Patents

Literature

32results about How to "Avoid secondary adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

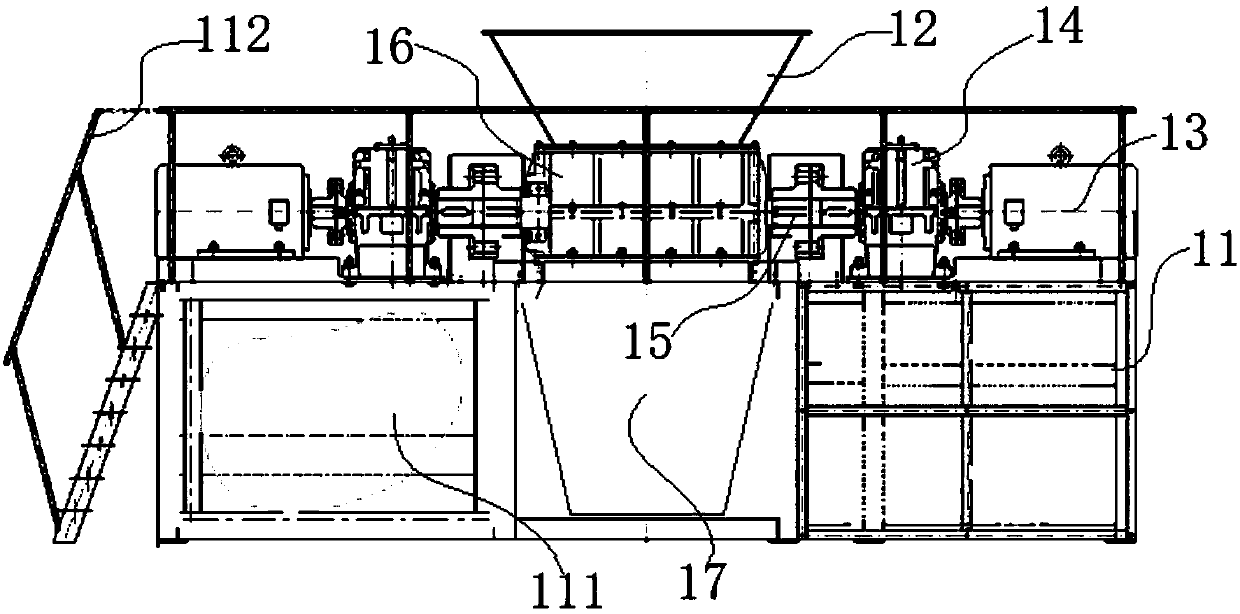

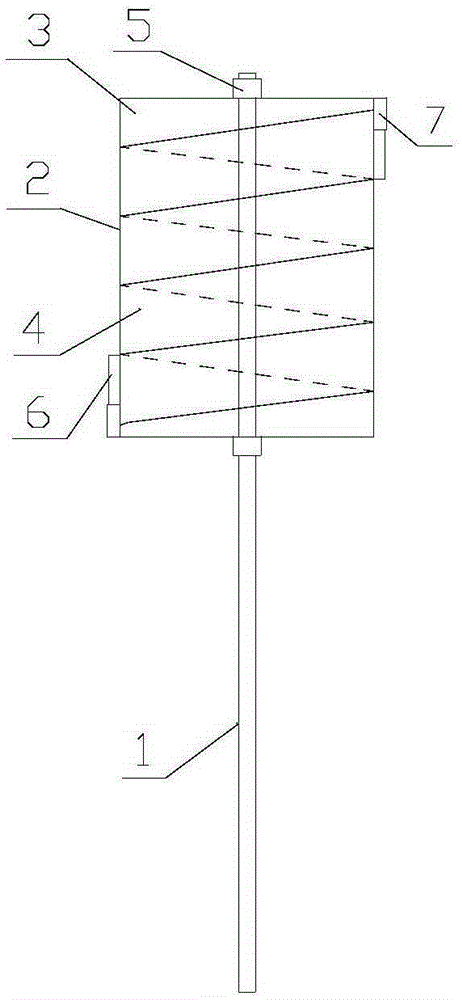

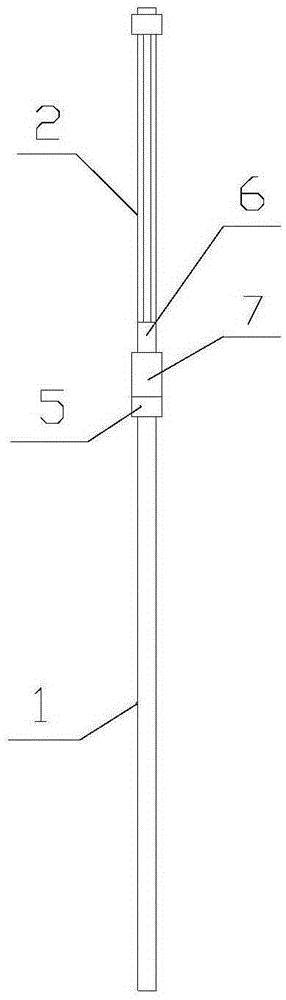

Floating technology for low-grade refractory weathering collophanite section desliming

InactiveCN104959239AAvoid secondary adsorptionImprove flotation efficiency andFlotationWet separationOre concentrateMining engineering

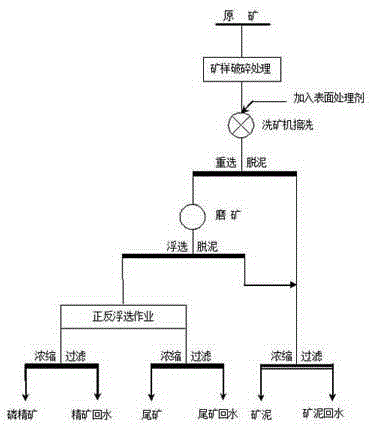

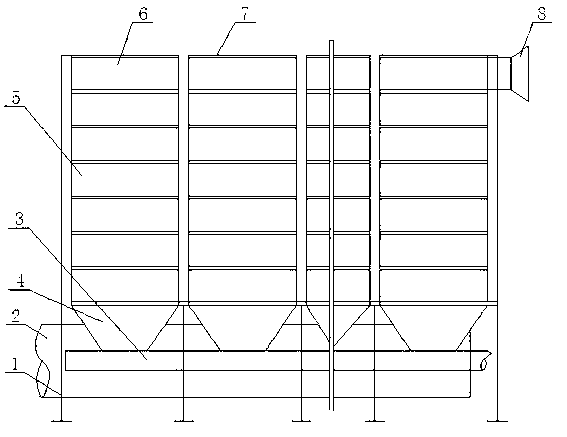

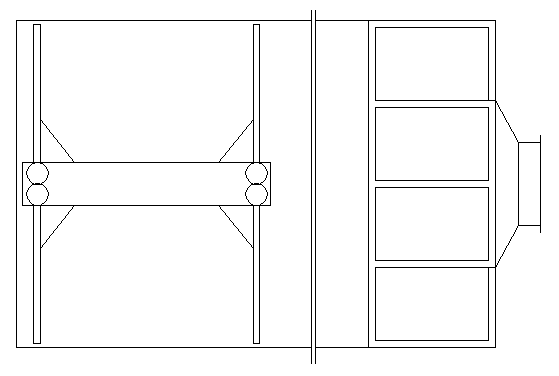

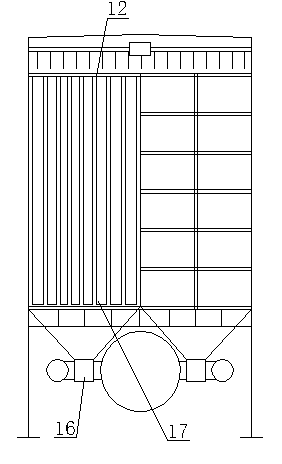

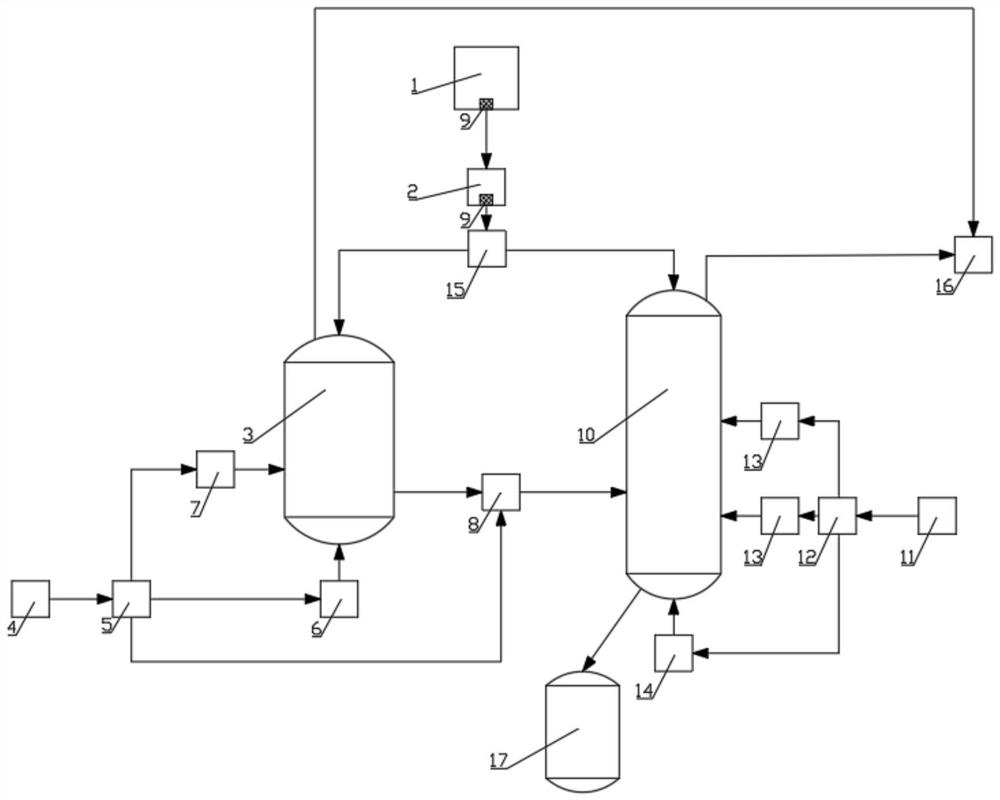

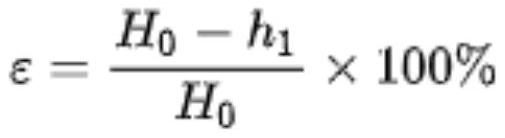

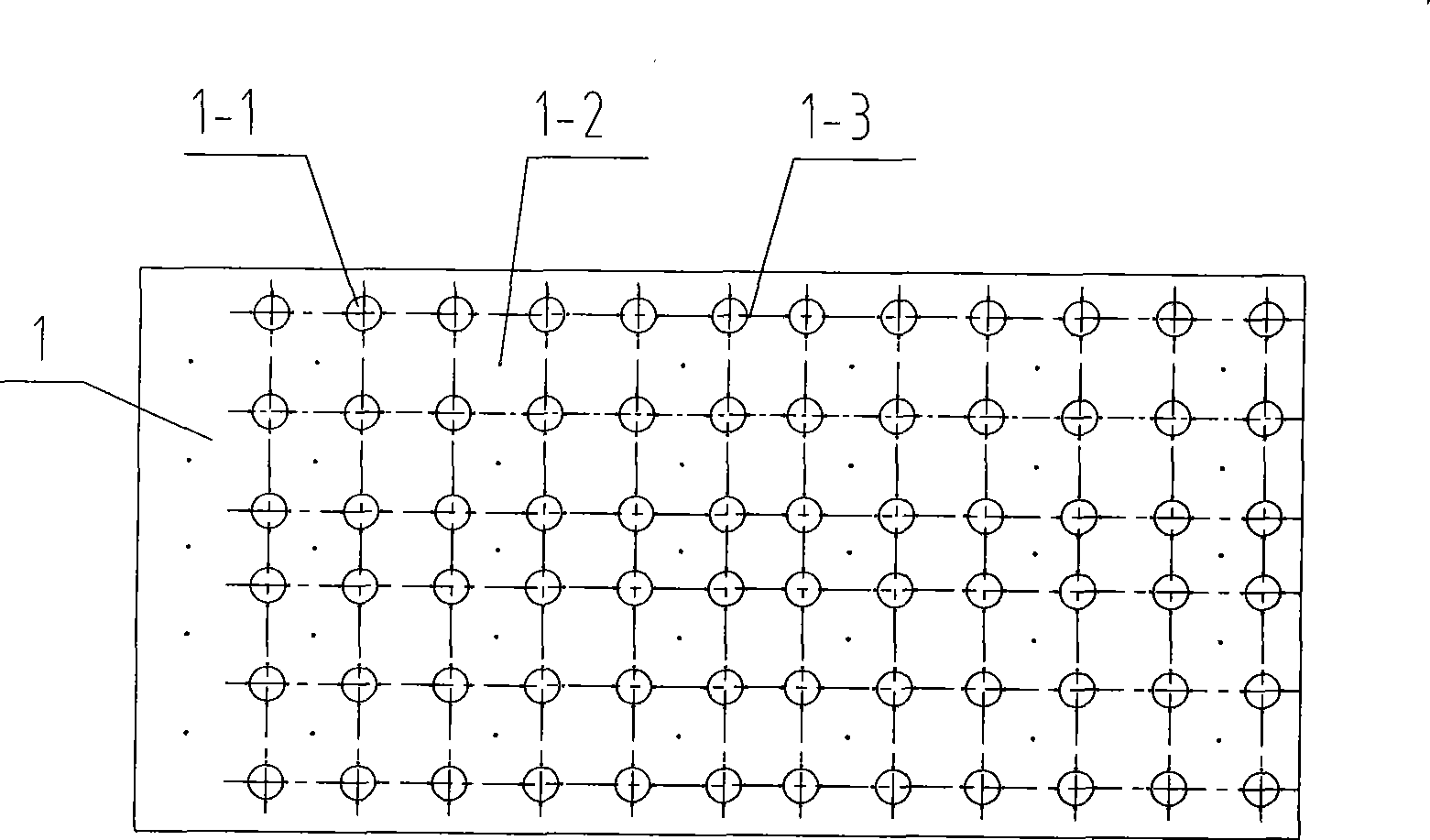

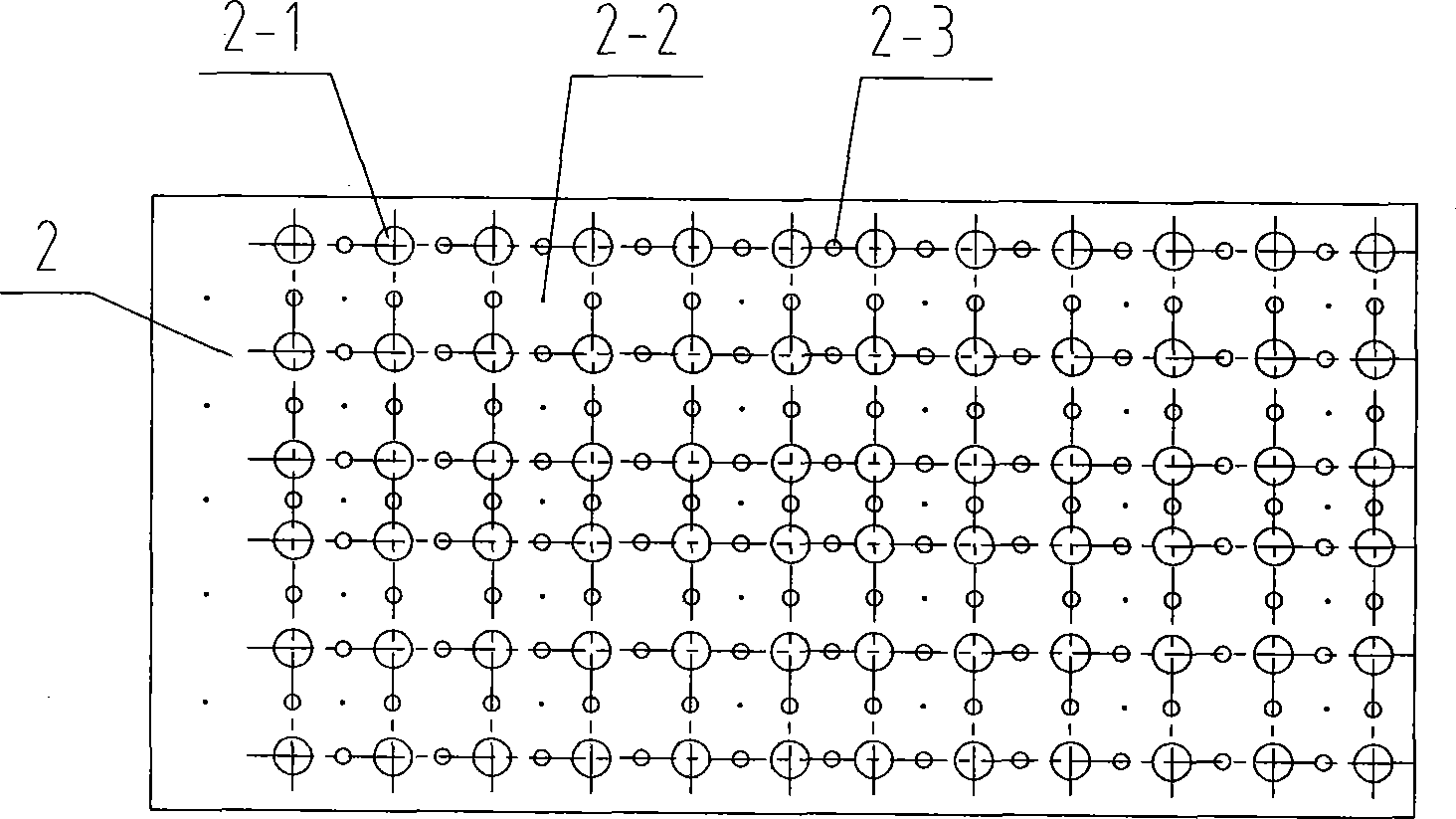

The invention provides a floating technology for low-grade refractory weathering collophanite section desliming. The technology comprises the steps that after coarse crushing and fine crushing are carried out on raw ore, a surface treating agent is added, and the raw ore is subjected to washing in an ore washer; washed pulp enters a shaking table to be subjected to a first-section desliming, coarse particle minerals are subjected to next desliming, and fine silt serves as slurry and is processed; the ore grinding treatment is carried out on the coarse particle minerals, ore grinding pulp is subjected to second-segment desliming, deslimed pulp is subjected to the positive and negative floating operation, and floating concentrate and floating tailings are obtained; after concentrating and filtering are carried out on the floating concentrate, a phosphorus concentrate product and concentrate backwater are obtained, the concentrating and the filtering are carried out on positive floating tailings and negative floating tailings, a tailings product and tailings backwater are obtained, deslimed two-section slurry is subjected to the concentrating and the filtering, and a slurry product and slurry backwater are obtained; according to needs, the concentrate backwater, the tailings backwater and the slurry backwater are back to the floating operation and backwater points of the ore washer to be subjected to recycling. The phosphorus concentrate quality can be improved, and the resource utilization of the low-grate collophanite is achieved.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

