Composite material of imitated wood anaglyph furniture and manufacturing method thereof

A technology of composite materials and imitation wood materials, applied in the field of furniture production, can solve the problems of long carving time, unaffordable consumption by ordinary households, and large dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

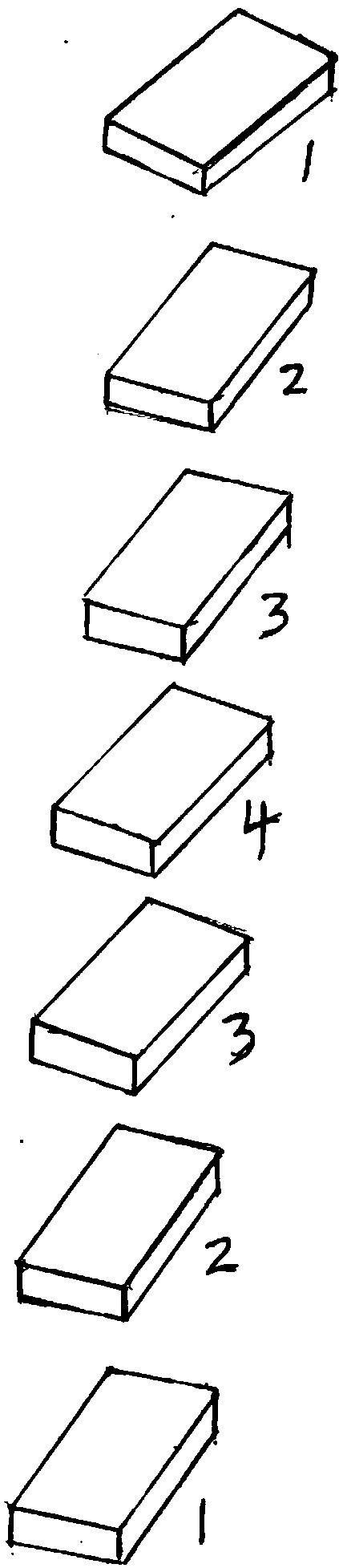

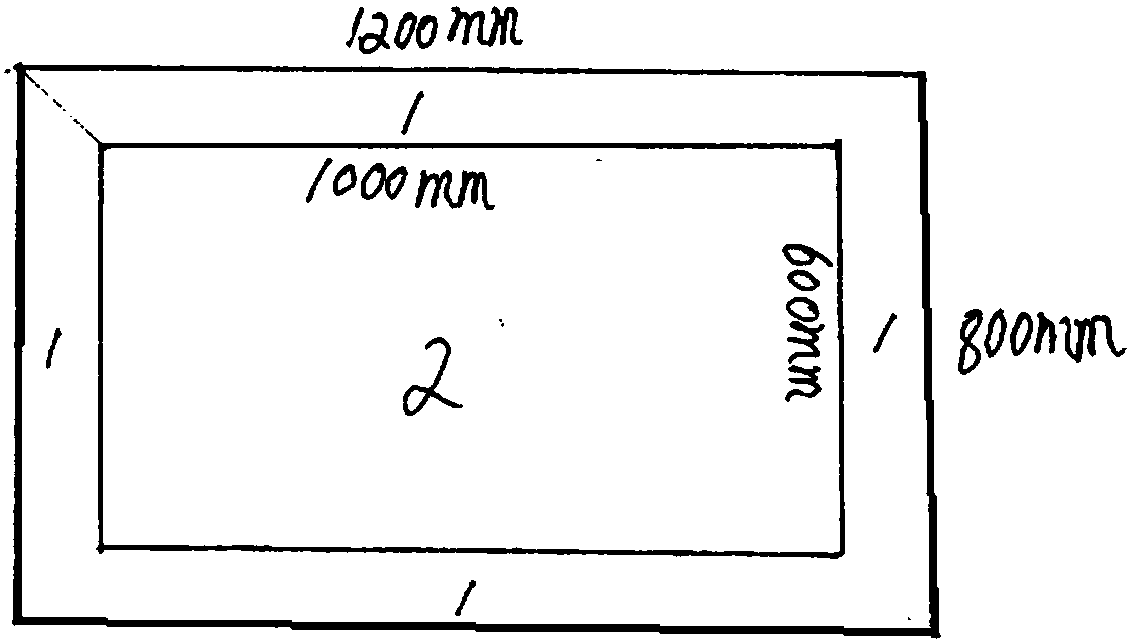

[0025] Embodiment 1 Imitation wood relief table top (120x80cm)

[0026] Such as figure 2 As shown, the wood structure requires a 36mm thick oak board to make a frame, and put it on a horizontal platform, install a silicone mold and fix it; first lay a layer of imitation wood material, and white cement 1 kg, 0.15 kg of red powder, 0.05 kg of black iron oxide powder, 0.08 kg of yellow powder, 0.05 kg of glass fiber chopped shreds, 0.6 kg of water, spread on the surface of the silicone mold after stirring evenly and shake it flat, sprinkle a layer of No. 425 Ordinary black cement powder is used for shaping to prevent the imitation wood material from flowing, and then put two layers of glass fiber mesh cloth with an aperture of 8mm, and then lay a layer of 1 kg of No. 425 ordinary cement, 3 kg of fine sand, and 0.6 kg of water. The finished cement mortar is vibrated and leveled, and then a layer of No. 425 ordinary black cement powder is sprinkled; in the middle, a spoonful of N...

