Patents

Literature

38results about How to "Mix reaction evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

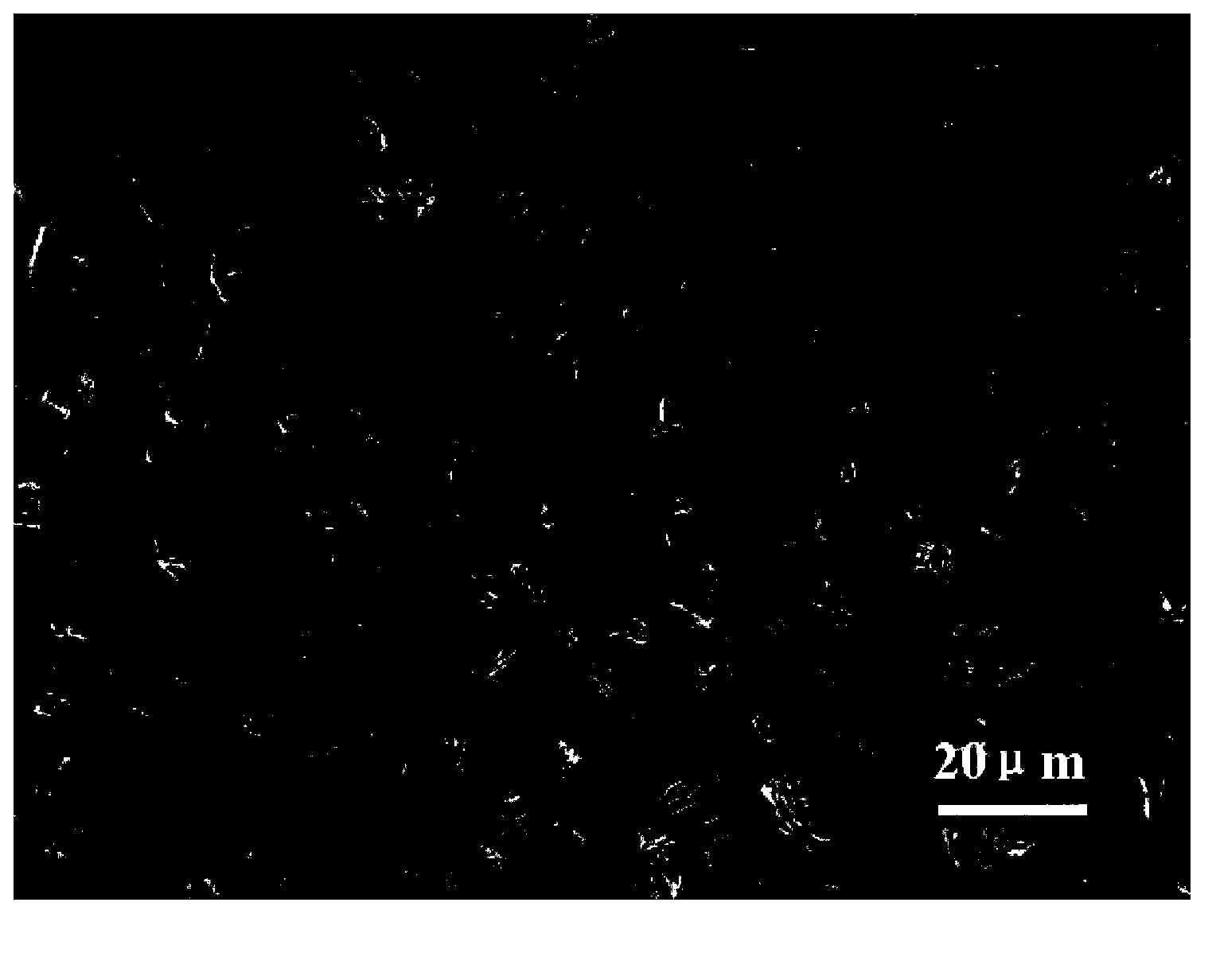

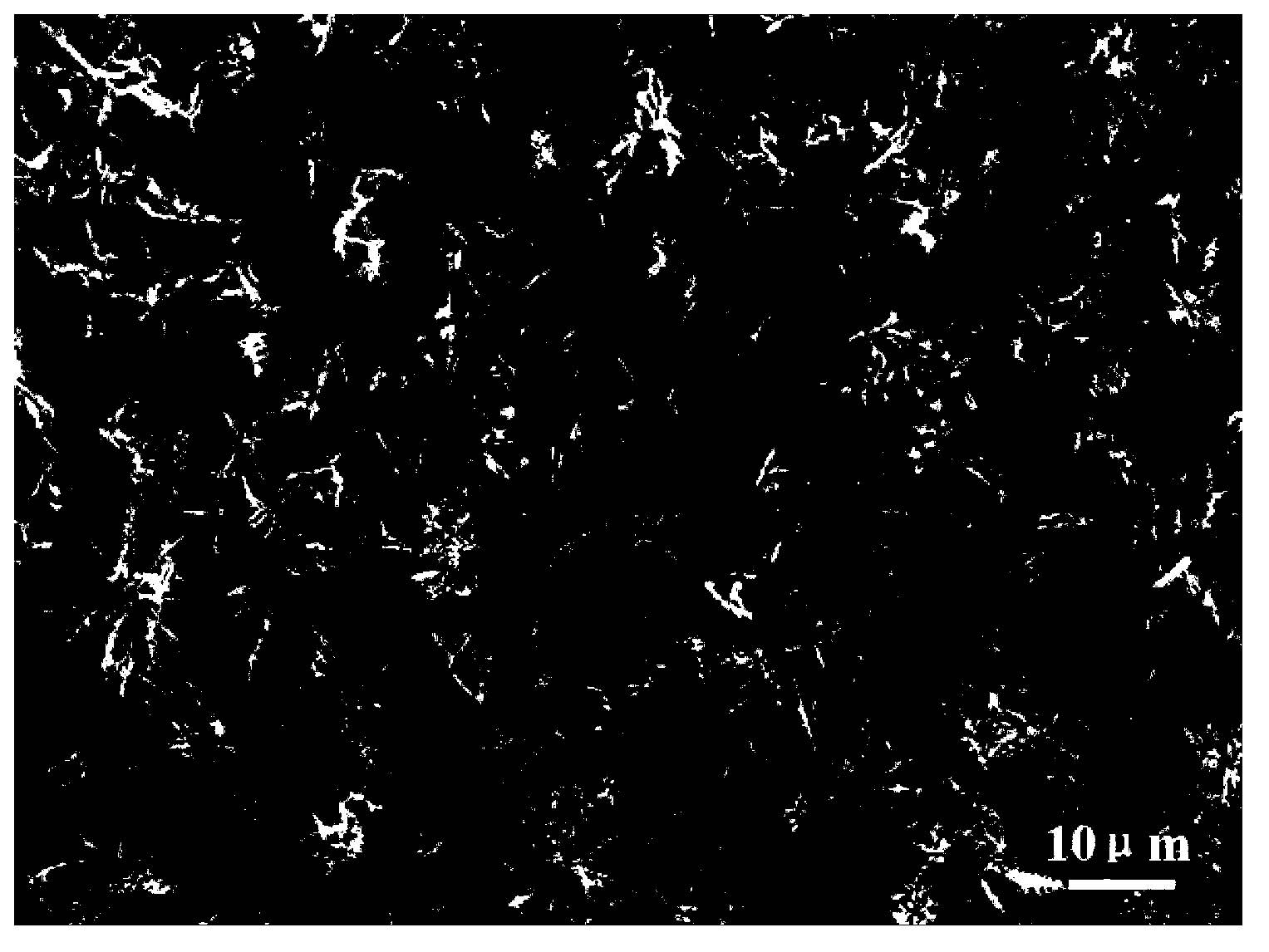

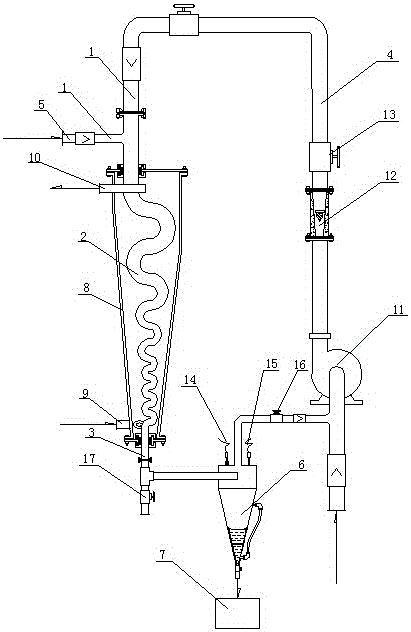

Method for continuously preparing ultrafine sliver powder on basis of microchannel mixed reaction system

ActiveCN104209529ASolve technical problems in mass productionIncrease productivityFiltrationSodium ascorbate

The invention belongs to the field of preparation of metal ultrafine powder materials and particularly relates to a method for continuously preparing ultrafine sliver powder on the basis of a microchannel mixed reaction system. According to the method, an oxidation solution containing soluble silver salt and nitric acid and a reduction solution containing ascorbic acid or sodium ascorbate are continuously conveyed to the microchannel mixed reaction system respectively through driving devices, mixing is carried out in a Y-type tee joint or a tee joint in the microchannel mixed reaction system, wherein the Y-type tee joint or the tee joint serves as a mixing unit of reactive materials, the mixed solutions flow out of reaction microchannels after being subjected to a reaction in the reaction microchannels in the microchannel mixed reaction system, standing is carried out on obtained reaction products, washing and sediment are carried out on the products, and ultrafine sliver powder of different morphologies and sizes can be obtained after suction filtration and drying. According to the method, control over the crystallization morphologies and the sizes of ultrafine sliver powder particle products can be achieved by adjusting the components of the oxidation solution, the components of the reduction solution, the molar concentration, the temperature and other parameters.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing temperature-resistance nano AgCl SOL

InactiveCN1850613AImprove adsorption capacityEasy to washSilver halidesChlorideTemperature resistance

The invention discloses a method for preparing high temperature-resistant nano AgCl sol, comprising the steps of: a. preparing soluble chloride solution 0.01-0.2 mol / L, mixing it with dispersant 0.01-2 mol / L in the molar mass ratio of 1 to (1-4), and dispersing uniformly at a speed of 400-1000 r / min; b. heating the prepared solution to 25 deg.C-100 deg.C, regulating pH value of solution to 2-9, uniformly dropping in AgNO5 0.05-0.5mol / L and dispersant 0.01-2mol / L in the molar mass ratio of 1 to (0.25-10) at a speed of 0.01-0.1 ml / min, and dispersing uniformly at 1000-1500 r / min for 10-45 min, and processing the prepared nano sol with ultrasonic for 1 h. And its beneficial effect: at a certain temperature, the absorption of nano silver sol on fabric is high, and the nano silver sol is firm to absorb and uneasy to wash out.

Owner:DONGHUA UNIV

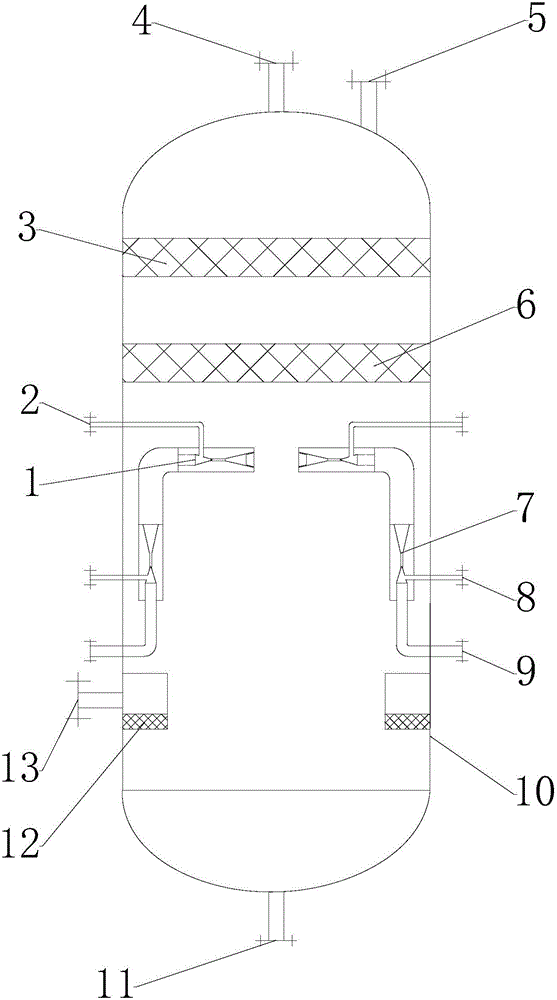

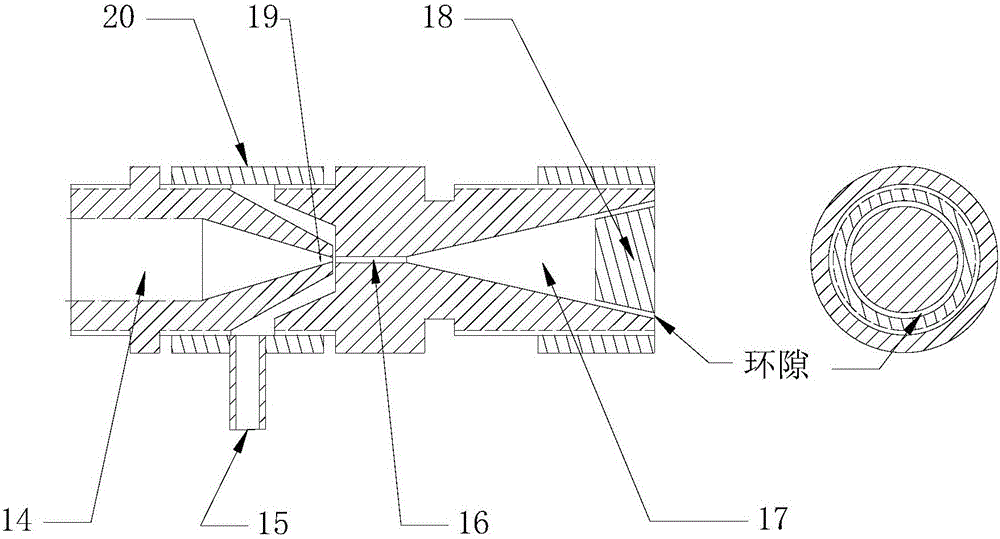

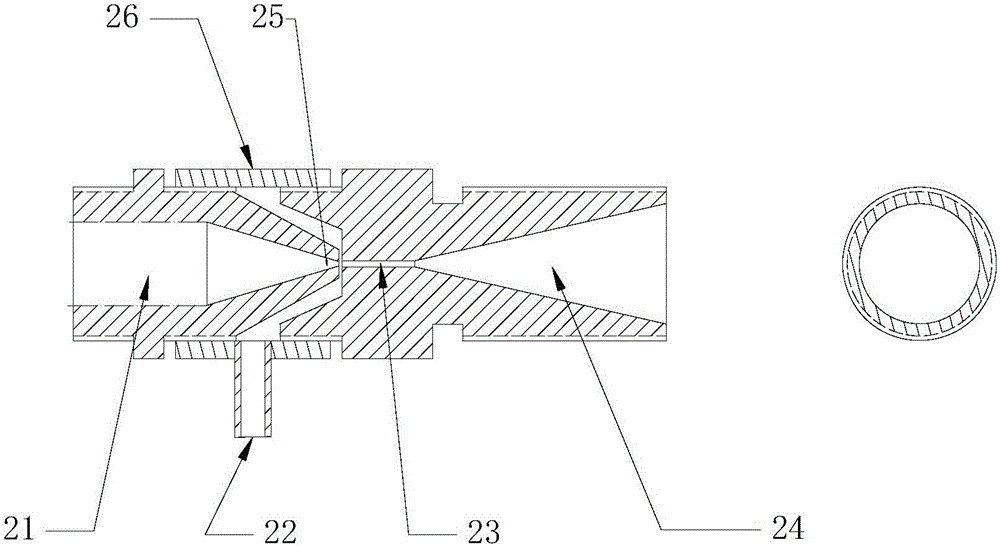

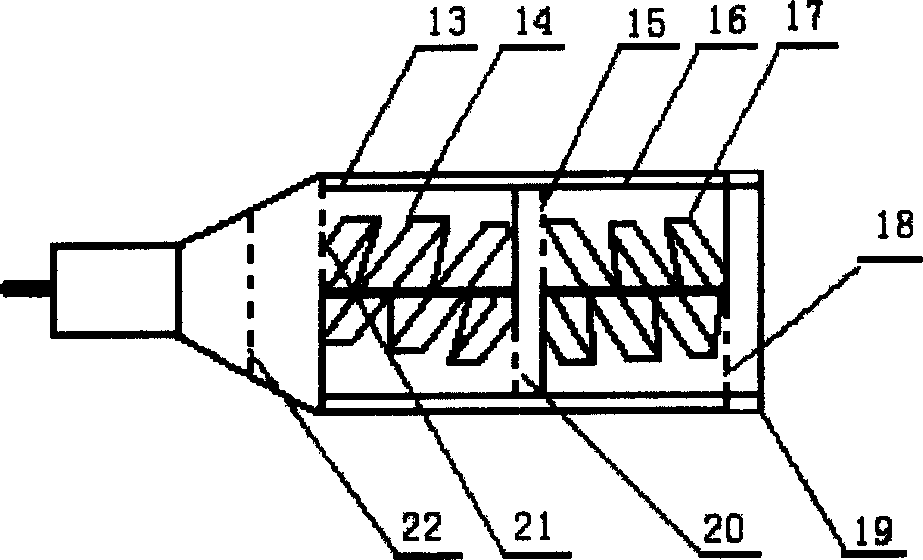

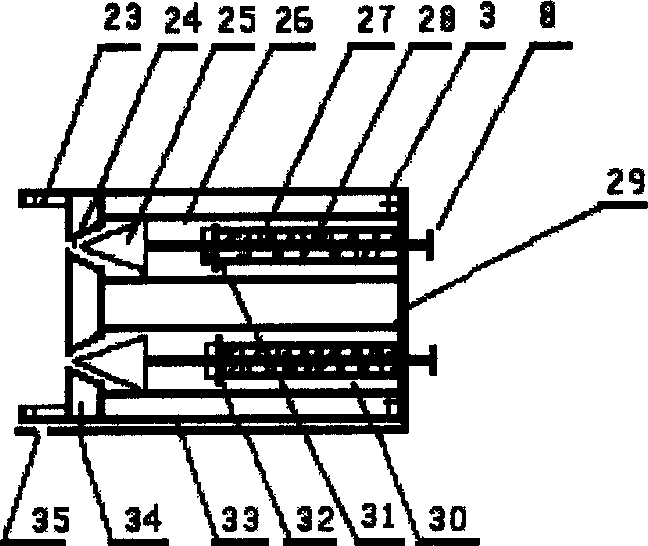

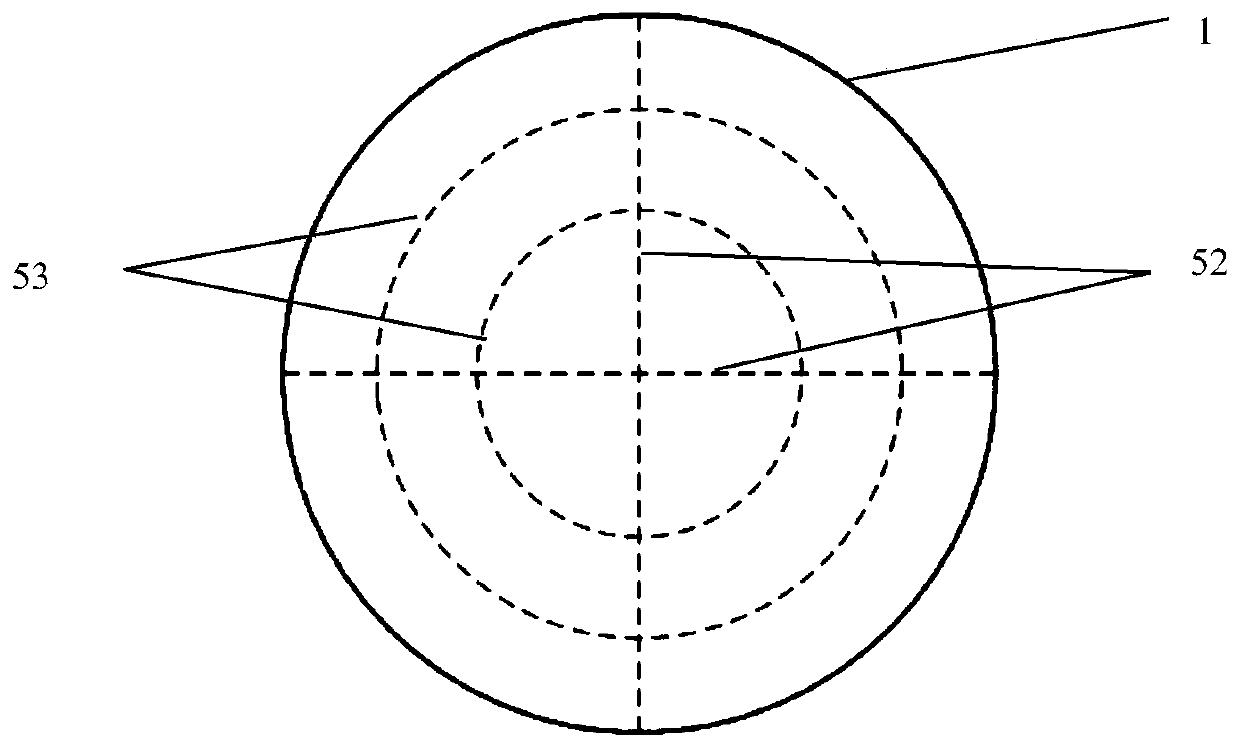

Impinging stream polyphase reactor

ActiveCN106179146ASimple structureAdded convective mixing sectionLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsAlkyl transferEmulsion

The invention is an impingement flow multiphase reactor, which relates to liquid-liquid mixed multiphase reaction. The reactor mixes the high-viscosity and low-viscosity fluids uniformly into a low-viscosity emulsion at a lower temperature and in a short period of time through the raw material injection premixer, and then sprays out a ring-shaped liquid film at high speed through multiple jets hitting the nozzles of the reactor The phase impact strengthens the reaction, so that the reaction can be carried out quickly and fully. The impinging flow multiphase reactor introduced by the invention has simple structure, no stirring parts, is not easy to leak, has a large contact area of reaction liquid, can realize rapid and efficient mixed reaction of immiscible fluids in large-scale production, and has high product selectivity. It can be applied to reaction devices with high fluid viscosity, liquid-liquid immiscibility and rapid mixing reaction between liquids in fine chemical industry, petrochemical industry, pharmaceutical industry, biochemical industry and other industrial processes, especially liquid acid catalyzed isobutane alkylation reaction .