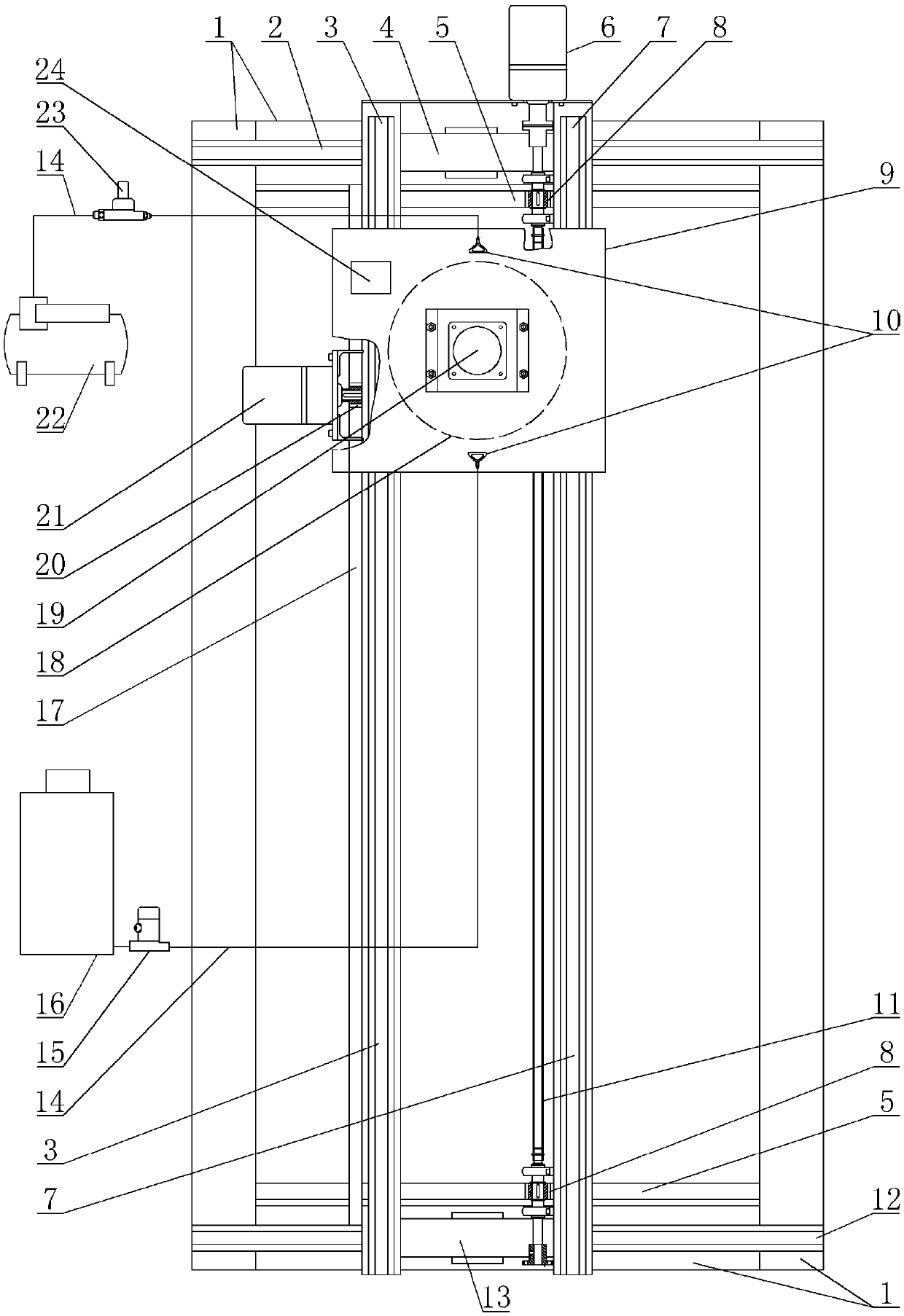

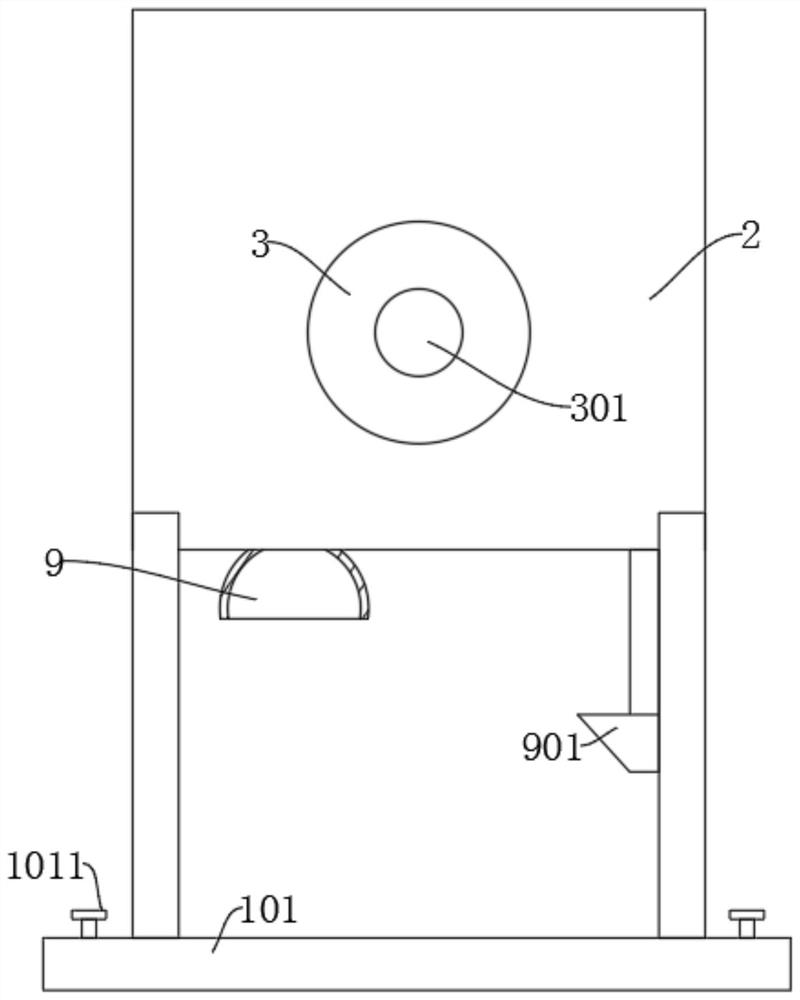

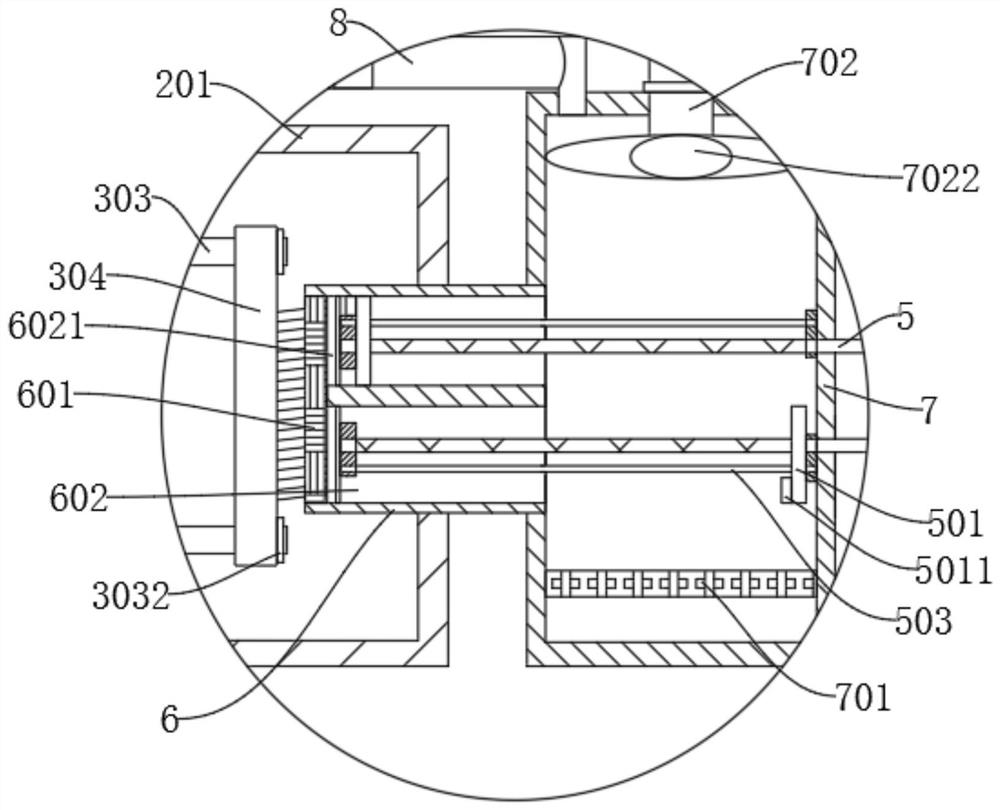

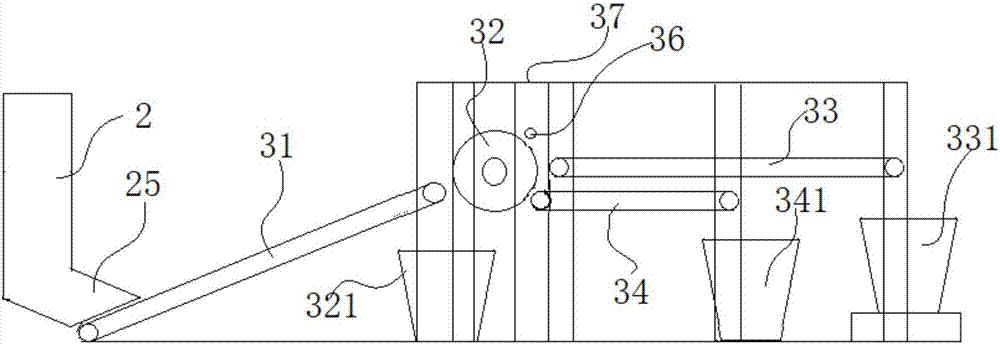

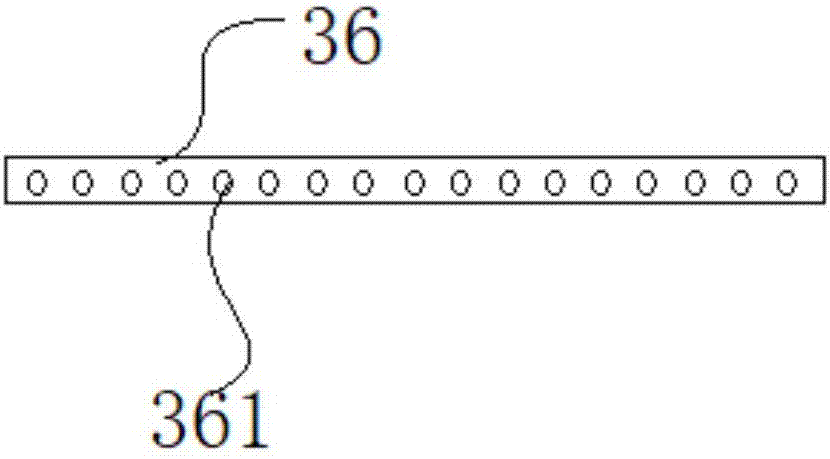

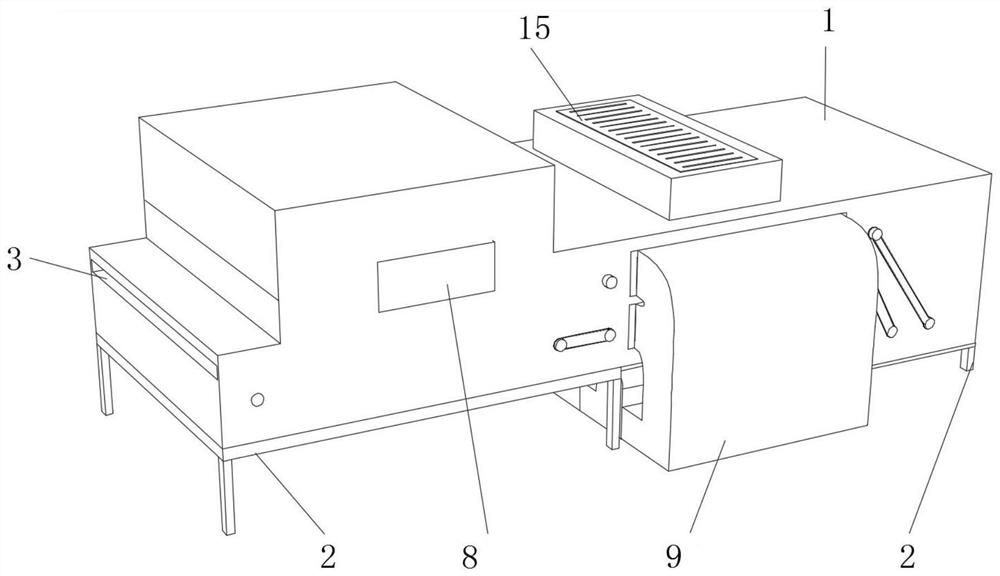

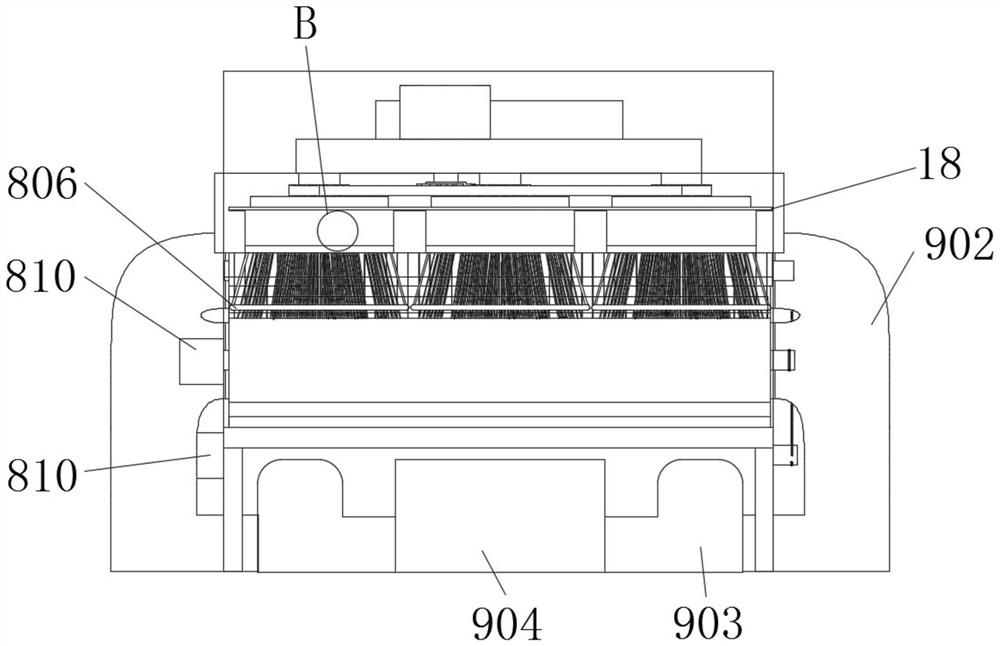

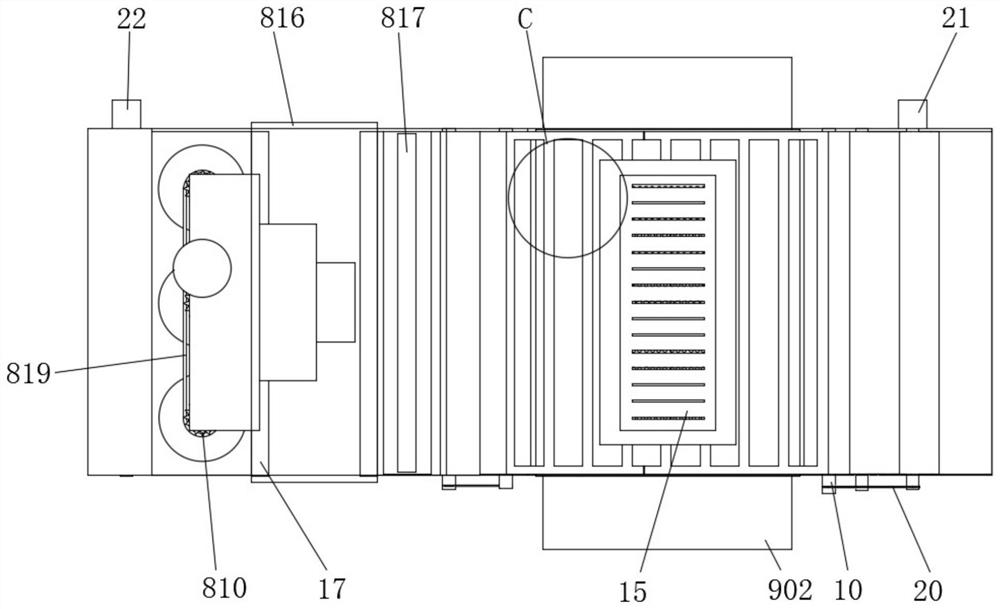

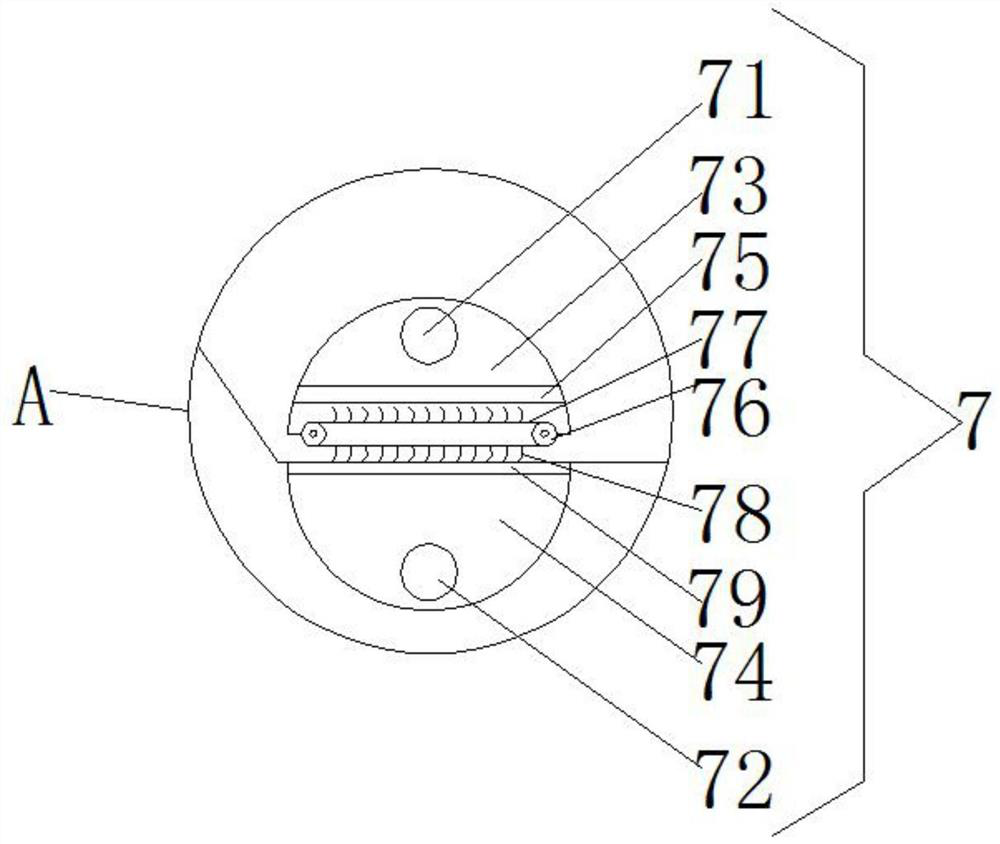

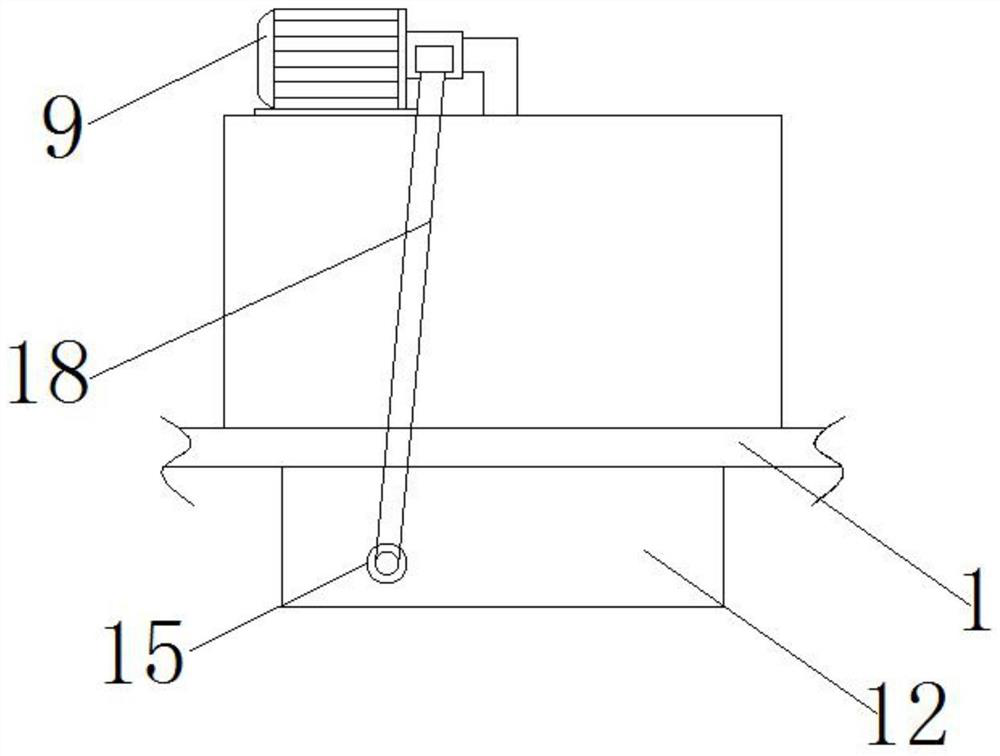

Textile ironing device

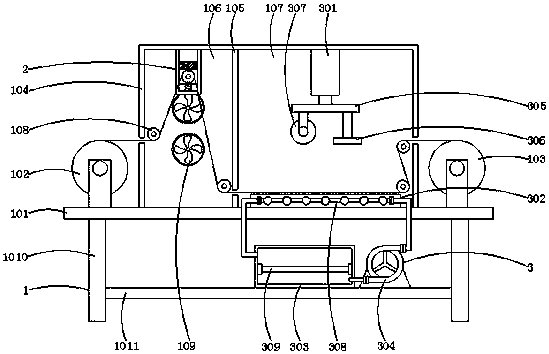

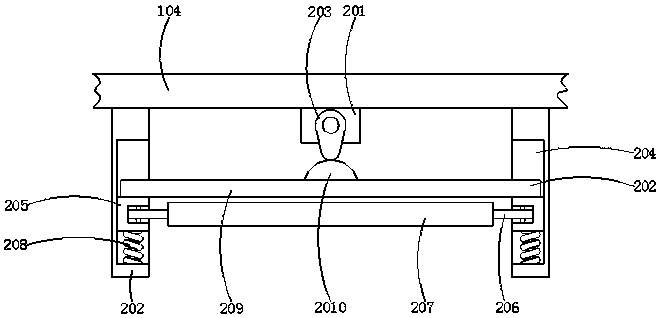

InactiveCN109183341AAchieve clearingGuarantee product qualityMechanical cleaningPressure cleaningEngineeringTextile

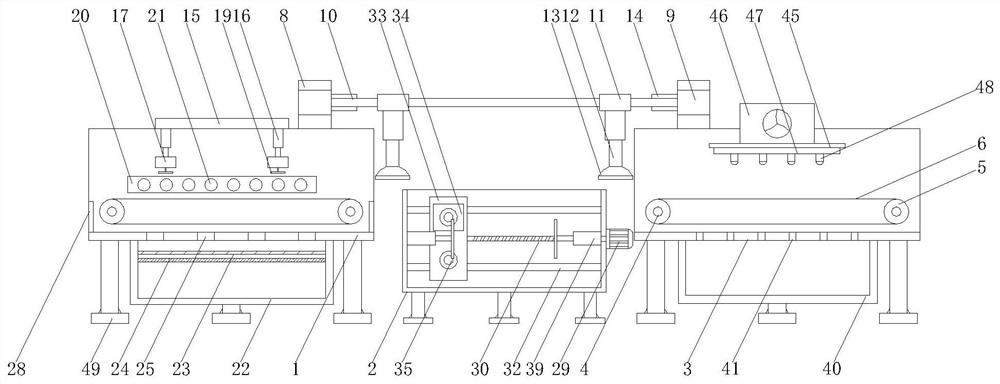

The invention provides a textile ironing device and relates to the technical field of textile equipment. The textile ironing device realizes treatment on dust on a fabric and ensures the ironing effect of the fabric. The textile ironing device comprises a base device, a dust removing device and an ironing device. The base device is provided with the dust removing device and the ironing device. Thebase device comprises a work table. The top of the work table is fixedly provided with a feeding roller, a collection roller and an operation box. The interior of the operation box is divided into adust removal chamber and an ironing chamber through a partition plate. A suction fan is arranged in the dust removal chamber. Through cooperation of a rotary motor, a cam, a curved block, a dust removing roller, a return spring and the suction fan, the impurities shaken out of the dust removal chamber are sucked out so that impurities are prevented from being adsorbed onto the fabric again, impurities on the fabric are removed, the subsequent ironing is promoted, the quality of the fabric is guaranteed and the wrinkles are reduced.

Owner:射阳县汇佳纺织有限公司

Glass erosion liquid and preparation method thereof

The invention relates to a vitreous etching bath, which comprises 0.5%-8% microcosmic salt, 0.5%-8% pyrophosphate, 0.01%-0.5% inorganic alkaline, 5%-45% surface activator and 39%-93% water. The preparing method comprises the following steps: adding the microcosmic salt and the pyrophosphate in the water, heating in order to dissolve; adding inorganic alkaline and non-ionic surface activator and mixing. The invention can remove greasy dirt, fingerprint, particles and sio2 for buffed glass base plate, which can removes the impurity and Ceo2 on the glass, achieves the request of the environmental protection.

