Method for continuously preparing ultrafine sliver powder on basis of microchannel mixed reaction system

A reaction system and micro-channel technology, applied in the field of preparation of metal ultra-fine powder materials, can solve the problems of large volume production equipment, difficult product precision control, poor batch stability, etc., to improve production efficiency and product batch stability. performance, reduce equipment investment costs, and improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

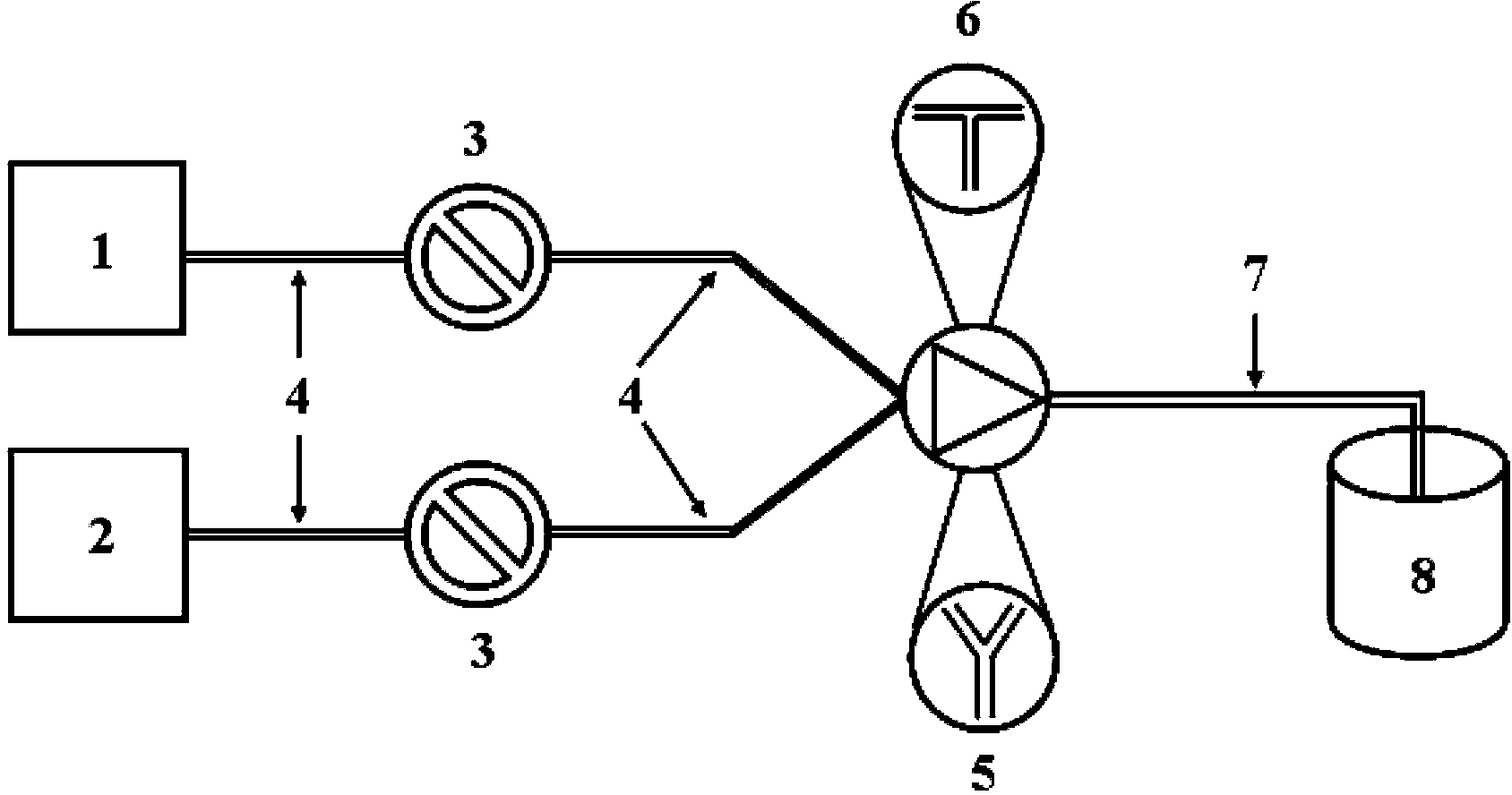

[0040] Build a microchannel mixed reaction system, such as figure 1 shown. The internal diameter of two as transmission microchannel 4 is 3 millimeters, and one end of the latex tube that length is 0.5 meter is connected with an end of two peristaltic pumps 3 respectively, and the other end of described two latex tubes is respectively connected with a loader. The container 1 (material is glass) of oxidizing solution and the container 2 (material is glass) of a loading reducing solution; The other end of described two peristaltic pumps is 3 millimeters respectively as the internal diameter of transmission microchannel 4 respectively, A latex tube with a length of 1 meter is connected with two symmetrical ports of a Y-shaped tee 5 made of glass as a mixing unit of the reactant (the internal diameter of the symmetrical port is 3 millimeters), and the rest of the Y-shaped tee is One interface (inner diameter is 4 millimeters) connects one as the inner diameter of reaction microch...

Embodiment 2

[0045] The microchannel mixed reaction system built is basically the same as the microchannel mixed reaction system in Example 1, except that the inner diameter of the transmission microchannel is 4 millimeters, the inner diameter of the symmetrical interface of the Y-shaped tee is 5 millimeters, and the remaining one interface The inner diameter is 6 mm and the inner diameter of the reaction microchannel is 6 mm.

[0046] Utilize the above-mentioned microchannel mixing reaction system to continuously prepare ultrafine silver particle powder:

[0047] (1) Dissolve 22.5g of silver nitrate in 115ml of deionized water to prepare a silver nitrate solution, add 1.5ml of nitric acid (65-68% mass concentration) into the silver nitrate solution under stirring, and then add 35ml of absolute ethanol , the obtained mixed solution is used as the oxidation solution; 15g of ascorbic acid is dissolved in 150ml of deionized water as the reduction solution; in the container;

[0048] (2) Con...

Embodiment 3

[0051] The microchannel mixed reaction system built is basically the same as the microchannel mixed reaction system in Example 1, except that the internal diameter of the transmission microchannel is 2.5 mm, the length is 2 mm, and the Y-shaped tee is made of stainless steel and three interfaces. With an inner diameter of 2.5 mm, the reaction microchannel has an inner diameter of 3 mm and a length of 1.5 meters.

[0052] Utilize the above-mentioned microchannel mixed reaction system to continuously prepare ultra-fine silver powder:

[0053] (1) Dissolve 7.5g of silver nitrate in 120ml of deionized water to prepare a silver nitrate solution, add 1.5ml of nitric acid (65-68% mass concentration) into the silver nitrate solution under stirring, and then add 30ml of absolute ethanol , the obtained mixed solution is used as the oxidation solution; 15g of ascorbic acid is dissolved in 150ml of deionized water as the reduction solution; in the container;

[0054] (2) Control the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com