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

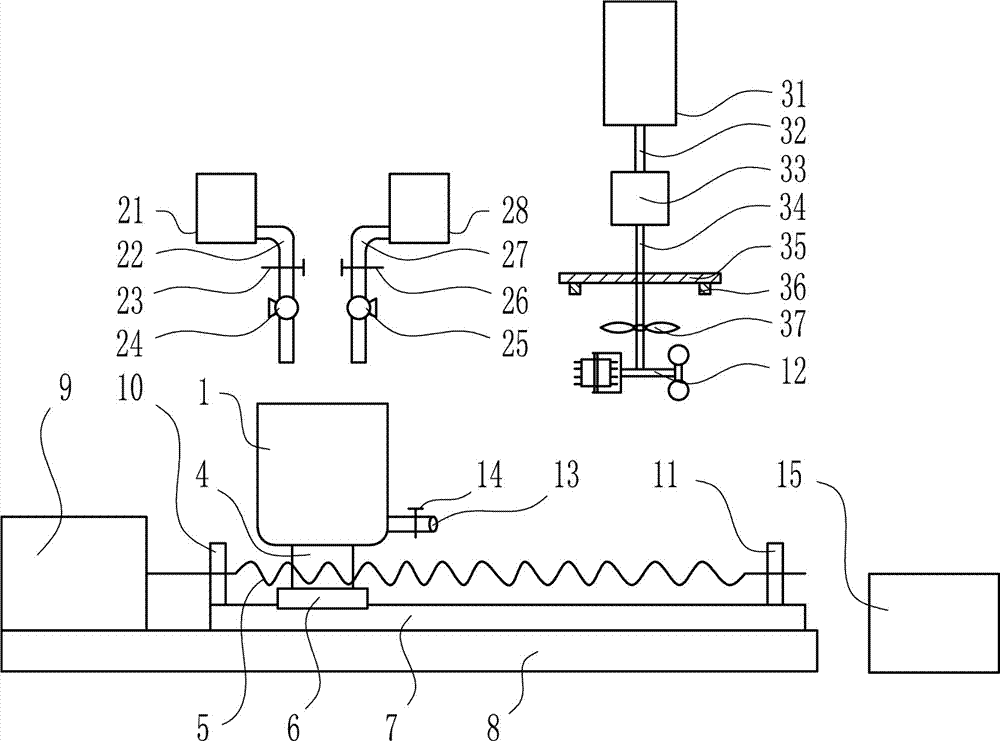

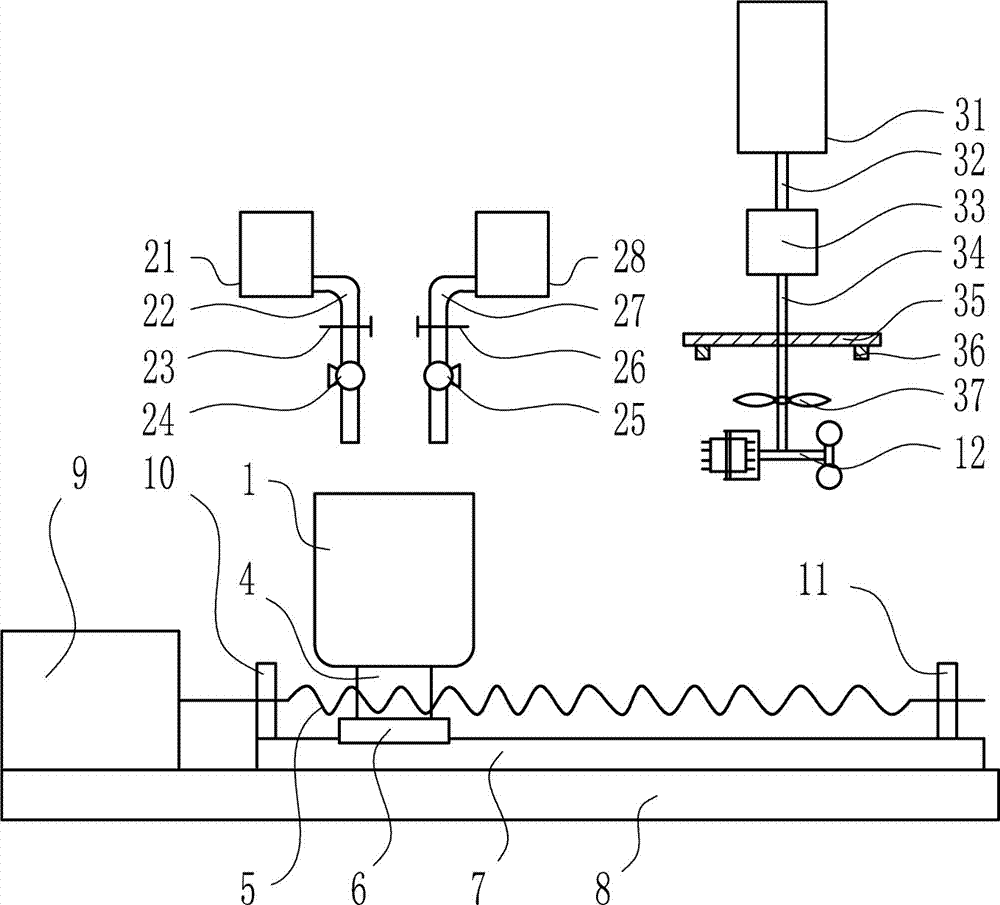

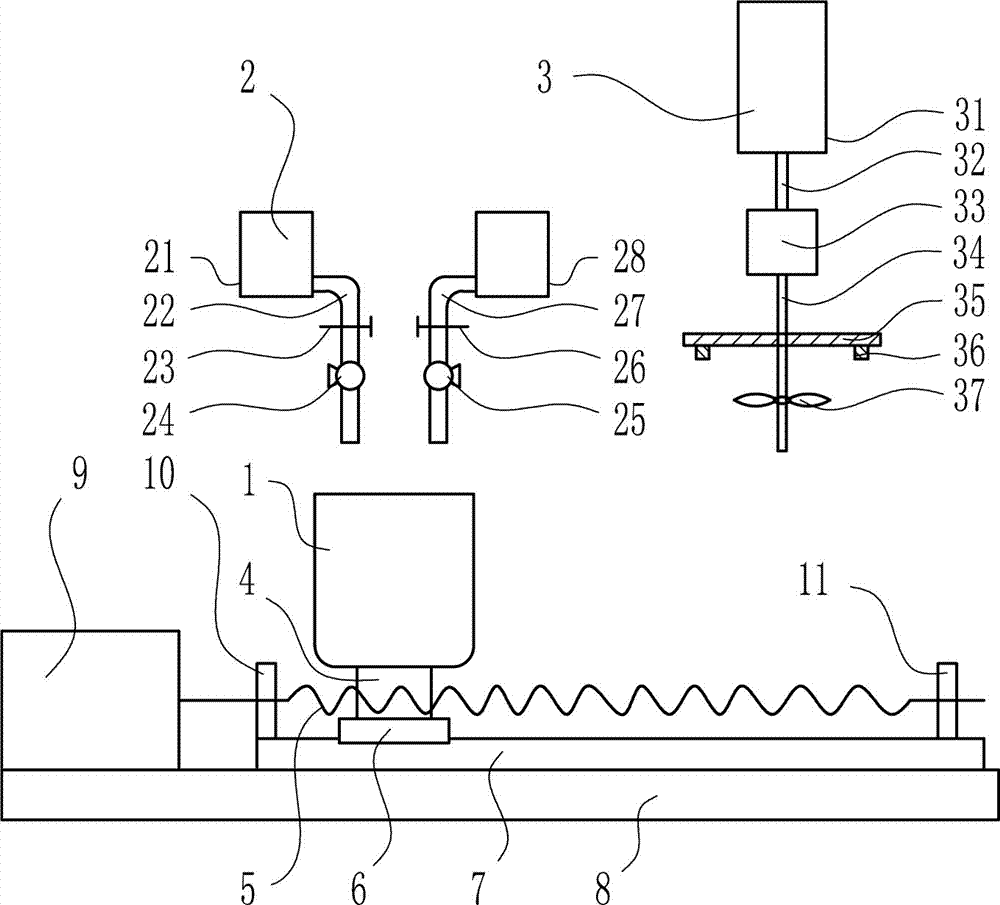

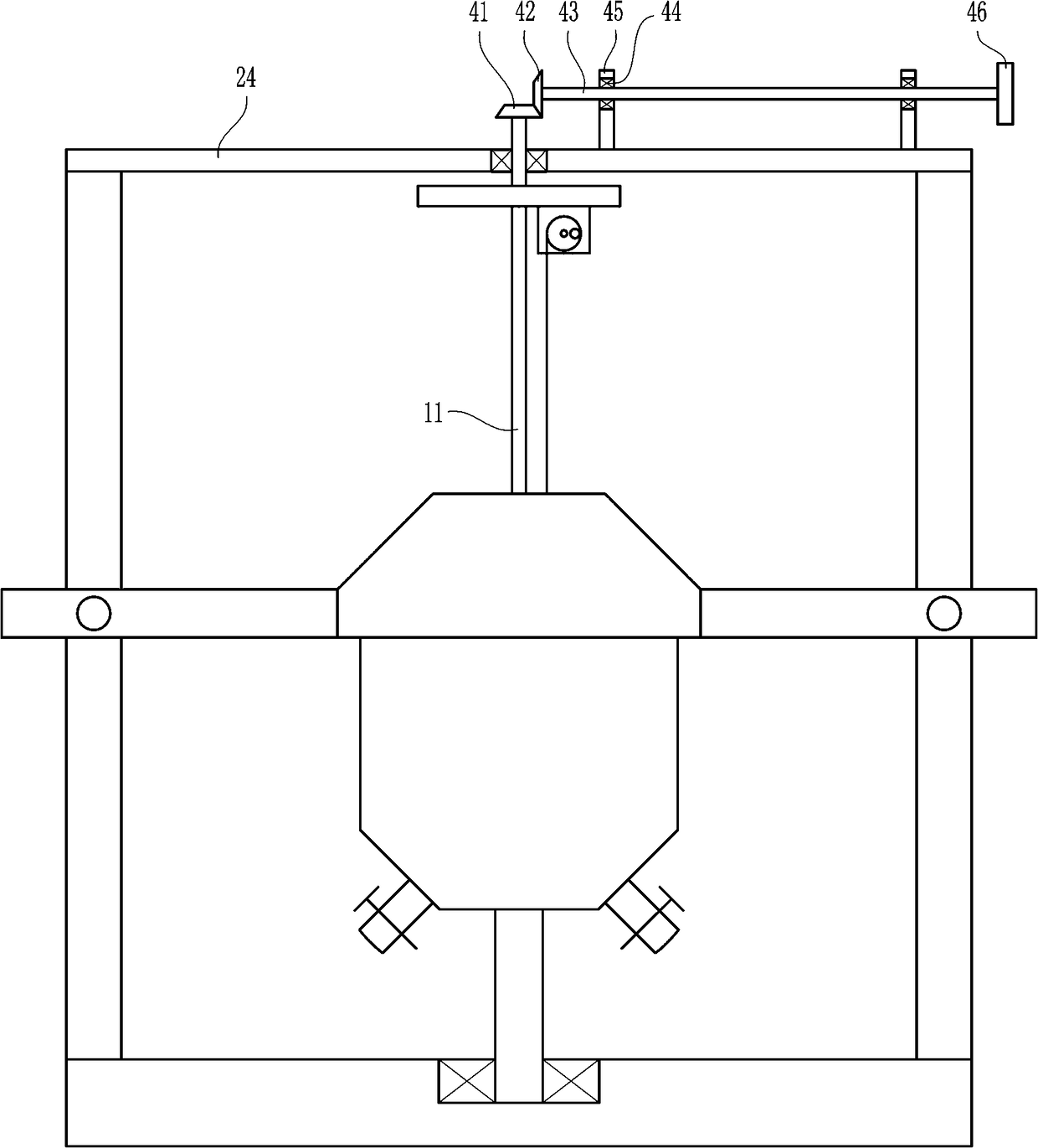

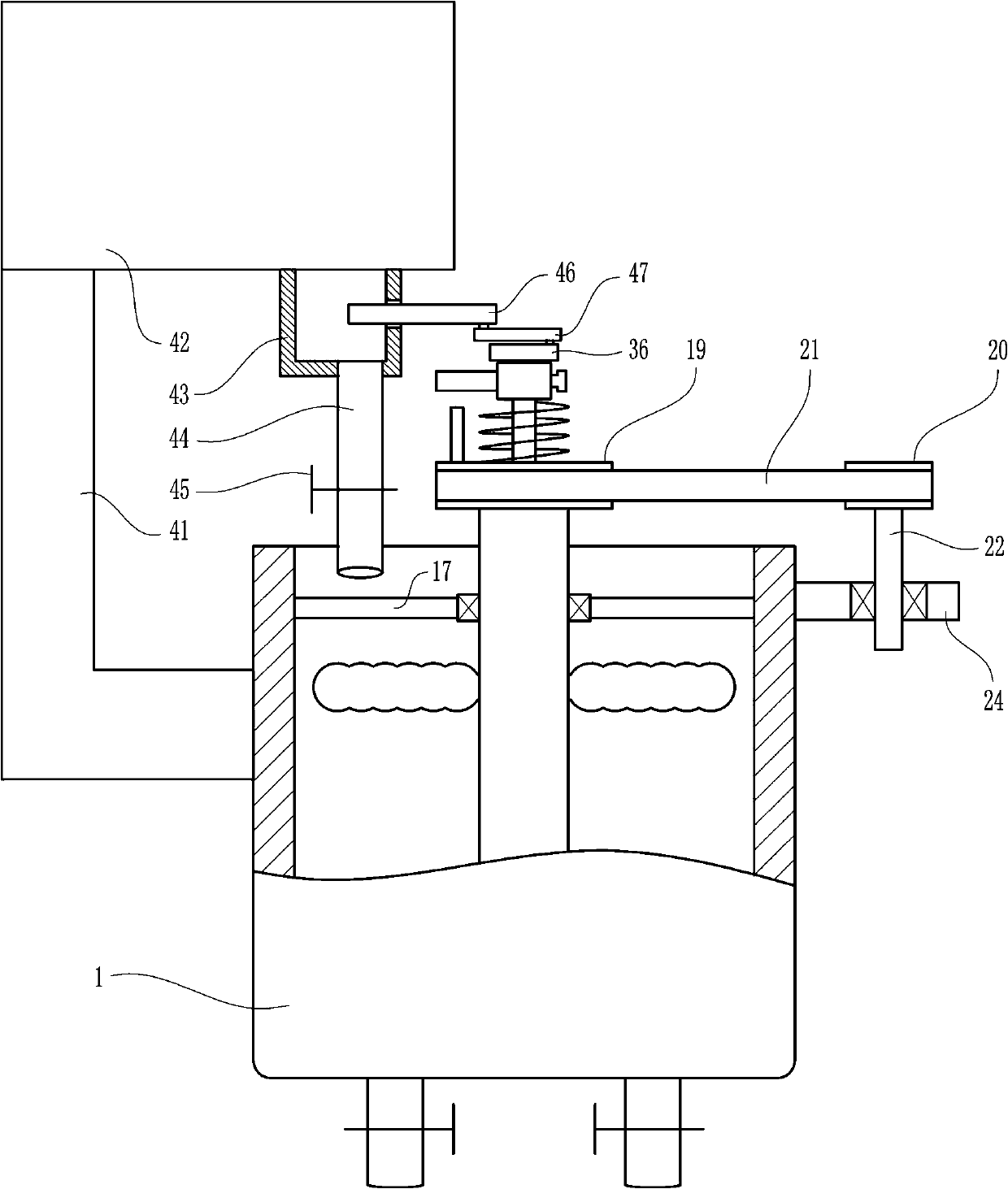

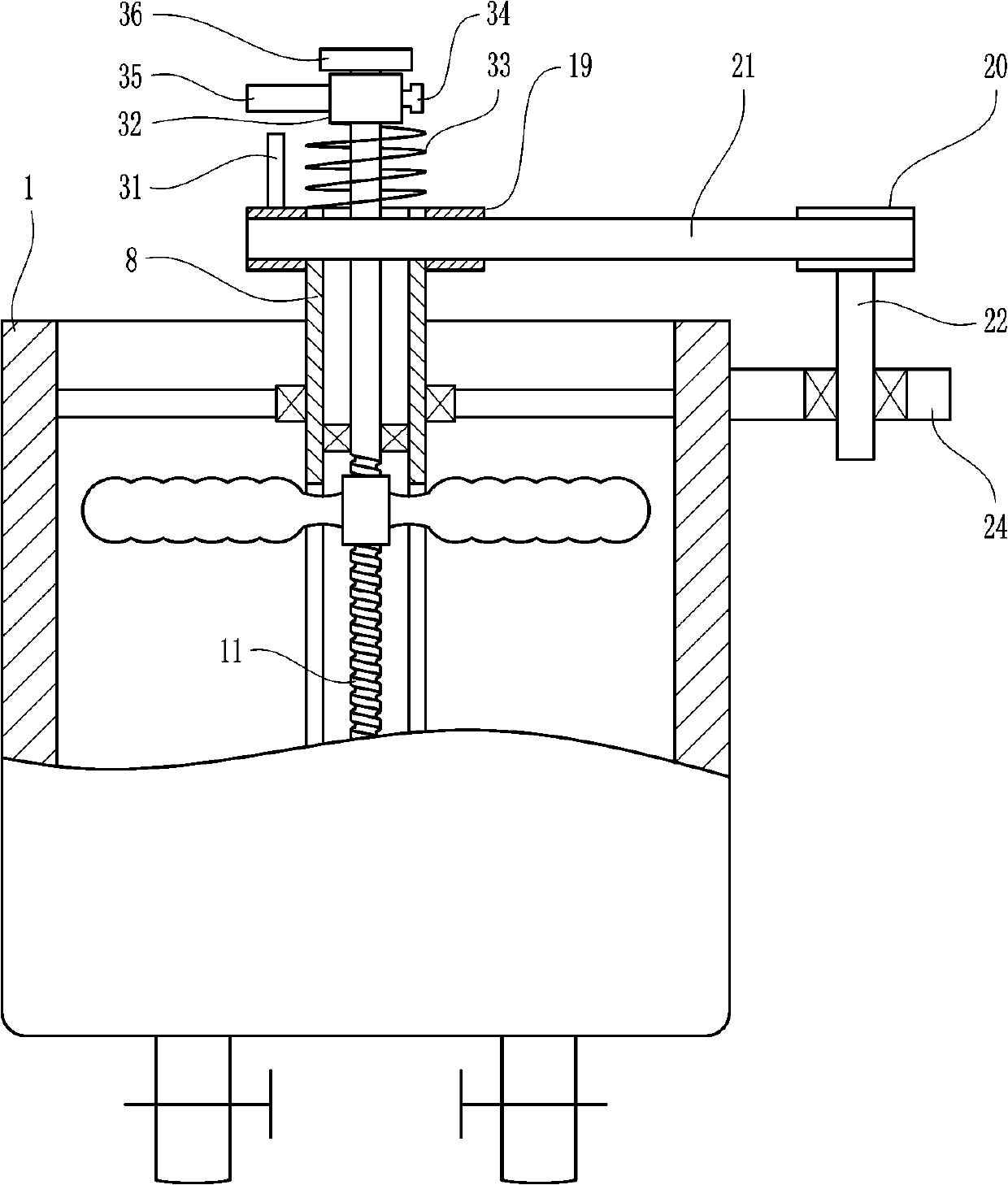

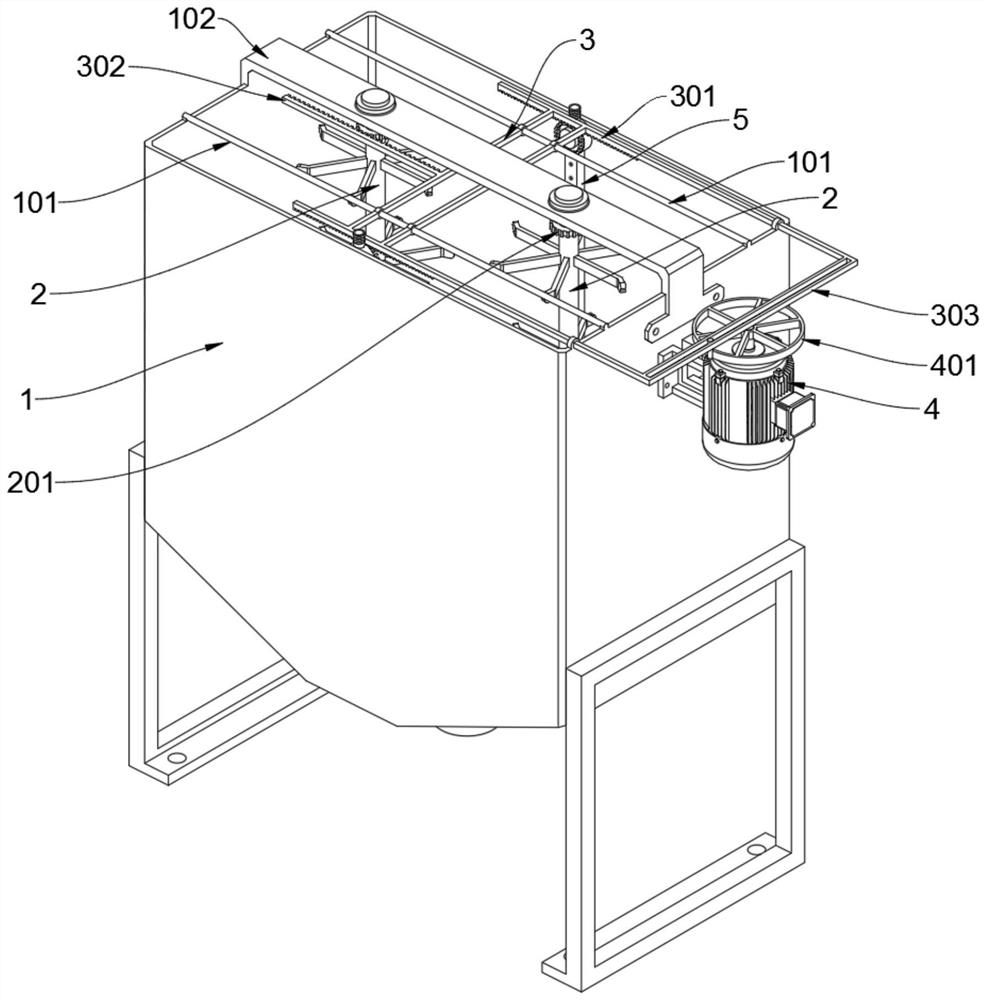

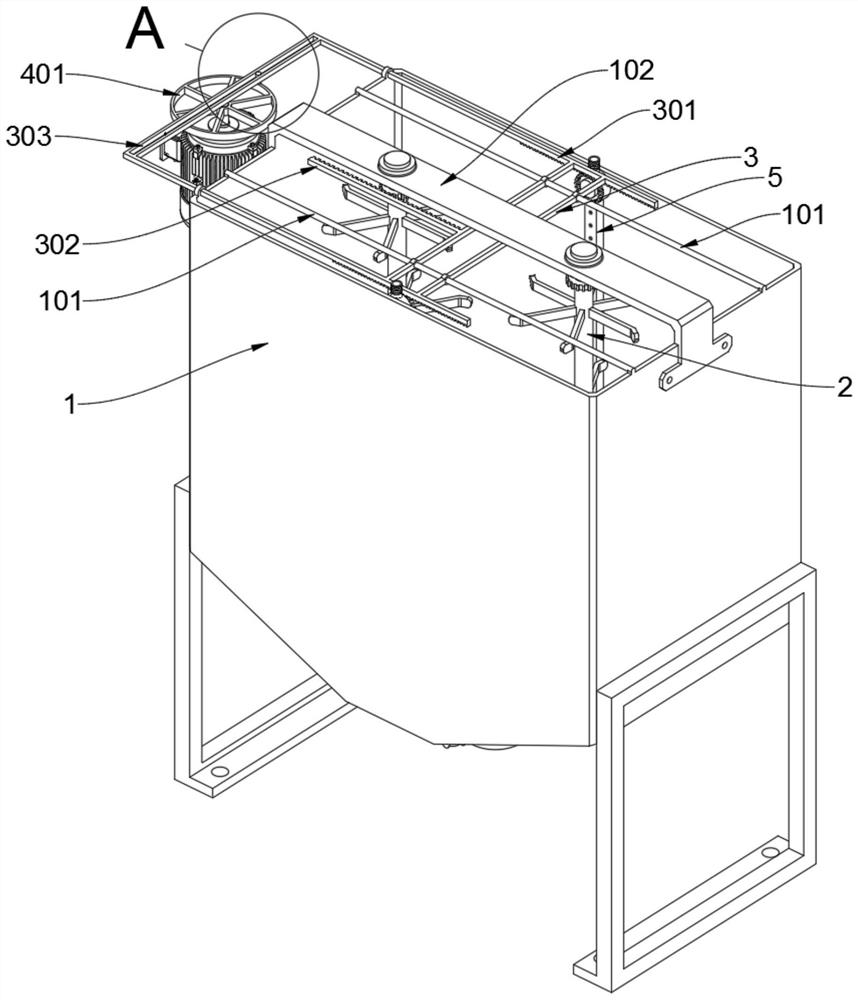

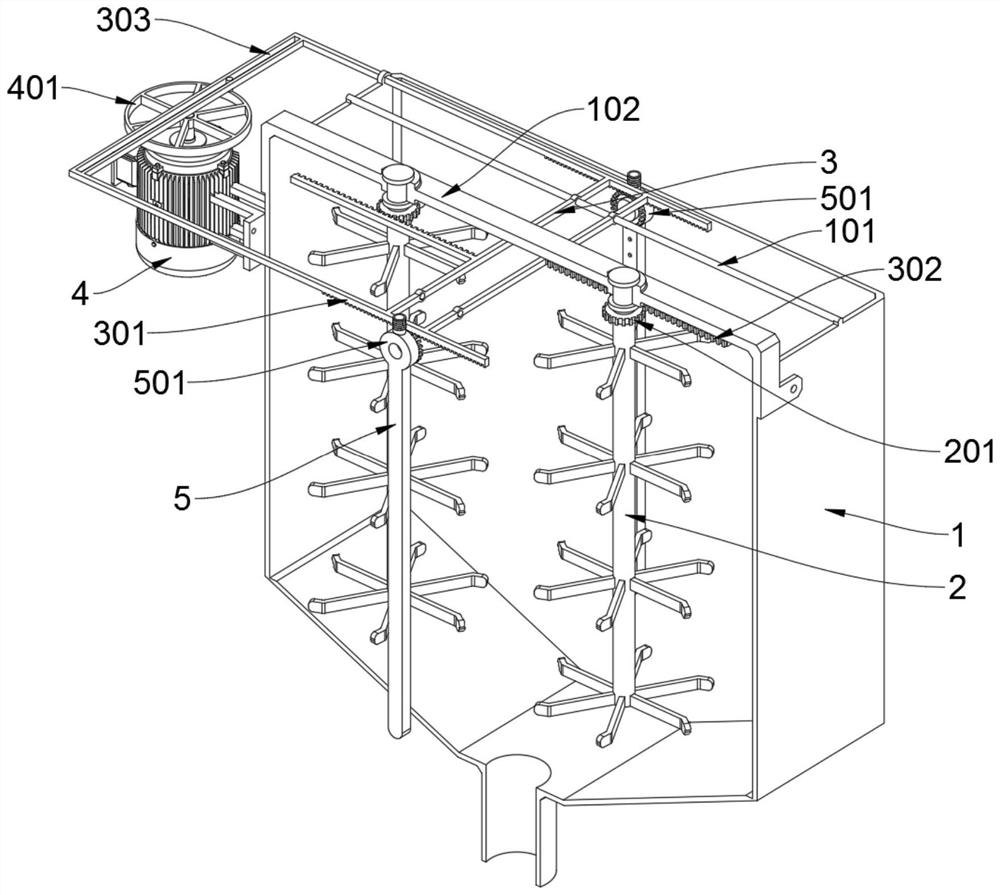

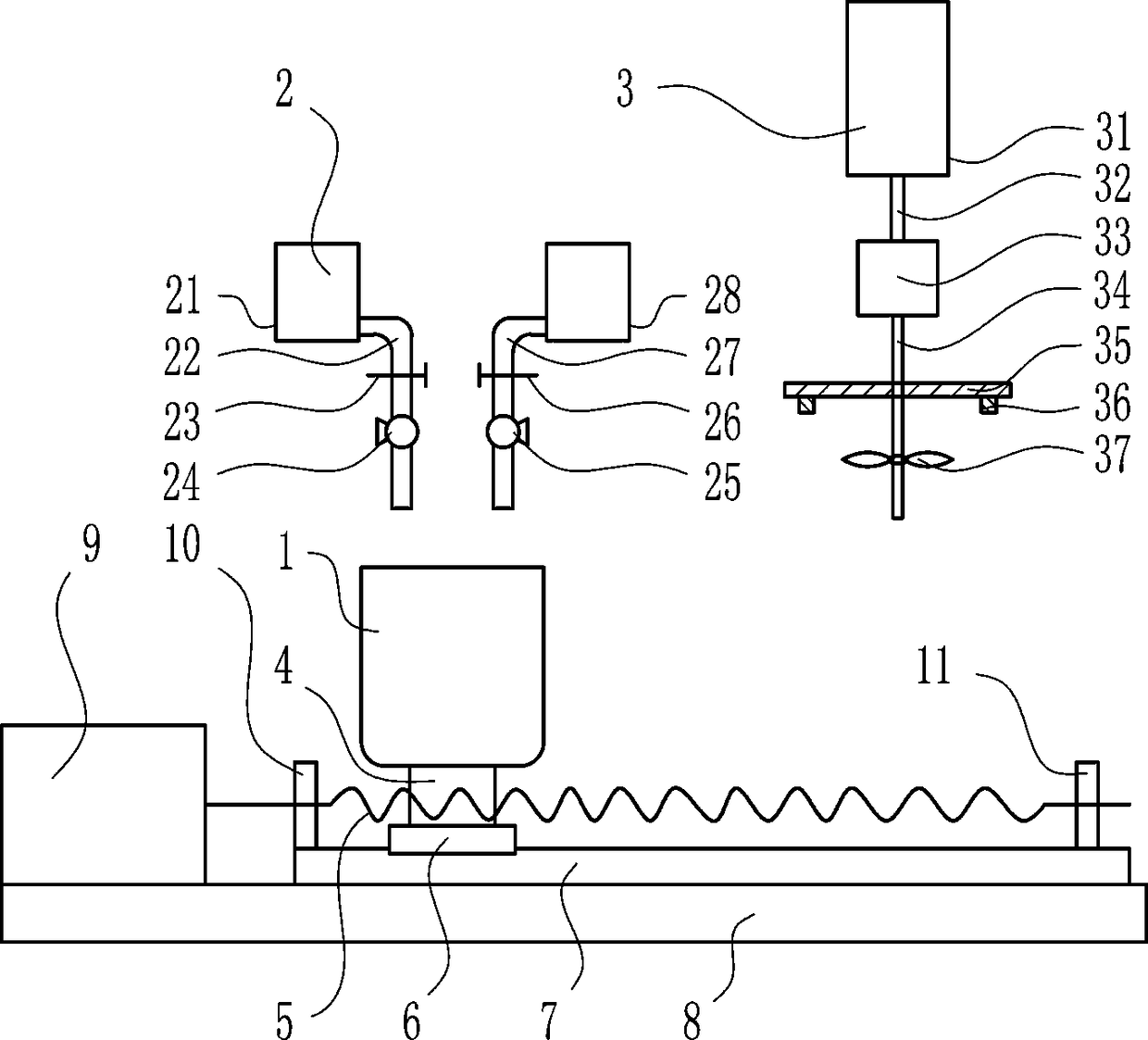

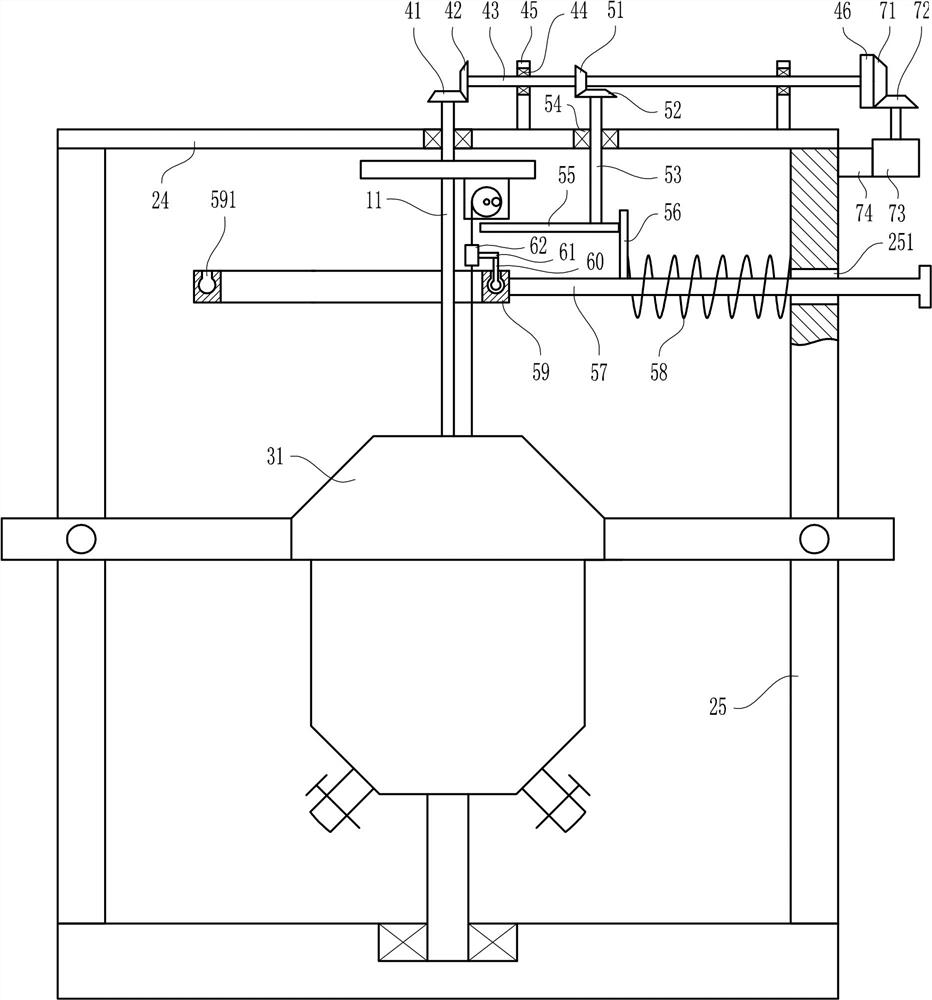

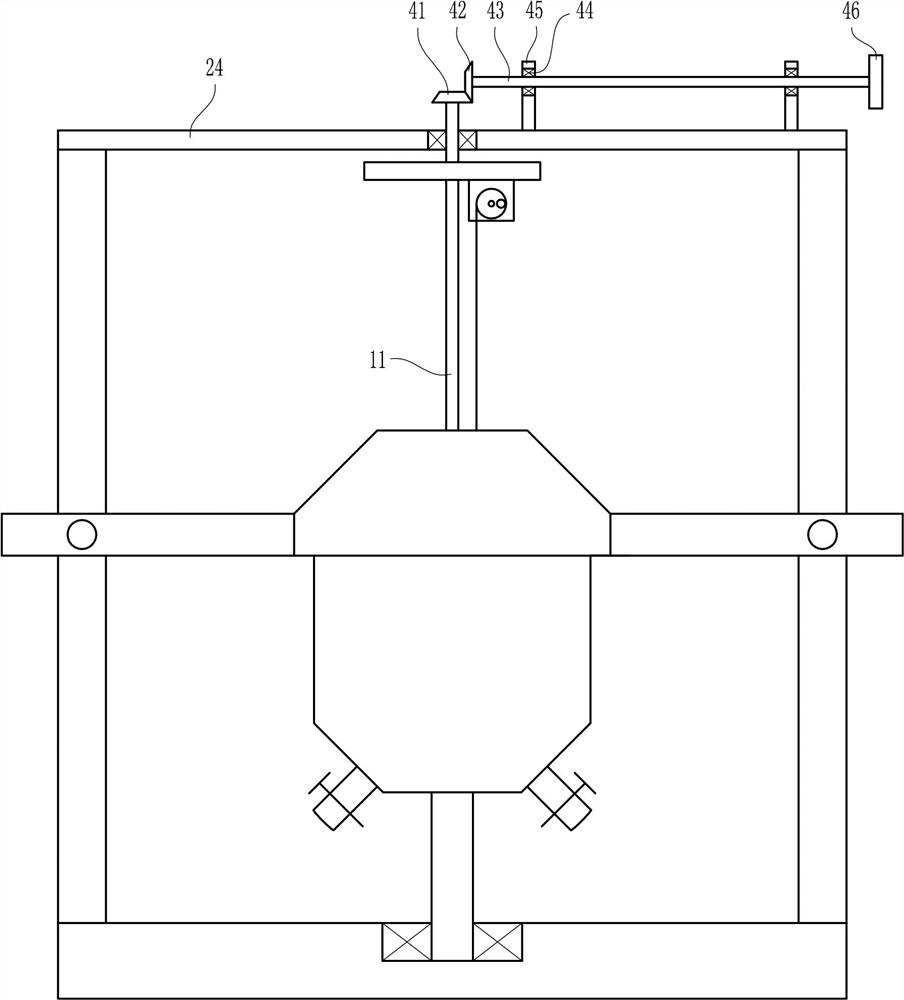

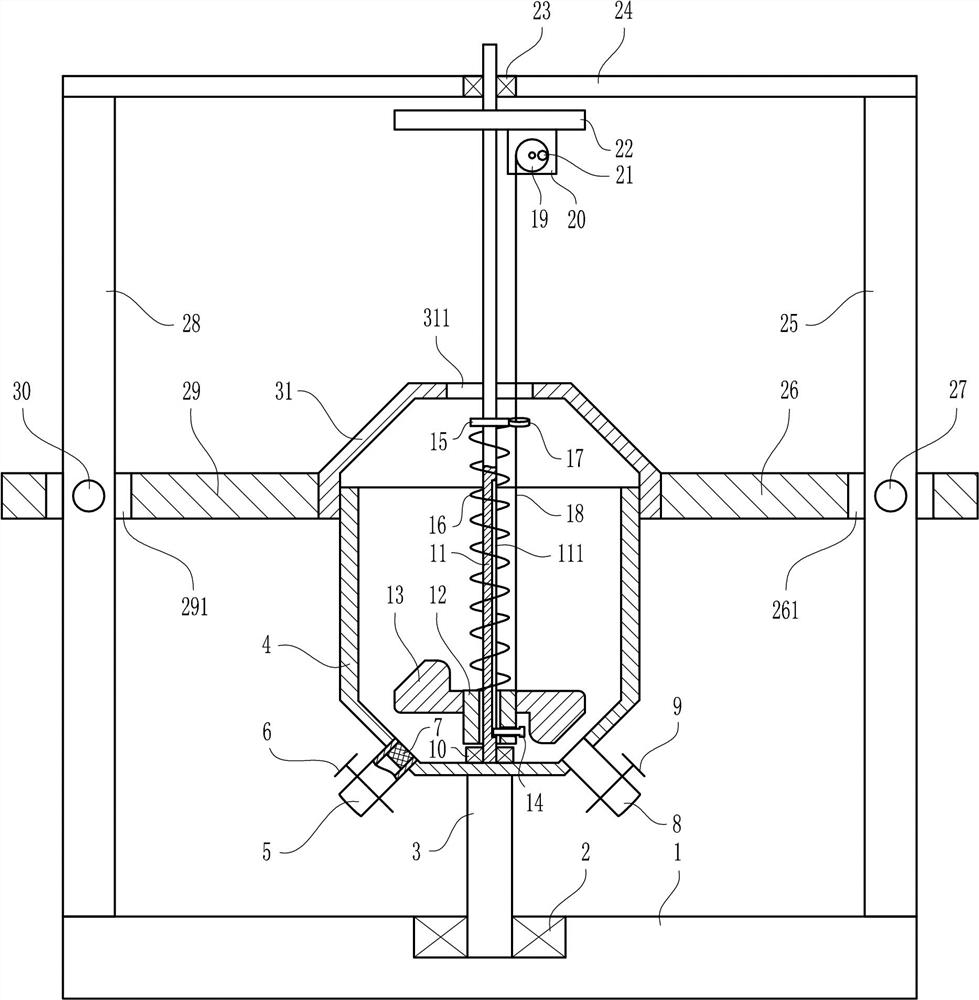

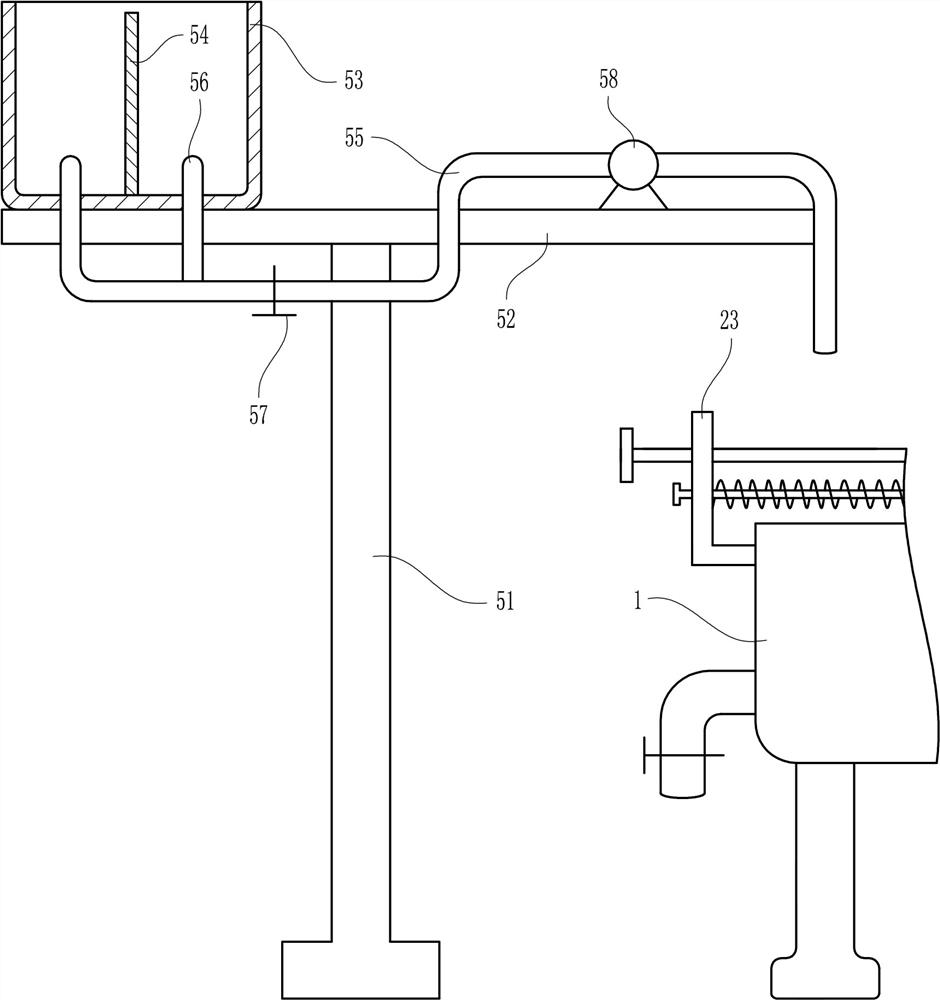

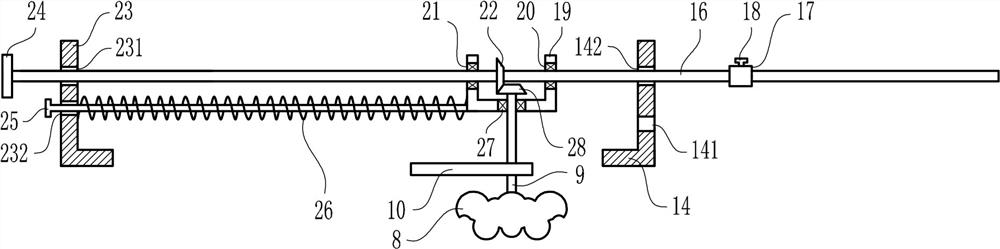

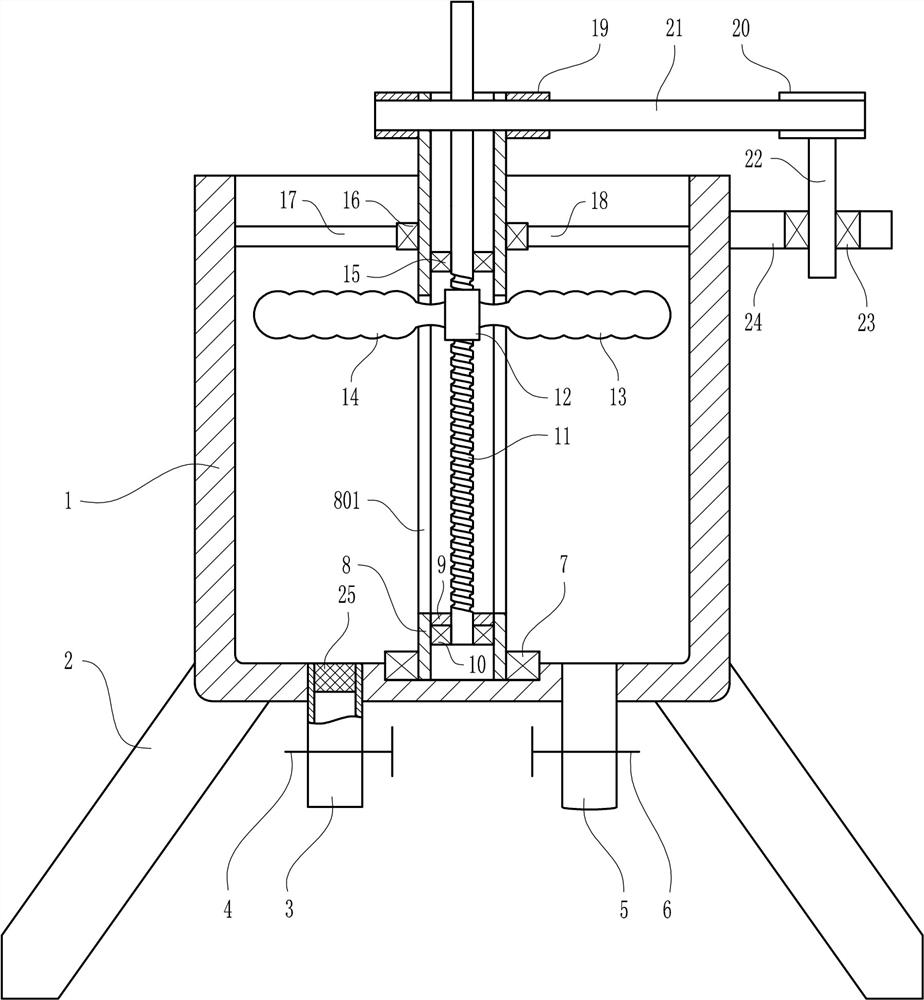

Uniform mixing type co-precipitation precipitation device for rare earth ore precipitation

InactiveCN106947860AMix reaction evenlyGood mix reactionProcess efficiency improvementRare earthPrecipitation

The invention relates to a co-precipitation precipitation device for rare earth ore precipitation, in particular to a uniform mixing type co-precipitation precipitation device for rare earth ore precipitation and aims at achieving the technical purpose of providing the uniform mixing type co-precipitation precipitation device for rare earth ore precipitation. To achieve the above technical purpose, the uniform mixing type co-precipitation precipitation device for rare earth ore precipitation is provided and comprises a precipitation cylinder, a material liquid conveying device, a mixing and stirring device, a nut, a lead screw, a sliding block and the like. The mixing and stirring device is arranged on the right side of the material liquid conveying device and arranged above the precipitation cylinder. The nut is arranged below the precipitation cylinder and fixedly connected with