Ash removing agent as well as preparation method and application thereof

A technology of ash remover and active agent, applied in the field of ash remover and its preparation, can solve the problems of high heavy metal content, great human injury and high treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

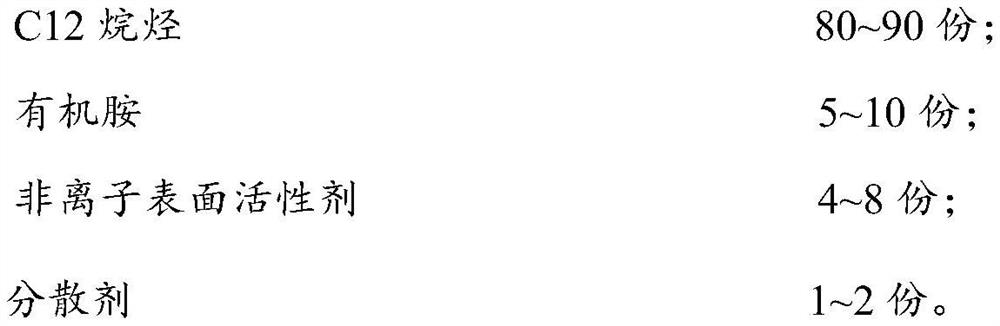

[0036] Embodiment 1 provides a kind of deashing agent, and its component and preparation method are as follows:

[0037]

[0038] Add C12 alkanes and organic amines to the production kettle in turn, stir well, then add nonionic surfactant and dispersant, stir evenly and transparently at room temperature to get the deashing agent.

Embodiment 2

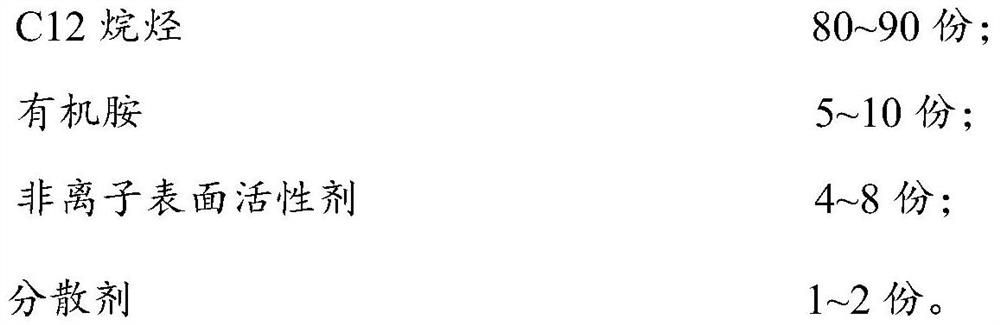

[0040] Embodiment 2 provides a kind of deashing agent, and preparation method is the same as embodiment 1, and its component content is as follows:

[0041]

Embodiment 3

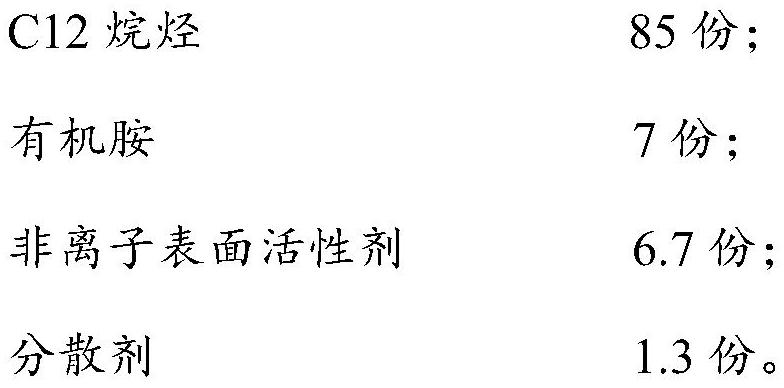

[0043] Embodiment 3 provides a kind of deashing agent, and preparation method is the same as embodiment 1, and its component content is as follows:

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com