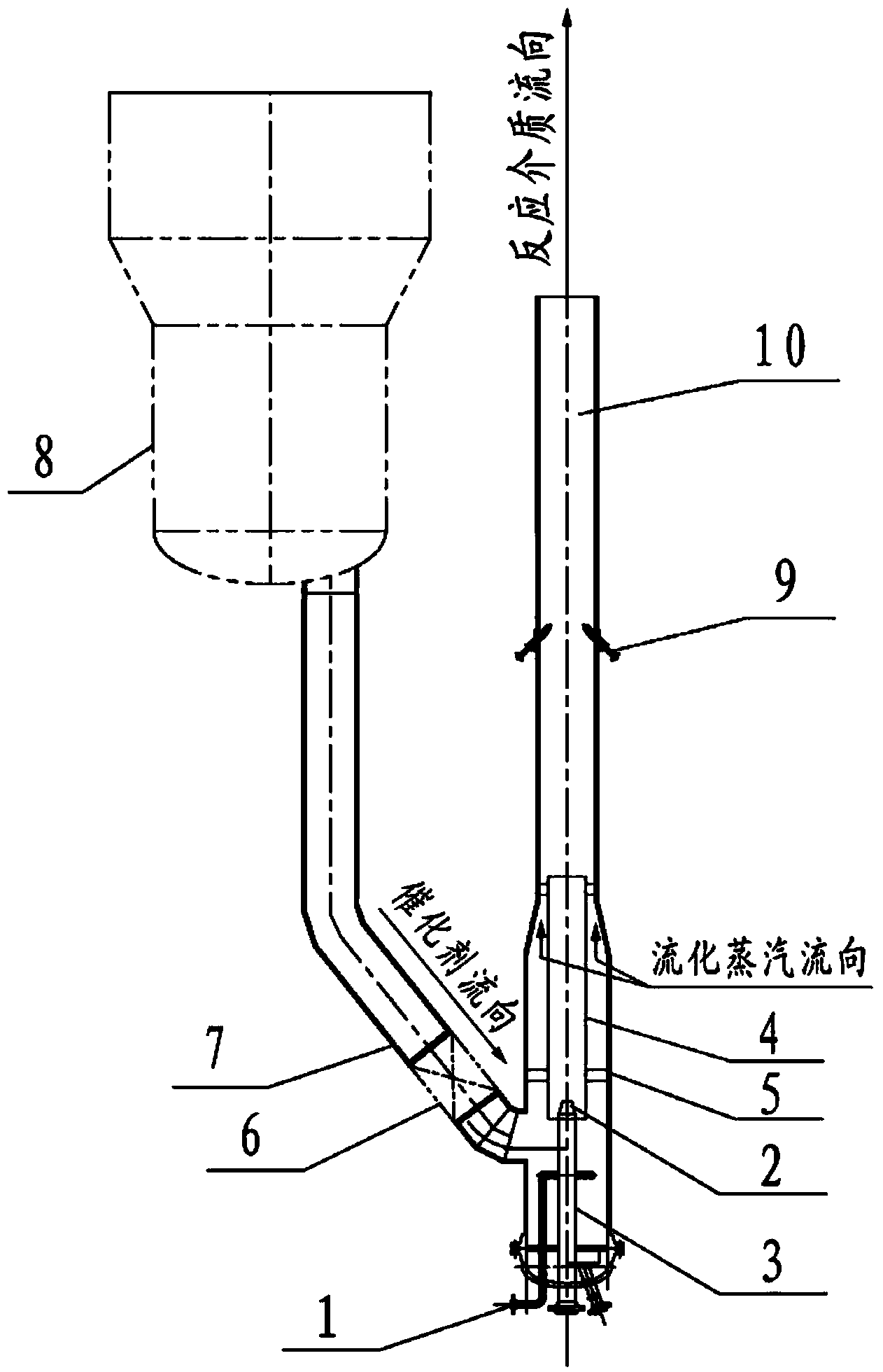

[0028] The cross-sectional schematic view of the riser reactor pre-lifter of the present invention is as follows figure 1 shown.

[0029] The riser reactor pre-lifter includes: a fluidized steam ring 1 , a pre-lift steam nozzle 2 , a pre-lift steam pipe 3 , an inner delivery pipe 4 , an expanding section 5 , a single-acting slide valve 6 and a regeneration inclined pipe 7 . Wherein, the expansion section 5 is arranged at the bottom of the riser reactor 10, and the inner delivery pipe 4 and the pre-lift steam pipe 3 are arranged in the expansion section 5. The u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com