the precipitation cylinder. The nut is arranged on the lead screw and matched with the lead screw. According to the uniform mixing type co-precipitation precipitation device for rare earth ore precipitation, a manner of separation of the precipitation cylinder, the material liquid conveying device and the mixing and stirring device is adopted.

Owner:湖州杉伍家纺有限公司

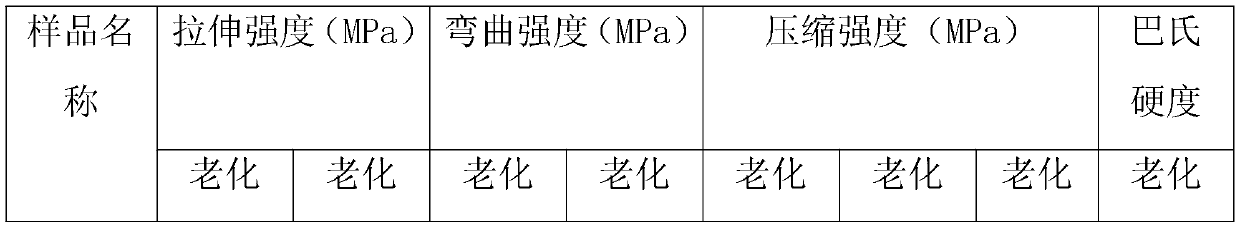

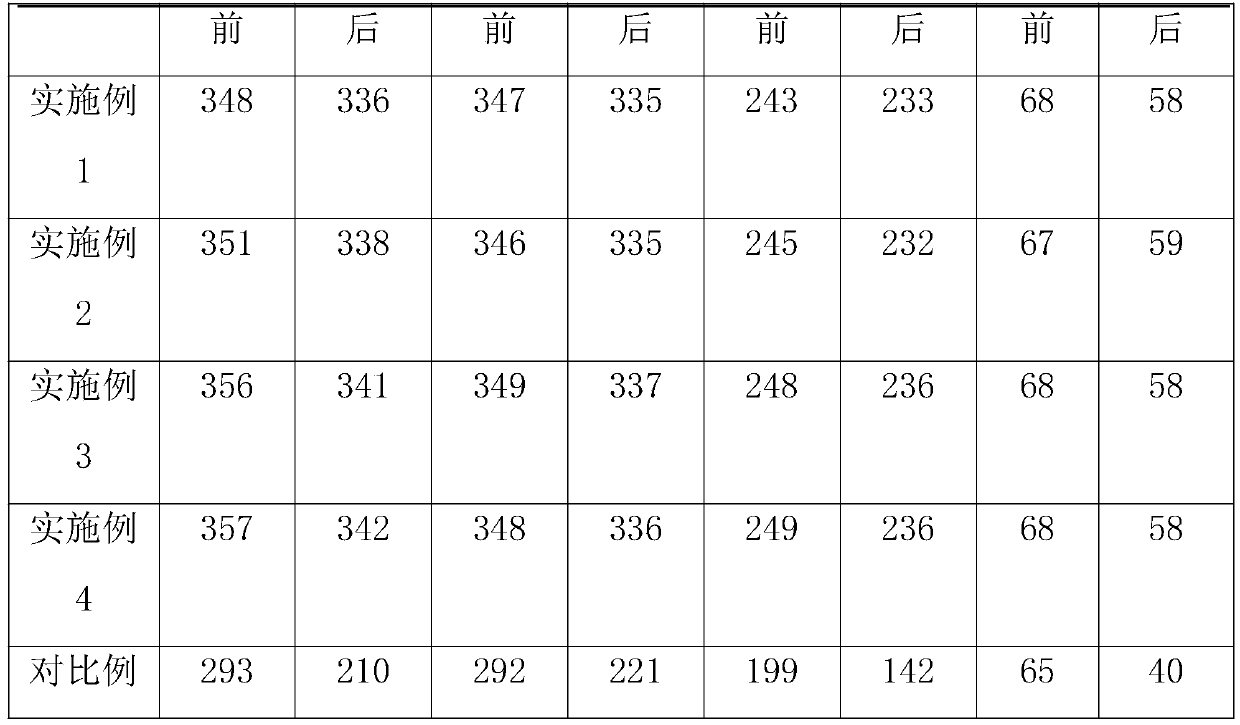

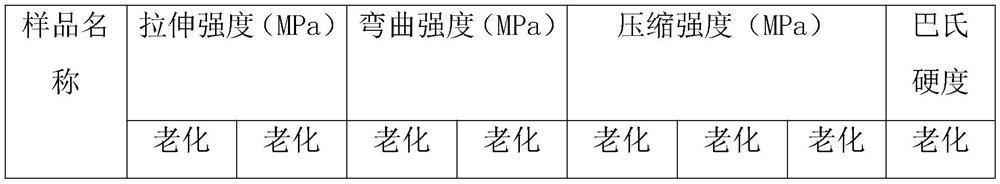

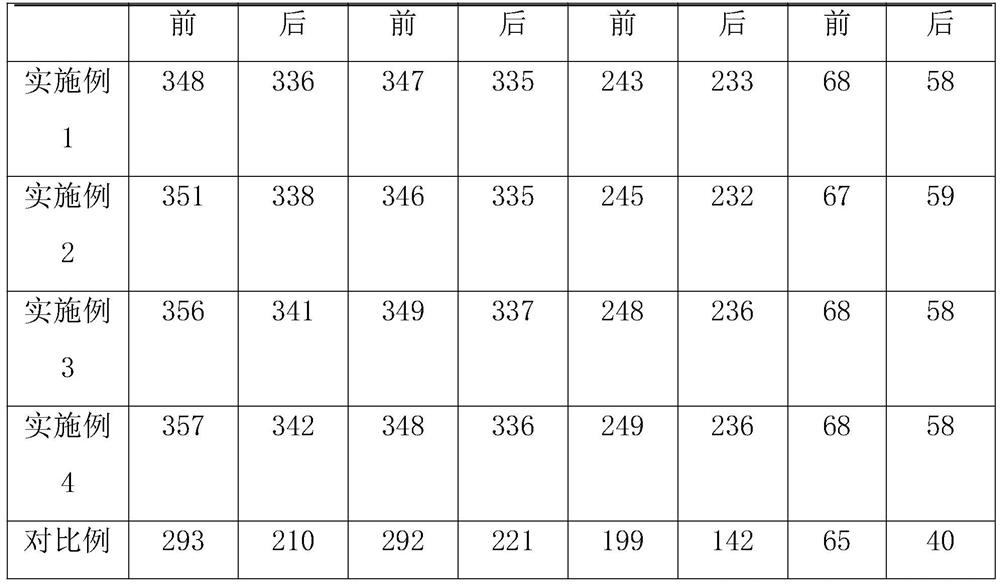

Anti-aging glass fiber reinforced plastic material and preparation method thereof

The invention provides an anti-aging glass fiber reinforced plastic material. The anti-aging glass fiber reinforced plastic material is prepared from the following raw materials in parts by weight: 100 parts of unsaturated polyester resin, 2-8 parts of styrene, 1-3 parts of a curing agent, 1-3 parts of an accelerant, 80-120 parts of glass fibers, 10-40 parts of an illite functional powder material, 1-3 parts of a coupling agent I, 1-2 parts of zinc oxide and 5-6 parts of graphene. The preparation method comprises the following steps: pickling illite powder, washing with water to be neutral, drying, and modifying with a coupling agent II to obtain the illite functional powder material. The illite functional powder material is added and compounded with other raw materials, so that the crosslinking degree between macromolecular chains can be increased; the anti-aging glass fiber reinforced plastic material is particularly suitable for marine environments such as ships, and the salt fog resistance, the aging resistance and the strength of the anti-aging glass fiber reinforced plastic material are remarkably improved compared with those of a common glass fiber reinforced plastic material.

