Stepping?negative pressure compartment pulse reverse?suction?ash removal deduster?

A reverse suction, step-by-step technology, applied in separation methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of shortened fan life, high operating costs, and difficulty in changing bags, and achieve long service life and operation. Low cost, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

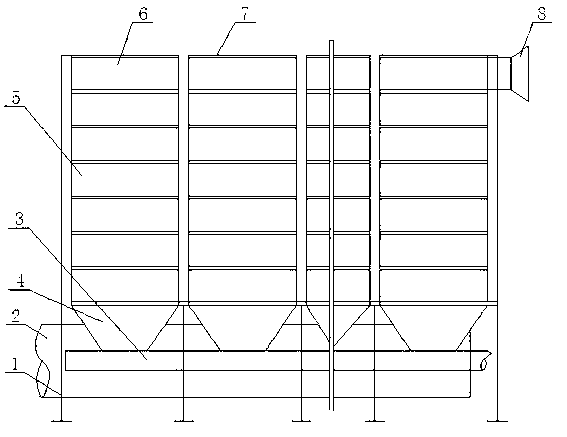

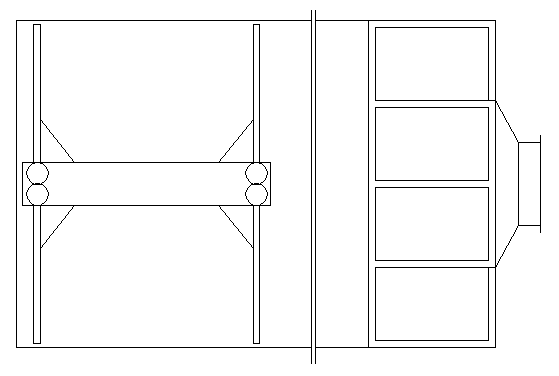

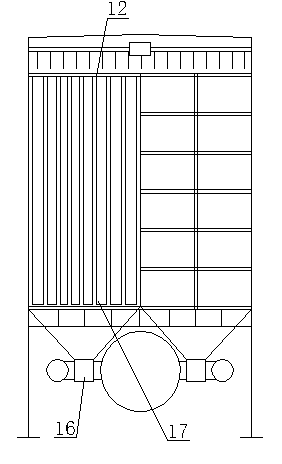

[0012] The specific implementation of the step-by-step negative pressure compartment pulse reverse suction air dust removal and dust collector according to the present invention will be described in detail with reference to the accompanying drawings.

[0013] The dust collector structure includes: bottom platform 1, air inlet pipe 2, pneumatic ash conveying pipe 3, ash hopper 4, filter bag chamber 5, clean air chamber 6, top cover 7, clean air outlet 8, pulse valve 9, air bag 10. It is composed of spray pipe 11, flower plate 12, biaxial DC motor 13, roller 14, guide rail 15, three-way valve 16 and filter bag 17. The filter bag chamber 5 is provided with compartment partitions, the clean air chamber 6 is a through chamber, the air inlet pipe 2 is arranged between two ash hoppers 4, the three-way valve 16 is installed at the outlet of the ash hopper 4, and the pneumatic ash conveying pipe 3 also serves as a back suction For the air duct, one dust collector only has one air bag 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com