Embodiment 2

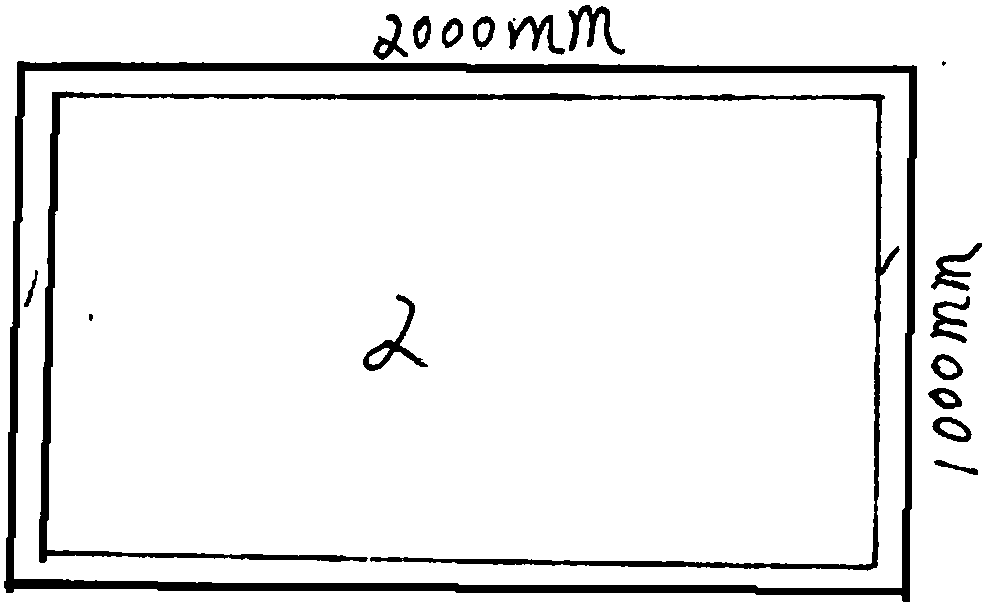

[0027] Embodiment 2 Imitation wood relief table teeth

[0028] Such as Figure 4 and 5As shown, the wood structure requires (18mm thick tooth bar, 50mm high and 780mm long. Tooth head 18mm thick, 50mm high, 1180mm long) oak to make a frame, put it on a horizontal platform, and put the silicone mold into the frame; then Lay a layer of imitation wood material first, (according to the requirements of imitation wood material formula 1, 0.5 kg of white cement, 0.08 kg of red powder, 0.03 kg of black powder, 0.04 kg of yellow powder, 0.02 kg of glass fiber chopped shreds, 0.3 kg of 1 kg of water, 1 kg of white cement for tooth heads, 0.15 kg of red powder, 0.05 kg of black powder, 0.08 kg of yellow powder, 0.05 kg of glass fiber chopped shreds, 0.6 kg of water), shake flat, and then sprinkle a layer of No. 425 Ordinary black cement powder, then put a second layer of glass fiber mesh cloth with an aperture of 8mm, and then lay a layer of cement mortar (0.5 kg of No. 425 ordinary ce...

Embodiment 3

[0029] Embodiment 3 table legs

[0030] Such as Figure 6 As shown, the wood structure requires 18mm thick, 80mm high, and 600mm long oak boards to make a frame, put the silicone mold into the frame and fix it; , 0.08 kg of red powder, 0.03 kg of black powder, 0.04 kg of yellow powder, 0.02 kg of glass fiber chopped shreds, 0.3 kg of water, spread it on the surface of the silicone mold after stirring evenly, and shake it flat, sprinkle a layer of No. 425 ordinary black cement The powder is used for shaping to prevent the imitation wood material from flowing, and then put two layers of glass fiber mesh cloth with an aperture of 8mm, and then lay a layer of cement mixed with 0.5 kg of No. 425 ordinary cement, 1.5 kg of fine sand, and 0.3 kg of water. Mortar, shake it flat, and spread a layer of No. 425 ordinary black cement powder; in the middle, use a scoop of cement (about 0.5 kg), 0.3 kg of water, and 10 scoops of plastic foam particles to fill it with cement foam, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com