Owner:CHENGDE RENHE MINING CO LTD

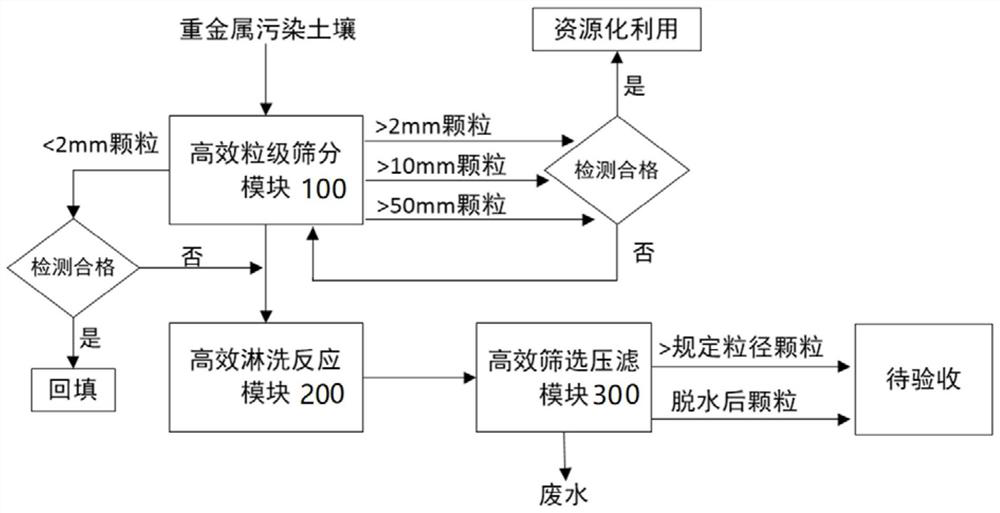

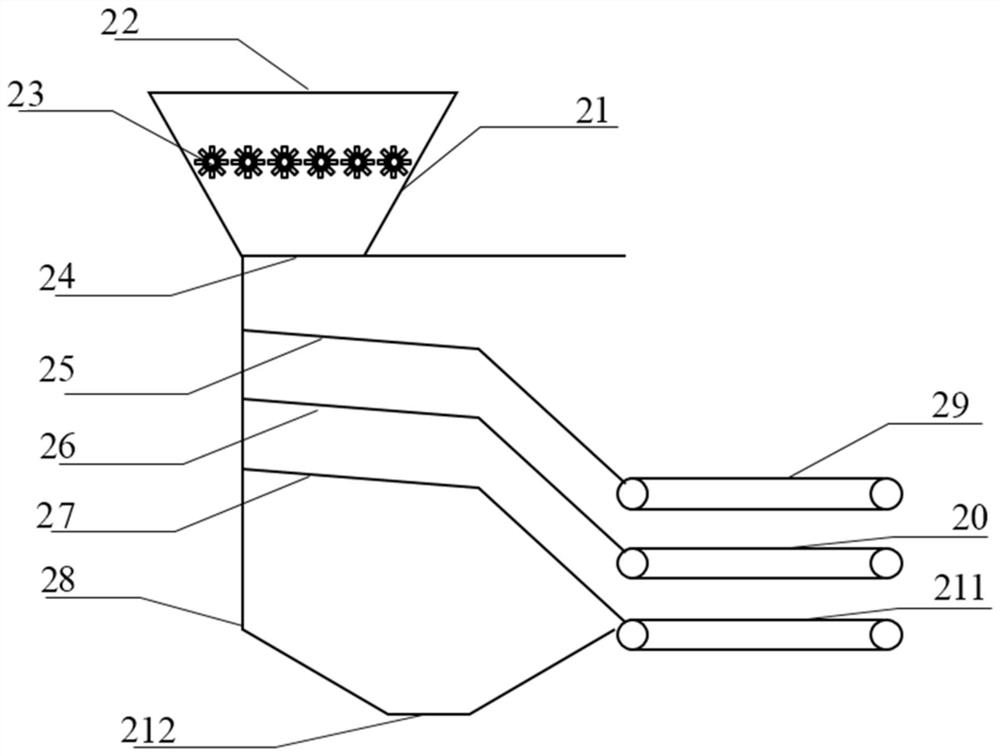

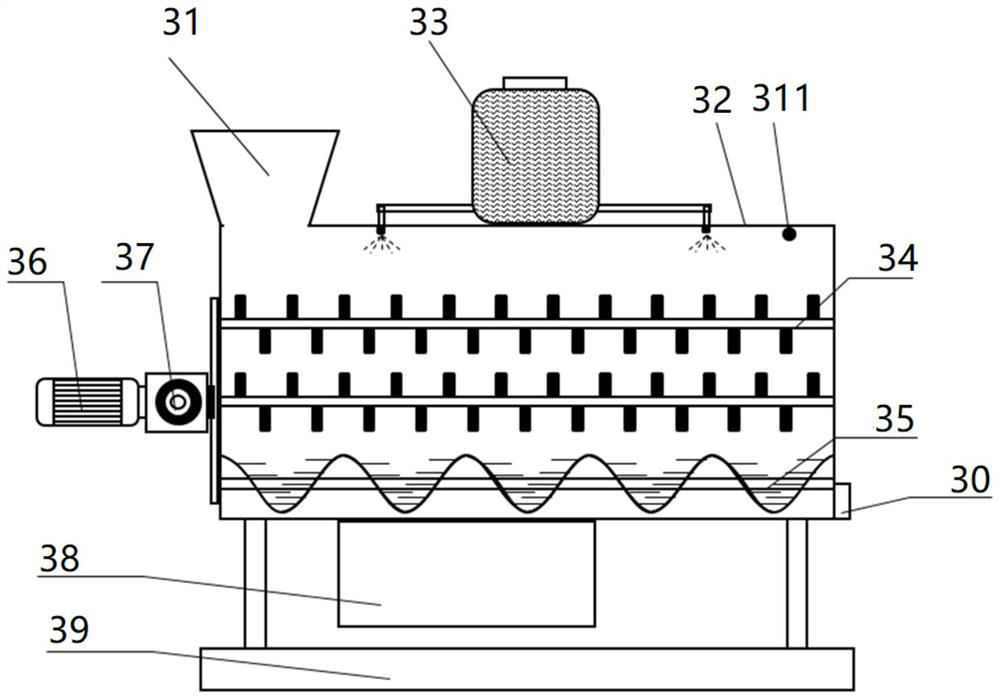

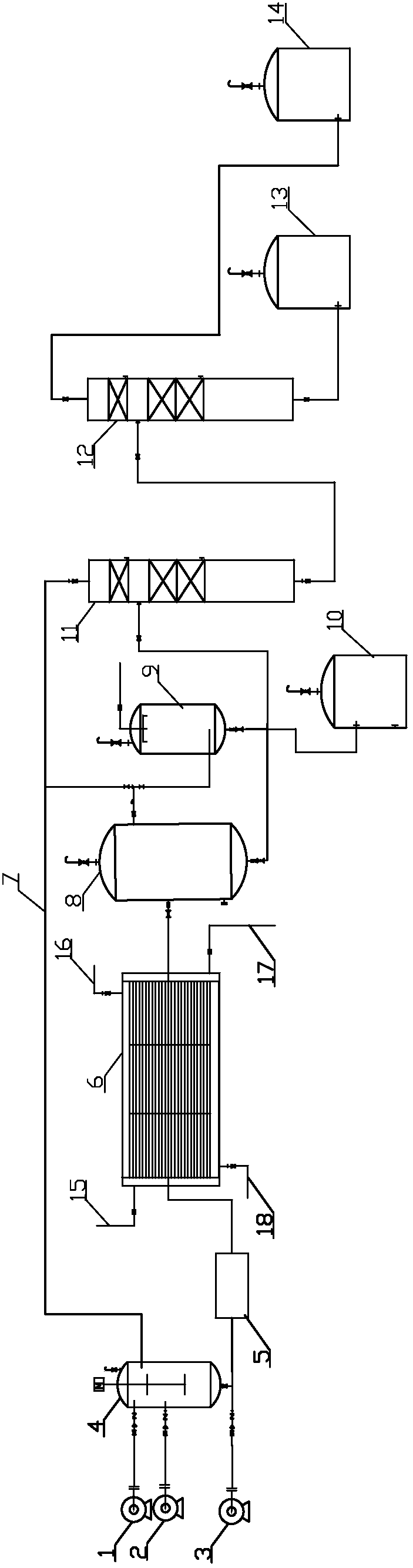

Integrated efficient leaching equipment for heavy metal contaminated soil

ActiveCN112588806AAvoid wastingAvoid deficienciesSievingScreeningSoil scienceEnvironmental engineering

The invention provides integrated efficient leaching equipment for heavy metal contaminated soil, which comprises an efficient fraction screening module configured to perform efficient fraction screening on contaminated soil so as to separate soil with a particle size less than a specified particle size for input into an efficient leaching reaction module, thereby achieving a function of reducingthe leaching remediation amount, an efficient leaching reaction module configured to add a medicament in a corresponding mode for leaching according to a heavy metal pollutant concentration detectionresult and promote a pollutant leaching separation function through efficient stirring and ultrasonic oscillation, and an efficient precipitation and filter pressing module configured to screen and filter the soil discharged by the efficient leaching reaction module.

Owner:苏州精英环保有限公司

Technology and device for preparing chloroacetic acid through catalytic chlorination by means of micro-channel reactor

ActiveCN108640828AImprove reaction efficiencyReduce difficultyOrganic compound preparationCarboxylic compound preparationAcetic acidAcetic anhydride

The invention relates to chloroacetic acid,in particular to a technology and device for preparing chloroacetic acid through catalytic chlorination by means of a micro-channel reactor. The technology comprises the following steps that acetic acid and acetic anhydride are pretreated to form a mixed solution,the mixed solution and liquid chlorine are mixed in a pipeline in front of a pre-catalytic tank,and the mixture enters the pre-catalytic tank with a solid acid catalyst SO42- / ZrO2-Eu2O3 attached to the inner wall; then the mixture enters the micro-channel reactor with a solid acid catalyst SO42- / ZrO2-Eu2O3 attached to the inner wall of a micro channel,reaction is carried out,and chloroacetic acid reaction liquid is obtained; after gas-liquid separation,a chloroacetic acid product is evaporated out. According to the technology,solid superacid SO42- / ZrO2-Eu2O3 is attached to the inner wall of the pre-catalytic tank and the inside of the micro channel of the micro-channel reactor,the reaction efficiency is improved,the consumption of chlorine is reduced,the difficulty of subsequent treatment is reduced,and the operation cost is reduced.

Owner:山东民基新材料科技有限公司

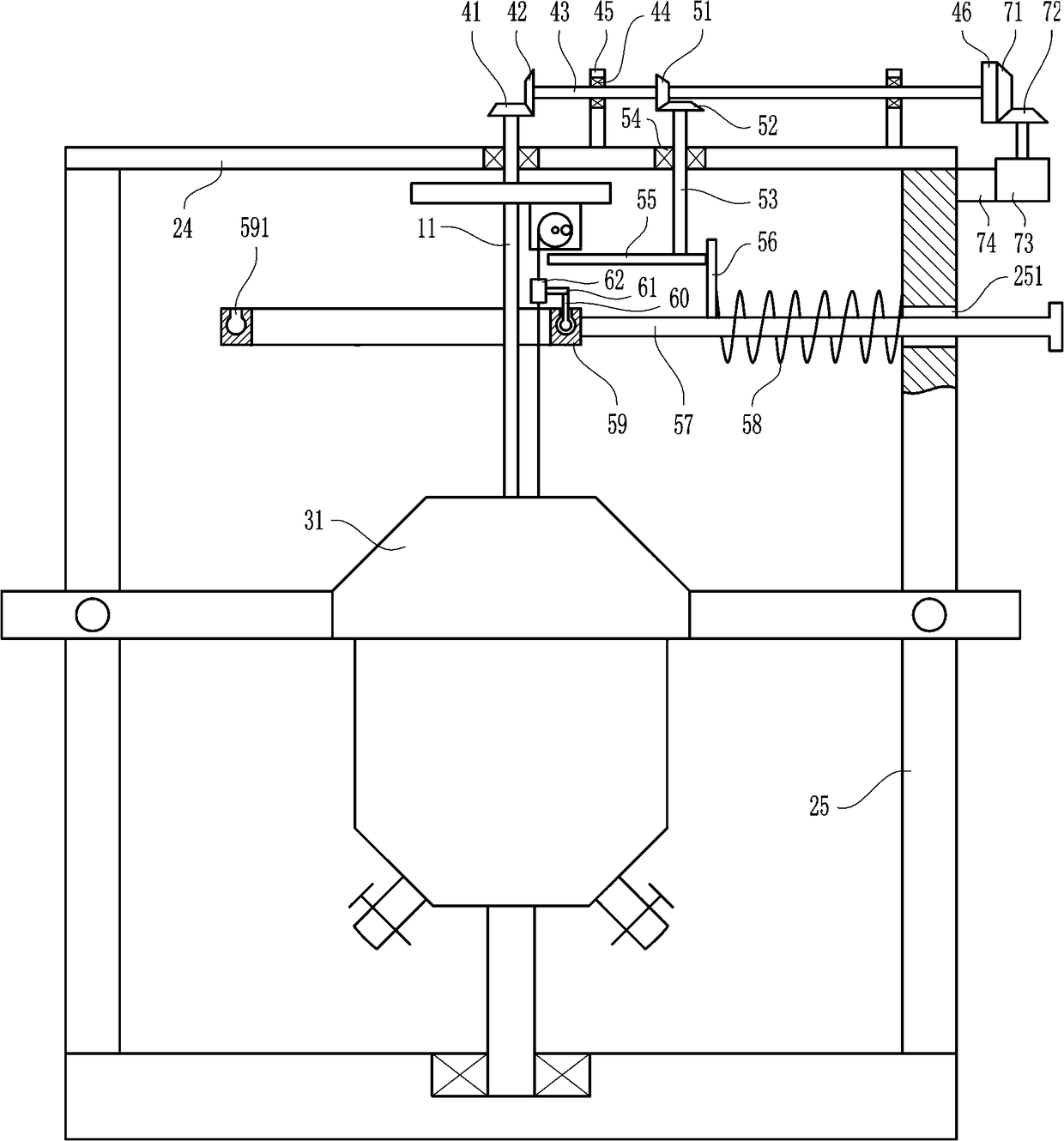

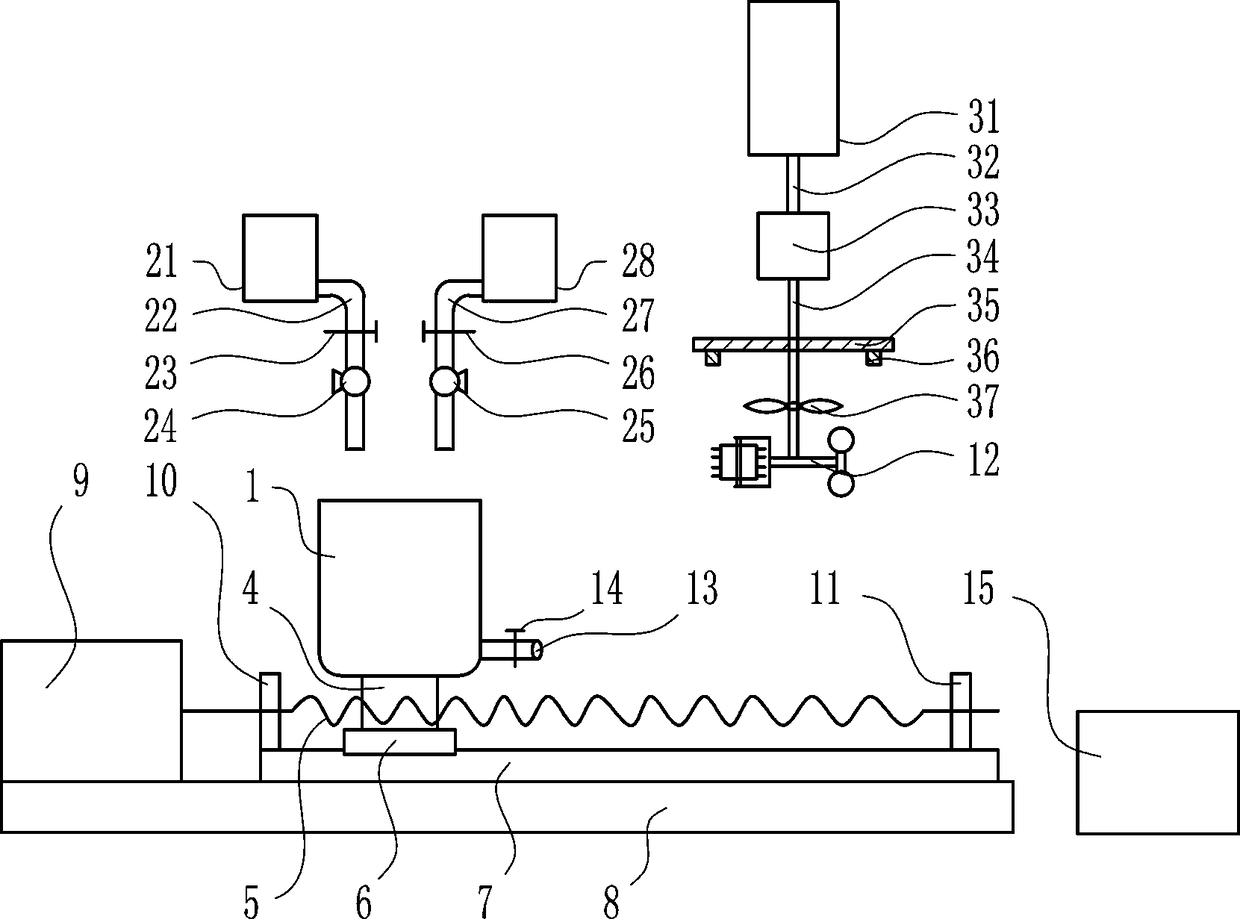

Multi-mode stirring type co-precipitation precipitation device for rare earth

ActiveCN109126669AVarious mixing methodsEasy to operateChemical/physical/physico-chemical stationary reactorsProcess efficiency improvementRare earthUltimate tensile strength

The invention relates to a co-precipitation precipitation device for rare earth, in particular to a multi-mode stirring type co-precipitation precipitation device for the rare earth. To solve the technical problem of providing the multi-mode stirring type co-precipitation precipitation device, capable of being adjusted and stirring rare earth mixture liquid in various ways, for the rare earth, thetechnical scheme of the multi-mode stirring type co-precipitation precipitation device for the rare earth is that the multi-mode stirring type co-precipitation precipitation device for the rare earthcomprises various parts such as a base, a first bearing, a support shaft, a cylinder, a drain pipe, a first valve, a filter screen, a discharge pipe, a second valve, a second bearing and long connecting shaft; the first bearing is embedded in the base; the lower end of the support shaft and the first bearing are in interference connection. The multi-mode stirring type co-precipitation precipitation device for the rare earth has the advantages of being easy to adjust and capable of stirring the rare earth mixture liquid in various ways, realizing uniform mixing reaction of the rare earth mixture liquid, having simple structure, easy operation and low labor intensity, and being time-saving and labor-saving.

Owner:东港智科产业园有限公司

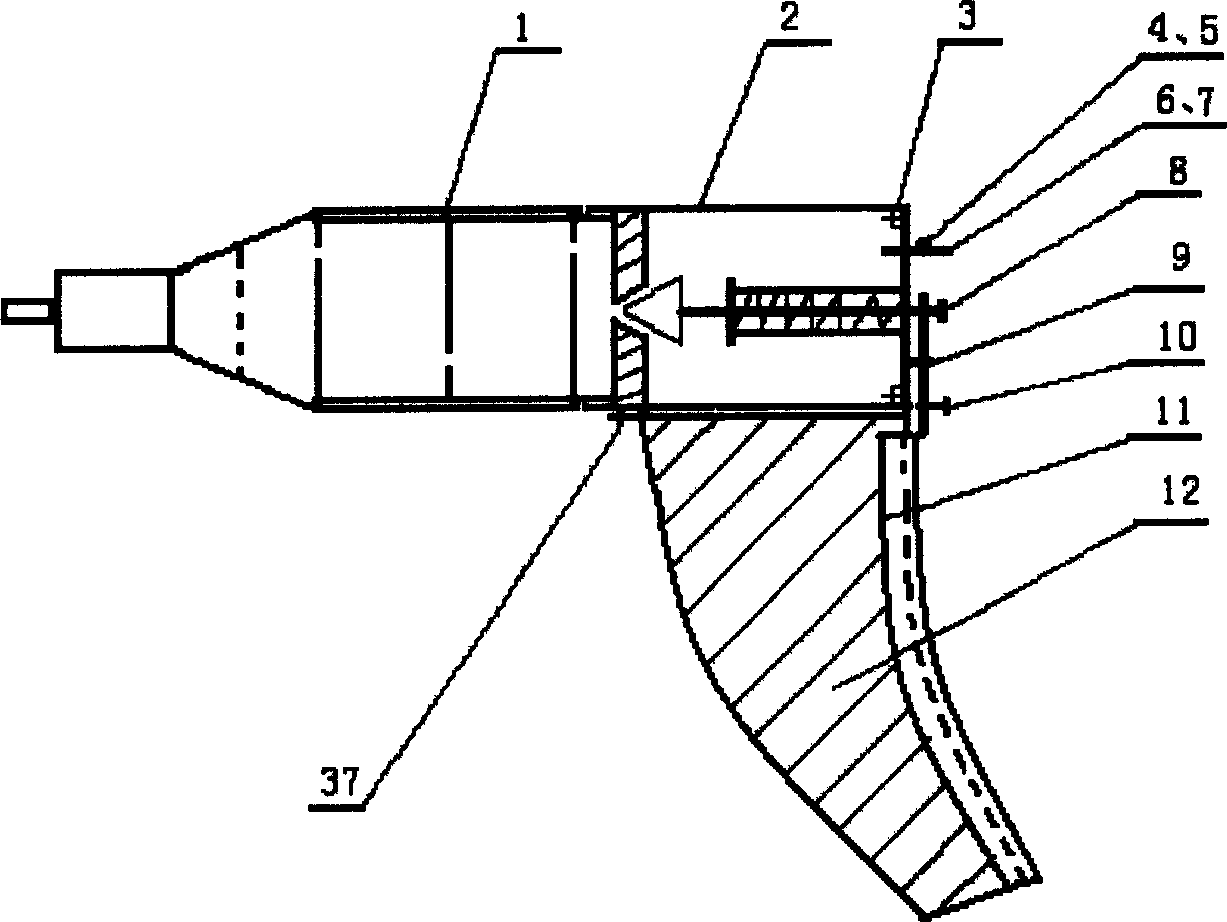

Double component nanometer material spray gun

InactiveCN1672803AMix reaction evenlyImprove responseLiquid spraying apparatusMaterial supplyNanometre

The double component nanometer material spray gun has one nozzle with material mixing reaction bin; one gun body with the first material bin and the second material bin, material bin leading flow channel and flow channel controlling valve; and one gun handle hinged to the gun body and with gun switch and spray amount controller. The material mixing reaction bin makes the nanometer materials mix and react homogeneously. The spray gun is matched with pressurized material supply system for spraying various kinds of double component material.

