Method for preparing carbon-supported transition metal silicides from rice husks

A transition metal, supported technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of unfavorable large-scale production, low output, high equipment requirements, etc., to achieve low density and high output tall, bulky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

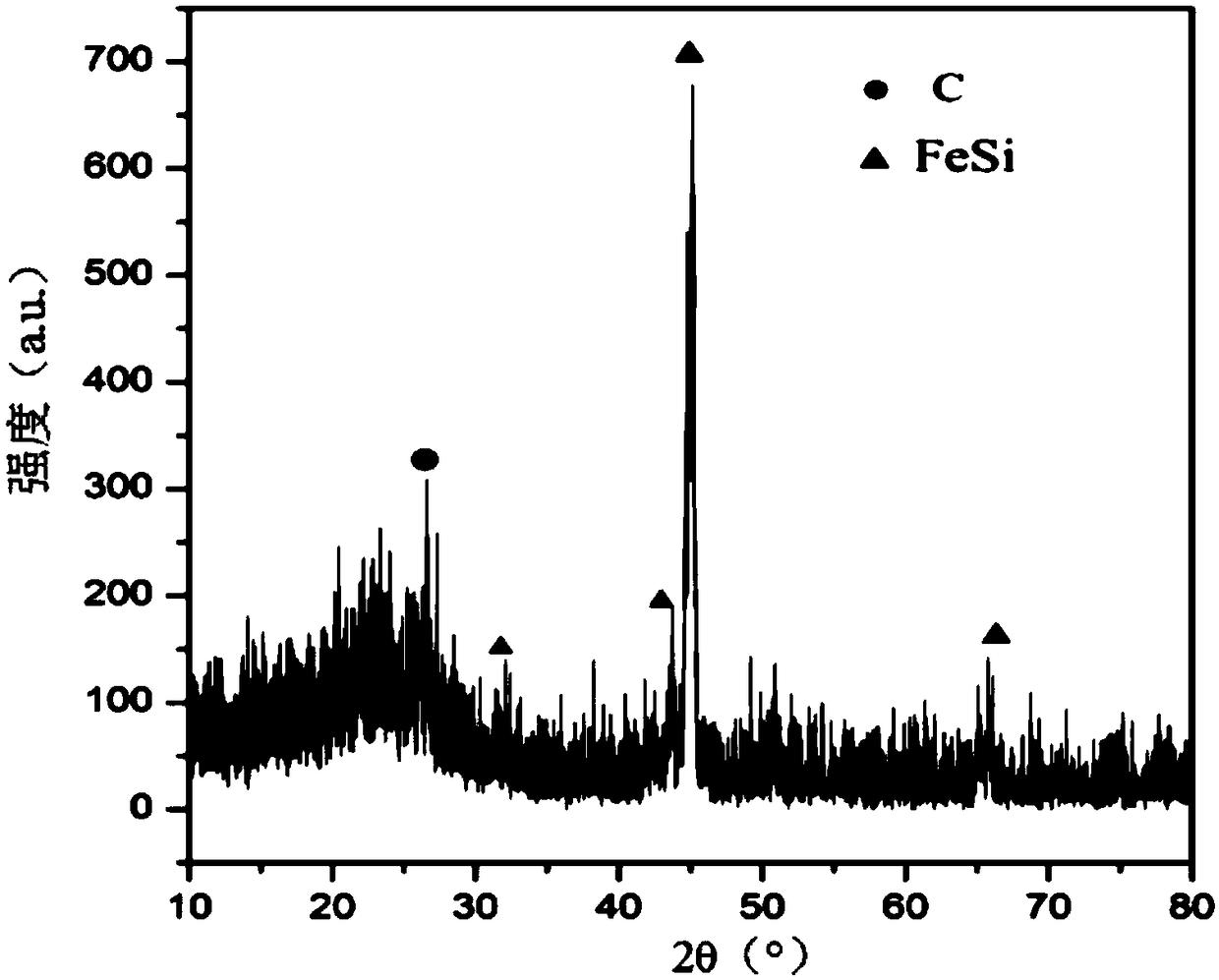

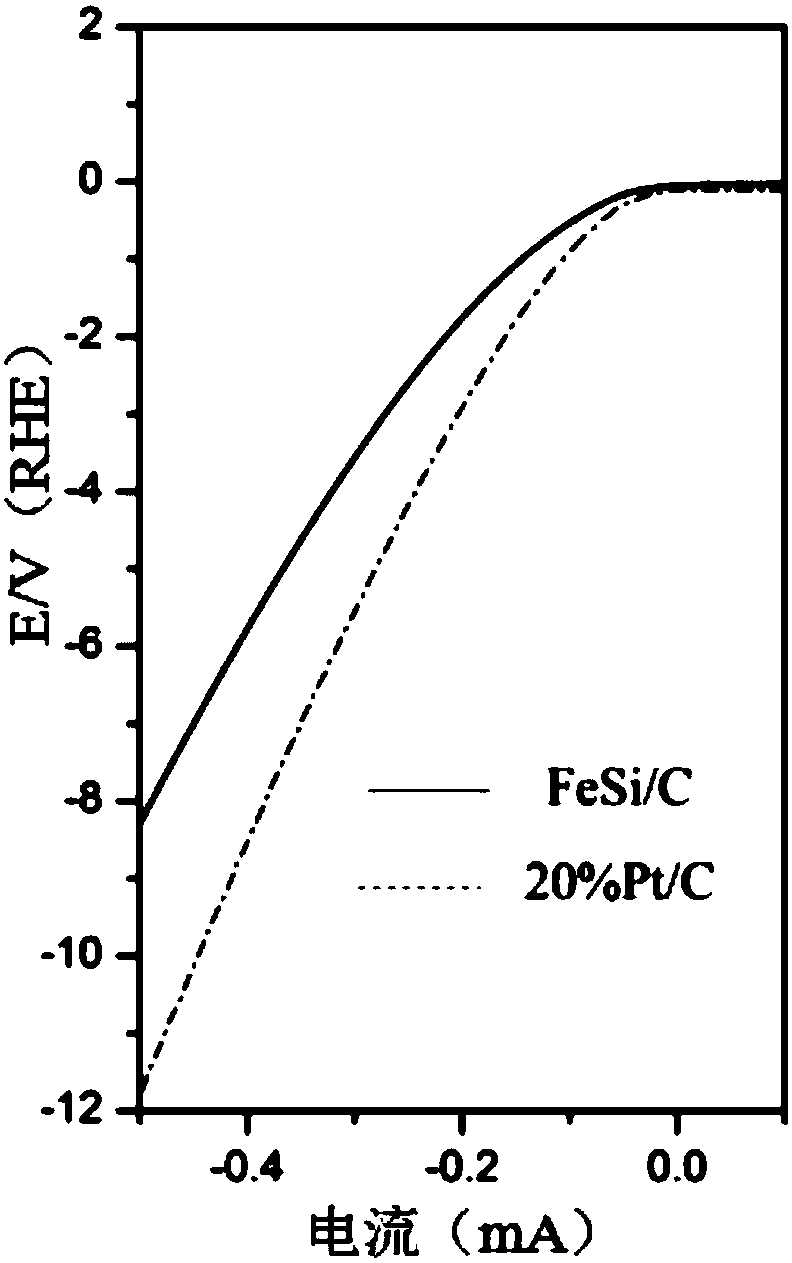

[0025] Specific embodiment one: the method for preparing carbon-loaded transition metal silicides from rice husks in this embodiment is characterized in that the method is carried out according to the following steps:

[0026] Step 1. Rice husks are crushed to obtain rice husk fragments. Sodium lauryl sulfate is prepared into a 0.05mol / l aqueous solution, and 50mL is taken, and 3g of rice husk fragments are added. min. Stir at room temperature for 2 hours, let stand for 2 hours, wash with distilled water and ethanol in turn, and dry at 60°C for 24 hours;

[0027] Step 2, preparing FeCl with a concentration of 2mol / l 3 150ml aqueous solution, add 9g ZnCl 2 As a pore-forming agent, ultrasonically treat for 15 minutes under the condition of ultrasonic power of 100W, then stir at 500r / min at room temperature for 10h, then add the rice husk fragments treated in step 1, and stir at 500r / min at room temperature. Stirring at low temperature for 10 hours, washing with distilled water...

specific Embodiment approach 2

[0032] Specific embodiment two: the method for preparing carbon-loaded transition metal silicides from rice husks in this embodiment is characterized in that the method is carried out according to the following steps:

[0033] Step 1: The rice husk is crushed to obtain rice husk fragments, and polyethyleneimine is prepared into a 0.05mol / l aqueous solution, and 50mL is taken, 3g of rice husk fragments are added, and ultrasonic treatment is performed for 15min under the condition of ultrasonic power of 100W, at a speed of 400r / min, Stir at room temperature for 2 hours, let stand for 2 hours, wash with distilled water and ethanol in turn, and dry at 60°C for 24 hours;

[0034] Step 2, configure the sodium tungstate (Na 2 WO 4 ) aqueous solution 150ml, add 9g ZnCl 2 (pore-forming agent), under the condition of ultrasonic power of 100W, sonicate for 15min, then stir at 400r / min at a rotating speed and room temperature for 10h, then add the rice husk fragments treated in step 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com