A microgravity suspension centrifugal spinning method

A centrifugal spinning and centrifugal spinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as low safety, low efficiency, discontinuous fibers, etc., and achieve the effect of avoiding high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

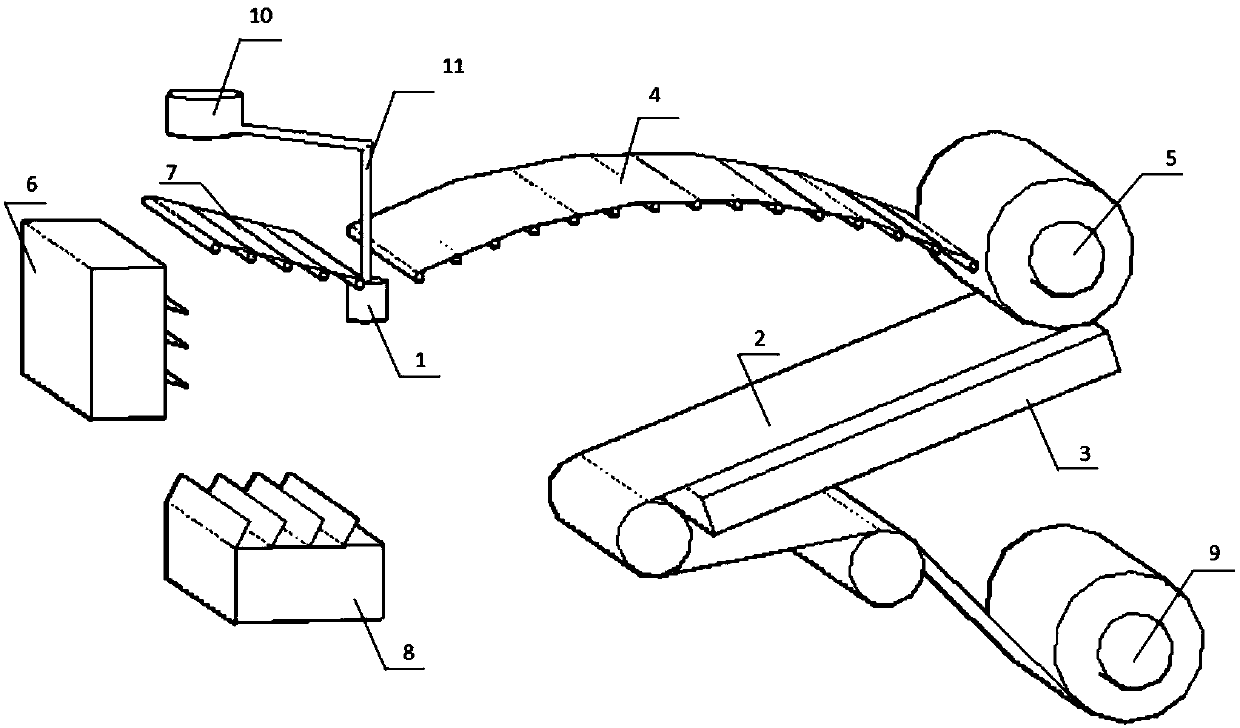

[0025] During centrifugal spinning, the angle between the cloth guide belt of the fiber collection device and the plane at the bottom of the centrifugal spinning tank is 5°, and the straight line between the center point of the cloth guide belt and the center point of the bottom of the centrifugal spinning tank The distance is 50cm, the width of the cloth guide belt of the fiber collection device is 40cm, a negative pressure generator is installed under the cloth guide belt, the suction port of the negative pressure generator is set opposite to the lower surface of the cloth guide belt, The distance between the lower surfaces is 1cm, and the air volume of the negative pressure generator is 200m 3 / h, between the centrifugal spinning pot and the fiber collection device, a first temperature control plate with a radian of 0.04rad is set, the width of the first temperature control plate is 50cm, and the lower surface of the first temperature control plate is arranged parallel to ea...

Embodiment 2

[0027] During centrifugal spinning, the angle between the cloth guide belt of the fiber collection device and the plane at the bottom of the centrifugal spinning tank is 40°, and the straight line between the center point of the cloth guide belt and the center point of the bottom of the centrifugal spinning tank The distance is 150cm, the width of the cloth guide belt of the fiber collection device is 100cm, a negative pressure generator is installed under the cloth guide belt, the suction port of the negative pressure generator is set opposite to the lower surface of the cloth guide belt, The distance between the lower surfaces is 1cm, and the air volume of the negative pressure generator is 500m 3 / h, between the centrifugal spinning pot and the fiber collection device, a first temperature control plate with a radian of 0.08rad is set, the width of the first temperature control plate is 110cm, and the lower surface of the first temperature control plate is arranged parallel t...

Embodiment 3

[0029] During centrifugal spinning, the angle between the guide belt of the fiber collection device and the plane where the bottom of the centrifugal spinning tank is located is 25 。 , the straight-line distance between the central point of the cloth guide belt and the center point of the bottom of the centrifugal spinning tank is 100cm, the width of the cloth guide belt of the fiber collection device is 70cm, and a negative pressure generator is set under the cloth guide belt to generate negative pressure. The air suction port of the device is set opposite to the lower surface of the cloth guide belt, the distance between the air suction port and the lower surface of the cloth guide belt is 1cm, and the air volume of the negative pressure generator is 350m 3 / h, between the centrifugal spinning tank and the fiber collection device, a first temperature control plate with a radian of 0.06rad is set, the width of the first temperature control plate is 80cm, and the lower surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com