Owner:TAIYUAN UNIV OF TECH

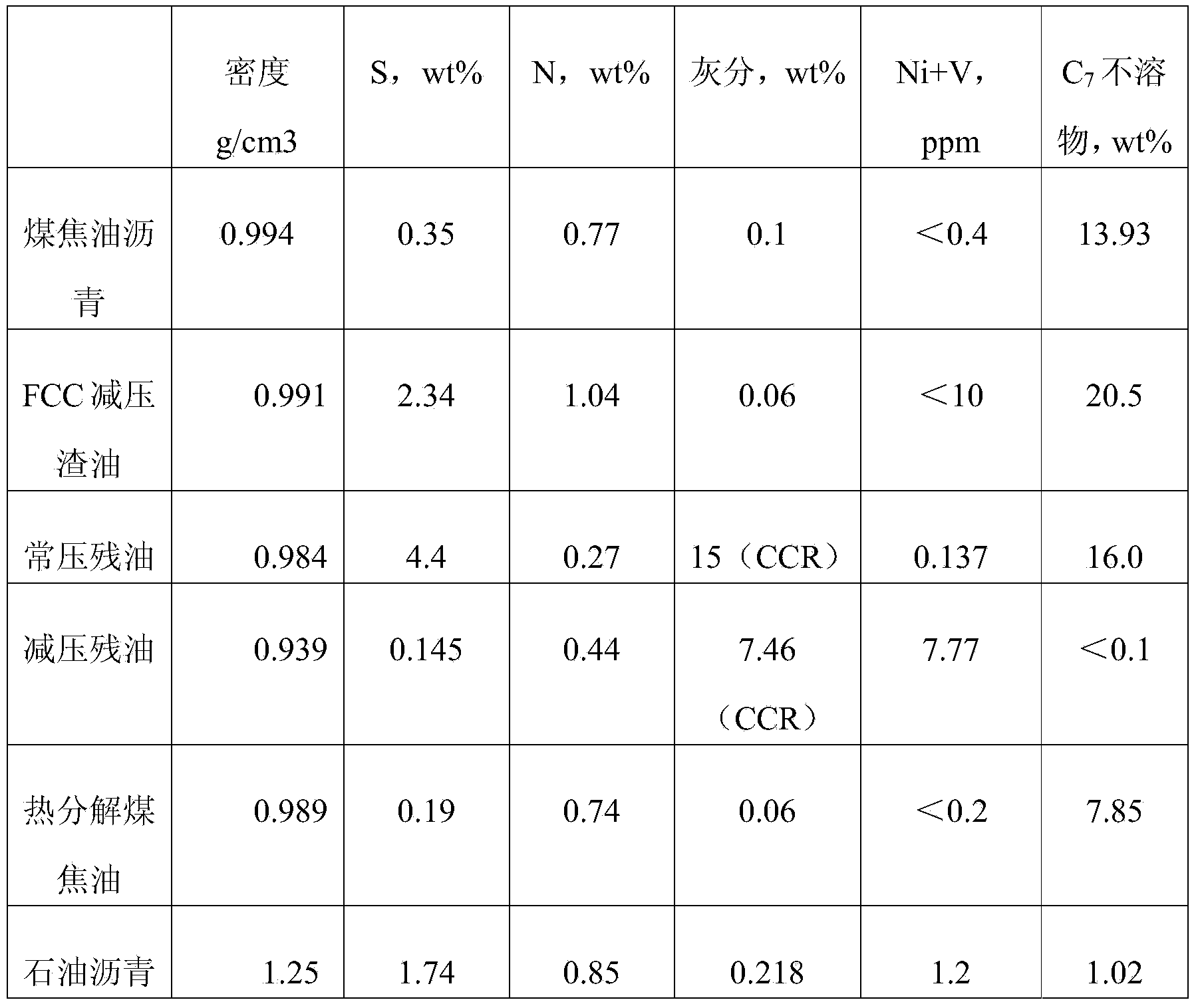

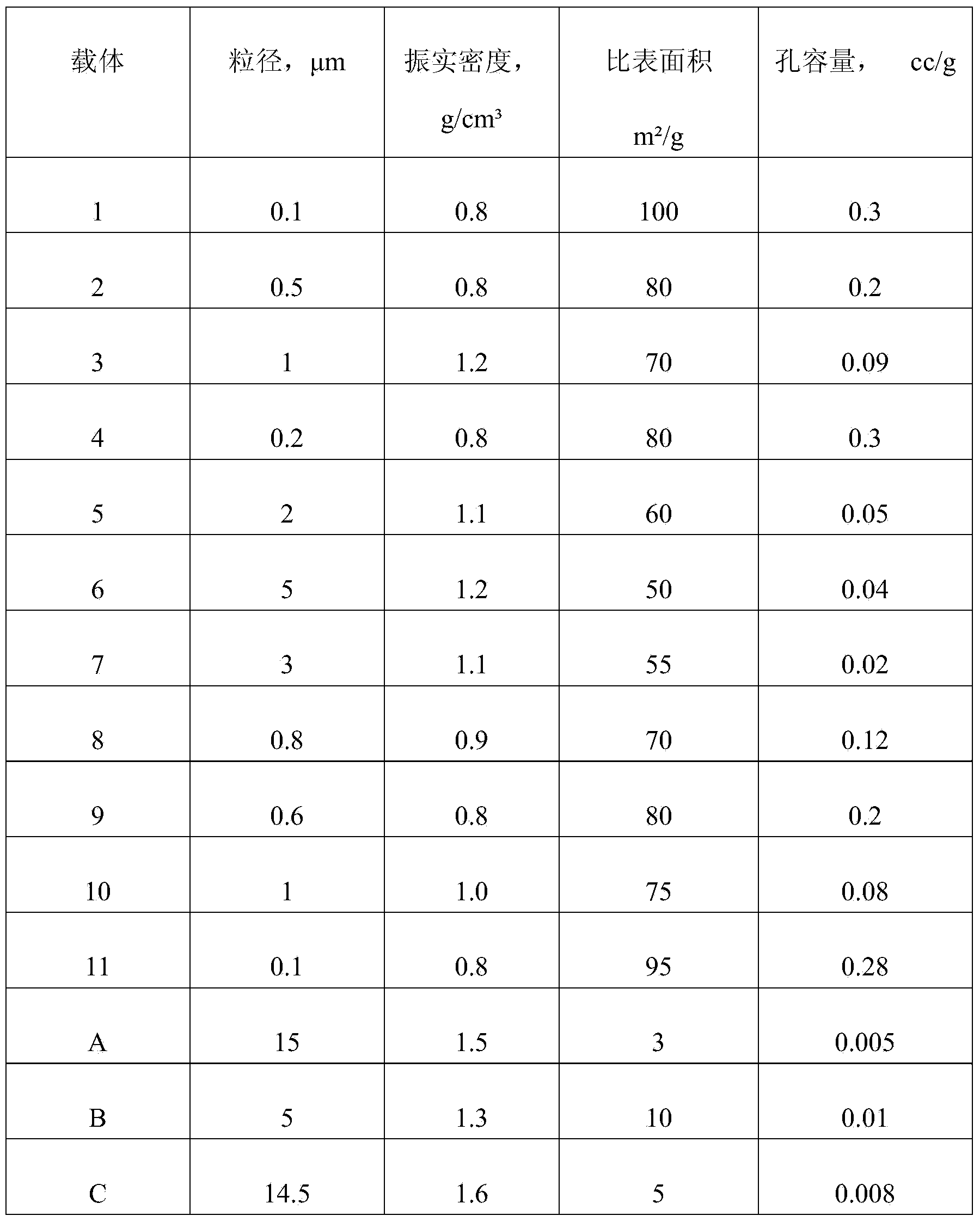

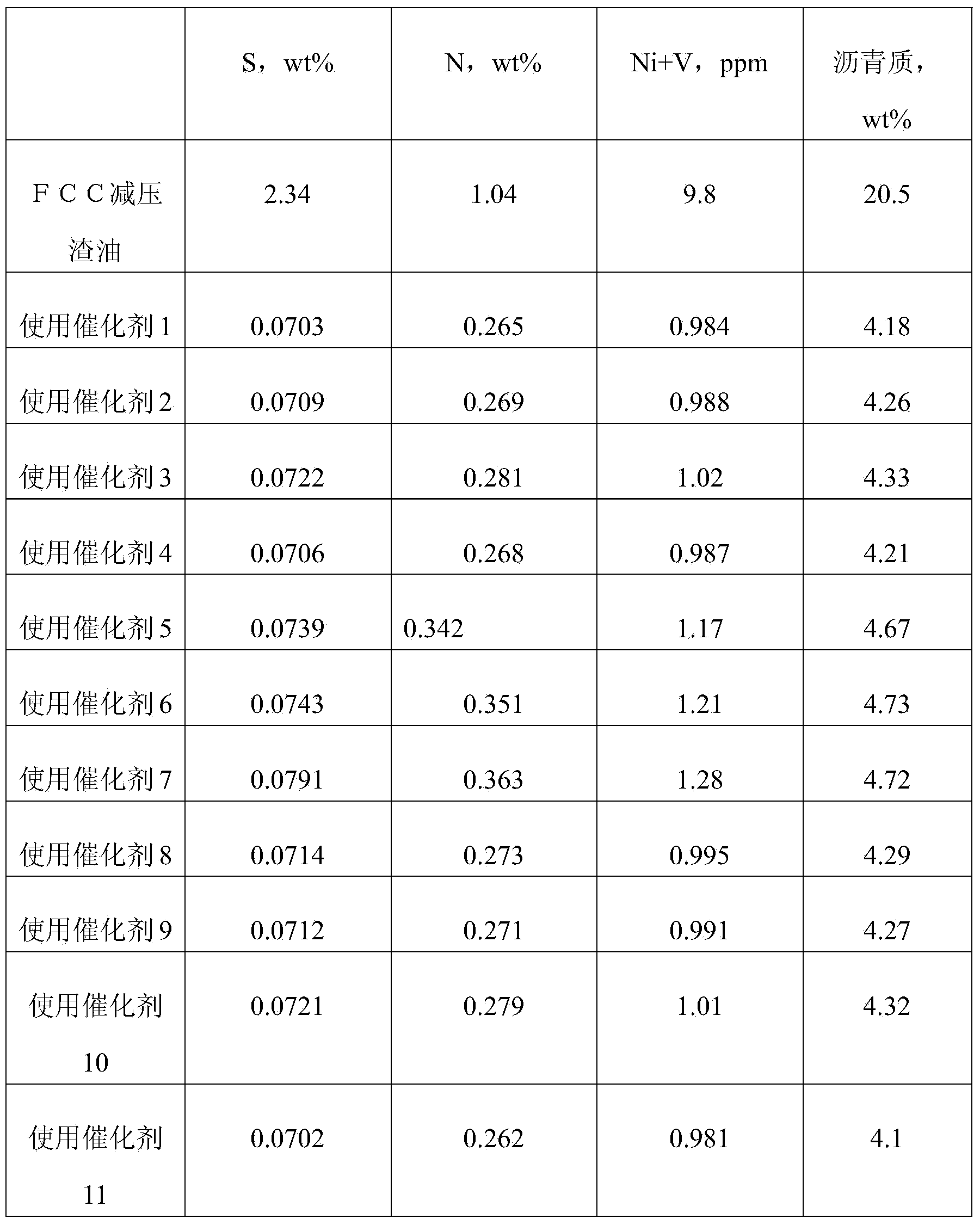

Catalyst carrier, preparation method thereof and heavy oil hydrogenation catalyst prepared therefrom

ActiveCN103894169AHigh activitySmall particle sizeCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention discloses a preparation method of a catalyst carrier. The method comprises the following steps: (1) carrying out heat treatment on the raw material in the non-oxide gas atmosphere under the normal pressure at a temperature of 400-520 DEG C for 1-12 hours to obtain intermediate phase pellets, wherein the raw material comprises one or a mixture of more materials in coal tar pitch and petroleum heavy oil; (2) carrying out carbonization on the intermediate phase pellets in the non-oxide gas atmosphere under the normal pressure at a temperature of 900-1300 DEG C for 0.5-6 hours. The invention also discloses the properties of the prepared carrier, and a hydrogenation catalyst prepared from the catalyst carrier. The catalyst carrier is small in particle size, low in density and easy to disperse, has larger specific surface area and pore volume, and is beneficial to the load of active components, thus being suitable for preparing s heavy oil hydrogenation thermal decomposition catalyst which can be used for removing sulfur, nitrogen, metal and heavy impurities in the oil.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

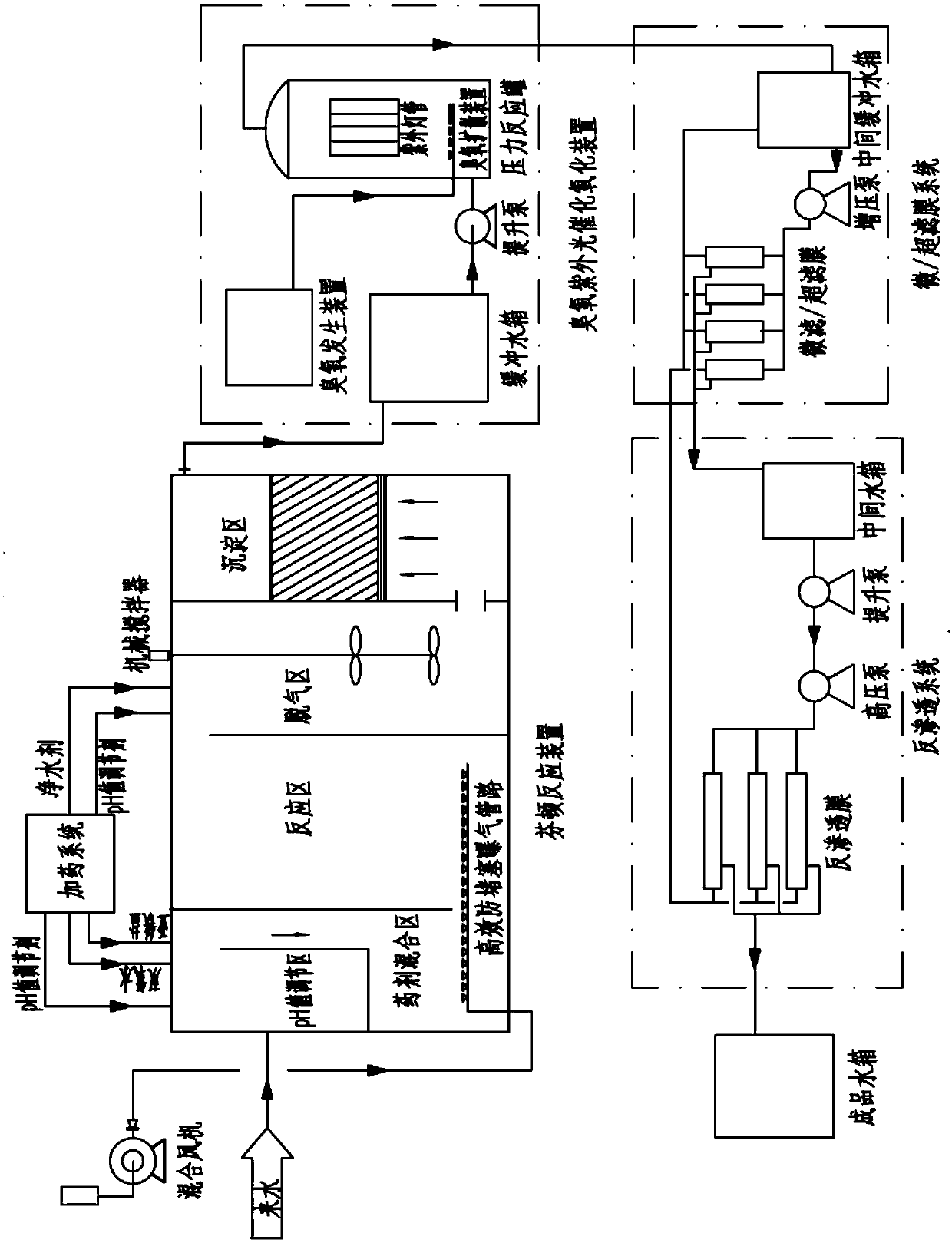

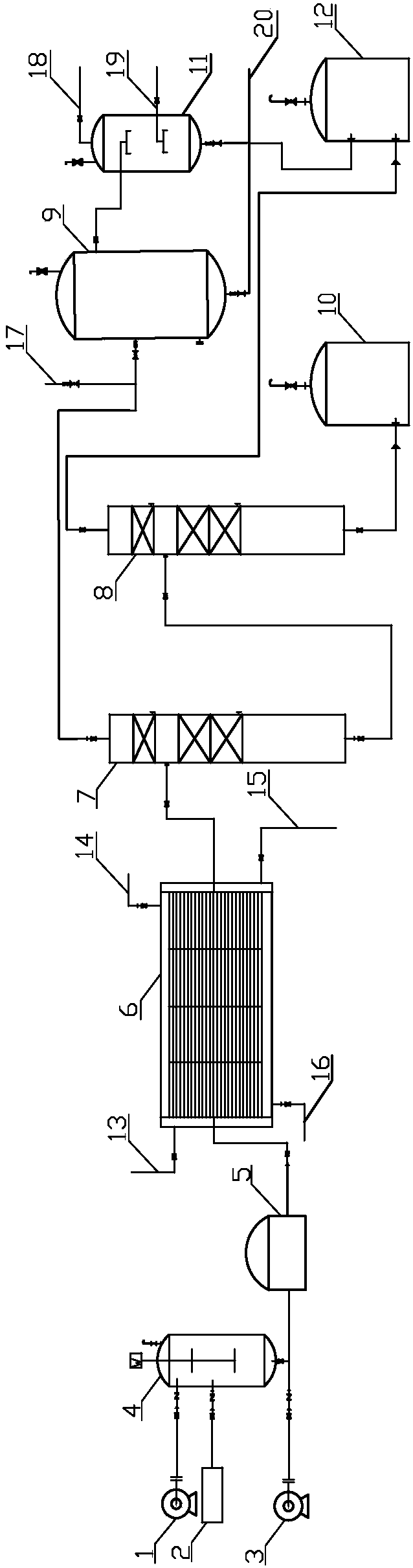

Process method for treating refractory CODs (chemical oxygen demands) in produced water of high-sulfur-content gas field

InactiveCN110563223AReduce dosageReduce outputWaste water treatment from quariesWater/sewage treatment by irradiationVolatile phenolsUltrafiltration

The invention belongs to the technical field of ground engineering of oil and gas fields and in particular relates to a process for removing refractory CODs (chemical oxygen demands) in produced waterof a high-sulfur-content gas field. Aiming at situations that refractory COD components in produced water of a high-sulfur-content gas field and CODs in fed water after pretreatment are generally 1000mg / L and are refractory CODs, and to achieve resource recycling of the produced water of the high-sulfur-content gas field, the invention discloses the process applicable to removal of refractory CODs in produced water of the high-sulfur-content gas field, a treatment process of "Fenton oxidation+ozone ultraviolet photocatalytic oxidation+micro / ultrafiltration membrane+reverse osmosis membrane" is adopted, and organic components such as refractory CODs and volatile phenols in the produced water of the high-sulfur-content gas field can be degraded and removed. In a situation that the CODs of produced water are less than or equal to 1000mg / L, the process is adopted for treatment, and CODs of an effluent after treatment qualification are less than or equal to 50mg / L.

Owner:中石化石油工程技术服务有限公司 +1

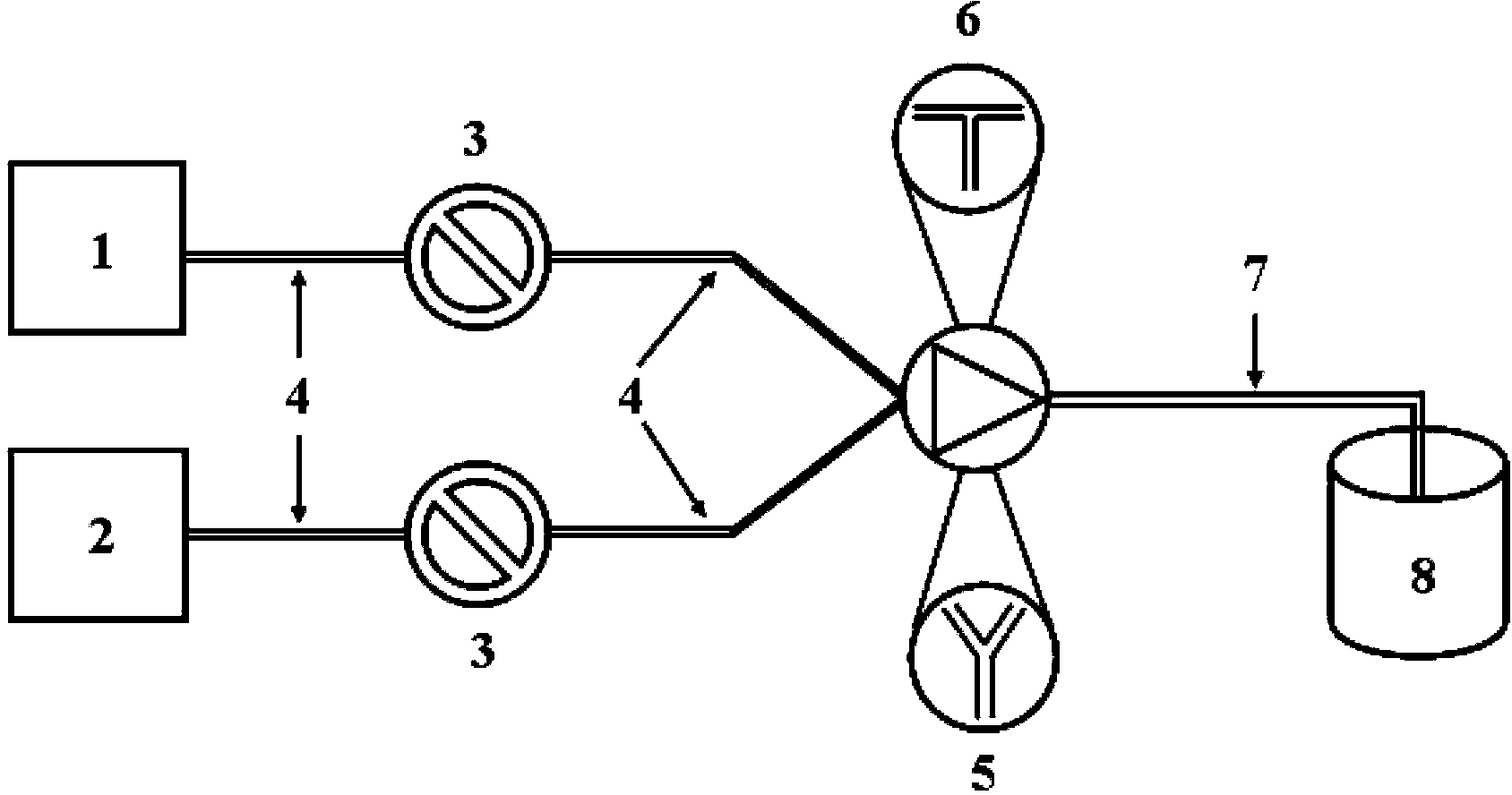

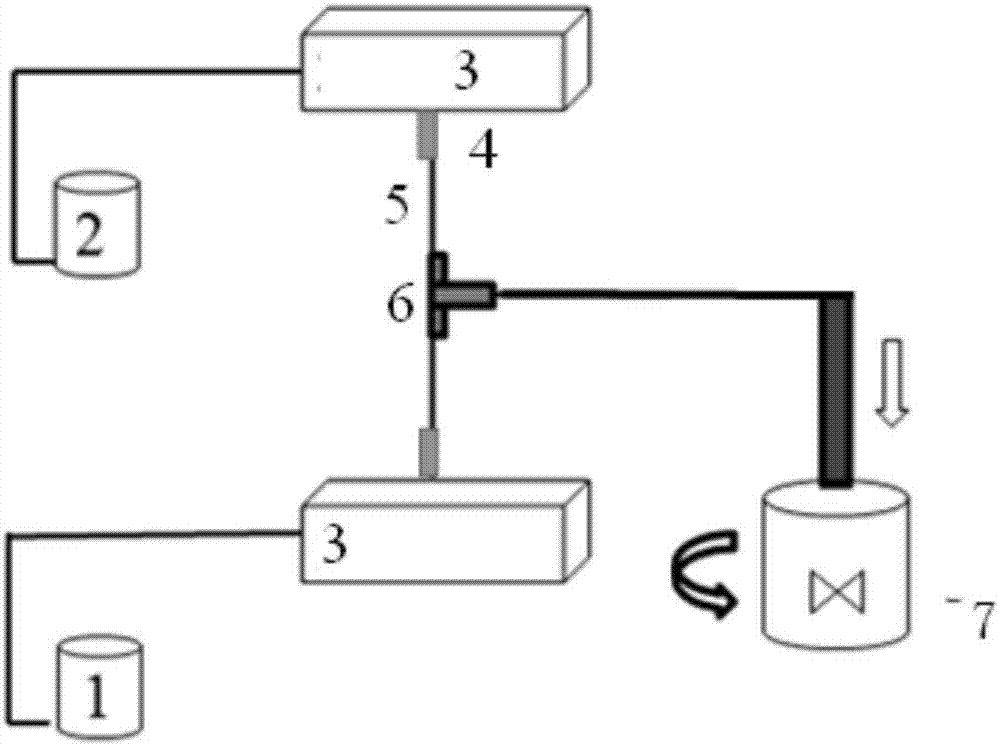

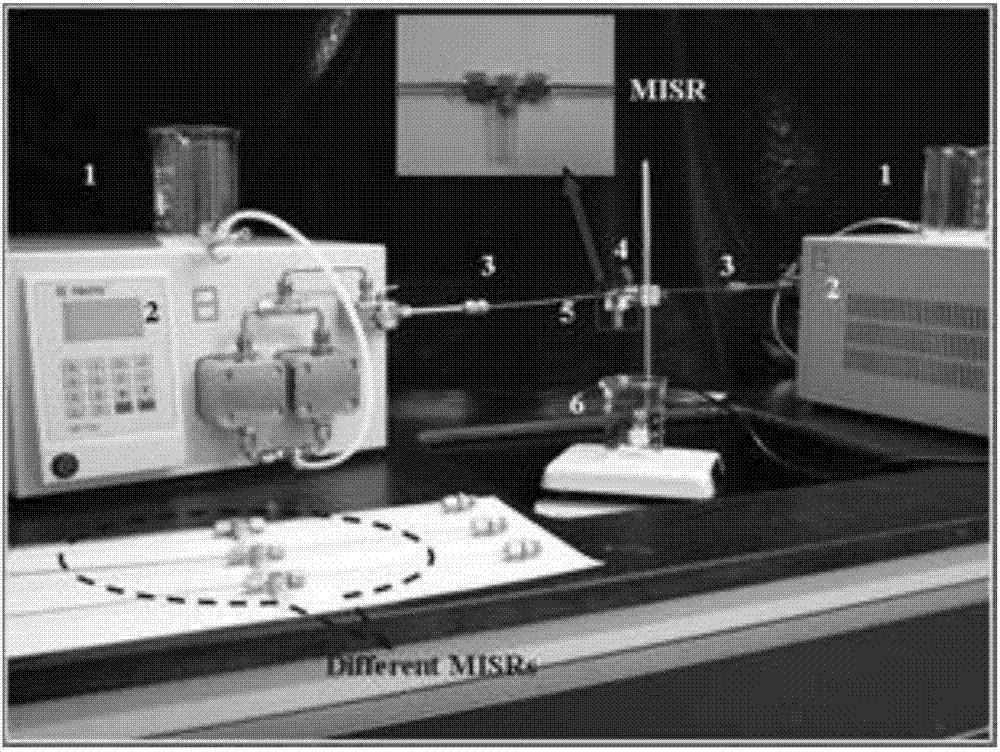

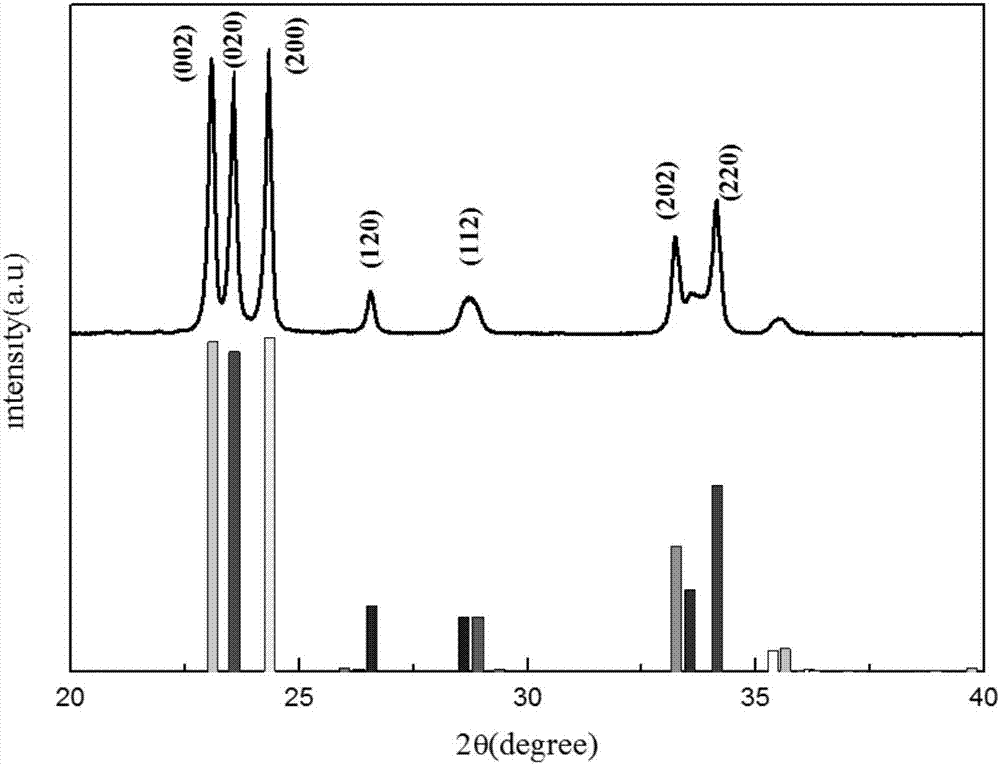

Apparatus and method for preparing ultrafine WO3

InactiveCN107500360AEnhanced Mixed Reaction ProcessWell mixedTungsten oxides/hydroxidesNanotechnologyTungstateEngineering

The invention discloses an apparatus and a method for preparing ultrafine WO3, and belongs to the technical field of powder metallurgy, and the apparatus and the method can be applied to the preparation of the ultrafine WO3 powder. The apparatus comprises two liquid reservoirs for storage of reaction liquids and constant-flux pumps which are respectively connected with the liquid reservoirs, the constant-flux pumps are connected with a T-type tee by capillary tubes, the vertical end of the T-type tee is a reaction liquid outlet, and the apparatus belongs to a micro impinging stream reactor. The reaction method is as follows: a hydrochloric acid solution and a tungstate solution are impacted and mixed through the T-type tee connector to synthesize precursor tungstic acid, and the precursor tungstic acid is calcined to obtain the ultrafine WO3 powder. The preparation method and the apparatus can be used to strengthen the mixing reaction process of components to obtain the WO3 with a regular morphology, small particle size and narrow particle size range. The method has the advantages of simple process, high control precision, continuous production and many other advantages, and has a good industrialization prospect.

