Activated carbon regeneration device and method

A regeneration device and activated carbon technology, applied in separation methods, filter regeneration, filtration and separation, etc., can solve problems such as environmental pollution, high energy consumption, economic and resource waste, and achieve strong process applicability, saving regeneration cycle, and improving The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

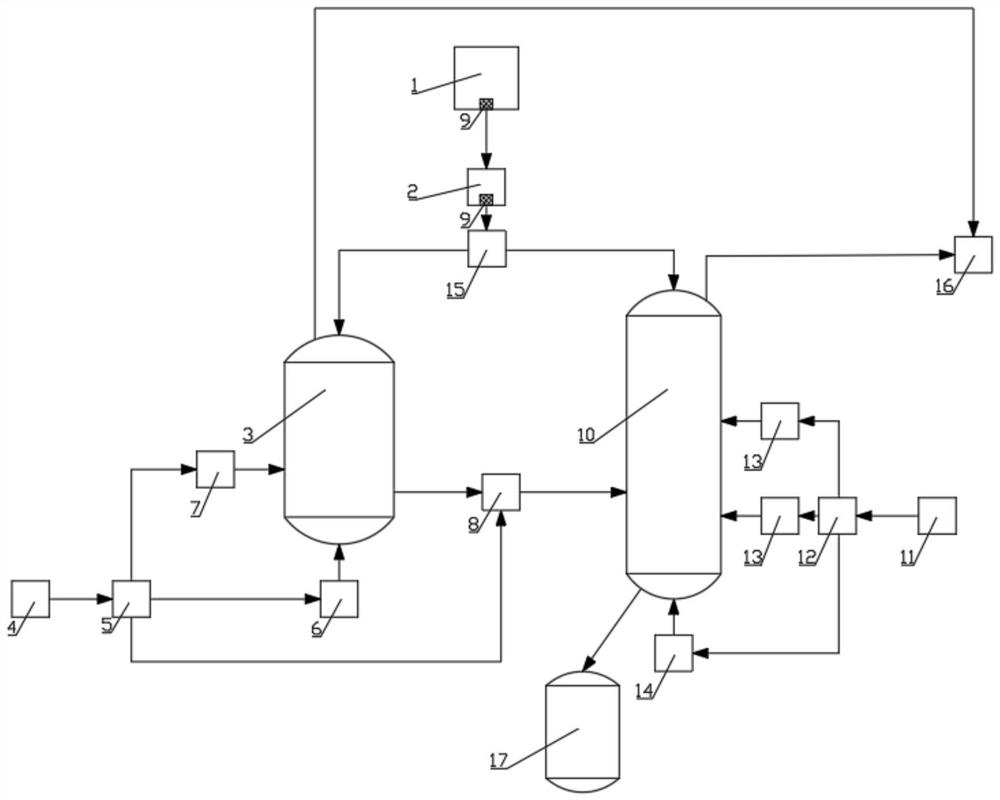

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] see figure 1 , The device of the present invention includes: a storage and feeding system, a carbonization and desorption system, and an activated hole reaming system;

[0033] The storage and feeding system includes an activated carbon storage bin 1, a feeder 2, and a channel diverter 15 that are sequentially connected by pipelines. The bottoms of the activated carbon storage bin 1 and the feeder 2 are respectively provided with auxiliary feeders 9, and the channel turns to The device 15 communicates with the carbonization desorber 3 and the high temperature activation hole reamer 10 respectively;

[0034] The carbonization desorption system includes a carbonization desorption device 3, a carrier gas preprocessor 5, a carrier gas injector 6, a carrier gas distributor 7, and a delivery controller 8, wherein the carrier gas injector 6, the carrier gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com