Owner:天津晶岭电子材料科技有限公司

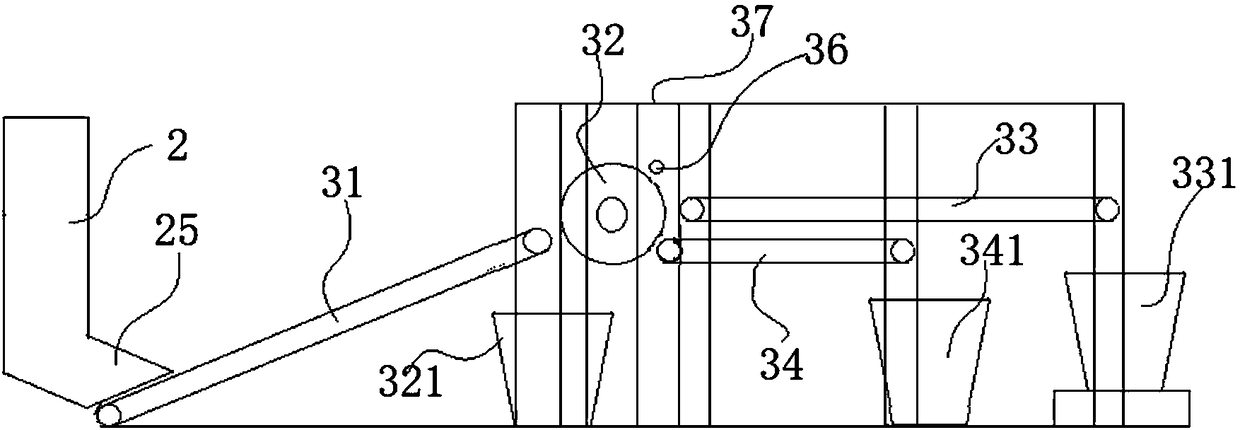

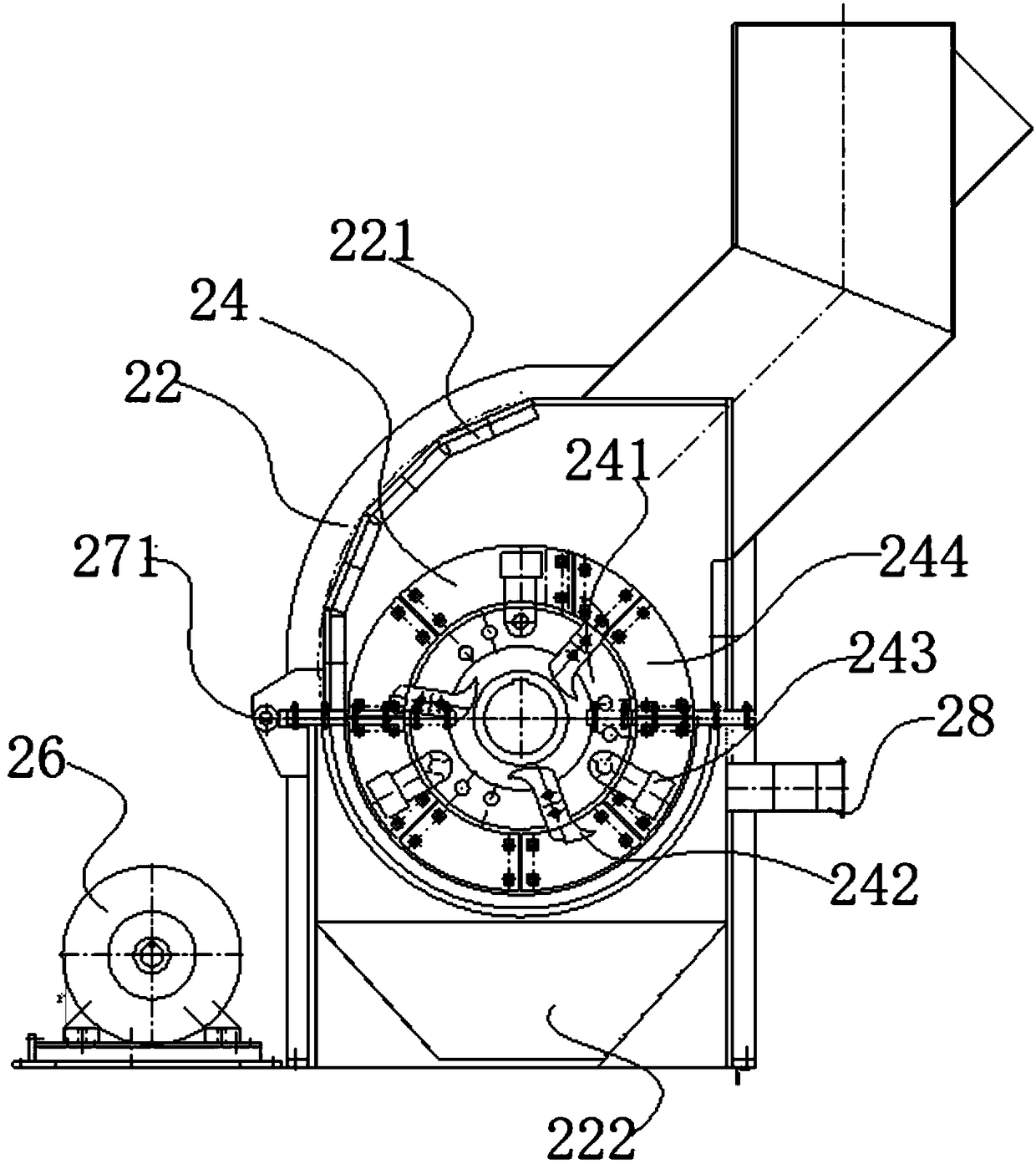

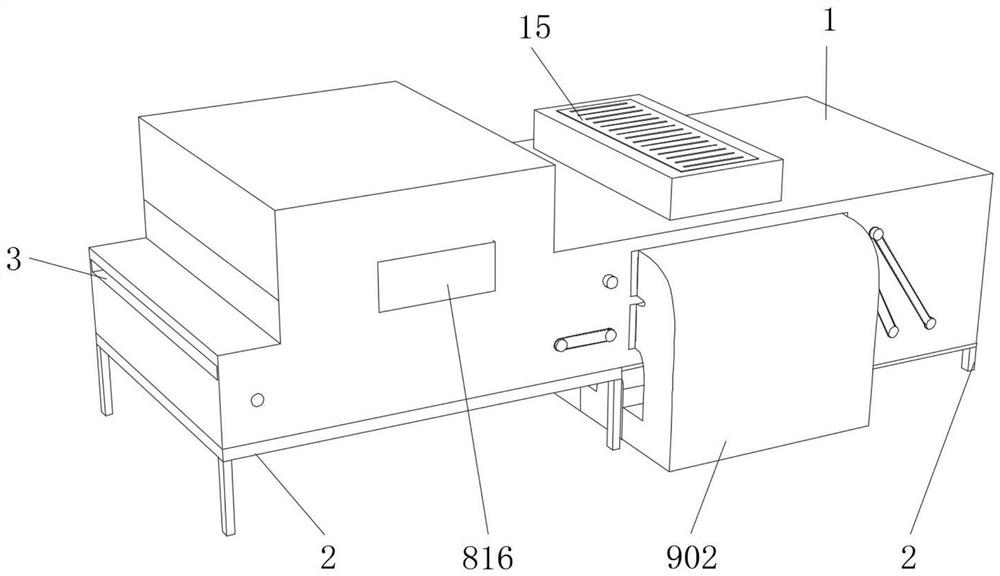

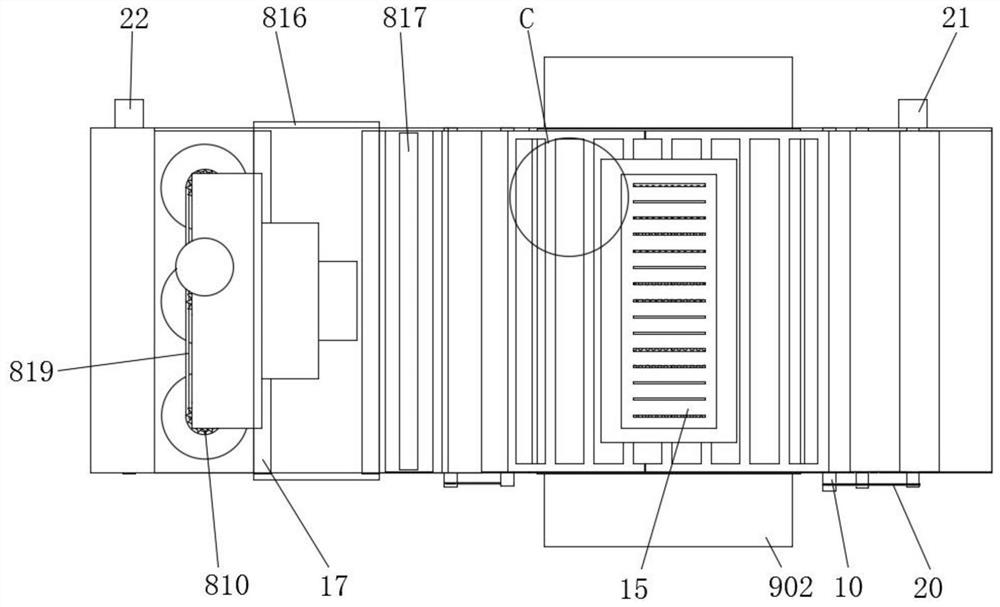

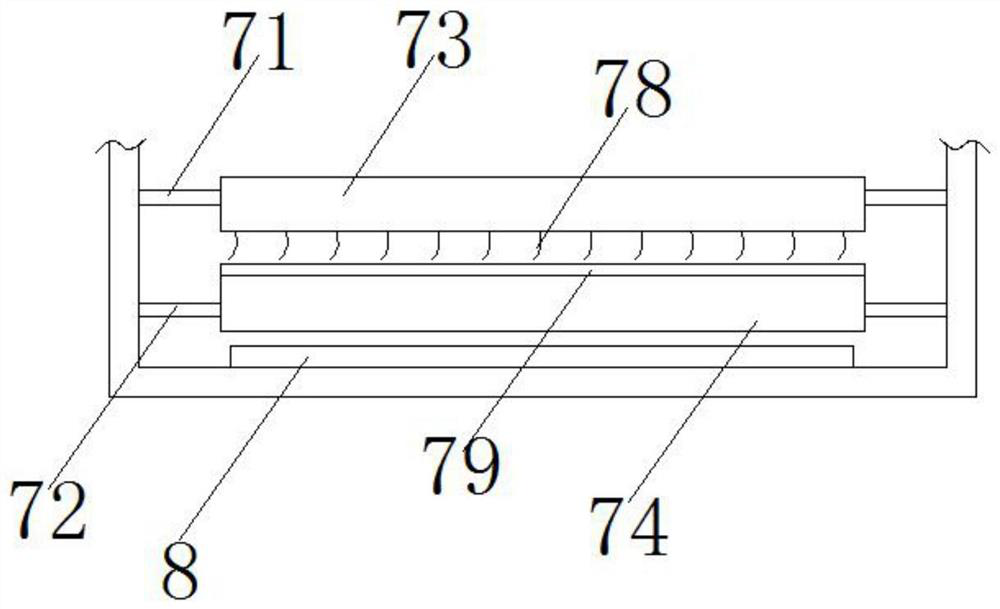

Crushing and classification device for light and thin metal, and treatment process thereof

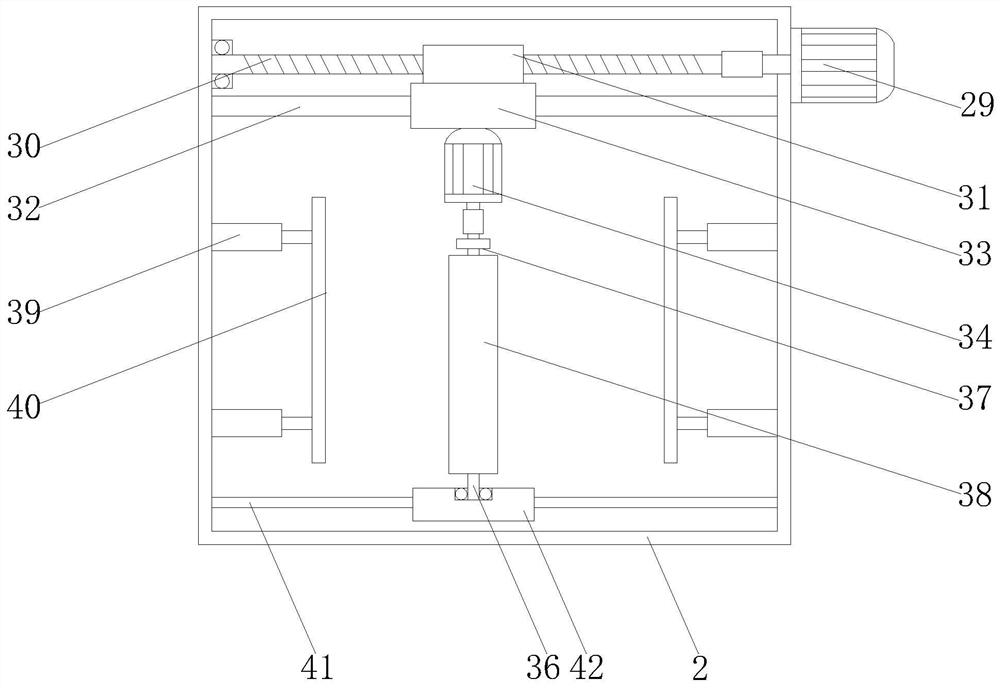

InactiveCN108057495AAchieve the purpose of breakingEasy to operateDirt cleaningMagnetic separationThin metalFixed frame

The invention discloses a crushing and classification device for light and thin metal, and a treatment process thereof, and belongs to the technical field of classification after metal crushing. The crushing and classification device disclosed by the invention comprises a crushing device and a classification device which are arranged according to working procedures and connected through a loadingconveying belt, and the crushing device comprises a hollow case, a charge hopper formed in the top of the case, and a crushing mechanism in the case; the overall diameter of the crushing mechanism isslightly less than the width of the case, and the crushing mechanism comprises a movable cutter head, a movable cutter, a fixed cutter and a fixed cutter head; each of the movable cutter head and thefixed cutter head is annular; the classification device comprises a frame-shaped fixed frame and a magnetic roller fixed to the fixed frame through a bearing, and the loading conveying belt and a discharge conveying belt which are fixed to the fixed frame separately are arranged at the two sides of a roller surface of the magnetic roller; the tail end of the loading conveying belt is close to theroller surface of one side of the magnetic roller, and reserved with a non-iron material falling gap; and the beginning end of the discharge conveying belt is infinitely next to the roller surface ofthe other side of the magnetic roller. The problems of time waste and labor waste of metal crushing and manual classification after crushing are solved.