Owner:BEIJING UNIV OF CHEM TECH

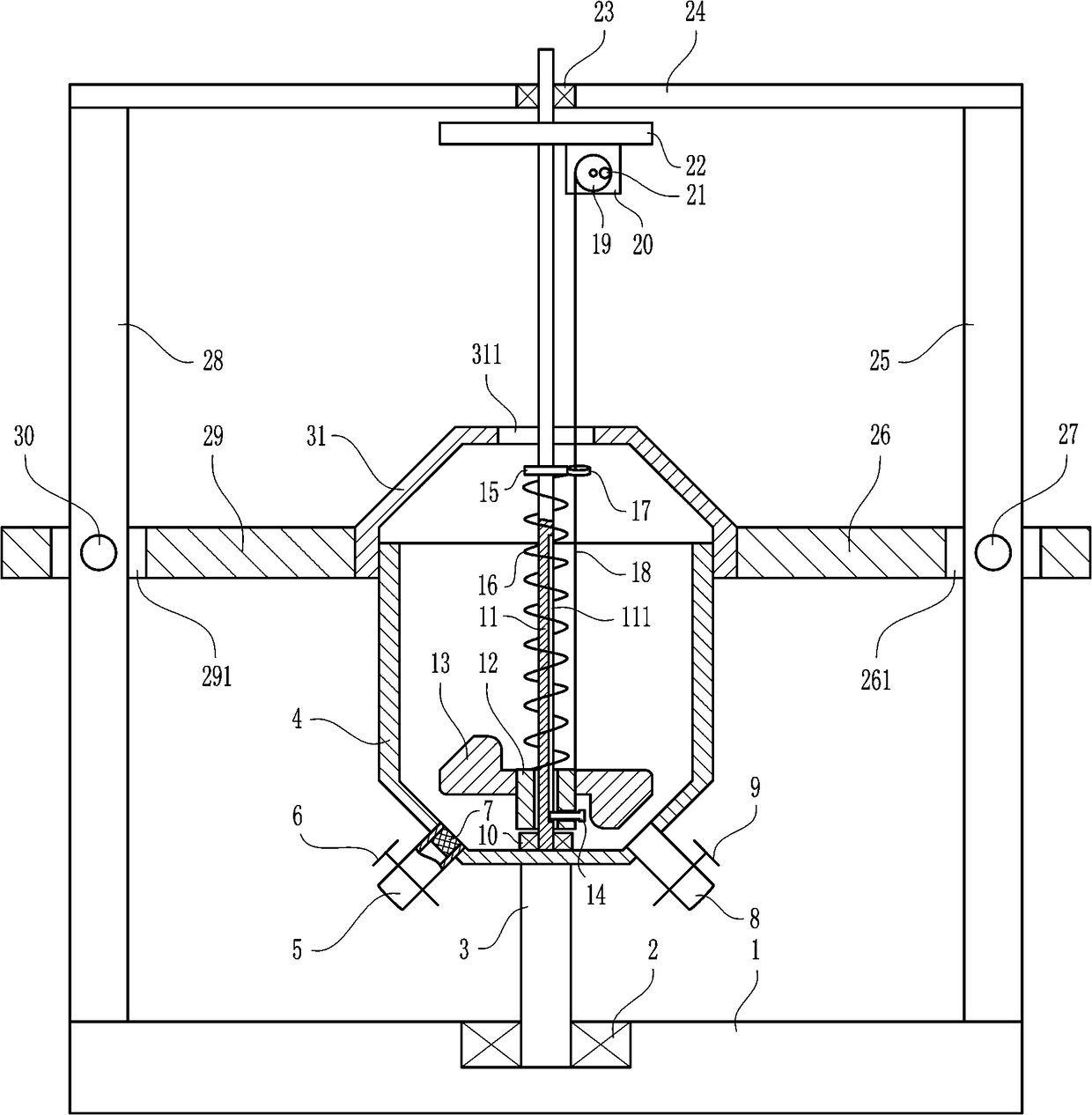

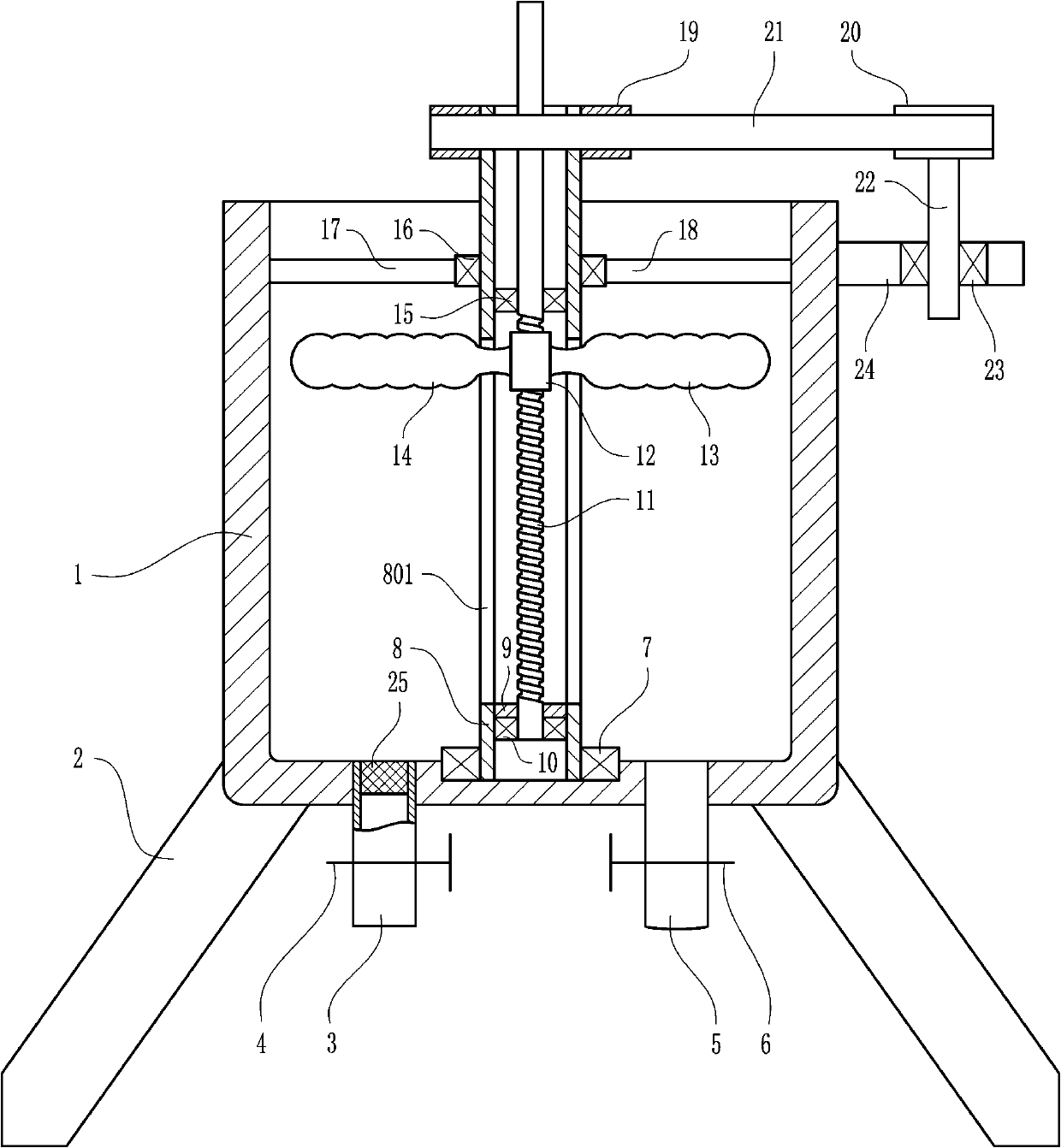

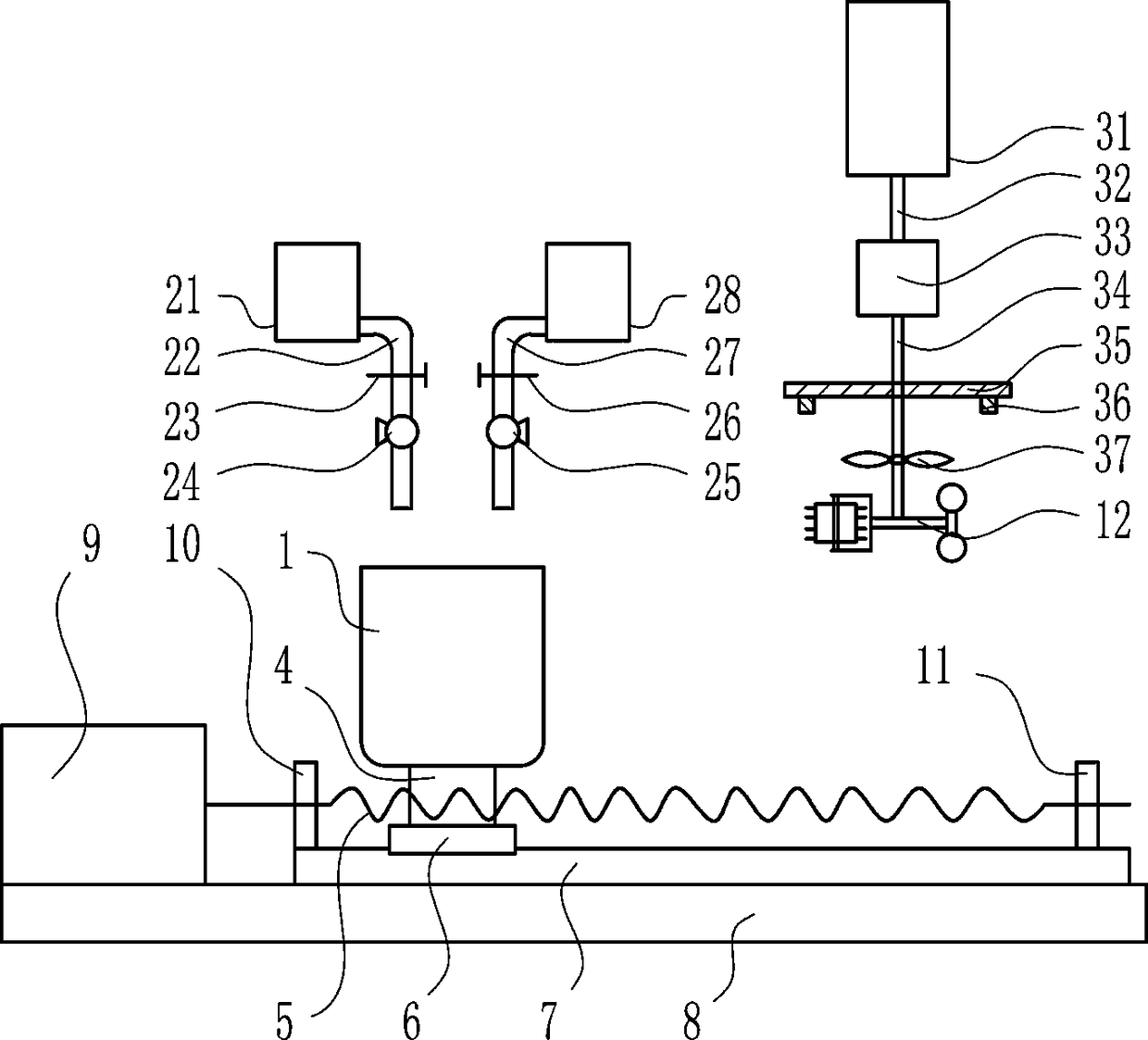

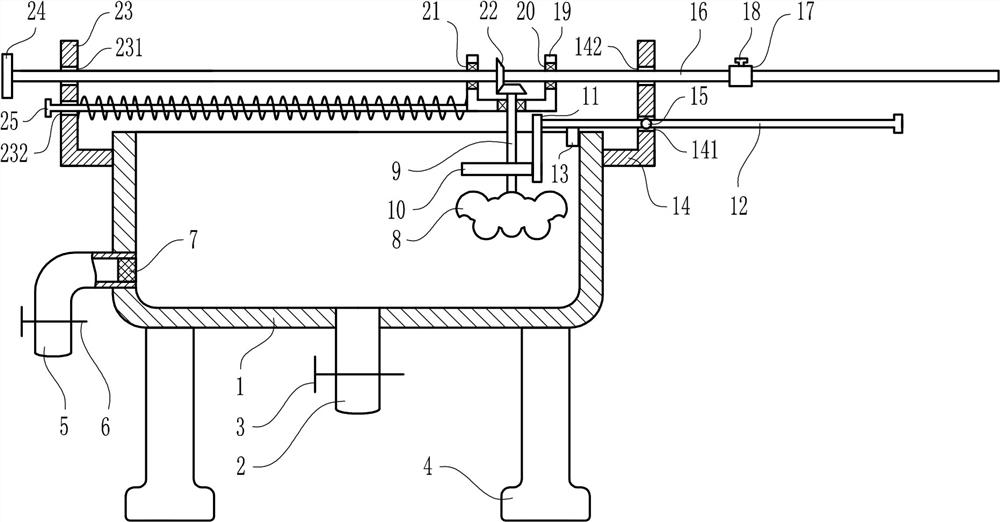

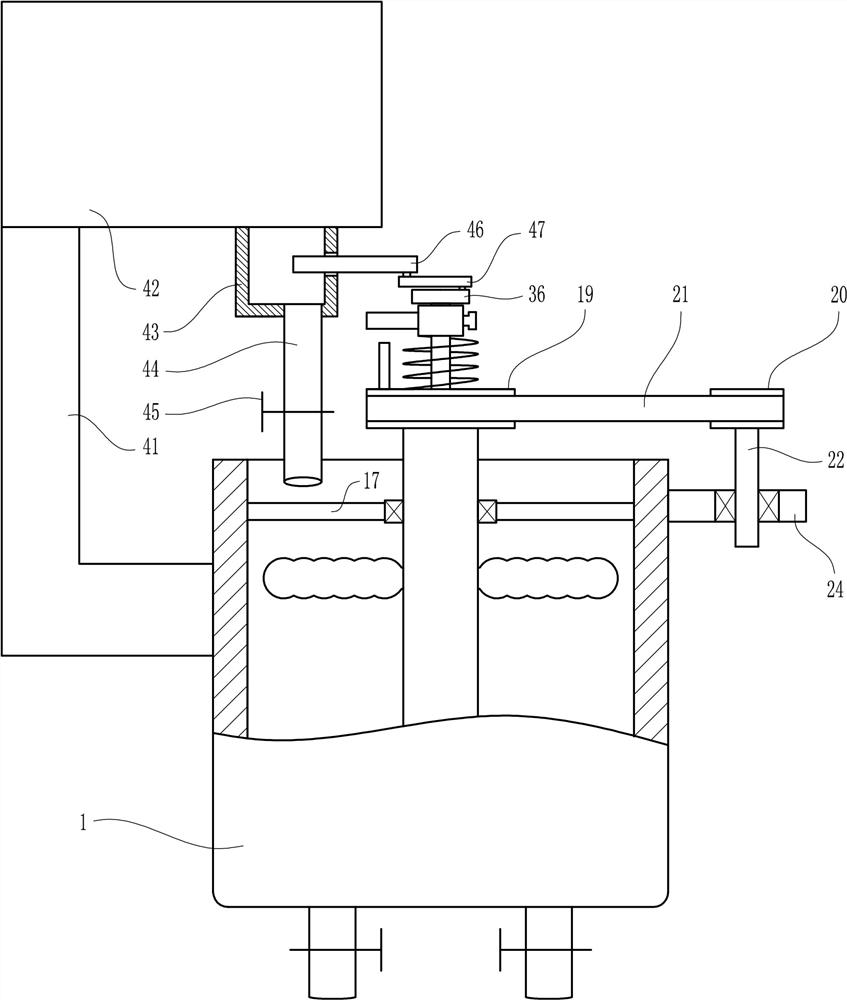

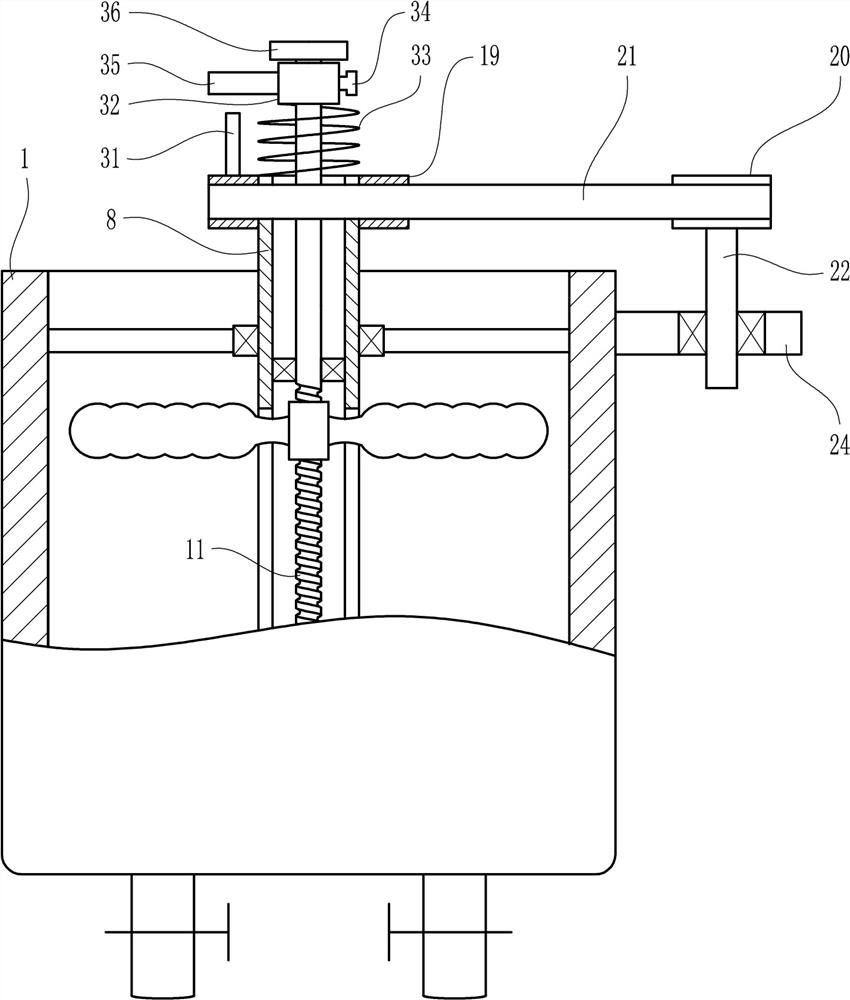

Liftable stirring type co-precipitation settling device for rare earth

ActiveCN109097608AImprove the mixing effectSmooth rotationProcess efficiency improvementRare earthCarbonate

The invention relates to a co-precipitation settling device for rare earth, in particular to a liftable stirring type co-precipitation settling device for the rare earth. The liftable stirring type co-precipitation settling device for the rare earth can be adjusted and can perform liftable stirring on rare earth mixture liquid. The liftable stirring type co-precipitation settling device for the rare earth comprises a precipitation cylinder, supporting legs, a drainage pipe, a first valve, a discharge pipe, a second valve, a first bearing, a rotating pipe, a gasket, a second bearing, a lead screw, a nut and the like. The supporting legs are located under the precipitation cylinder, the supporting legs are connected with the precipitation cylinder, and the supporting legs are arranged in a left-right symmetric mode. The liftable stirring type co-precipitation settling device for the rare earth can be adjusted and can perform liftable stirring on the rare earth mixture liquid, the mixed reaction of the rare earth mixture liquid is uniform, the quality of generated rare earth carbonate is good, the improvement the quality of obtained products is facilitated, time and efforts are saved,and the structure is simple.