Owner:安徽华龙环保技术工程有限公司

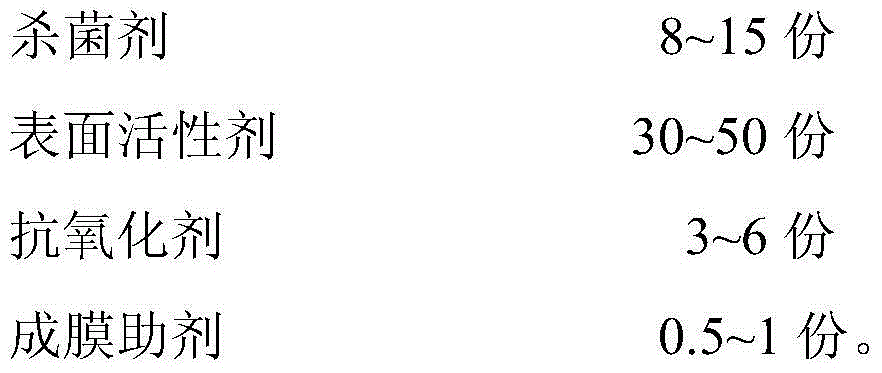

Antibacterial screen cleaning agent

InactiveCN104694268ANo escapeNot corrosiveInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAntioxidantCleansing Agents

The invention provides an antibacterial screen cleaning agent, which is composed of the following components by mass: 8-15 parts of a bactericide, 30-50 parts of a surfactant, 3-6 parts of an antioxidant, and 0.5-1 part of a film-forming auxiliary agent. After use, the cleaning agent provided by the invention can effectively remove the dust and bacteria adsorbed on a screen and form a protective film on the screen surface, and can continuously and effectively prevent dust secondary adsorption and bacteria breeding.

Owner:大连市西岗区众源生办公设备商行

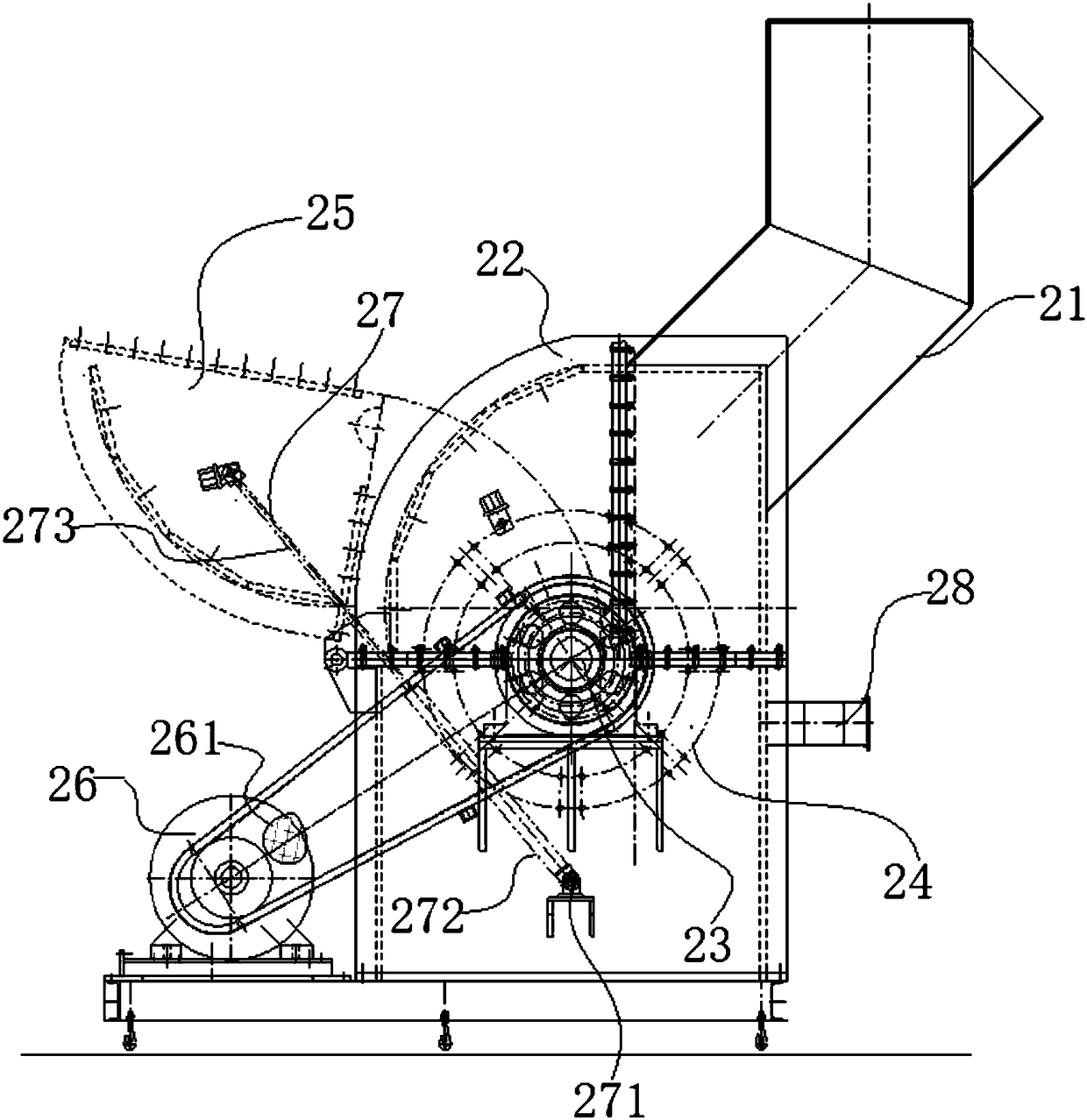

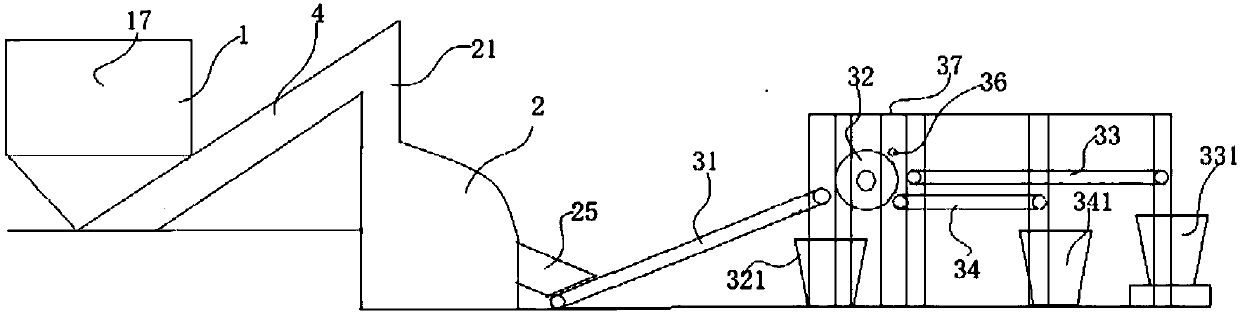

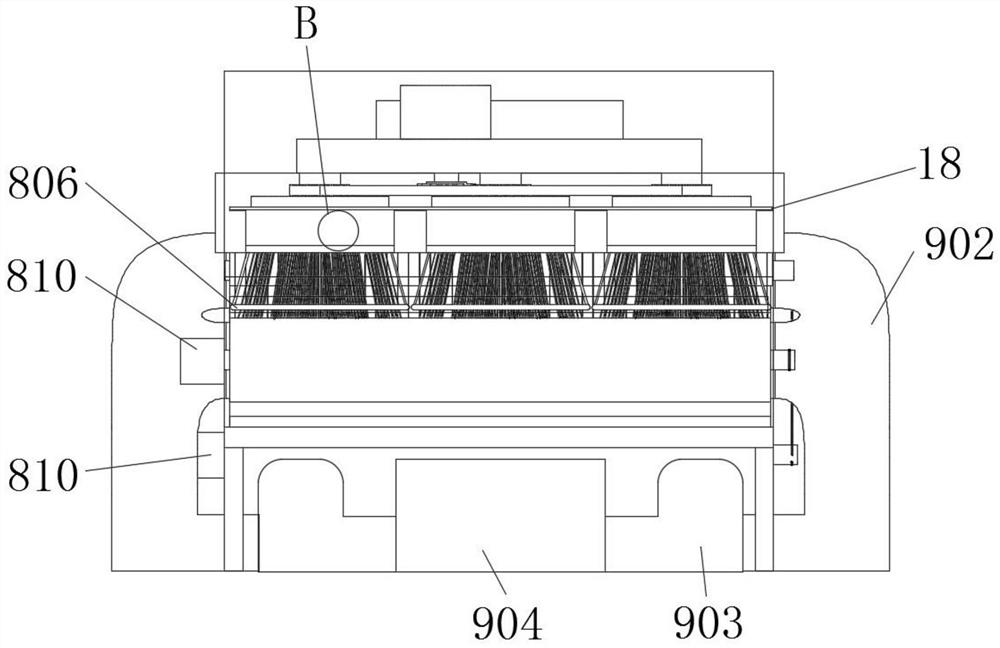

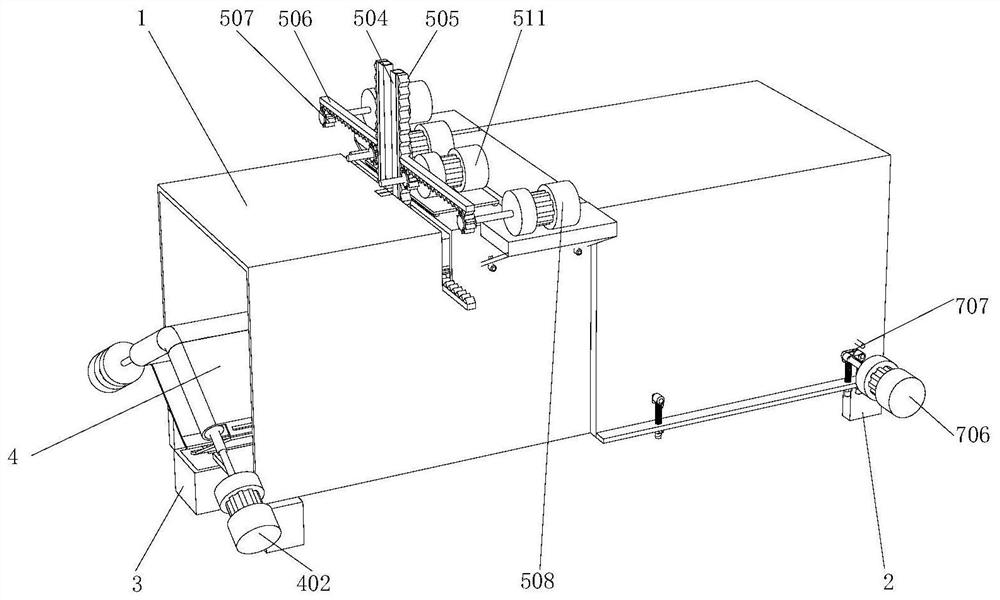

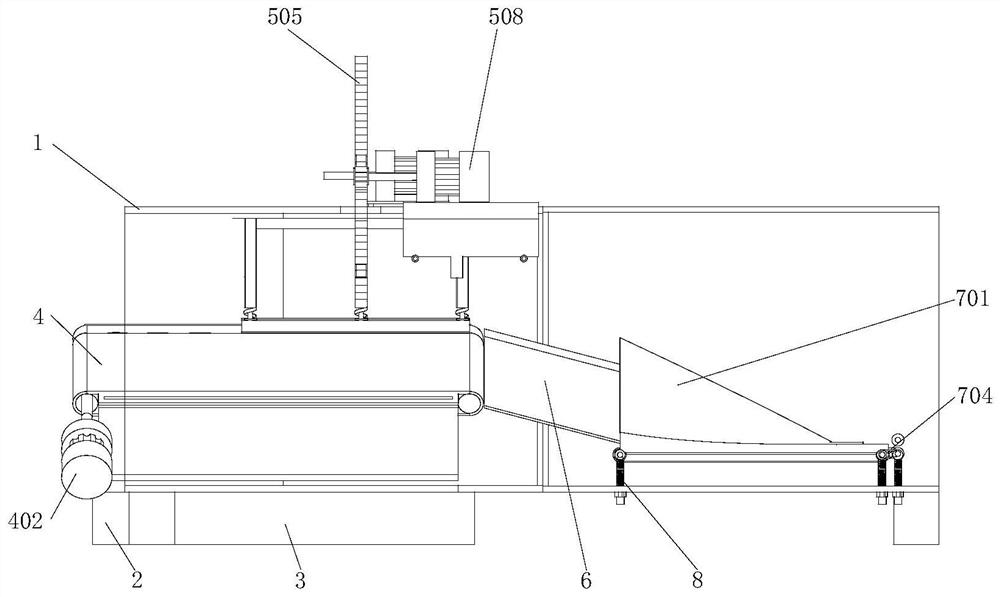

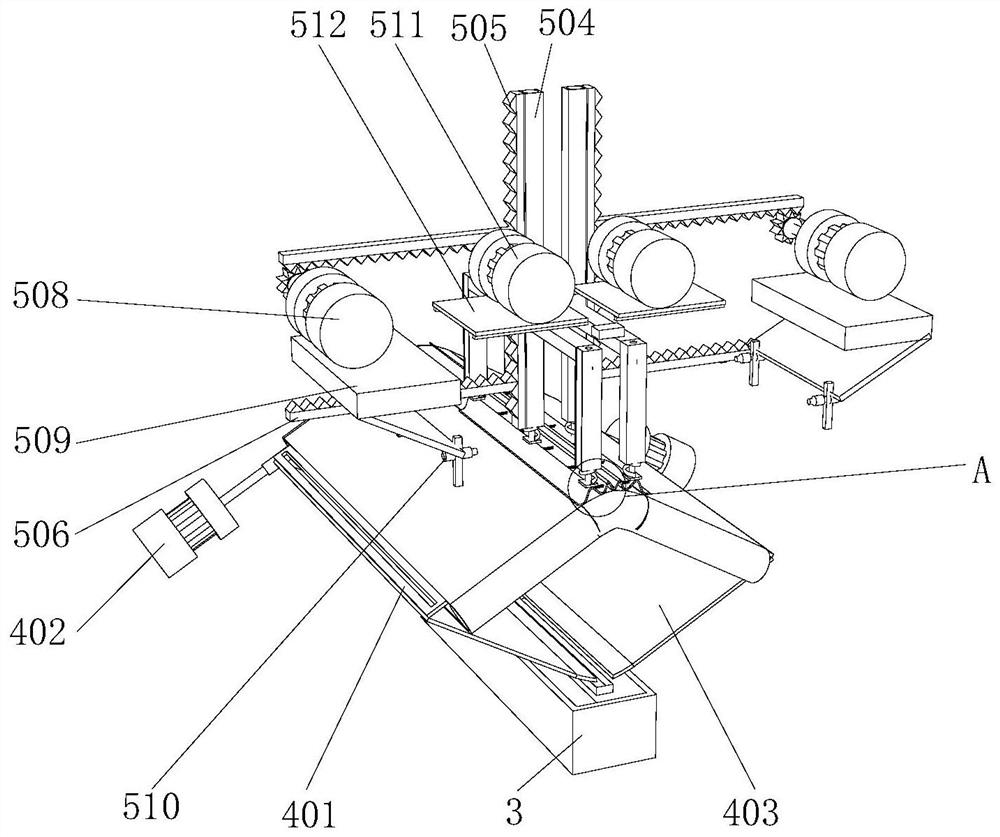

Light and thin metal fine crushing treatment device and fine crushing and sorting process thereof

InactiveCN107890939AAvoid material jamsPrevent lockDirt cleaningMagnetic separationThin metalEngineering

The invention discloses a light and thin metal fine crushing treatment device and a fine crushing and sorting process thereof and belongs to the technical field of metal crushing and sorting. The light and thin metal fine crushing treatment device comprises a tearing device, a crushing device and a sorting device which are arrayed according to working processes. The tearing device and the crushingdevice are connected through a feeding packing auger. The crushing device and the sorting device are connected through a feeding conveyor belt. The tearing device comprises a frame-shaped rack and afeed port fixed to the middle portion of the upper end face of the rack and further comprises a tearing mechanism. The crushing device comprises a hollow machine box, a feeding hopper formed in the top of the machine box and a crushing mechanism in the machine box. The sorting device comprises a frame-shaped fixing frame and a magnetic roller fixed to the fixing frame through a bearing. The two sides of the roller face of the magnetic roller are provided with a feeding conveyor belt and a discharging conveyor belt which are fixed to the fixing frame. The starting end of the discharging conveyor belt is infinitely attached to the roller face of the other side of the magnetic roller. By means of the light and thin metal fine crushing treatment device and the fine crushing and sorting processthereof, the problems that time and labor are wasted in metal crushing and manual sorting after crushing.

Owner:安徽华龙环保技术工程有限公司

Leather cleaning device in production

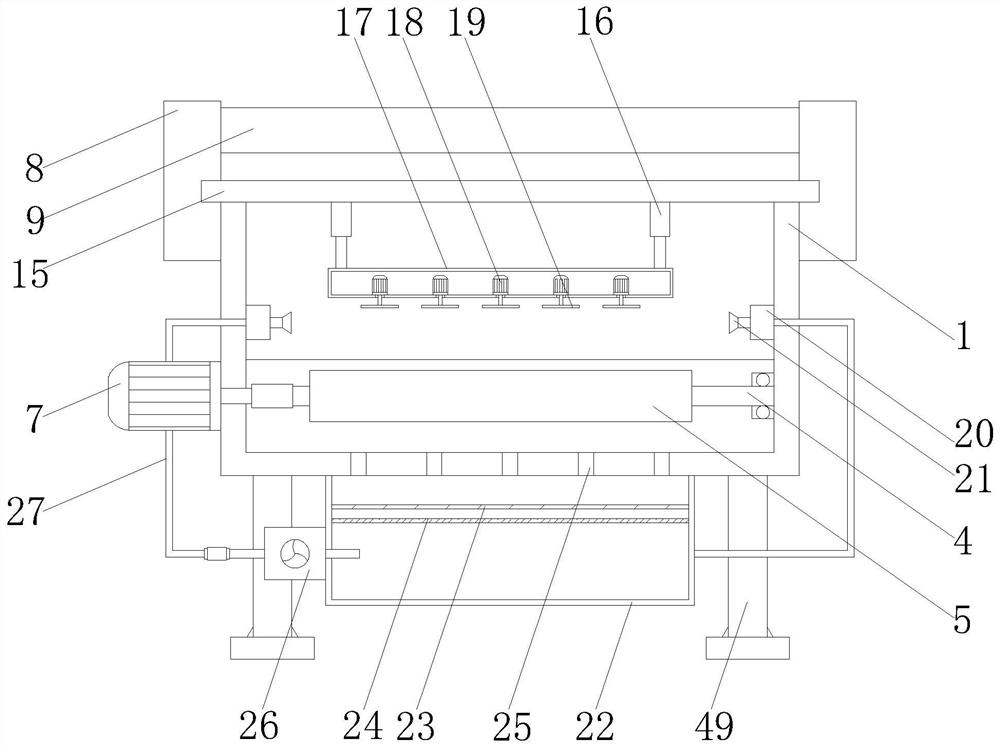

ActiveCN111719302AAvoid savingImprove adsorption capacityMechanical cleaningPressure cleaningAir filtrationAir filter

The invention relates to the technical field of leather cleaning, in particular to a leather cleaning device in production. The leather cleaning device comprises a machine shell, a bracket, a feedingopening, a discharging opening, a first transferring device, a second transferring device, a third transferring device, a leather cleaning mechanism, a drying mechanism, a rotary shaft, a cylinder, anarc-shaped baffle, an air filtering box, an air inlet, a filtering net plate, a filter screen, an electrostatic absorption device, a fixed plate, a baffle, a triangular belt, a second driving motor and a third driving motor. The machine shell is arranged at the top end of the bracket, the second driving motor is connected to the position, close to the tail end, of the left side of the machine shell, the third driving motor is arranged on the left side of the machine shell, the air filtering box is arranged on the right side of the top end of the machine shell, the feeding opening is formed inthe front surface of the machine shell, the discharging opening is formed in the back surface of the machine shell, the first transferring device is arranged in the machine shell, and the leather cleaning mechanism is arranged on the first transferring device. According to the leather cleaning device in the production, the problems that the leather cleaning is insufficiently thorough and the leather compaction degree is not ideal in the production are solved.

Owner:RUIAN DAHU SHOES IND CO LTD

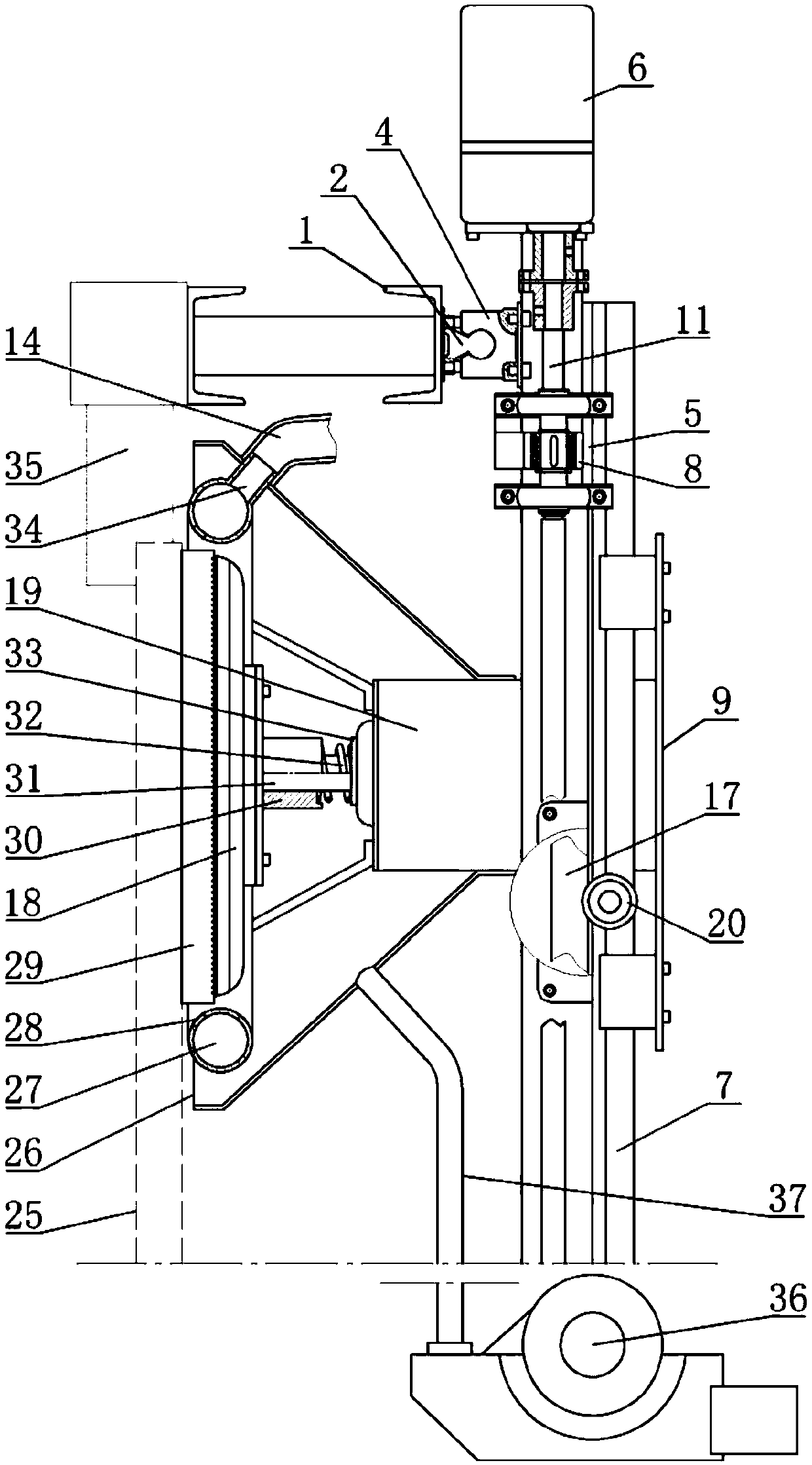

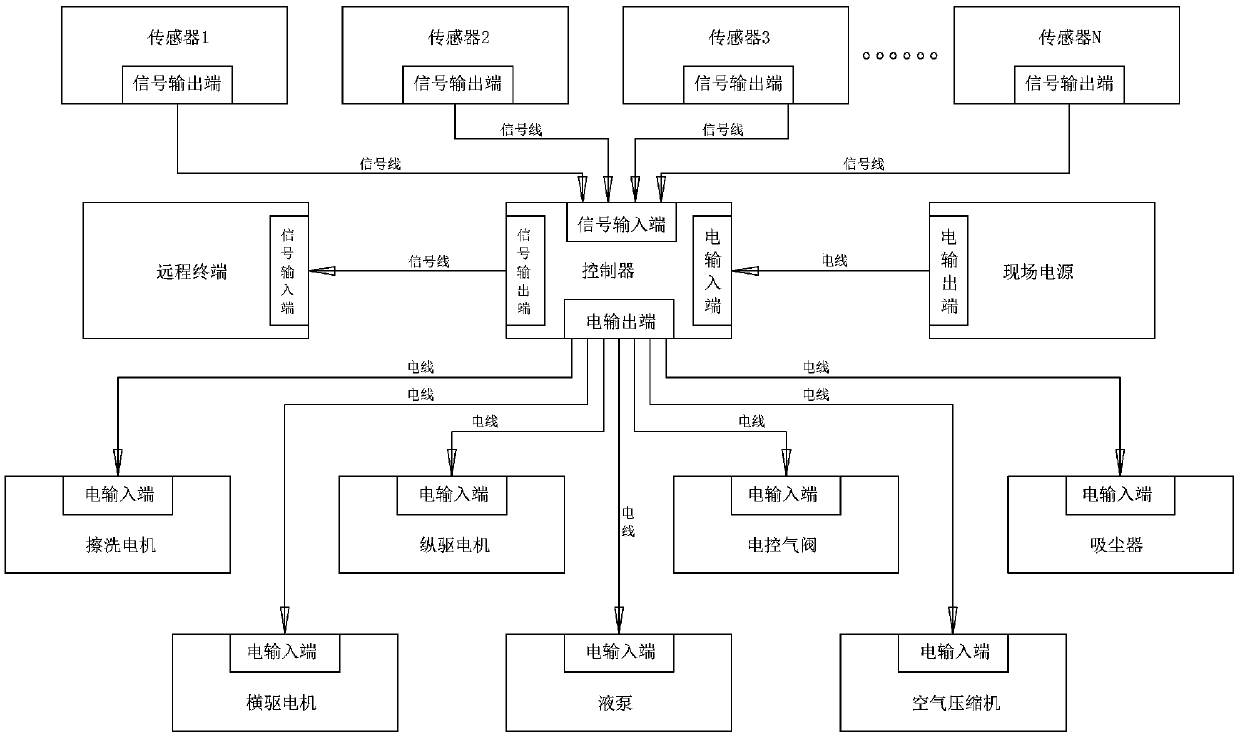

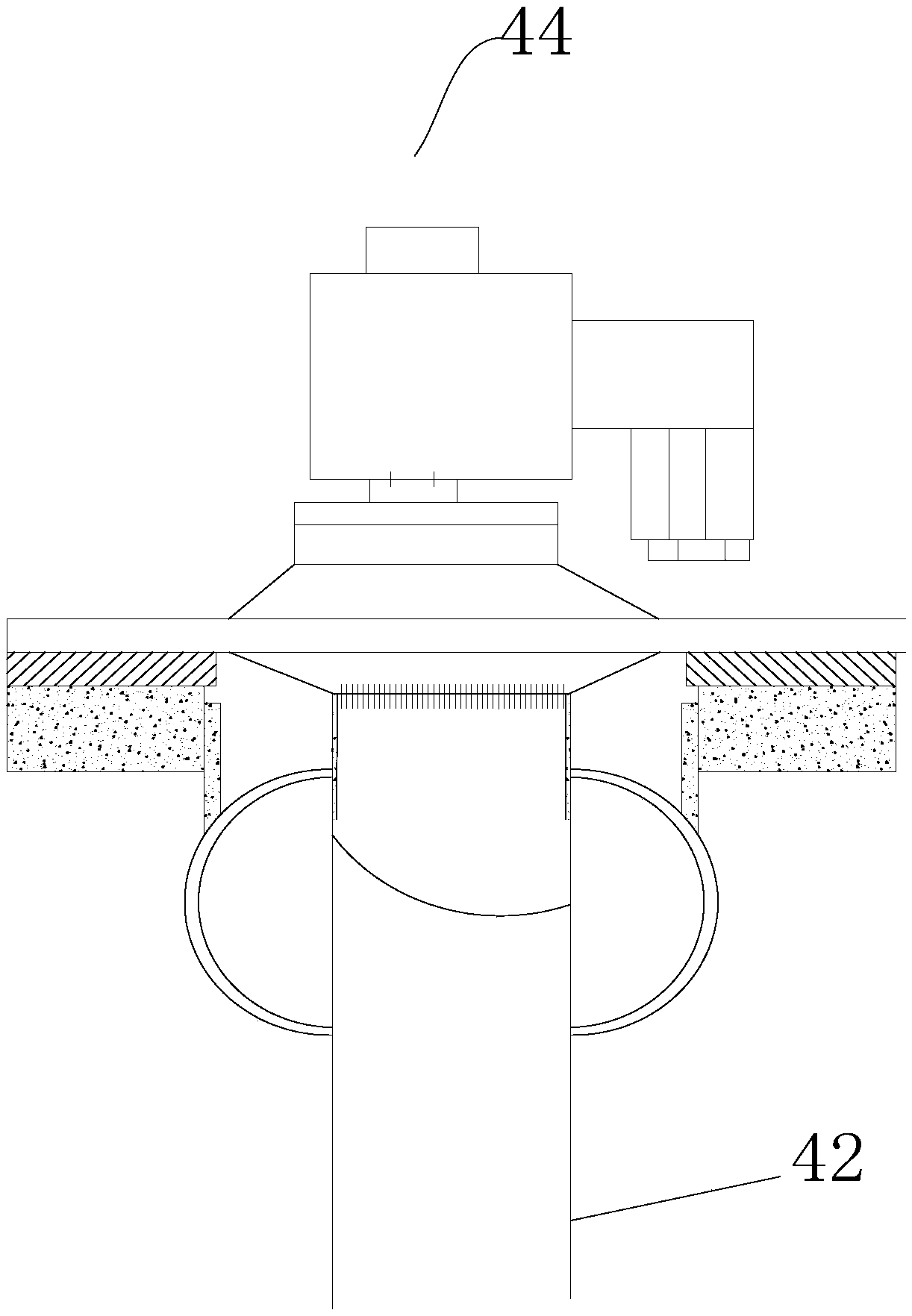

Dust removal device for glass screen

PendingCN109570176AImprove efficiencyImprove dust removal effectDirt cleaningFlexible article cleaningElectric machineryDrive motor

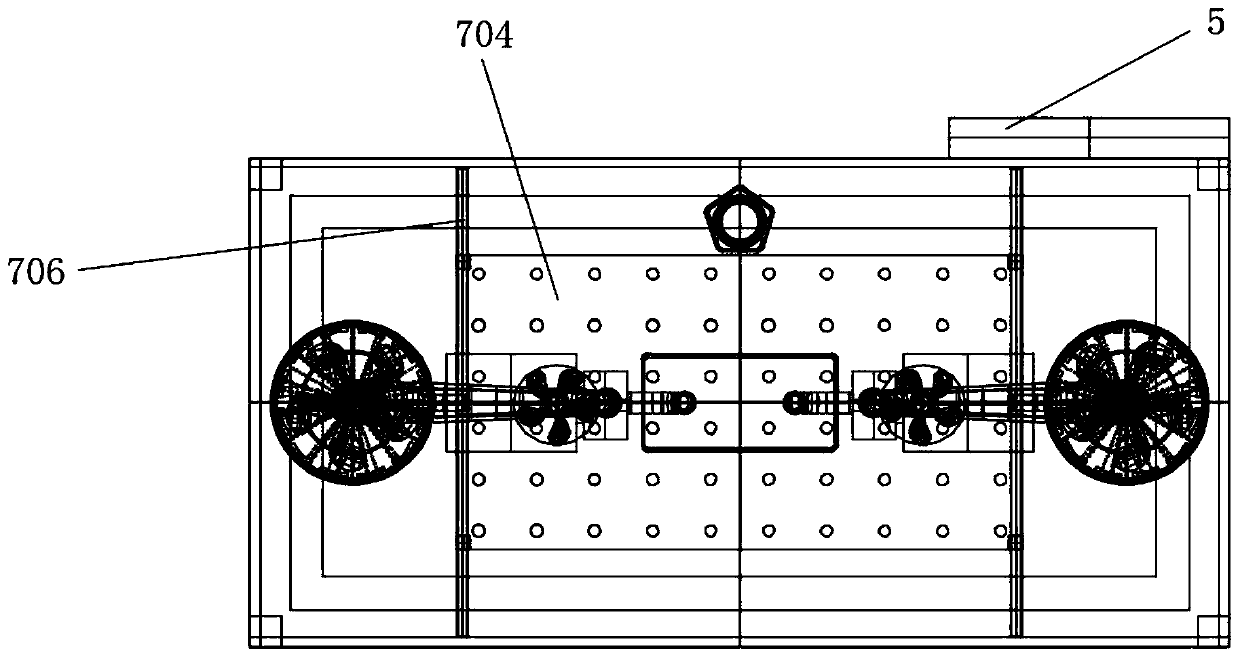

A dust removal device for a glass screen is specially used for removing dust on the glass screen of a central control room and is provided with a frame, a walking mechanism, a scrubbing mechanism anda controller. The walking mechanism is provided with an upper cross rail, a lower cross rail, a transverse drive motor, a transverse drive rack, a transverse drive gear, an upper slide carriage, a lower slide carriage, a left longitudinal rail, a right longitudinal rail, a scrubbing slide carriage, a longitudinal drive motor, a longitudinal drive rack and a longitudinal drive gear. The scrubbing mechanism is provided with a scrubbing disc and a scrubbing motor, the scrubbing motor is arranged between the left longitudinal rail and the right longitudinal rail. A body of the scrubbing motor is fixedly connected with the scrubbing slide carriage. One end of the scrubbing disc is in power connection with the scrubbing motor through a pressing mechanism, and a cleaning brush is mounted at the other end of the scrubbing disc. The motors are electrically connected with the controller. The frame is fixed around the glass screen, the cleaning brush is pressed on the surface of the glass screen,the transverse drive motor drives the scrubbing disc to shift left and right through a gear and rack pair, and the longitudinal drive motor drives the scrubbing disc to shift up and down through a gear and rack pair; and the scrubbing motor drives the scrubbing disc to rotate, dust on the glass screen of the central control room can be effectively removed, time and labor are saved, and efficiencyis high.