Owner:泰州市津专知识产权服务有限公司

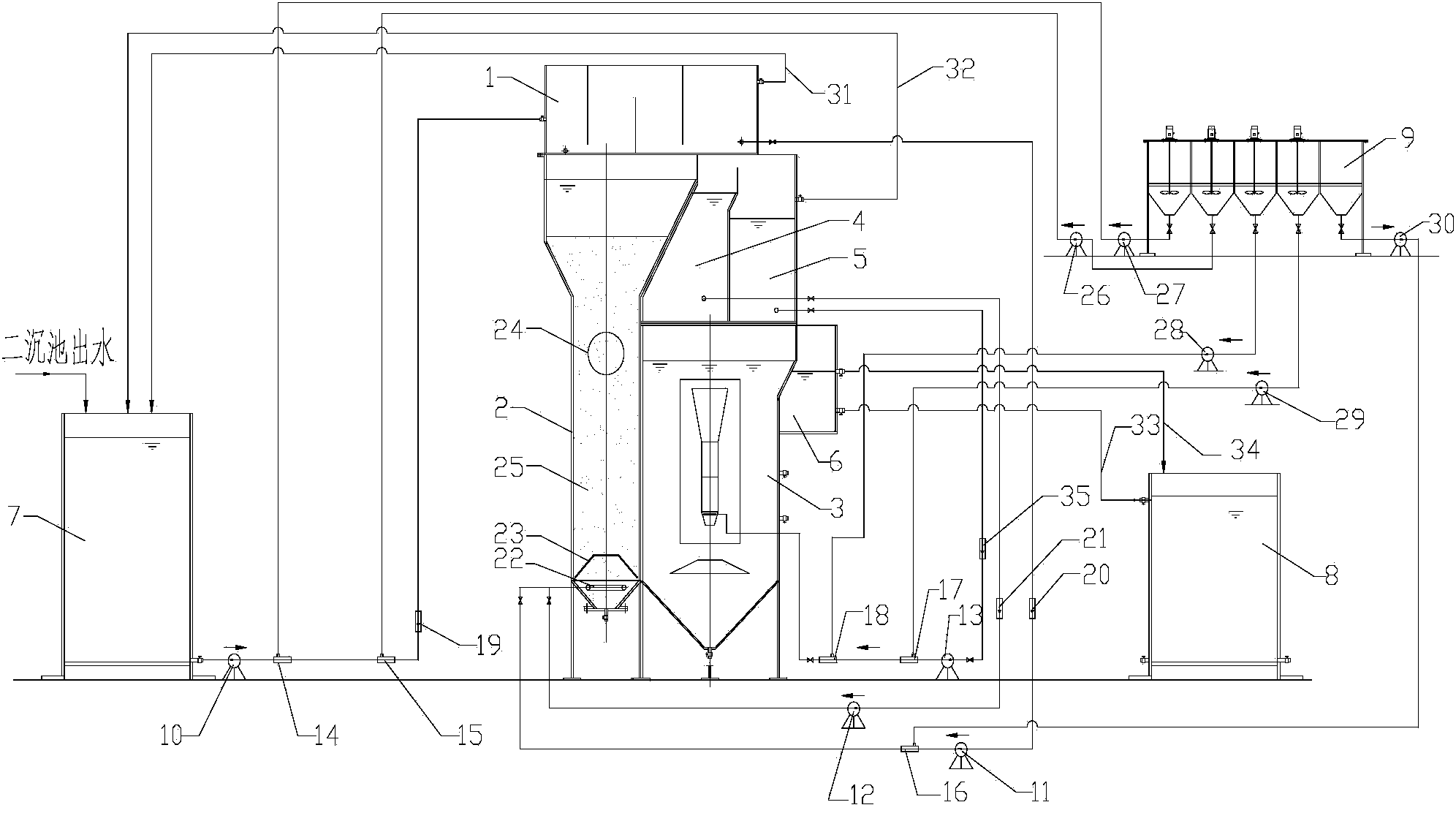

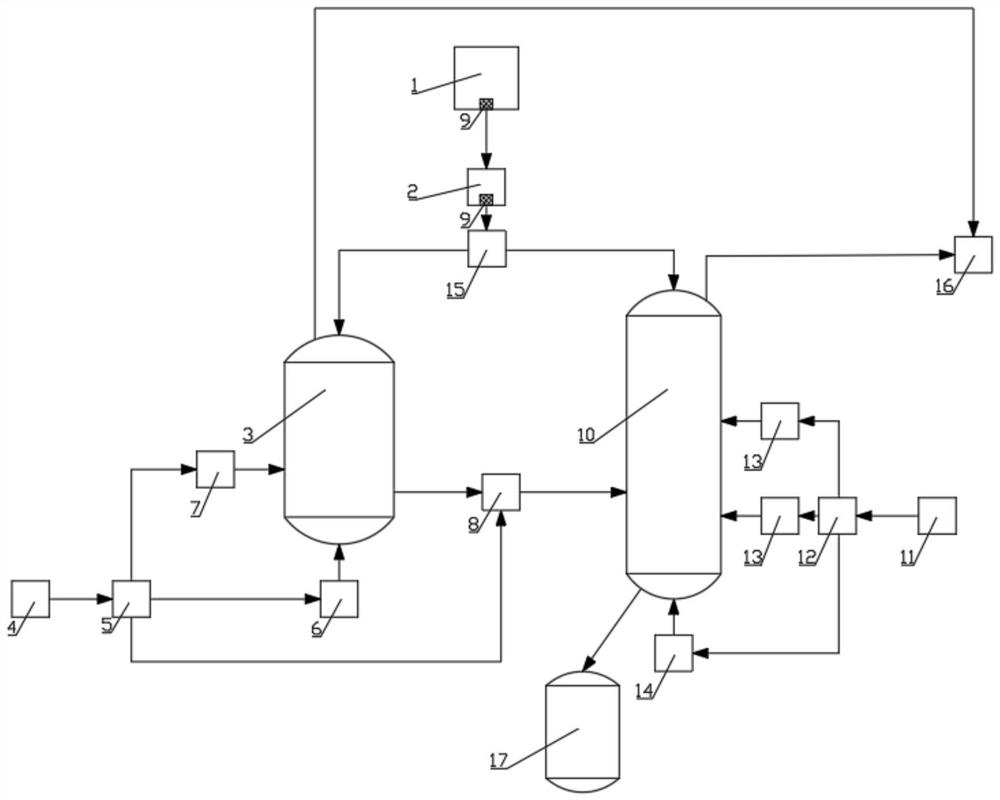

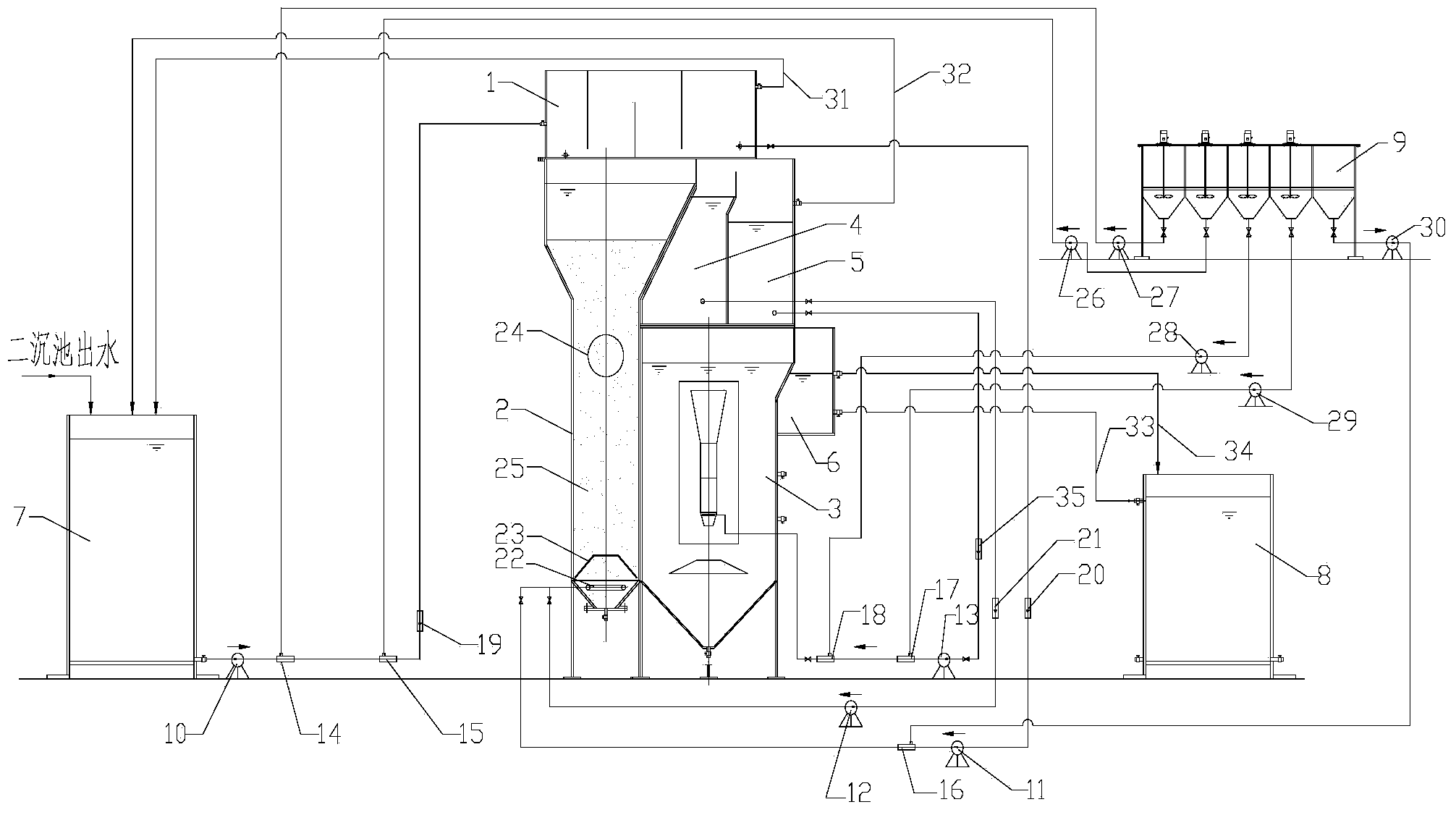

Integrated fluidized catalytic oxidation tower and method for deeply treating wastewater by using same

InactiveCN103771624AEasy to handleImprove processing efficiencyMultistage water/sewage treatmentChemical reactionFenton reagent

The invention discloses an integrated fluidized catalytic oxidation tower and a method for deeply treating wastewater by using the same. A balance adjusting unit of the catalytic oxidation tower is connected with a water distribution pipe at the bottom of a catalytic oxidation unit through a pipeline; the outer side of the upper part of the catalytic oxidation unit is provided with a circulating water tank, the outer side of the circulating water tank is provided with an intermediate water tank, and the top of the circulating water tank is connected with the intermediate water tank through an overflow port; the intermediate water tank is connected with a water distribution pipe of a coagulation sedimentation unit through a pipeline, and a water collecting basin is connected with the balance adjusting unit through a pipeline; the balance adjusting unit is connected with the water collecting basin through a first overflow pipe, and the intermediate water tank is connected with the water collecting basin through a second overflow pipe; a water outlet of a water outlet tank is connected with a clean water basin through a water outlet pipe. By using the integrated fluidized catalytic oxidation tower, the mass transfer efficiency and the chemical reaction speed are effectively increased, the oxidative degradation effect for organic pollutants in wastewater is improved, the dosage of a Fenton reagent can be reduced, and the yield of chemical sludge in the later coagulation process can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

Whole-plant water network monitoring device for thermal power plant

PendingCN114436353ARaise awareness of conservationImprove controlTreatment control/steeringProcess engineeringPower station

The invention discloses a thermal power plant whole plant water network monitoring device which comprises a mounting base, a pipeline monitoring mechanism is arranged at the top of the mounting base, and the pipeline monitoring mechanism comprises a mounting groove, a communicating pipe, a flow monitoring meter, a sewage guide pipe, a water guide pipe, a water storage cavity, a water invasion sensor, a water pump, a liquid guide pipe, an alarm and a monitoring camera. According to the invention, a whole-plant water consumption whole-process intelligent on-line supervision platform is established, a set of complete technical supervision system is established, a typical unit is taken as an example for trial, and through water balance test and application, power plant production management related personnel can master energy consumption, pollution discharge and energy quality conditions of each device in real time, supervise energy conditions and find problems in time, so that the power plant water consumption whole-process intelligent on-line supervision system is provided for the whole-plant water consumption whole-process intelligent on-line supervision. Real-time monitoring and management are achieved, saving consciousness of enterprise managers and employees is effectively improved, the energy quality control capability is improved, and real-time monitoring is carried out on water balance of the whole plant.

Owner:国家能源集团山西电力有限公司 +2

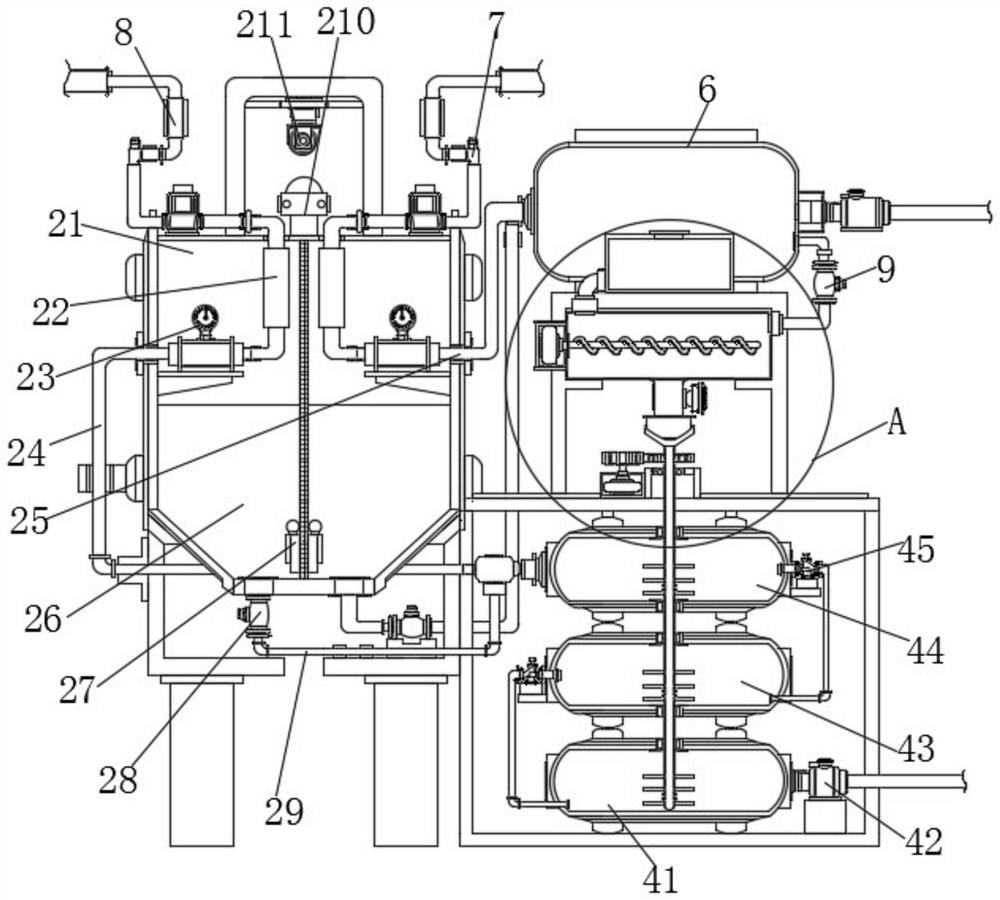

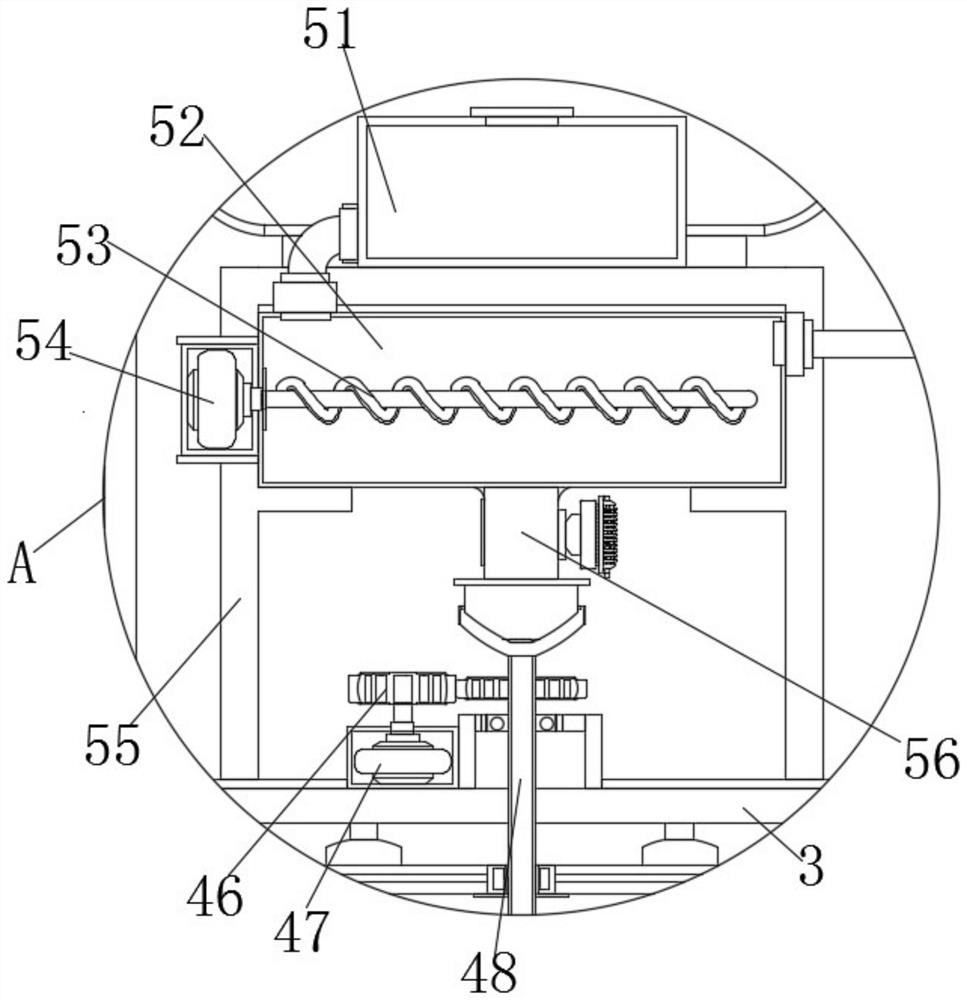

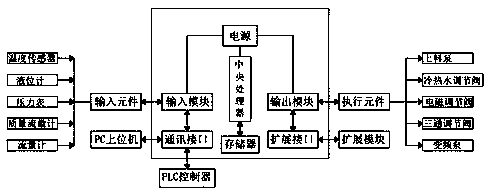

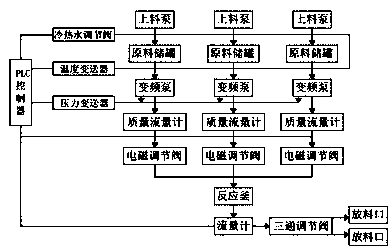

Control system for producing epoxy resin based on reaction kettle and automatic production method

InactiveCN109542038AMix reaction evenlyFully enclosedProgramme control in sequence/logic controllersSocial benefitsCommunication interface

The invention discloses a control system for producing epoxy resin based on a reaction kettle and an automatic production method. The control system comprises a PLC controller, an input component, aninput module, an output module, an execution component, a PC upper computer, a central processing unit, a communication interface, a power supply, and a memory. The input component comprises a temperature sensor, a liquid level meter, a pressure gauge, a mass flow meter, and a flow meter. The output component comprises loading pumps, a hot and cold water regulating valve, an electromagnetic regulating valve, a variable frequency pump, and a three-way regulating valve. The control system for producing epoxy resin based on the reaction kettle and the automatic production method enable the preheating, metering, conveying, mixing reaction and packaging of materials to be monitored and to be automatically adjusted by a PLC system, thereby realizing a complete sealing, automatic and continuous production process. The production process has a high production process efficiency, a stable product quality, a low labor cost, and environmental protection at the production site. The control systemfor producing epoxy resin based on the reaction kettle and the automatic production method have significant economic and social benefits, and ensure that the materials are uniformly mixed and reactedstrictly according to the mass ratio.

Owner:魏贵英

Method and device used for preparing dichloropropanol through micro channel chlorination reaction

PendingCN108727159AImprove reaction efficiencyReduce difficultyChemical/physical/physico-chemical microreactorsPreparation by halogen introductionDistillationBoiling point

The invention belongs to the field of dichloropropanol, and more specifically relates to a method and a device used for preparing dichloropropanol through micro channel chlorination reaction. The method comprises following steps: glycerin, and adipic acid are uniformly mixed so as to obtain a mixed solution, the mixed solution is mixed with hydrogen chloride in a pipeline before entering into a pre-reaction tank, and an obtained mixed material is introduced into the pre-reaction tank for pre-reaction, wherein the internal wall of the pre-reaction tank is attached with a solid acid catalyst; anobtained product is introduced into a micro channel reactor for chlorination reaction, wherein the internal wall of the micro channel reactor is provided with the solid acid catalyst; an obtained reaction product is introduced into a normal pressure tower for normal pressure distillation, the fractions collected from the top of the normal pressure tower are low-boiling-point substances, and are subjected to layering and water washing so as to obtain dichloropropanol; and the fractions collected from the bottom of the normal pressure tower are introduced into a pressure reduction tower for distillation so as to obtain dichloropropanol. According to the method, solid super strong acid SO4<2-> / ZrO2-Pr2O3 is attached onto the internal wall of the pre-reaction tank and the micro channel internal wall of the micro channel reactor, so that reaction efficiency is increased, the subsequent processing difficulty is reduced, and operation cost is reduced.

Owner:山东民基新材料科技有限公司

Method for preparing temperature-resistance nano AgCl SOL

InactiveCN100427402CImprove adsorption capacityNot easy to washSilver halidesChlorideTemperature resistance

The invention discloses a method for preparing high temperature-resistant nano AgCl sol, comprising the steps of: a. preparing soluble chloride solution 0.01-0.2 mol / L, mixing it with dispersant 0.01-2 mol / L in the molar mass ratio of 1 to (1-4), and dispersing uniformly at a speed of 400-1000 r / min; b. heating the prepared solution to 25 deg.C-100 deg.C, regulating pH value of solution to 2-9, uniformly dropping in AgNO5 0.05-0.5mol / L and dispersant 0.01-2mol / L in the molar mass ratio of 1 to (0.25-10) at a speed of 0.01-0.1 ml / min, and dispersing uniformly at 1000-1500 r / min for 10-45 min, and processing the prepared nano sol with ultrasonic for 1 h. And its beneficial effect: at a certain temperature, the absorption of nano silver sol on fabric is high, and the nano silver sol is firm to absorb and uneasy to wash out.

Owner:DONGHUA UNIV

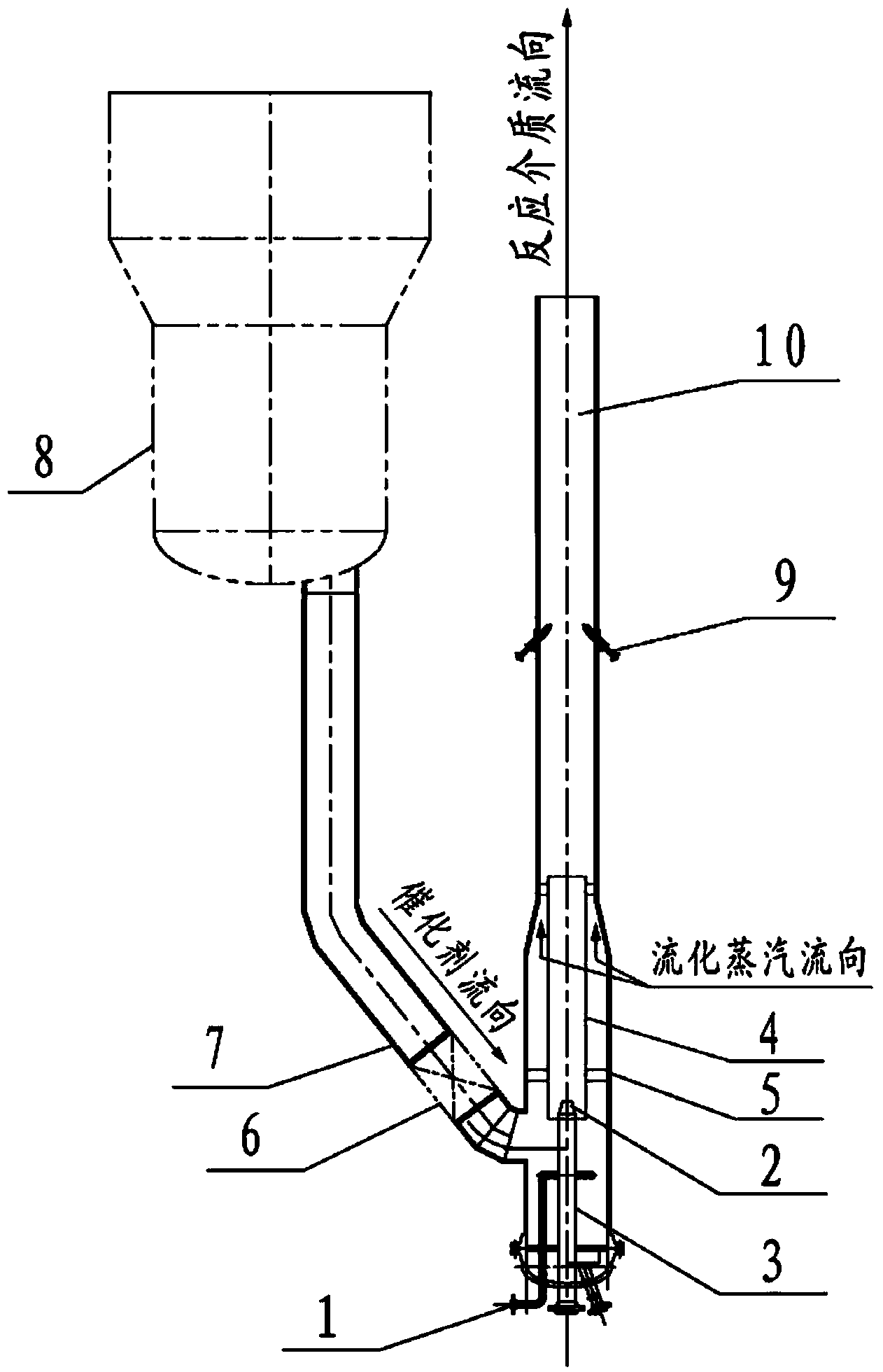

Lift pipe reactor pre-lifting device and process flow thereof

InactiveCN103849424AEnough buffer spaceSmall pressure fluctuationsCatalytic crackingChemical/physical processesSpray nozzleEngineering

The invention relates to a lift pipe reactor pre-lifting device and a process flow thereof. The lift pie reactor pre-lifting device comprises a fluidized vapor ring, a pre-lifting vapor nozzle, a pre-lifting vapor pipe, an expansion section, a single-action slide valve and a regeneration inclined pipe. An inner conveyor pipe is arranged in the expansion section, the lower part of the inner conveyor pipe is connected with the upper part of the pre-lifting vapor pipe, and the inner diameter of the pre-lifting device is twice as large as the inner diameter of the upper part of a lift pipe reactor. By adopting the method in which the inner conveyor pipe is increased, the inner diameter of the pre-lifting device is increased and therefore the structure of the expansion section is changed, the catalyst entering the expansion section has a sufficient buffering space, so that the blanking pressure fluctuation of the regeneration inclined pipe is reduced, the bias current generated by an S-shaped movement orbit can be eliminated, the pre-lifting vapor pipe can avoid the regeneration inclined pipe, the direct impact of the pre-lifting vapor on a blanking port of the regeneration inclined pipe can be avoided, the circulating capacity of the catalyst of a settlement regenerator can be increased, the catalyst in the lift pipe can be uniformly distributed, and the yield of a target product can be improved.

Owner:LUOYANG ZHIBANG PETROCHEM EQUIP

Sludge treatment sedimentation tank capable of reducing sludge flocculation

InactiveCN113429110AExpand the spraying rangeMix reaction evenlySludge treatment by de-watering/drying/thickeningRotary stirring mixersFlocculationSludge

The invention discloses a sludge treatment sedimentation tank capable of reducing sludge flocculation, and relates to the technical field of sewage treatment devices. The sludge treatment sedimentation tank capable of reducing sludge flocculation comprises a sedimentation tank body, wherein cross arm positioning shafts are symmetrically welded to an opening in the top end of the sedimentation tank body; a motor is arranged at the top end of the right outer wall of the sedimentation tank; the middle positions of the top ends of the inner walls of the front side and the rear side of the sedimentation tank are symmetrically and rotationally sleeved with flocculant spraying pieces; a cross arm positioning shaft is sleeved with the driving mechanism in the sliding manner; the driving mechanism comprises a first rack. Through mutual cooperation of first hollow spraying piece, second hollow spraying piece, scraping plate and like, when second hollow spraying piece continues to slide into first hollow spraying piece and is aligned with medicine spraying hole in first hollow spraying piece, high-pressure liquid in second hollow spraying piece flows out of aligned liquid spraying hole and impacts liquid spraying hole, and then medicine spraying hole is cleaned. Therefore, the phenomenon that the medicine spraying holes are blocked by dirt deposition is avoided.