Owner:赵澜越

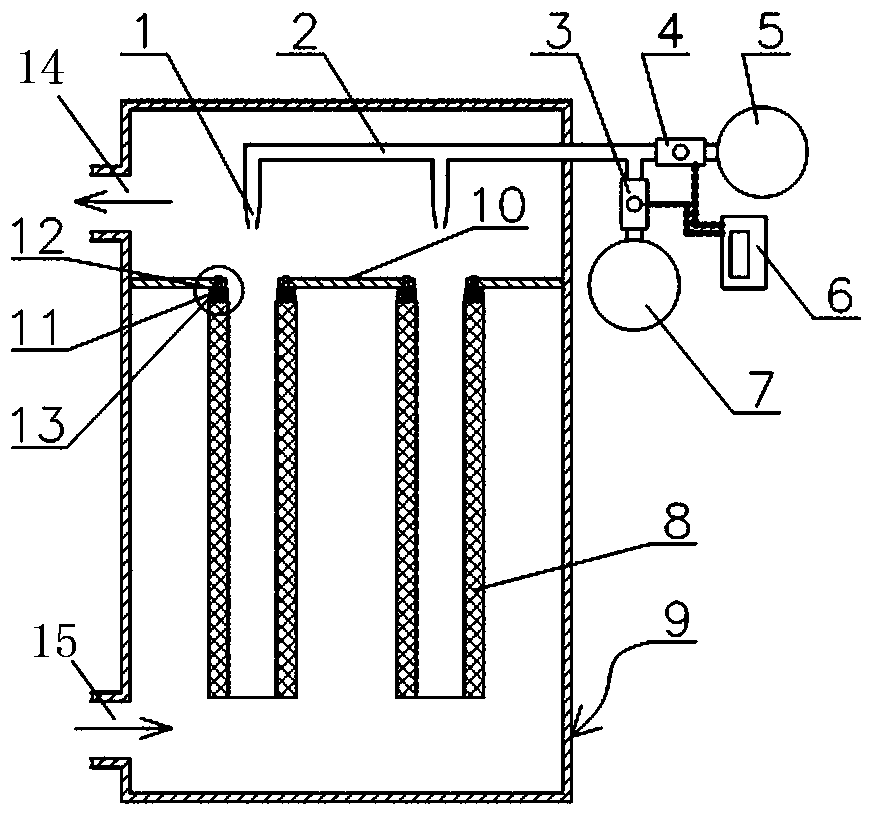

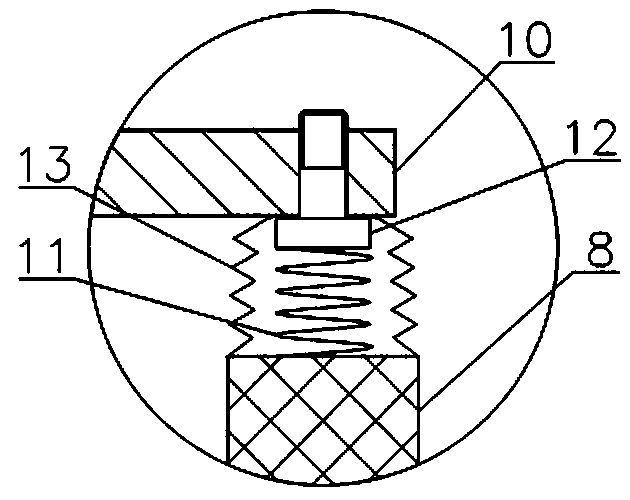

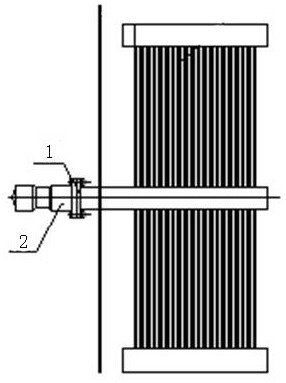

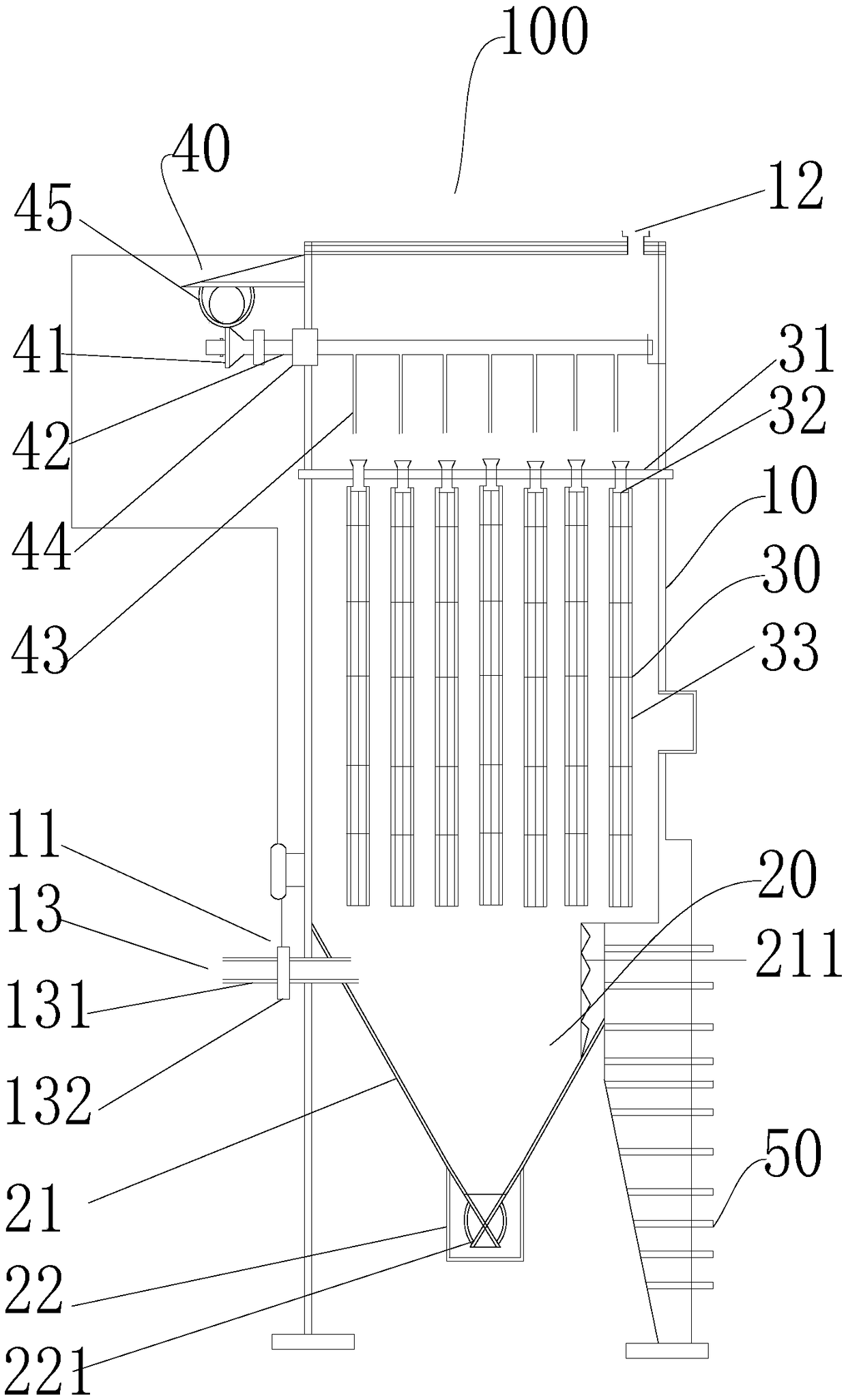

Segmented pulse backflushing air filter core regenerating system and method

PendingCN108579264ASubtractionImprove entrainment capacityDispersed particle filtrationTransportation and packagingInterference fitAir filter

The invention relates to the technical field of air purification, in particular to a segmented pulse backflushing air filter core regenerating system and a segmented pulse backflushing air filter coreregenerating method. The segmented pulse backflushing air filter core regenerating system comprises a dedusting box, filter cores mounted inside the dedusting box, and a pulse gas source arranged onthe outer side of the dedusting box, wherein a gas outlet and a gas inlet are formed in the upper side and the lower side of the dedusting box respectively; a partition board for fixing the filter cores is further arranged inside the dedusting box; the partition board is in interference fit with the dedusting box; inner holes are formed in the partition board; mechanical ash-cleaning pipes are arranged on the partition board at the lower ends of the inner holes; the bottoms of the mechanical ash-cleaning pipes are hermetically connected to the upper ends of the filter cores; a blowing pipe isarranged at the upper end of the dedusting box; the blowing pipe is connected with the pulse gas source; nozzles are formed in the lower end of the blowing pipe and in positions corresponding to the vertical positions of the filter cores. By virtue of segmented pulse blowing, through early release of an auxiliary pulse blowing gas flow, the weakening effect of the filtered gas flow inertia on a main pulse gas flow can be reduced and the entrainment effect of the main pulse blowing gas flow can be enhanced.

Owner:NANCHANG UNIV

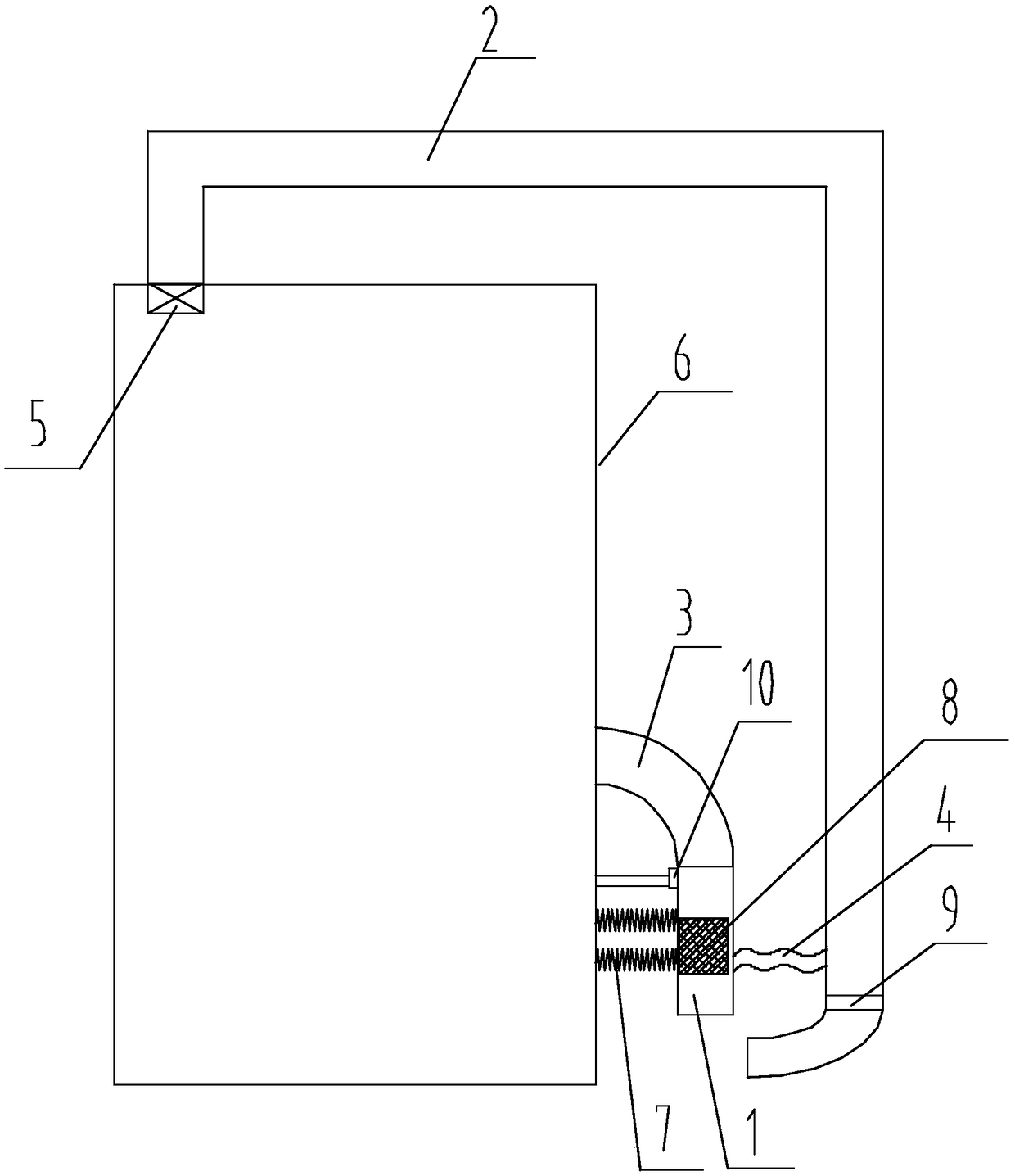

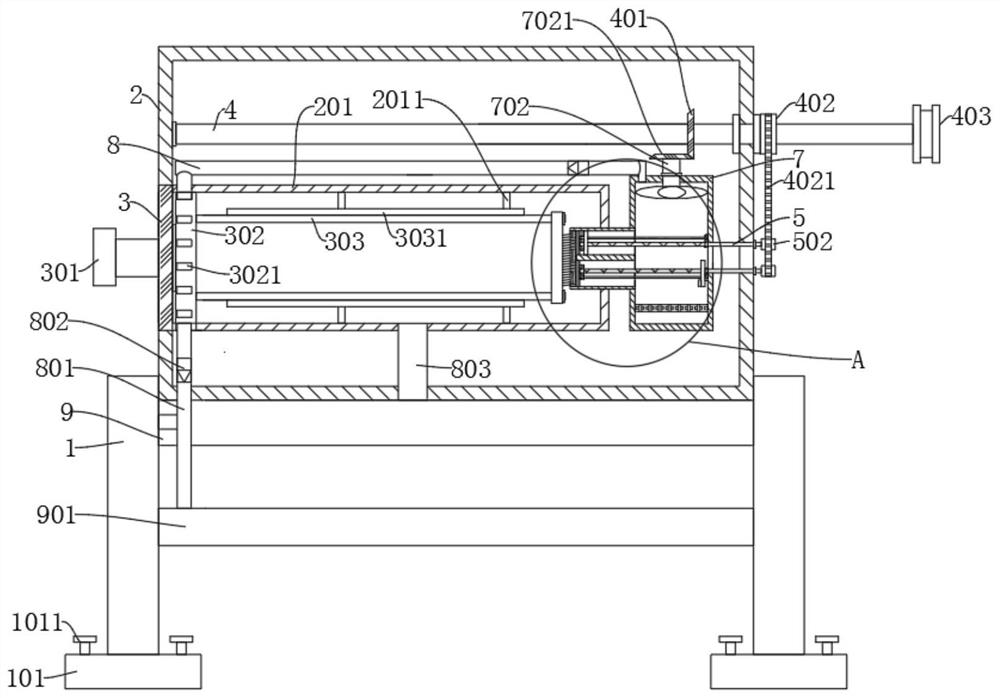

Welding sealing system and welding sealing process

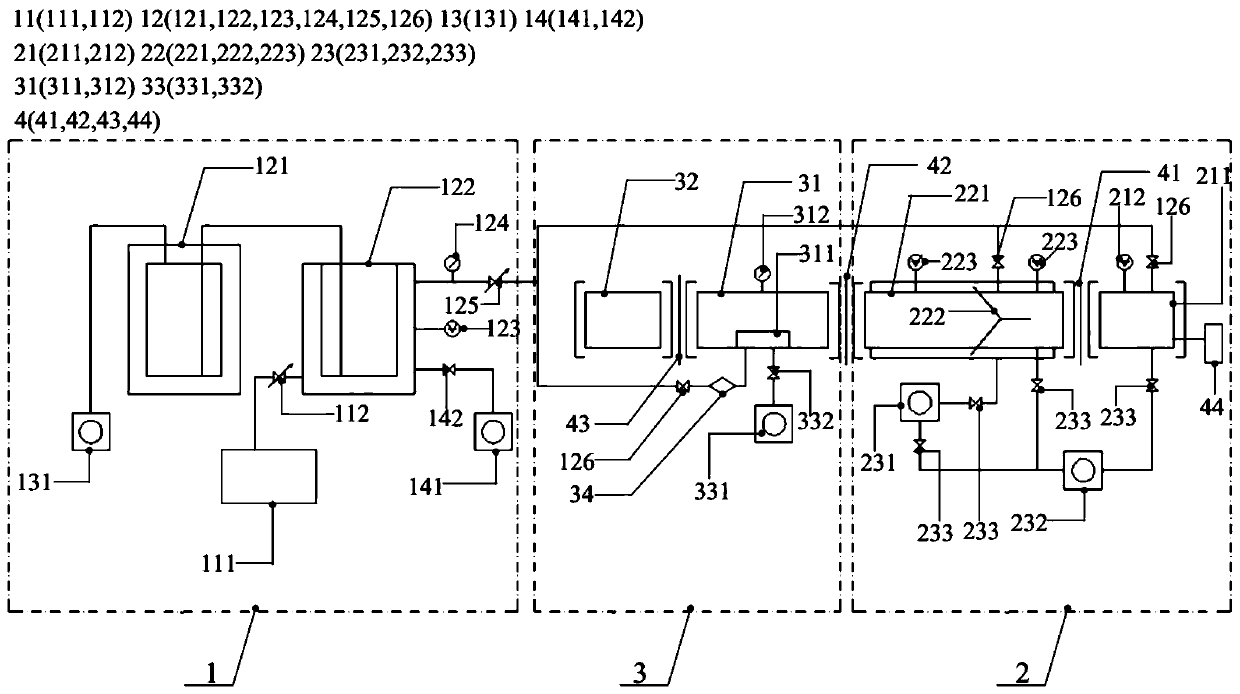

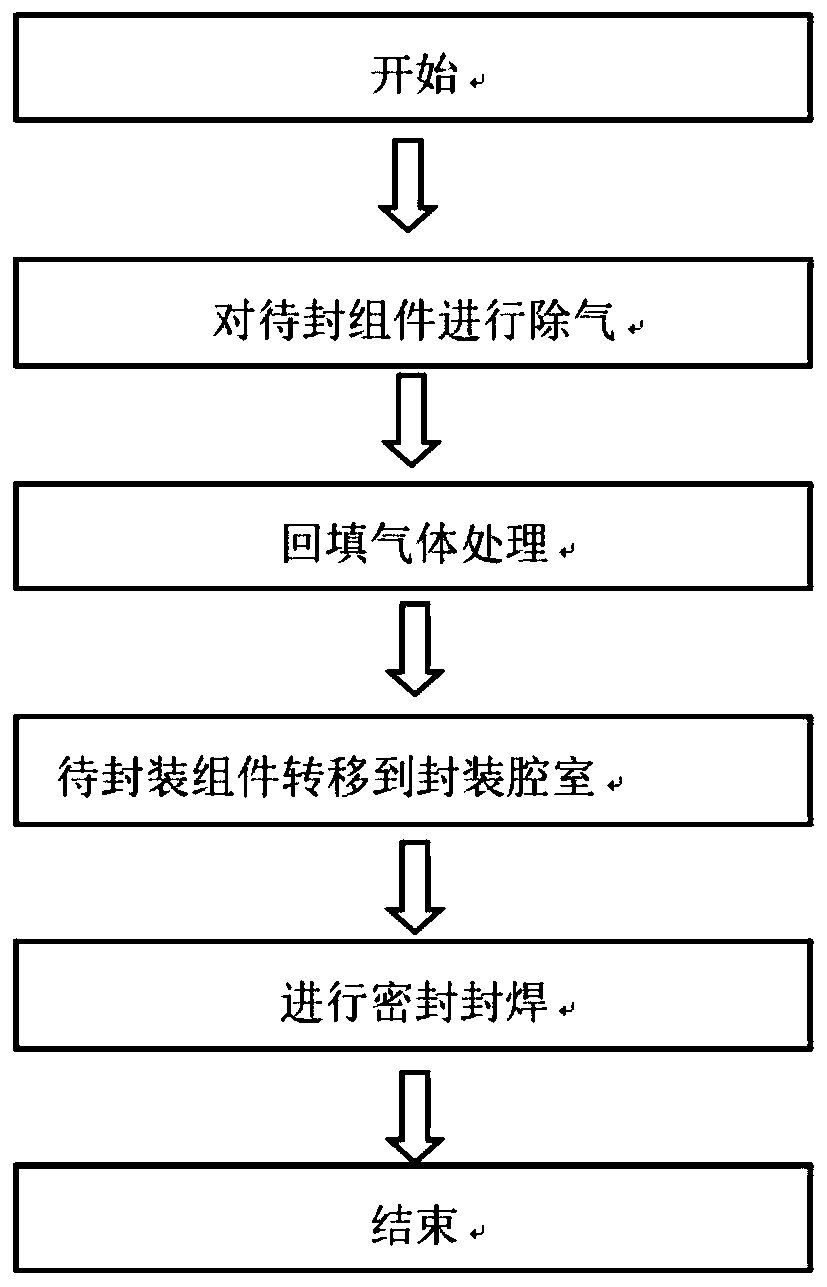

ActiveCN111302299AControl air pressureHigh purityDecorative surface effectsSemiconductor/solid-state device manufacturingThermodynamicsProcess engineering

The invention discloses a welding sealing system. The device comprises a gas filling module, a baking module, a welding module and a conveying module, the vapor content of less than 100PPM in the device can be realized, the internal gas pressure of the packaging body can be controlled within + / -500Pa, the purity of the backfill process gas is ensured to be higher than 99.5%, and the sealing requirements of military special processes such as energy storage welding sealing and the like are met. The four modules of the welding sealing system can operate independently and can also work cooperatively, the automation degree is high, and the mass production requirement can be met. The invention further discloses a welding sealing process, and the welding sealing system is applied, so that energystorage welding sealing of low-water-vapor and high-purity process gas can be realized.

Owner:BEIJING CHENJING ELECTRONICS

Shaking dust removal power transformation cabinet

PendingCN109119905AAvoid pollutionAvoid siltingSubstation/switching arrangement casingsEngineeringElectromagnetic valve

The invention provides a shaking dust removal power transformation cabinet, which comprises an air inlet pipe, an air outlet pipe, a first flexible pipe, a second flexible pipe, a fan and a cabinet body, wherein the first flexible pipe is installed on the cabinet body and communicated with an air inlet, and the air inlet pipe is installed on the cabinet body through springs; a first end of the airinlet pipe is connected and communicated with the first flexible pipe; the air inlet pipe is internally provided with a dust absorbing mechanism; the air outlet pipe is installed on the cabinet bodyand communicated with an air outlet, and a second end of the air inlet pipe is located in an air outlet direction of the air outlet pipe; the second flexible pipe is connected between the air inlet pipe and the air outlet pipe, and the end, which is connected with the air inlet pipe, of the second flexible pipe is sealed; and the springs and the second flexible pipe are located at two opposite sides of the air inlet pipe respectively, and the second flexible pipe is bent at an original length state of the springs. In the invention, the air inlet pipe starts shaking under a rebound effect of the springs so as to enable the dust absorbing mechanism to remove the dust; and an electromagnetic valve is open, the air outlet pipe starts to discharge the air so as to blow the dust discharged froman inlet section of the air inlet pipe, and thus the dust is avoided from being accumulated at the inlet end of the air inlet pipe and being secondarily absorbed after the fan is turned on.

Owner:安徽蓝润正华电子有限公司

Textile dust collecting device of textile machine for spinning

ActiveCN112553753ASolve the problem of blockingEliminate static electricityDrying gas arrangementsAuxillary apparatusSpinningStructural engineering

The invention discloses a textile dust collecting device of a textile machine for spinning, and belongs to the technical field of textile machines. The textile dust collecting device of the textile machine for spinning comprises a mounting frame and a mounting box, wherein the mounting box is fixedly connected to the mounting frame, a dust suction hood is fixedly connected to the bottom of the mounting box, a storage box is fixedly connected in the mounting box, the storage box communicates with the dust suction hood through a third air pipe, an air suction box is fixedly connected in the mounting box, an air suction mechanism is arranged in the air suction box, the air suction box communicates with the storage box through a filter box, a filter screen is fixedly connected in the filter box, an air inlet hole is formed in the filter box, a mounting plate is fixedly connected in the air inlet hole, and a reciprocating lead screw is rotationally connected to the mounting plate. Accordingto the textile duct collecting device, positive ions and negative ions are blown to the filter screen, static electricity on fluff is eliminated, the fluff is blown into the storage box, and therefore the problem that the filter screen is always blocked by the fluff is solved.

Owner:吴江新生针纺织有限责任公司

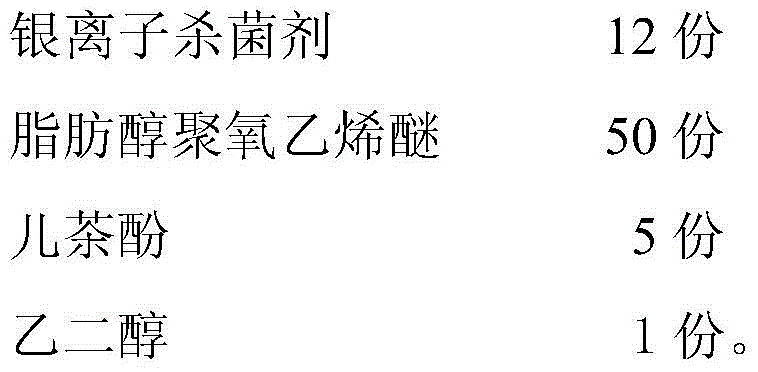

Antibacterial screen cleaning agent and preparation method thereof

InactiveCN106753878AHas a cleaning effectExtraordinary sterilizationCationic surface-active compoundsOrganic detergent compounding agentsAntioxidantCleansing Agents

The invention relates to an antibacterial screen cleaning agent, which is prepared from the following drugs by weight: 56-80 parts of a chitin bactericide, 62-80 parts of an antibacterial agent, 45-70 parts of fatty alcohol polyoxyethylene ether, 40-65 parts of dodecyl dimethyl benzyl ammonium chloride, 33-50 parts of dipropylene glycol dimethyl ether, 28-50 parts of ethylenediamine tetraacetic acid disodium, 50-75 parts of an antioxidant, 22-35 parts of texanol ester alcohol, 20-35 parts of ethanol, 20-35 parts of menthol, 15-30 parts of jasmine essence, and 60-80 parts of deionized water. The invention also discloses a preparation method of the cleaning agent. The cleaning agent provided by the invention not only has cleaning function, but also has extraordinary sterilization, anti-static, and screen protecting effects, can effectively remove dust and bacteria adsorbed on a screen and form a protective film on the screen surface, and also can continuously and effectively prevent secondary adsorption of dust and bacteria breeding.

Owner:GUANGXI UNIV

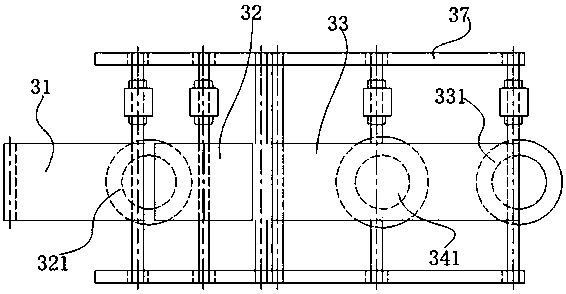

Classifying device used after fine crushing of waste metal and classifying method for classifying device

PendingCN107876212AEasy to operateClear classificationMagnetic separationStructural engineeringMechanical engineering

The invention discloses a classifying device used after fine crushing of waste metal and a classifying method for the classifying device and belongs to the technical field of classifying after metal crushing. The classifying device comprises a frame-shaped fixing frame and a magnetic roller fixed to the fixing frame through a bearing. A feeding conveying belt and a discharging conveying belt fixedto the fixing frame are arranged on the two sides of the roller face of the magnetic roller. The tail end of the feeding conveying belt is closed to the roller face of one side of the magnetic roller, and a non-iron material discharging clearance is reserved. The initial end of the discharging conveying belt is attached to the roller face of the other side of the magnetic roller infinitely. The width of the feeding conveying belt and the width of the discharging conveying belt are not smaller than the width of the magnetic roller. Due to rotation of the magnetic roller, iron materials and non-iron materials are classified, the iron materials are attracted by the magnetic roller and are then cut by the discharging conveying belt to be transferred, the non-iron materials directly fall through the discharging clearance, operation is simple, and classifying is definite. By means of the classifying device and the classifying method, the problem that in the prior art, time and labor are wasted due to manual classifying after metal is crushed.

Owner:安徽华龙环保技术工程有限公司

Stepping?negative pressure compartment pulse reverse?suction?ash removal deduster?

InactiveCN103316548AExtended service lifeAvoid secondary adsorptionDispersed particle filtrationFailure rateEngineering

The invention relates to a stepping?negative pressure?compartment pulse reverse?suction?ash removal deduster,?which?includes a bottom?platform, an air inlet?pipe,?a?pneumatic ash conveying?pipe,?ash buckets, a filter?bag?chamber,?a?clean?air chamber, a top cover, a clean?air outlet,?pulse valves, an air?pocket,?blowing pipes, a tubesheet, a double-shaft?direct current motor, rollers, a guide?rail,?three-way valves, and filter?bags. The?filter?bag?chamber is provided with a compartment baffle, and the clean air chamber is a communicated chamber. The?air inlet?pipe is disposed between the two ash buckets, the three-way valves are mounted at the outlets of the ash buckets, and the pneumatic ash conveying?pipe also serves as a reverse?suction pipe. The deduster is only provided with one air?pocket, two ends of which are respectively provided with two pulse valves and two corresponding blowing pipes. A walking mechanism composed of the?double-shaft?direct current motor, the rollers and the guide rail is disposed under the air?pocket. The air?pocket assembly and its walking mechanism are disposed in the clean air chamber. A PLC?program control?cabinet is employed to control the synchronous action of the three-way valves and the pulse valves, and walking of the?double-shaft?direct current motor according to the line space of the?filter?bags. The deduster provided in the invention has the advantages of simpler structure, reduced cost, more convenient installation and maintenance, low running cost, and reduced failure rate.

Owner:ZUNYI CITY GUI KE TECH

Activated carbon regeneration device and method

PendingCN113856656ASave consumptionSave regeneration cycleCombustible gas purificationFilter regenerationActivated carbonHigh energy

The invention relates to an activated carbon regeneration device and method. The activated carbon regeneration device comprises a storage and feeding system, a carbonization and desorption system and an activation and reaming system. A carrier gas pretreater, a carrier gas blowing device, a carrier gas distributor, an activated gas pretreater, an activated gas controller and an activated gas fluidizer are added before carbonization desorption carrier gas and high-temperature activated chambering activated gas enter a reactor, so that the carrier gas and the activated gas are uniformly distributed in the reactor, passive secondary adsorption of activated carbon is avoided, and the utilization efficiency of activation gas and the activation efficiency of activated carbon are improved. Besides, the device is not provided with mechanical rotating equipment, so that the mechanical damage to the activated carbon is small. The problems of high energy consumption, economic and resource waste and serious environmental pollution in the waste activated carbon treatment process can be solved and relieved.

Owner:SHAANXI YANCHANG PETROLEUM GRP

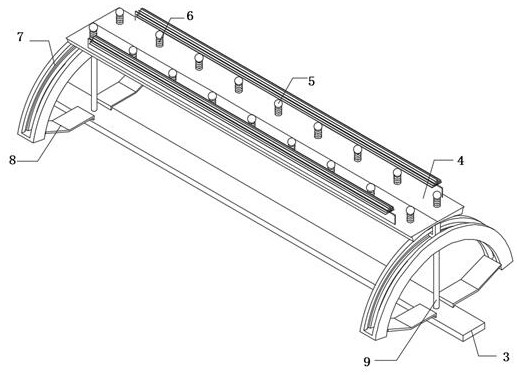

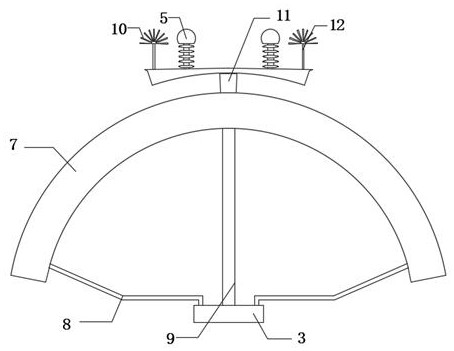

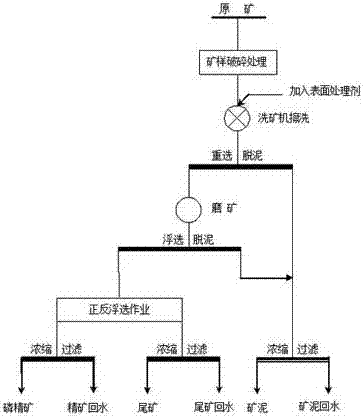

Pneumatic hammer type anode rapping device

PendingCN114029168AAvoid secondary dustAvoid secondary adsorptionElectrodes cleaningElectric machineDust control

The invention belongs to the technical field of anode rapping, and particularly relates to a pneumatic hammer type anode rapping device. The following scheme is provided: the pneumatic hammer type anode rapping device comprises a pneumatic knocking hammer and a rapping anvil, the pneumatic knocking hammer is composed of a magnetic piston, a base plate, a three-way electromagnetic valve and a return spring, and a dust reentrainment prevention assembly is arranged on the outer wall of the rapping anvil. The dust reentrainment preventing assembly comprises a fixing frame, a motor is fixedly connected to the inner wall of one side of the fixing frame, an output shaft of the motor is fixedly connected with a rotating shaft through a coupler, the rotating shaft is connected to the inner wall of one side of the fixing frame through a bearing, and rotating blades are fixedly connected to the outer wall of the rotating shaft. By arranging the dust collection pump, the dust collection box, the hollow plate and the dust collection plates, when the pneumatic knocking hammer drives the rapping anvil to remove dust on the anode plate, the dust collection pump is started, the dust collection pump partially absorbs dust raised by vibration through dust collection holes in the dust collection plates at the two ends, and dust raising source points at the anode plate are treated; and the condition of secondary raising of dust is further prevented.

Owner:中电国核(北京)节能环保科技有限公司

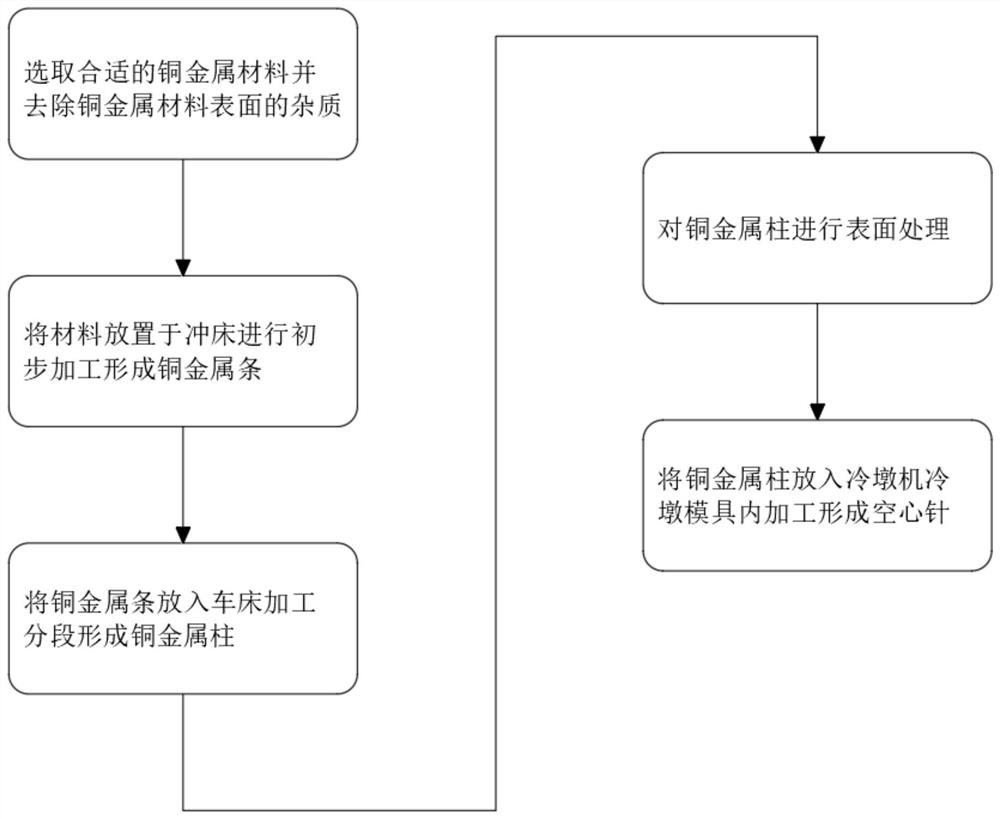

Stamping method used for hollow pin copper bar cold heading and forming and capable of achieving quick positioning and forming

PendingCN113600726AAvoid secondary adsorptionAchieve the purpose of removingNeedlesMachiningCopper metal

The invention relates to the technical field of copper bar cold heading and stamping, in particular to a stamping method used for hollow pin copper bar cold heading and forming and capable of achieving quick positioning and forming. The stamping method comprises the steps of selecting a proper copper metal material, removing impurities on the surface of the copper metal material, placing the material on a stamping press for preliminary machining to form a copper metal strip, putting the copper metal strip on a lathe for machining and segmenting to form copper metal columns, performing surface treatment on the copper metal columns, and putting the copper metal columns into a cold heading mold of a cold heading machine for machining to form hollow pins. According to the stamping method used for hollow pin copper bar cold heading and forming and capable of achieving quick positioning and forming, a copper bar cold heading and forming method is adopted so as to increase the production quantity of the hollow pins per unit time and improve the production efficiency of the hollow pins.

Owner:天长市仁宝五金科技有限公司

A low-grade refractory weathered collophosite desliming flotation process in stages

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Mechanism for preventing rubbing filtering packet of pulse bag-type dust remover

ActiveCN101433790AAccelerated settlementAvoid secondary adsorptionDispersed particle filtrationEngineeringMechanical engineering

The invention provides a filter bag antifriction mechanism for a pulse bag-type duster, which comprises an upper tube sheet, a lower tube sheet, filter bags and a cage, wherein the upper tube sheet and the lower tube sheet are arranged up and down and connected into a frame through a plurality of connecting rods; the upper tube sheet and the lower tube sheet are provided with a plurality of upper tube sheet holes and a plurality of lower tube sheet holes correspondingly; the filter bags are sleeved outside the cage, and bag mouths of the filter bags are clamped into the lower tube sheet holes through elastic snap rings; sleeves are arranged on nut caps on the upper end of the cage and arranged between the upper tube sheet holes and the lower tube sheet holes; flanges are arranged on the top of the sleeves, and edges of the flanges are pressed on orifices of the upper tube sheet holes; a blowpipe which is connected with a draught fan is arranged between the upper tube sheet and the lower tube sheet; and the lower tube sheet is provided with a plurality of uniformly distributed blowing holes. The filter bag antifriction mechanism for the pulse bag-type duster has strong structural performance, reduces the manufacturing cost, avoids mutual friction between the filter bags, prolongs the service life of the filter bags, accelerates dust settlement, improves the dust removal efficiency and the dust removal effect, has obvious energy-saving effect, and is particularly suitable for processing dust with thin particles and strong viscosity.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