Owner:张锐

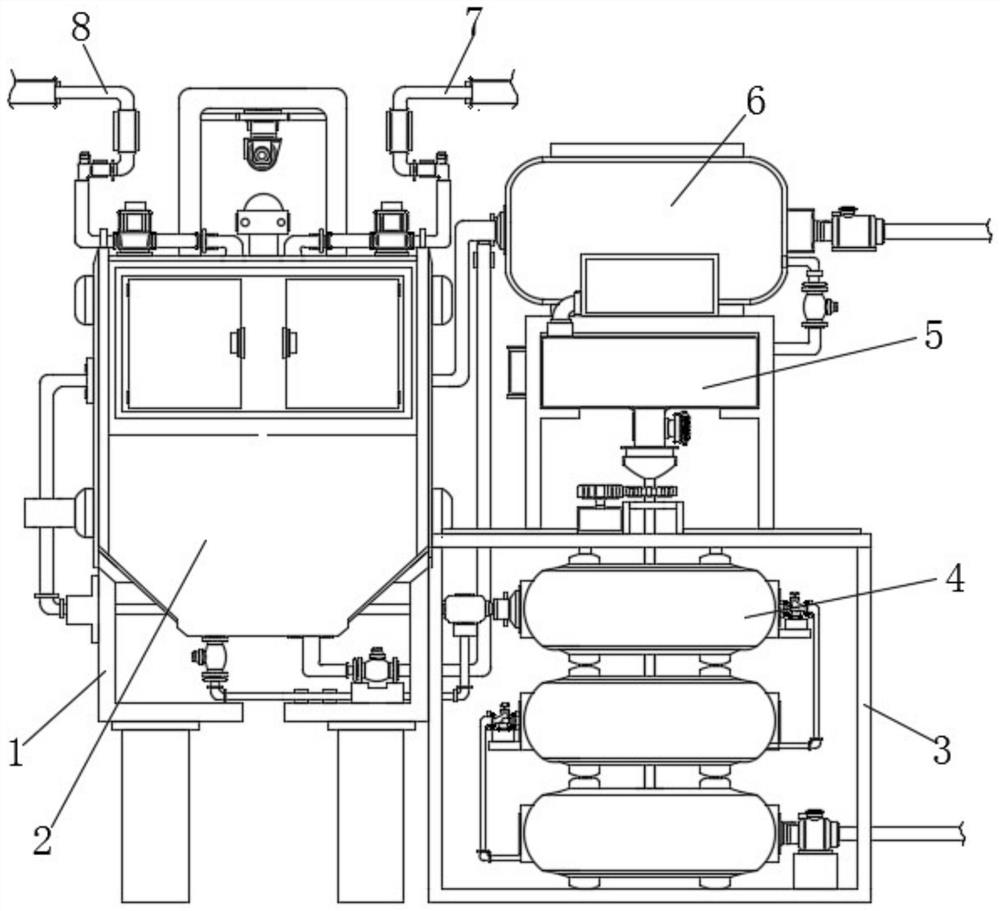

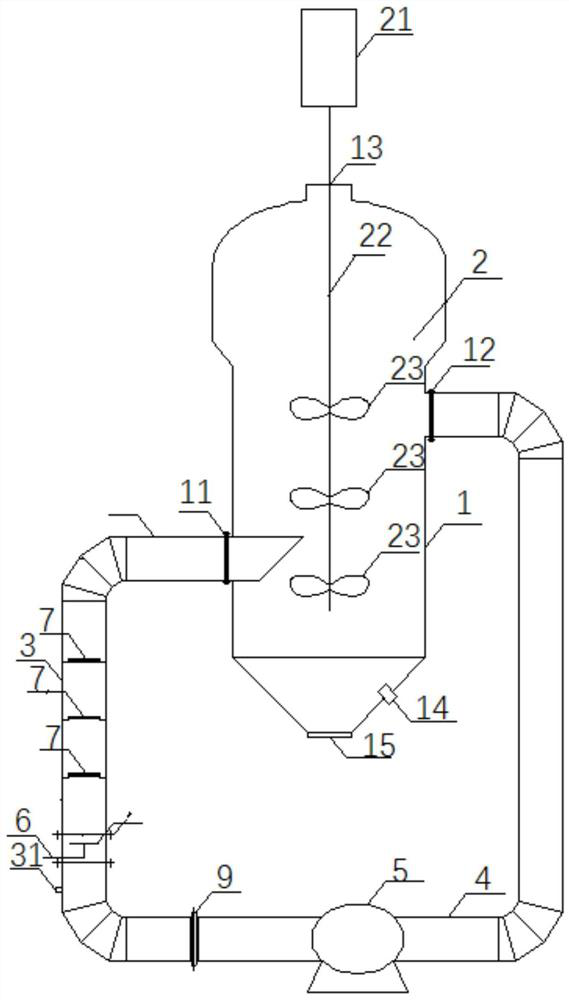

Activated carbon regeneration device and method

PendingCN113856656ASave consumptionSave regeneration cycleCombustible gas purificationFilter regenerationActivated carbonHigh energy

The invention relates to an activated carbon regeneration device and method. The activated carbon regeneration device comprises a storage and feeding system, a carbonization and desorption system and an activation and reaming system. A carrier gas pretreater, a carrier gas blowing device, a carrier gas distributor, an activated gas pretreater, an activated gas controller and an activated gas fluidizer are added before carbonization desorption carrier gas and high-temperature activated chambering activated gas enter a reactor, so that the carrier gas and the activated gas are uniformly distributed in the reactor, passive secondary adsorption of activated carbon is avoided, and the utilization efficiency of activation gas and the activation efficiency of activated carbon are improved. Besides, the device is not provided with mechanical rotating equipment, so that the mechanical damage to the activated carbon is small. The problems of high energy consumption, economic and resource waste and serious environmental pollution in the waste activated carbon treatment process can be solved and relieved.

Owner:SHAANXI YANCHANG PETROLEUM GRP

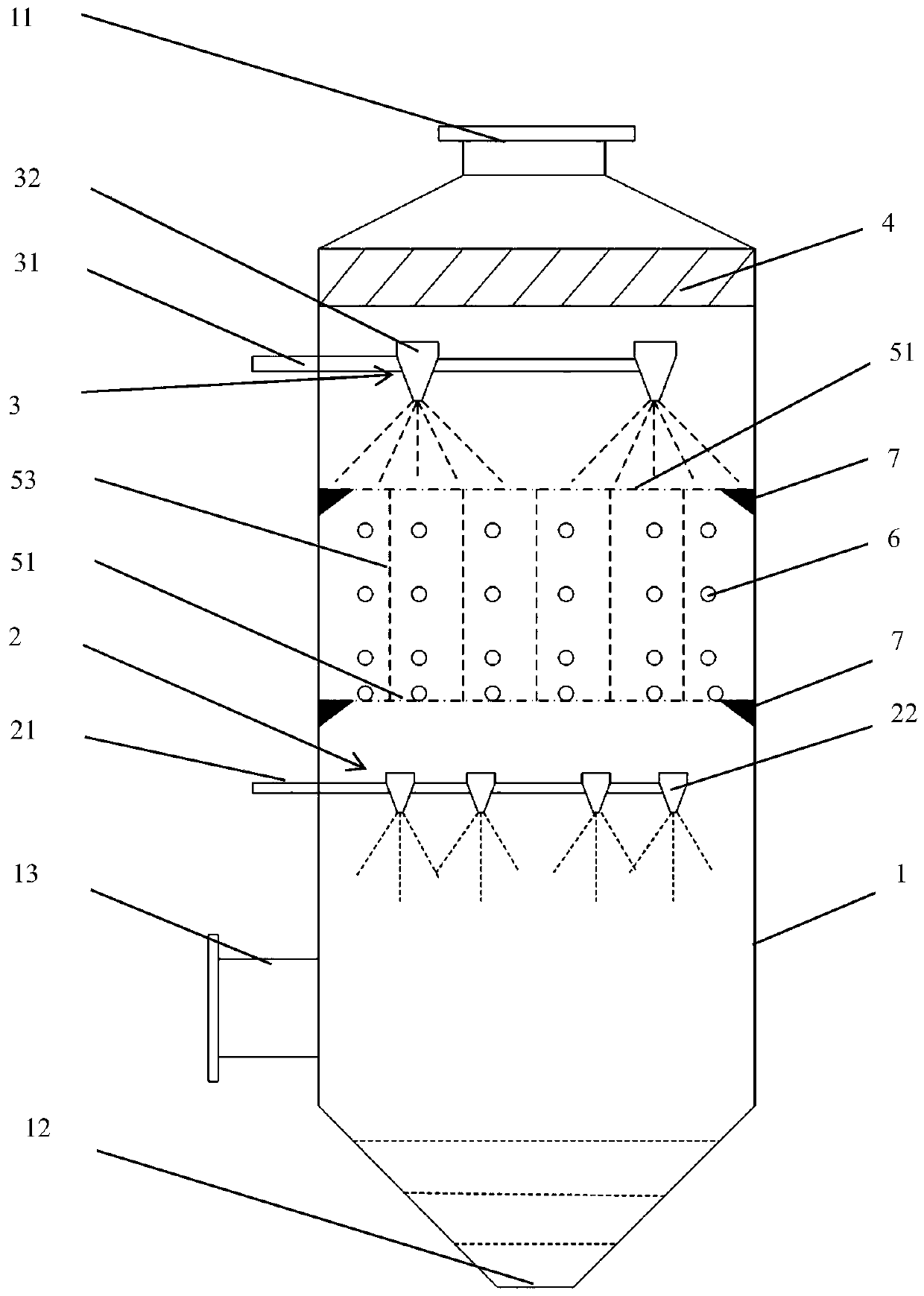

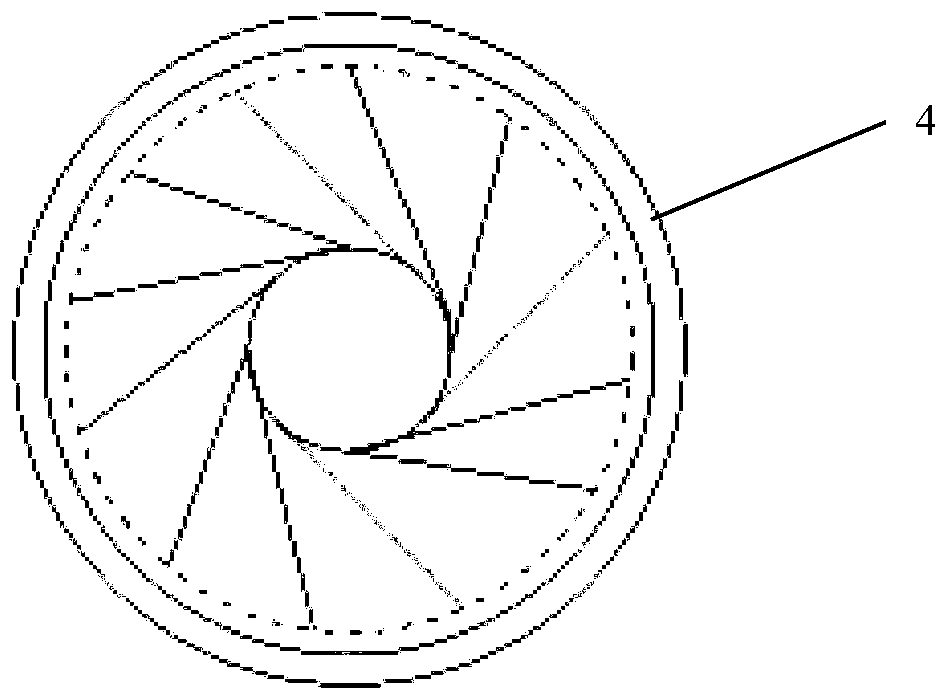

Novel ship waste gas washing and desulfurizing device

InactiveCN111036048AAdaptableNot prone to cloggingGas treatmentDispersed particle separationDieselingProcess engineering

The invention discloses a novel ship waste gas washing and desulfurizing deviceinvention, and relates to the technical field of marine diesel engine tail gas treatment. The device comprises a desulfurization tower, a cooling spraying layer, a main spraying layer and a rotational flow plate demister are sequentially arranged in the desulfurization tower from bottom to top, the device further comprises a grid structure, a plurality of floating balls and two annular flow guide plates, which are arranged in the desulfurization tower, the grid structure is arranged between the cooling spraying layer and the main spraying layer, a plurality of isolated small accommodating cavities are formed between the grid structure and the desulfurization tower, the floating balls are respectively arranged inthe small accommodating cavities, and the two annular flow guide plates are fixed on the inner wall of the desulfurization tower. The ship waste gas washing and desulfurizing device has the advantages of low blocking possibility and easy washing of the floating balls in the accommodating cavities, high working condition adaptability, low investment, low operation and maintenance cost and the like, the wet desulphurization efficiency can be remarkably improved, and the side wall effect of airflow is avoided by arranging the annular flow guide plates to make sulfur oxide and washing liquid fully mixed and reacted.

Owner:SHANGHAI MARITIME UNIVERSITY

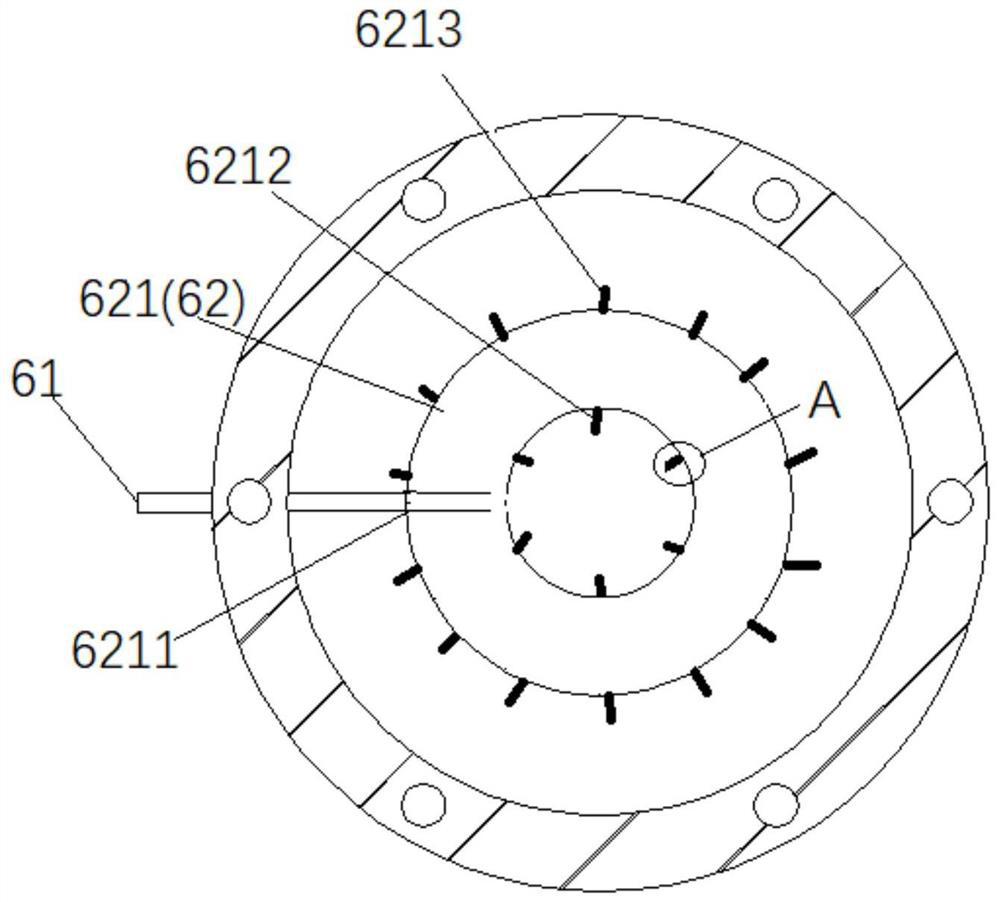

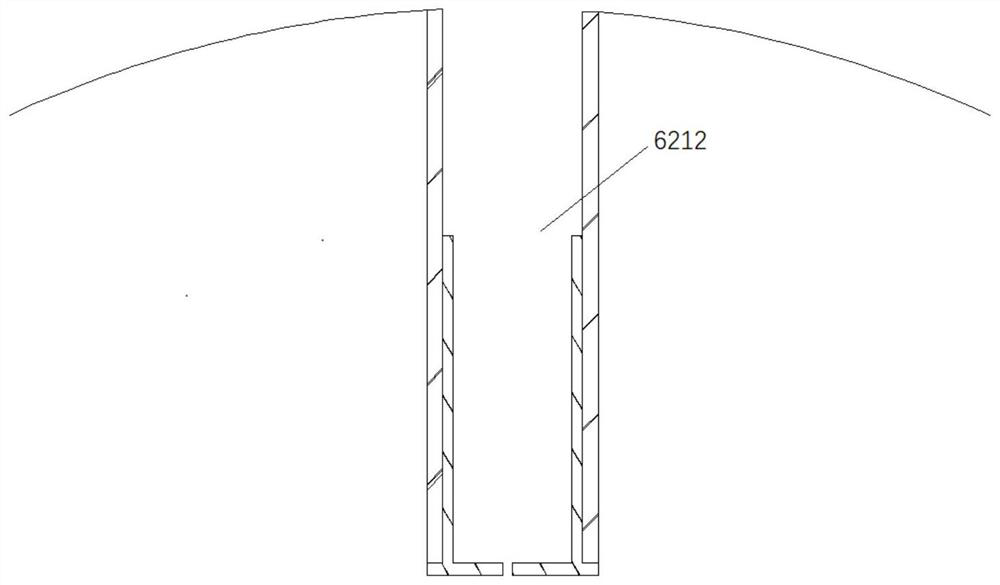

External circulation ammonification reactor

InactiveCN112657451AEasy to replaceEvenly distributedChemical/physical/physico-chemical stationary reactorsThermodynamicsEngineering

The invention discloses an external circulation ammoniation reactor. The external circulation ammoniation reactor comprises a settling separator, a stirring device, a lifting pipe, a return pipe, a circulating pump, a gas distributor and a plurality of mesh grids, wherein the gas distributor comprises a gas inlet pipe and a gas ammonia nozzle, the gas ammonia nozzle is detachably installed at the gas outlet end of the gas inlet pipe, the gas ammonia nozzle horizontally sprays gas, and the multiple mesh grids are arranged in the lifting pipe at intervals and located above the gas distributor. The gas ammonia nozzle is detachably installed on the gas inlet pipe, the gas ammonia nozzles with different hole diameters can be replaced conveniently, the requirements for different gas phase treatment capacities can be met, the nozzles conduct horizontal spraying, the problem that slurry blocks gas spraying holes can be avoided, flocculent solid particles can be detached through the mesh, and the viscosity is reduced. And on the other hand, the mesh breaks large-size bubbles in the central area of the lifting pipe, so that the bubble breaking probability and the bubble surface updating rate are increased, the specific surface area of the bubbles is increased, and the gas-liquid two-phase mass transfer reaction rate can be effectively increased through the mesh structure.

Owner:HUBEI UNIV OF EDUCATION

High-efficiency production device for preparing hydrochloric acid by drying hydrogen chloride through water absorption

InactiveCN105712297AImprove qualityIncrease productivityChlorine/hydrogen-chlorideCyclonic separationWave shape

The invention discloses a high-efficiency production device for preparing hydrochloric acid by drying hydrogen chloride through water absorption. The high-efficiency production device comprises a wave-shaped reaction tube, wherein the wave-shaped reaction tube comprises two inlet pipes, a reaction pipeline and an outlet pipe which are of an integrated structure, the two inlet pipes are respectively connected with a hydrogen chloride gas storage tank and a distilled water storage tank by virtue of a gas inlet pipe and a liquid inlet pipe, the outlet pipe is communicated with the top of a cyclone separation tank, the top of the cyclone separation tank is also connected with the gas inlet pipe by virtue of a hydrogen chloride gas recycling pipe, and a liquid outlet pipe at the bottom of the cyclone separation tank is connected to a finished product hydrochloric acid storage tank; a reaction pipeline of a wave-shaped tube reactor is a wave-shaped tube body, a cooling pipe is sheathed outside the reaction pipeline of the wave-shaped tube reactor, a cooling water inlet is formed in the bottom of the cooling pipe, and a hot water outlet is formed in the top of the cooling pipe. The high-efficiency production device has the advantages that distilled water and hydrogen chloride are forcedly transplaced for multiple times in a reducing wave-shaped tube, so that the contact area is expanded, mixing and reaction are uniform, the production efficiency is high, and the product quality is high; meanwhile, the device structure is simple, and the manufacturing cost and the operating cost are respectively low.

Owner:NANYANG NORMAL UNIV

Integrated fluidized catalytic oxidation tower and method for deeply treating wastewater by using same

InactiveCN103771624BEasy to handleImprove processing efficiencyMultistage water/sewage treatmentChemical reactionSludge

The invention discloses an integrated fluidized catalytic oxidation tower and a method for deeply treating wastewater by using the same. A balance adjusting unit of the catalytic oxidation tower is connected with a water distribution pipe at the bottom of a catalytic oxidation unit through a pipeline; the outer side of the upper part of the catalytic oxidation unit is provided with a circulating water tank, the outer side of the circulating water tank is provided with an intermediate water tank, and the top of the circulating water tank is connected with the intermediate water tank through an overflow port; the intermediate water tank is connected with a water distribution pipe of a coagulation sedimentation unit through a pipeline, and a water collecting basin is connected with the balance adjusting unit through a pipeline; the balance adjusting unit is connected with the water collecting basin through a first overflow pipe, and the intermediate water tank is connected with the water collecting basin through a second overflow pipe; a water outlet of a water outlet tank is connected with a clean water basin through a water outlet pipe. By using the integrated fluidized catalytic oxidation tower, the mass transfer efficiency and the chemical reaction speed are effectively increased, the oxidative degradation effect for organic pollutants in wastewater is improved, the dosage of a Fenton reagent can be reduced, and the yield of chemical sludge in the later coagulation process can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

A homogeneous mixed co-precipitation device for rare earth ore precipitation

InactiveCN106947860BMix reaction evenlyGood mix reactionProcess efficiency improvementRare earthCoprecipitation

The invention relates to a co-precipitation precipitation device for rare earth ore precipitation, in particular to a uniform mixing type co-precipitation precipitation device for rare earth ore precipitation and aims at achieving the technical purpose of providing the uniform mixing type co-precipitation precipitation device for rare earth ore precipitation. To achieve the above technical purpose, the uniform mixing type co-precipitation precipitation device for rare earth ore precipitation is provided and comprises a precipitation cylinder, a material liquid conveying device, a mixing and stirring device, a nut, a lead screw, a sliding block and the like. The mixing and stirring device is arranged on the right side of the material liquid conveying device and arranged above the precipitation cylinder. The nut is arranged below the precipitation cylinder and fixedly connected with the precipitation cylinder. The nut is arranged on the lead screw and matched with the lead screw. According to the uniform mixing type co-precipitation precipitation device for rare earth ore precipitation, a manner of separation of the precipitation cylinder, the material liquid conveying device and the mixing and stirring device is adopted.

Owner:湖州杉伍家纺有限公司

A kind of anti-aging fiberglass material and preparation method thereof

The invention provides an aging-resistant FRP material, which is prepared from the following raw materials in parts by weight: 100 parts of unsaturated polyester resin, 2-8 parts of styrene, 1-3 parts of curing agent, 1-3 parts of accelerator, 80-120 parts of glass fiber, 10-40 parts of illite functional powder material, 1-3 parts of coupling agent, 1-2 parts of zinc oxide, 5-6 parts of graphene. The preparation method is to pickle the illite powder, wash it with water until it is neutral, dry it, and use a coupling agent for secondary modification to obtain the illite functional powder material. The addition of illite functional powder material and other raw materials of the present invention can increase the degree of cross-linking between polymer chains, and effectively improve the aging resistance and mechanical strength of the FRP material. The aging-resistant FRP material of the present invention is especially suitable for ships and other marine applications. environment, its salt spray resistance, aging resistance and strength are significantly improved compared with ordinary FRP materials.

Owner:CHENGDE RENHE MINING CO LTD

A multi-mode stirring co-precipitation device for rare earth

ActiveCN109126669BVarious mixing methodsEasy to operateChemical/physical/physico-chemical stationary reactorsRare earth metal compounds preparation/treatmentEngineeringAtmospheric sciences

The invention relates to a co-precipitation precipitation device for rare earth, in particular to a multi-mode stirring type co-precipitation precipitation device for the rare earth. To solve the technical problem of providing the multi-mode stirring type co-precipitation precipitation device, capable of being adjusted and stirring rare earth mixture liquid in various ways, for the rare earth, thetechnical scheme of the multi-mode stirring type co-precipitation precipitation device for the rare earth is that the multi-mode stirring type co-precipitation precipitation device for the rare earthcomprises various parts such as a base, a first bearing, a support shaft, a cylinder, a drain pipe, a first valve, a filter screen, a discharge pipe, a second valve, a second bearing and long connecting shaft; the first bearing is embedded in the base; the lower end of the support shaft and the first bearing are in interference connection. The multi-mode stirring type co-precipitation precipitation device for the rare earth has the advantages of being easy to adjust and capable of stirring the rare earth mixture liquid in various ways, realizing uniform mixing reaction of the rare earth mixture liquid, having simple structure, easy operation and low labor intensity, and being time-saving and labor-saving.

Owner:东港智科产业园有限公司

A movable stirring type co-precipitation device for rare earth

ActiveCN109097607BUniform responseLarge mixing rangeProcess efficiency improvementThermodynamicsEngineering

The invention relates to a coprecipitation device for rare earth, in particular to a movable stirring-type coprecipitation device for rare earth. The movable stirring-type coprecipitation device for the rare earth can be adjusted and can stir rare earth mixture liquid in a moving mode. According to the technical scheme, the movable stirring-type coprecipitation device for the rare earth comprisesa precipitation cylinder, a discharging pipe, a first valve, supporting legs, a liquid discharging pipe, a second valve, a filtering net, a large stirring plate, a first connecting shaft, a small cam,a contact plate and the like; and the discharging pipe is located on the lower portion of the precipitation cylinder and connected with the precipitation cylinder. The movable stirring-type coprecipitation device for the rare earth can be adjusted, can stir the rare earth mixture liquid in the moving mode, and can enable a mixing reaction of the rare earth mixture liquid to be even, the quality of a prepared product is improved advantageously, the production and development of enterprises are facilitated, and operation is convenient.

Owner:江苏鑫环球建设工程有限公司

A lifting and stirring coprecipitation device for rare earth

ActiveCN109097608BImprove the mixing effectSmooth rotationProcess efficiency improvementSoil sciencePhysical chemistry

The invention relates to a co-precipitation settling device for rare earth, in particular to a liftable stirring type co-precipitation settling device for the rare earth. The liftable stirring type co-precipitation settling device for the rare earth can be adjusted and can perform liftable stirring on rare earth mixture liquid. The liftable stirring type co-precipitation settling device for the rare earth comprises a precipitation cylinder, supporting legs, a drainage pipe, a first valve, a discharge pipe, a second valve, a first bearing, a rotating pipe, a gasket, a second bearing, a lead screw, a nut and the like. The supporting legs are located under the precipitation cylinder, the supporting legs are connected with the precipitation cylinder, and the supporting legs are arranged in a left-right symmetric mode. The liftable stirring type co-precipitation settling device for the rare earth can be adjusted and can perform liftable stirring on the rare earth mixture liquid, the mixed reaction of the rare earth mixture liquid is uniform, the quality of generated rare earth carbonate is good, the improvement the quality of obtained products is facilitated, time and efforts are saved,and the structure is simple.

Owner:泰州市津专知识产权服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com