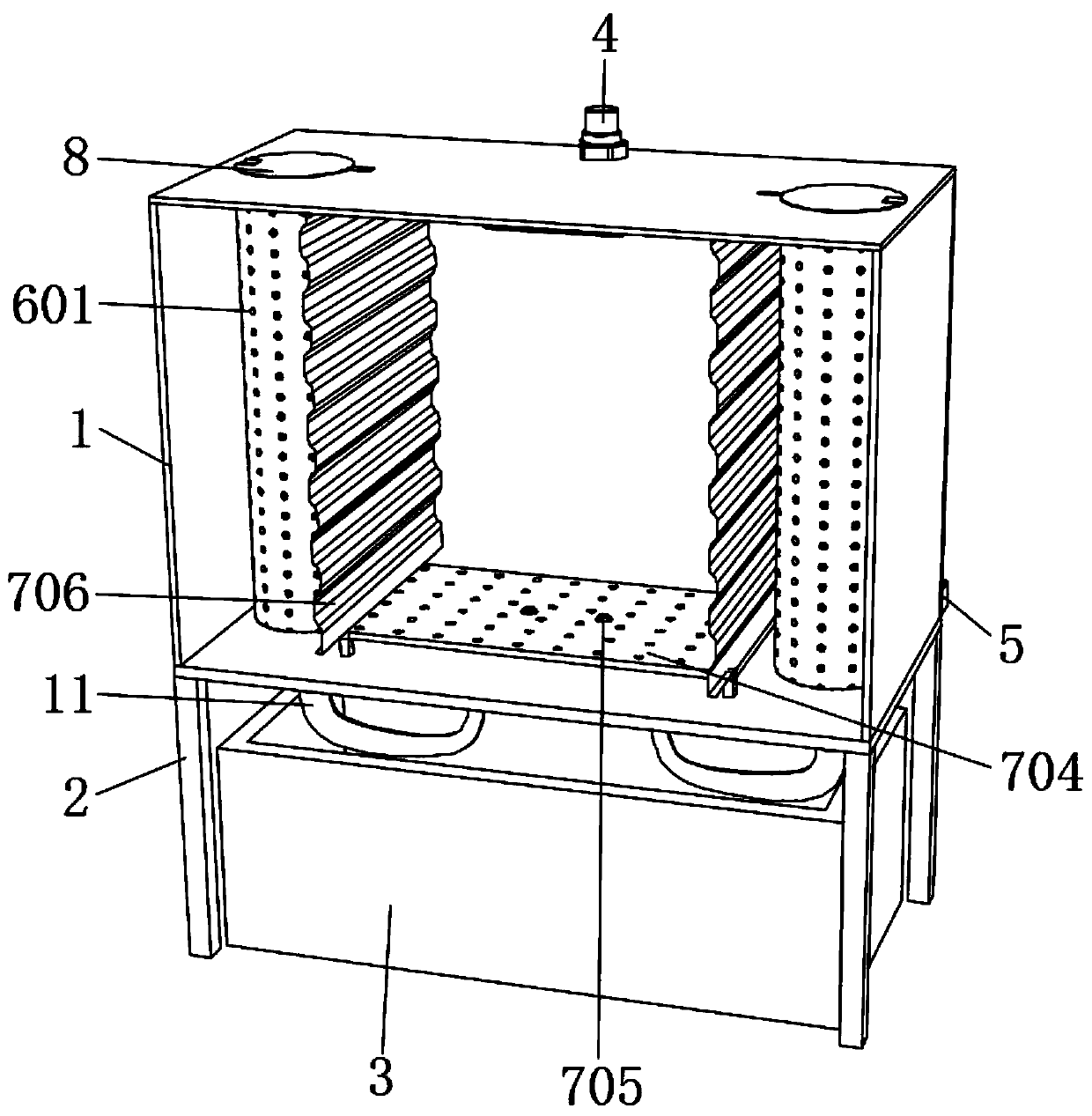

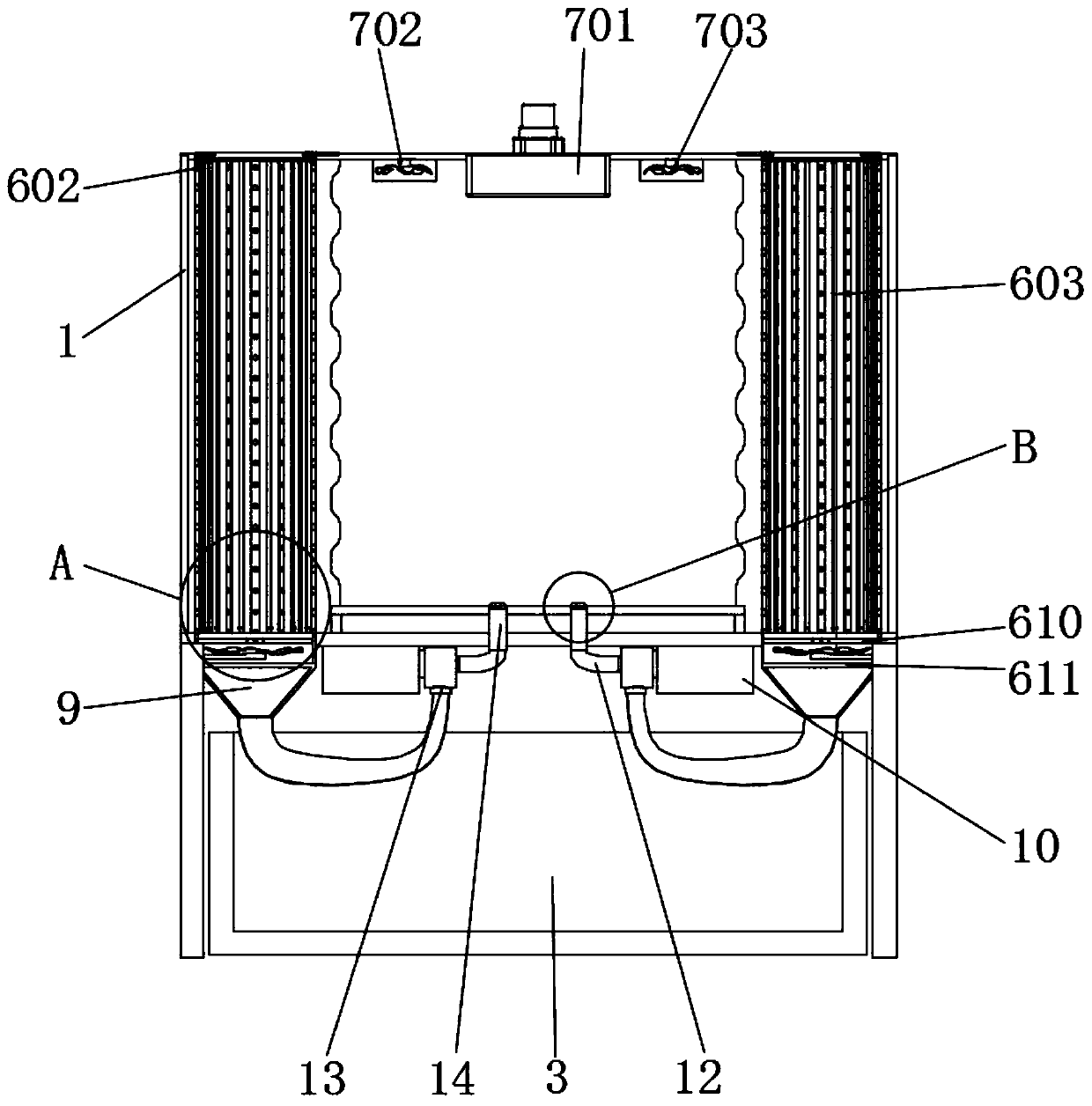

Textile fabric cleaning device capable of preventing secondary adsorption based on ultrasonic vibration cleaning

InactiveCN111575964AClean upComprehensive cleaningTextile treatment machine arrangementsTextile treatment cleaning apparatusUltrasonic vibrationSewage

The invention relates to the technical field of textile cleaning, and particularly relates to a textile fabric cleaning device capable of preventing secondary adsorption based on ultrasonic vibrationcleaning. The textile fabric cleaning device comprises a cleaning box, a support, a sewage tank, a water inlet, a control device, an anti-adsorption mechanism, a cleaning mechanism, a cover plate, a funnel, a water suction pump, a U-shaped hose, a hose, bolts and a guide pipe, wherein the cleaning box is arranged at the upper end of the support; the sewage tank is arranged at the lower end of thesupport; the control device is connected to the right side, close to the bottom end, of the back surface of the outer part of the cleaning box; the cleaning mechanism and the anti-adsorption mechanismare arranged in the cleaning box; the bottom end of the anti-adsorption mechanism penetrates through the bottom end of the cleaning box and is connected with the funnel, the bottom of the funnel is connected with the U-shaped hose; the top end of the right side of the U-shaped hose is movably connected with the right side of the lower surface of the water suction pump arranged at the bottom end of the outer part of the cleaning box through the bolts; and the water suction pump is connected with the bottom end of the guide pipe penetrating through the bottom of the cleaning box through the hose connected to the right side of the water suction pump. According to the textile fabric cleaning device, the problems that the cleaning effect of textile fabric is poor, and the fabric adsorbs dust for the second time in the cleaning process are solved.

Owner:谭化周

A cleaning and wiping device for sprayed parts of automobile plastic parts

InactiveCN109261605BEasy to transportEasy to take and moveDrying gas arrangementsCleaning using toolsTransmission beltElectric machinery

The invention discloses a cleaning and wiping device for sprayed parts of automobile plastic parts. The number is four, and transmission rollers are fixedly installed on the four transmission shafts, and two of the four transmission rollers form a group. The present invention facilitates the transportation of the parts to be cleaned by setting the transmission shaft, the transmission roller, the transmission belt and the transmission motor; Components are moved between the pretreatment box, the cleaning box and the drying box, which reduces the use of labor, improves the transportation efficiency of parts, helps to speed up the cleaning work, and improves the practicability of the device. The suction cup transports one part at a time into the cleaning box, which is conducive to targeted cleaning and ensures the cleaning effect of the device.

Owner:罗晓忠

A leather cleaning device in production

ActiveCN111719302BAvoid savingImprove adsorption capacityMechanical cleaningPressure cleaningAir filtrationAir filter

The invention discloses that the invention relates to the technical field of leather cleaning, in particular to a leather cleaning device in production, including a casing, a bracket, a material inlet, a material outlet, a first transmission device, a second transmission device, and a third transmission device , leather cleaning mechanism, drying mechanism, shaft, cylinder, arc baffle, air filter box, air inlet, filter plate, filter, electrostatic adsorption device, fixed plate, baffle, V-belt, the second drive motor, the first Three driving motors, the top of the bracket is placed with an organic casing, the left side of the casing is connected to the second driving motor near the end, the third driving motor is installed on the left side of the casing, the air filter box is installed on the right side of the top of the casing, and the front of the casing There is a material inlet, a material outlet on the back of the casing, a first transmission device inside the casing, and a leather cleaning mechanism above the first transmission device. The invention solves the problem of insufficient cleaning of leather during production. Problems with unsatisfactory leather compression.

Owner:RUIAN DAHU SHOES IND CO LTD

A cleaning and drying device for gauze production

ActiveCN108930110BImprove product qualityAvoid secondary adsorptionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsMetallurgyIndustrial engineering

The invention provides a cleaning drying device used for gauze production, and relates to the technical field of gauze production and manufacturing equipment. The cleaning drying device used for gauzeproduction comprises a base. The top of the base is fixedly provided with a cleaning box and a drying box. The drying box is divided into a dehydration chamber and a drying chamber. The cleaning boxis internally provided with a first cloth guide roller and a cleaning device. The cleaning device comprises an upper supporting rod and a lower supporting rod. Using the leaning drying device used forgauze production, through cooperation of an upper supporting rod, a lower supporting rod, an upper cleaning roll, a lower cleaning roll, a scraper blade, a rotating disk, and a banister brush, gauzedrives a driving belt to drive on the rotating disk, and the banister brush on the driving belt cleans the surface of the gauze. Under operation of the driving belt, the banister brush drives impurities into the upper cleaning roll, and the impurities on the banister brush are removed through the scraper blade. Impurities pass through the scraper blade and enter into the upper cleaning roll, and the impurities on the surface of the gauze are removed in cleaning, so that product quality of the gauze is improved.

Owner:陈剑璋

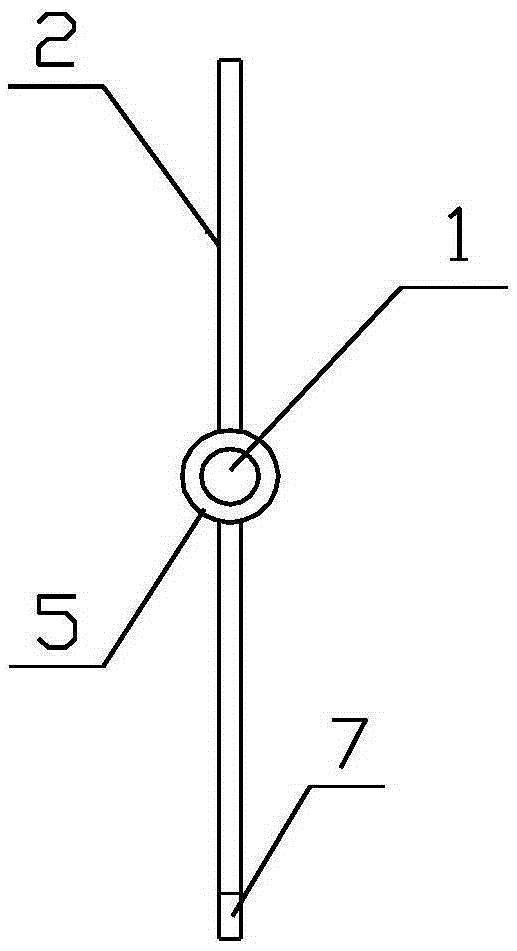

Racket for adhering thread residues

The invention relates to a racket for adhering thread residues. The racket comprises a racket rod and a racket body, wherein the racket body and the racket rod are fixedly connected, the racket body comprises a racket panel and carton sealing tape, the carton sealing tape winds on the surface of the racket panel, and fixing rods are disposed at two ends of the carton sealing tape. The racket for adhering thread residues is simple and convenient to manufacture, easy in material obtaining, and capable of well removing the thread residues and fabric yarn ends which are adhered to and accumulate on finished fabric due to static during production and avoiding secondary adhesion of the thread residues and fabric yarn ends.

Owner:GUILIN CHANGXIN MACHINERY MFG

A leather multi-stage squeezing device

ActiveCN112029915BEasy squeezeImprove squeeze efficiencyLeather pressing/rollingSkins/hides/leather/fur manufacturing apparatusStructural engineeringMechanical engineering

The invention provides a leather multi-stage squeezing device, which relates to the technical field of leather processing. The multi-stage water squeezing device for leather includes a casing, a bracket, a water collecting tank, a first transmission device, a water squeezing mechanism, an arc-shaped inclined plate, a flattening mechanism, an adjustment device, a bracket fixedly connected to the bottom of the casing, and a casing. A water collecting tank is arranged between the bottom bracket on the left end, and the water collecting tank is flexibly connected with the casing. The inside of the casing is provided with a first transmission device near the bottom. The left and right sides of the first transmission device are fixedly connected with the inner wall of the casing. The first transmission device There is a water squeezing mechanism on the top, and an arc-shaped sloping plate is installed on the right end of the first transmission device. Both sides of the arc-shaped sloping plate are fixedly connected with the inside of the casing. Adjusting device, the adjusting device slides through the bottom ends of both sides of the casing and is connected with the casing, thereby solving the problems of low water squeezing efficiency during the leather squeezing process and the secondary adsorption of the squeezed water by the leather.

Owner:台州玉釉新材料科技有限公司

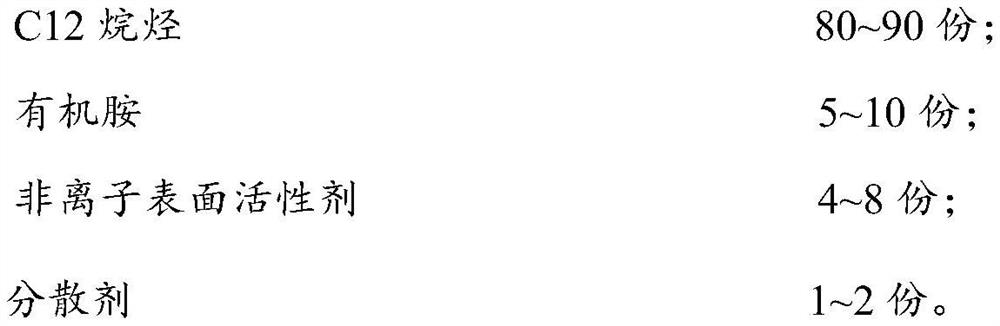

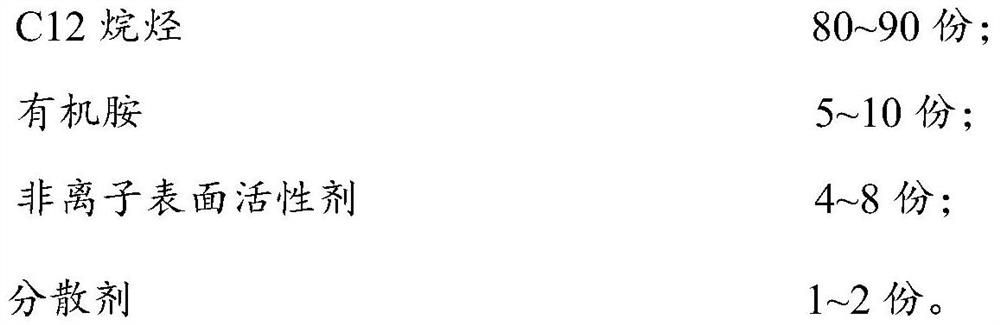

Ash removing agent as well as preparation method and application thereof

PendingCN114318353AImprove removal efficiencyAvoid adsorptionProcess efficiency improvementAlkaneActive agent

The invention provides an ash removal agent as well as a preparation method and application thereof. The ash removing agent comprises the following components: C12 alkane, organic amine, a nonionic surfactant and a dispersing agent. By adding the C12 alkane, the organic amine, the nonionic surfactant and the dispersing agent, the ash removal agent has an excellent ash removal effect on charcoal ash generated in stainless steel stamping cleaning. In addition, a strong acid or strong alkali system in a traditional scheme is avoided, so that the scheme of the invention is environment-friendly and lower in post-treatment cost, and the ash removal agent can be used for removing charcoal ash in stainless steel.

Owner:GUANGDONG REDSUNSTAR IND

Out-of-the-box sapphire wafer cleaning process

ActiveCN111185433BGuaranteed hydrophobicityAvoid secondary pollutionDrying solid materials with heatSemiconductor/solid-state device manufacturingWaferingOrganic solvent

The invention discloses a sapphire wafer cleaning process that can be used out of the box. It includes first using a cleaning agent and ultrapure water to ultrasonically wash the sapphire wafer multiple times to remove dirt and fine particles on the wafer surface; and secondly brushing the wafer to remove dirt and fine particles. Large particles on the surface of the wafer; then spray emulsifier on the wafer to control the adsorption state of the wafer surface; then use organic solvent to spray the wafer to avoid secondary adsorption of pollutants; finally use a spin dryer to dry the wafer, then let it stand and bake Dry. The invention can obtain a higher finished product yield by directly using the wafer during PSS production after cleaning the sapphire wafer.

Owner:江苏京晶光电科技有限公司

Low-pressure online long-bag pulse bag dust collector

InactiveCN109173462AExtended service lifeReduce resistanceDispersed particle filtrationFlue gasEngineering

The invention discloses a low-pressure online long-bag pulse bag dust collector. The dust collector is formed by a shell, an ash hopper assembly, a filter bag assembly and a pulse jetting assembly, flue gas enters the shell from an air inlet in the left sidewall of the shell, large particles first fall into the ash hopper assembly, small particles and the flue gas are deacidified by a high temperature generated by the ash hopper assembly, and then upwards flow into the filter bag assembly, are filtered by the filter bag assembly, and are accumulated on the inner wall of the filter bag assembly, the pulse jetting assembly is turned on, the pulse jetting assembly is formed by a gas storage tank, a blowing tube, nozzles and a pulse valve, and the pulse valve is turned on to make compressed air in the gas storage tank released into the blowing tube and jetted into the filter bag assembly through the nozzles, so vibration generated by the expansion of the filter bag assembly and reverse airflow make dusts adhered to the surface of a filter bag disengage from the filter bag assembly and fall into the ash hopper assembly in order to prevent secondary adsorption and reduce the resistance of the dust collector, thereby the service life of the filter bag is prolonged.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

Method for microwave drying of high-titanium slag

InactiveCN101545709BExtended service lifeAvoid microwave output power attenuationDrying solid materials with heatHearth type furnacesMicrowave cavityVentilation volume

The invention relates to a method for microwave drying of high-titanium slag, which comprises the following steps: taking the high-titanium slag of which the water content is between 1 and 2 percent as a raw material; adopting a continuous microwave drying device; according to relatively fixed microwave power, changing the ventilation volumes of different microwave cavities and further adjusting parameters of the transporting rate of materials in the microwave cavities, the thickness of the material and the like; and mounting a stirrer and cavity clapboards in the microwave drying device. Theventilation volumes of ventilation devices in the microwave cavities are controlled to be between 1,247 and 2,250 m<3> / h, the speed rate of a conveying belt is between 0.5 and 2 meters per minute, the thickness of material layers is controlled to be between 1 and 5 centimeters, an air exhaust deduster is arranged at the top end of a discharge device, and the stirrer and the cavity clapboards are arranged on the microwave drying device, thus the method achieves the effect that the mass water content of the high-titanium slag is dried to be 0.3 percent from 1 to 2 percent by effectively controlling the drying temperature of the high-titanium slag to be between 70 and 76 DEG C.

Owner:KUNMING UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com